Round bar stock arranging device

A sorting device and bar material technology, applied in packaging and other directions, can solve the problems of bulky machines, inconvenient installation, and troubles, and achieve the effect of compact machine, fast speed and high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

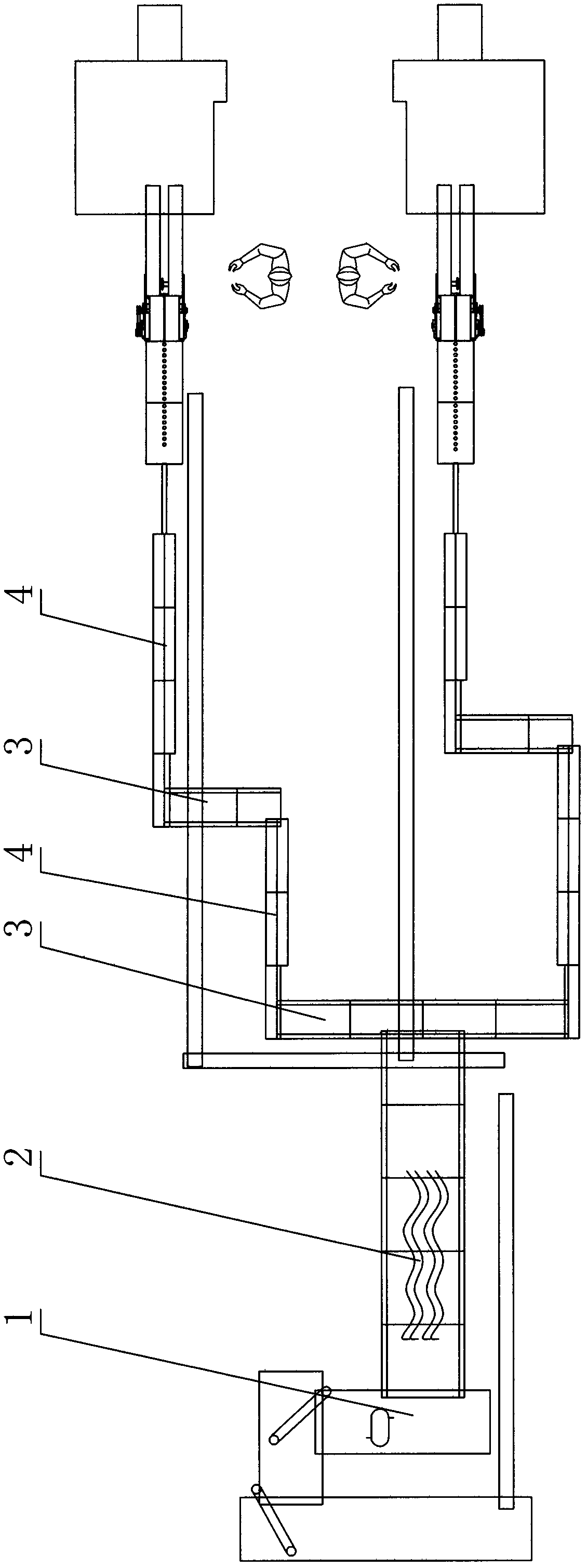

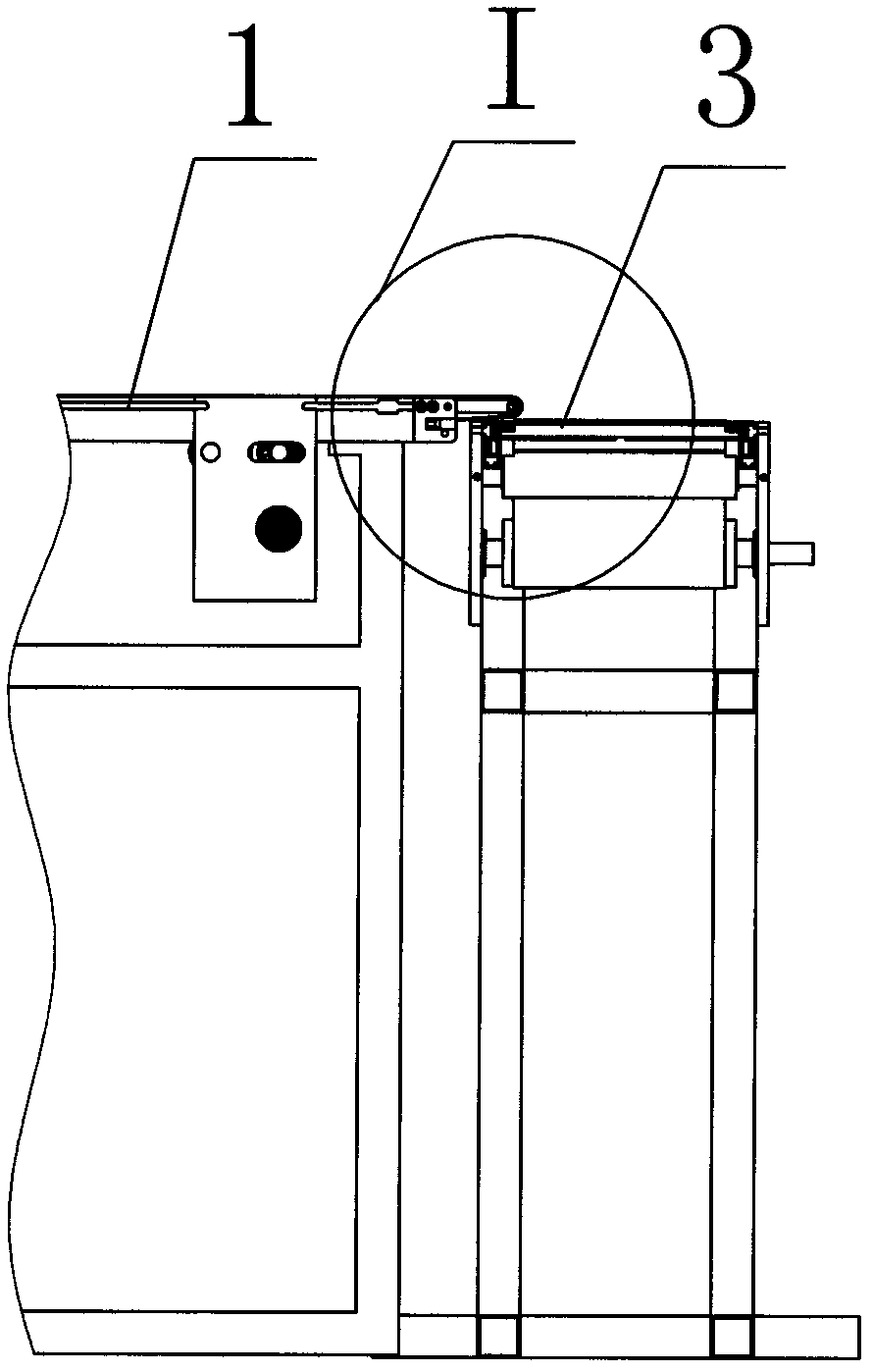

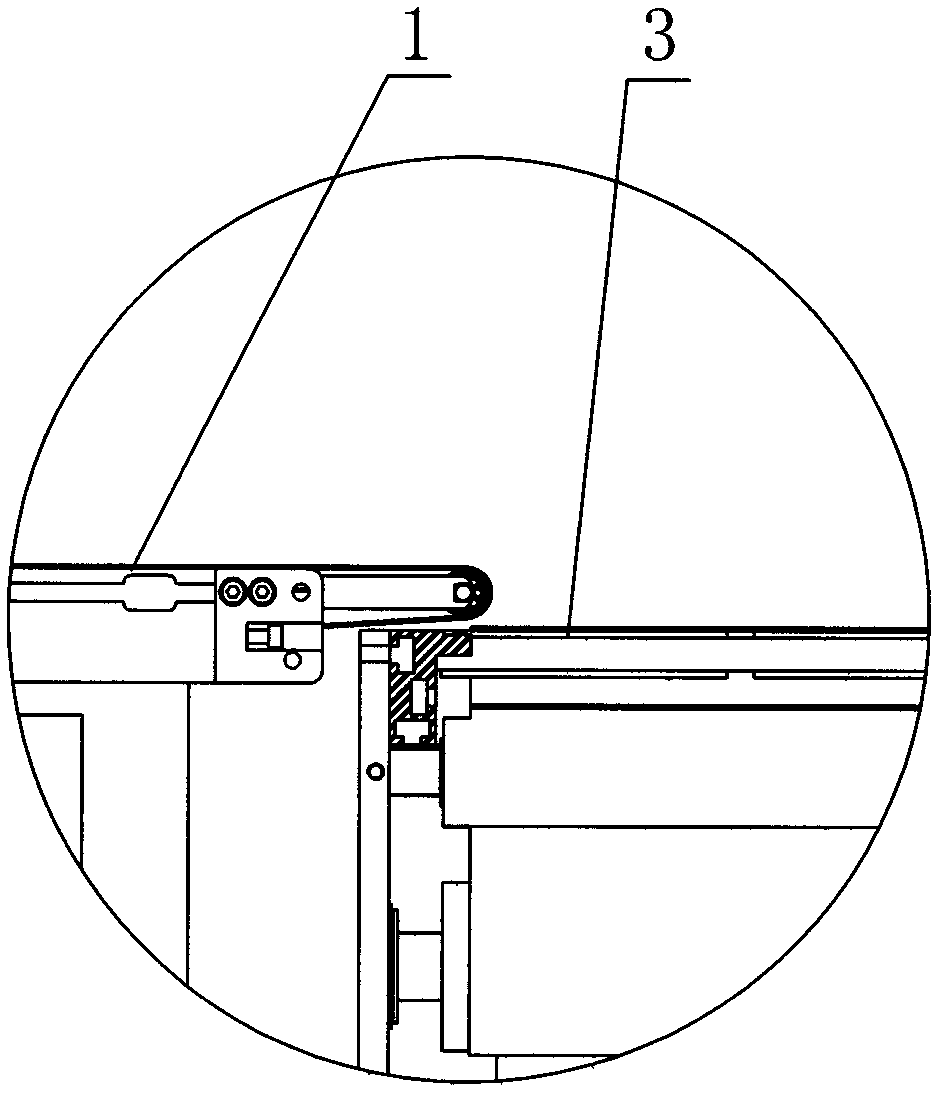

[0017] With reference to the attached drawings, this round bar finishing device includes a feeding platform 1 and a conveying unit. The feeding platform 1 is provided with a wave-shaped distribution tank 2. After the round bar is placed on the feeding platform 1, it first passes through The wavy distribution trough 2 is sorted; the conveying unit includes a plane conveying unit 3 and a V-shaped conveying unit 4, and the plane of the plane conveying unit 3 is a smooth conveyor belt driven by a conveying roller and a transmission motor. And described V-shaped conveying unit 4 is then made of two conveying belts 5,6, and two conveying belts 5,6 form V-shaped, and described plane conveying unit 3 and V-shaped conveying unit 4 are connected mutually, and plane The conveying unit 3 and the V-shaped conveying unit 4 basically form a right angle, and the plane conveying unit 3 is directly connected with the feeding platform 1. Since the materials on the feeding platform 1 pass through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com