Patents

Literature

38results about How to "Easy to withstand high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive plastic and its processing method and apparatus

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

Easily workable high-performance polyimide material and its preparation method

InactiveCN1428361AEasy to processEasy to withstand high temperatureDiphenyl etherDiaminodiphenyl ether

The present invention uses 4,4-diphenyl ether tetrahydric dianhydride and 4,4'-diaminodiphyl ether as polymerization monomer, and adopts the solution polycondensation method combining chemical imidation process and thermal imidation process to synthesize the high-temp.-resistant and solvent-resistant polyimide resin. Said invented polyimide resin possesses good working property, the polyimide plate material die-moulded by using said polyimide resin possesses high strength and fire resistance, its glas-stransition temperature is 267.7 deg.C, 5% thermal weight loss temperature is 543.1 deg.c, tensile strength is 145 MPa, impact strength is 192 KJ / sq.m, compressive strength is 1635 MP and oxygen index is 46.2.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing polyphenylene sulfide/graphene composite material through in situ polymerization

The invention belongs to the technical field of nanometer polymer composite materials and particularly relates to a method for preparing a polyphenylene sulfide / graphene composite material through in situ polymerization. The method includes enabling graphene, sodium sulfate, assistant, solvent and dichlorobenzene to have in situ polycondensation reaction in a reaction kettle and conducting separation, purification and drying to obtain the polyphenylene sulfide / graphene composite material. By means of the method, raw materials are easy to obtain, the reaction condition is mild, the yield is high, the method is applicable to industrial production, the obtained composite material can improve the toughness of polyphenylene sulfide, meanwhile heat conduction performance, conductivity and other comprehensive performances are further improved, and the method has considerable economical value and provides a new way for the graphene modified polyphenylene sulfide.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

Oil and water well sealing and plugging agent and preparation method thereof

ActiveCN102504781ASatisfy the requirements of sealing blow-byEasy to prepareDrilling compositionCuring (chemistry)Oil field

The invention relates to the technical field of oilfield chemistry, in particular to an oil and water well sealing and plugging agent and a preparation method of the oil and water well sealing and plugging agent. The oil and water well sealing and plugging agent is suitable for sealing and plugging an oil and water well. The oil and water well sealing and plugging agent consists of the following raw materials: XP lost circulation additive, G-class oil-well cement, blast furnace KZ micro powder, borax and water. The oil and water well sealing and plugging agent has the beneficial effects that the oil and water well sealing and plugging agent is simple to prepare, is convenient to construct, is safe and reliable and has high plugging strength; the oil and water well sealing and plugging agent has the characteristics of excellent suspension stability, low initial viscosity, easiness for pumping, high temperature resistance, high curing strength and the like and is mainly applied to non-corresponding production layers caused by poor cementing quality or damage to a sleeve above and below a perforated section of the oil and water well; the requirements on sealing and plugging of the oil and water well can be met; and currently, the oil and water well sealing and plugging agent is accumulatively implemented for over 90 well times, good sealing and plugging effects are obtained and the water injection efficiency is also improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

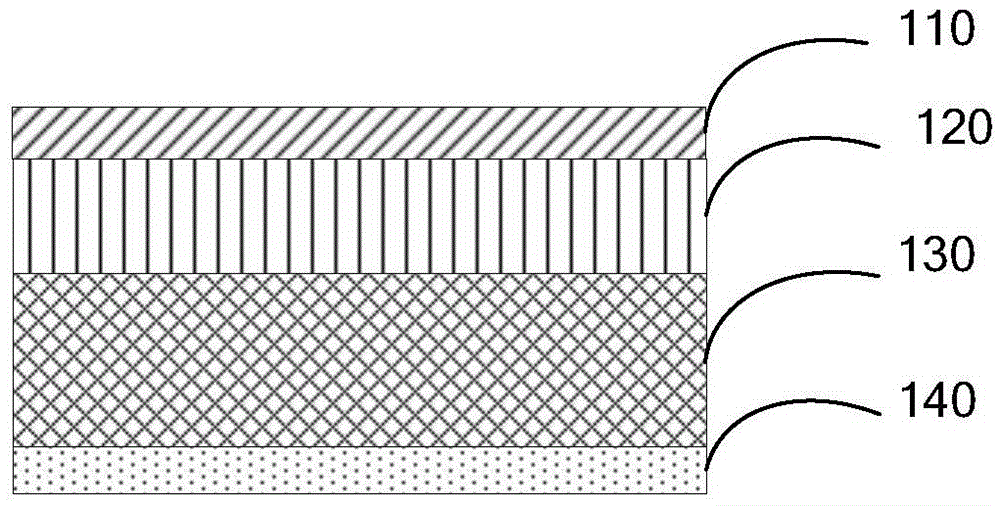

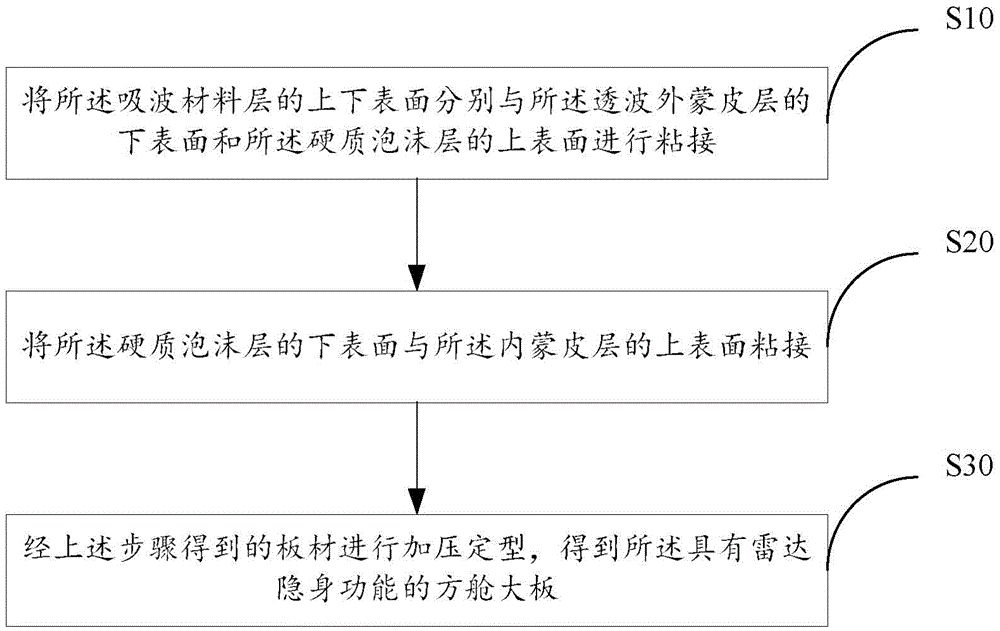

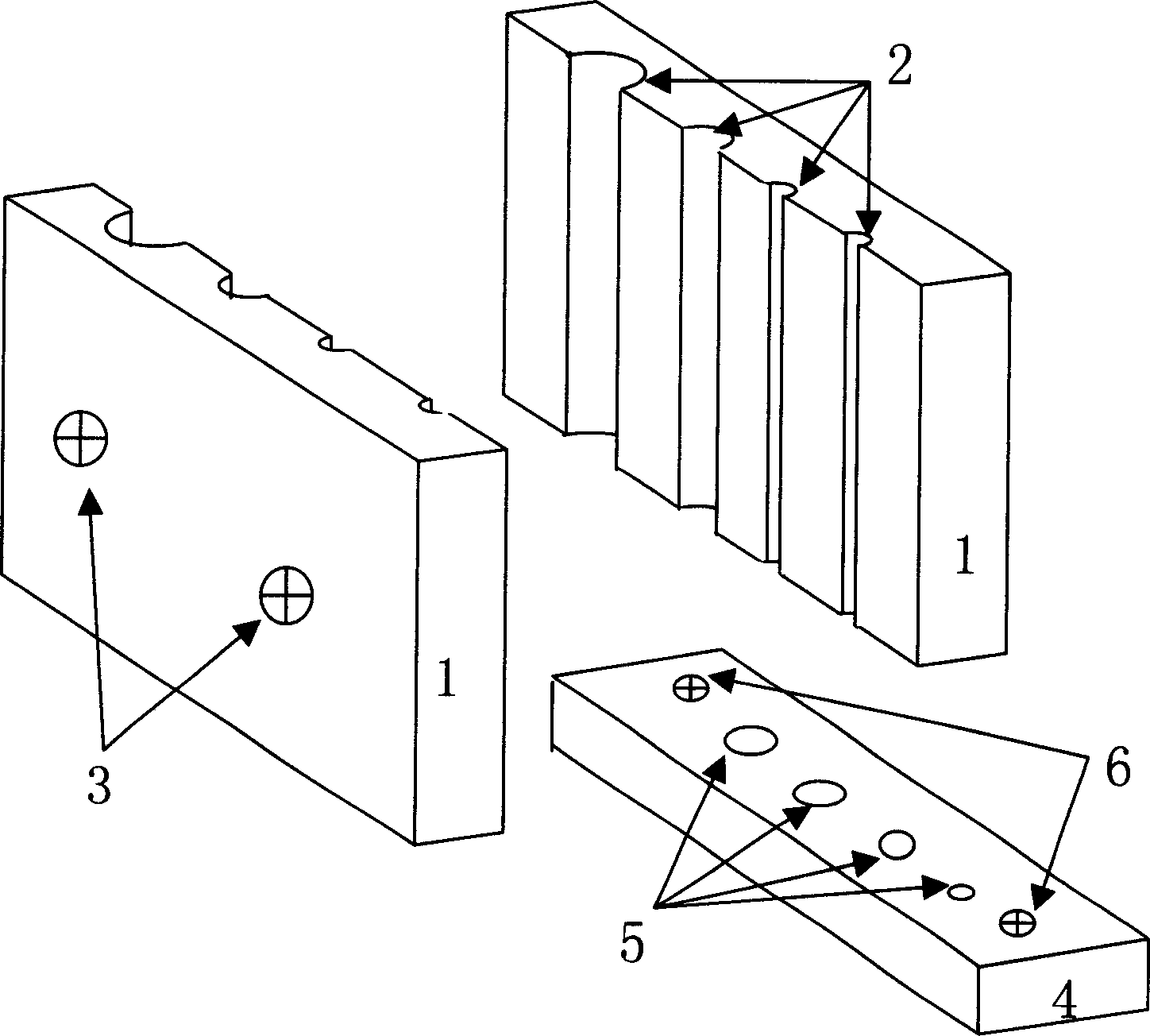

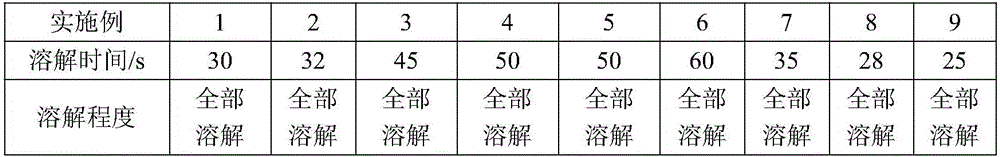

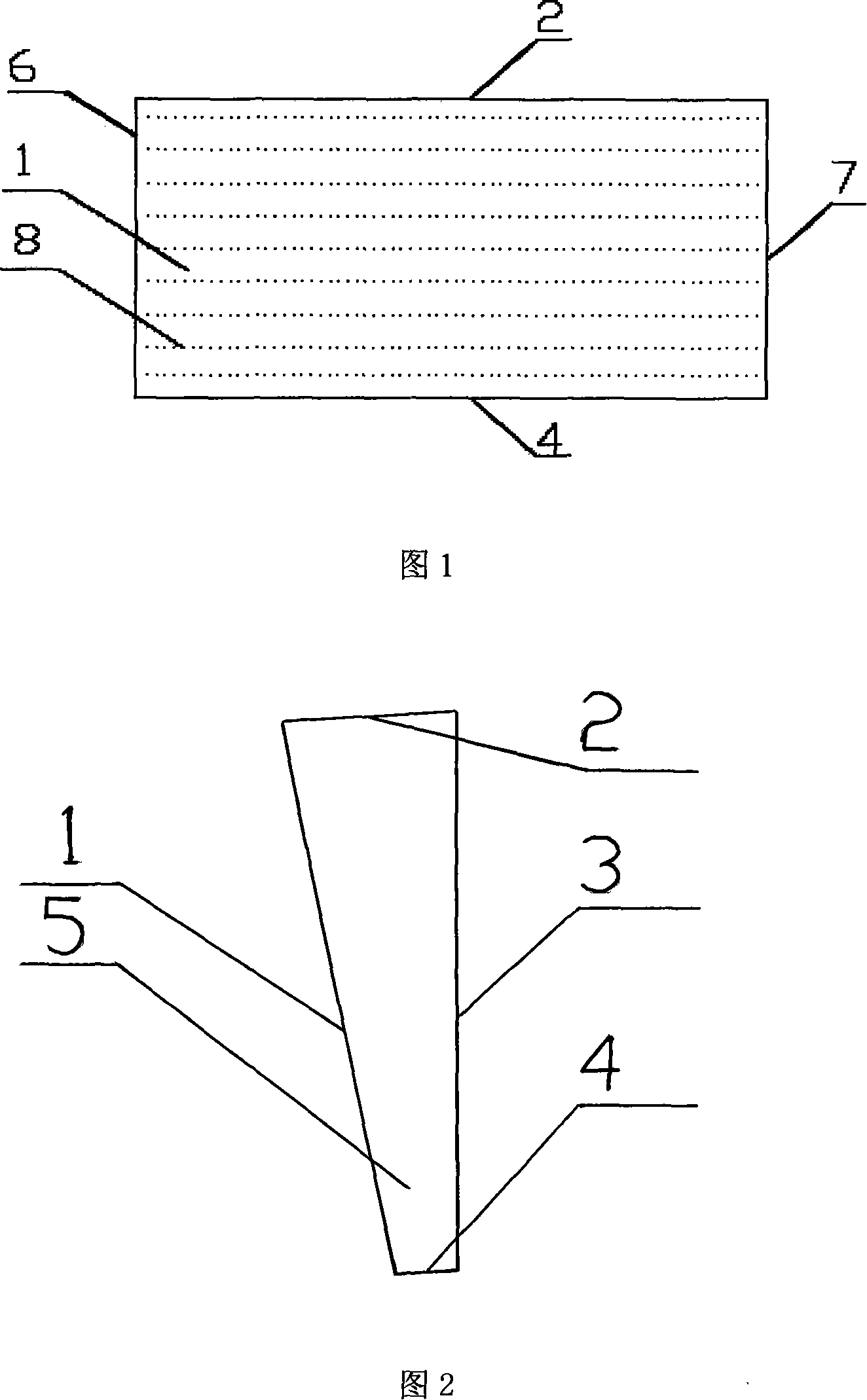

Big shelter board with radar stealth function and preparation method thereof

InactiveCN105643997ASimple structureLow densitySynthetic resin layered productsLaminationBroadbandSizing

The invention provides a big shelter board with a radar stealth function. The big shelter board is manufactured through adhering, pressurizing and sizing by a wave-transparent outer skin layer, a wave-absorbing material layer, a hard foam layer and an inner skin layer. According to the big shelter board with the radar stealth function, disclosed by the invention, the adopted wave-absorbing material layer has a function of absorbing broadband radar waves, and meanwhile, the big shelter board has the characteristics of high modulus, low deformation, high temperature resistance, corrosion resistance, easiness in machining, and the like; a more complex structure is needed for achieving the same wave absorbing effect by a radar wave-absorbing material, wave-absorbing foam, a wave-absorbing patch or thin film and the like of a traditional big shelter board, so that the big shelter board provided by the invention has the advantages that a forming technology can be effectively simplified, the surface density of the big shelter board is reduced, and the wave-absorbing performance is increased.

Owner:CHINA ACADEMY OF ENG PHYSICS FUNCTION MATERIAL RES INST

Preparation method of electrochemical combined electrode

This invention relates to a method for processing electrochemical combination electrodes sealed by the nm flexible epoxy resin material including: 1, inserting a working electrode matrix material into a conductive support copper rod wrapped with an insulation pyrocondensed tube, a hole Ag reference electrode is welded to the support copper rod, the bottom of a hole Pt counter-electrode is welded to the support copper rod, the hole Ag reference electrode, the hole Pt counter-electrode and the working electrode matrix are arrayed from inside to outside with the working electrode at the middle, the tops of which are at a same plane, the support copper rods of them are fixed by a pyrocondensed tube and put into a die set and fixed, 2, casting the nm flexible epoxy resin material onto the die set to deaerate and cure it, 3, taking out the electrode after cooling it and polishing it.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Water-based environment-friendly metal welding base metal protective agent and preparation method thereof

ActiveCN106141501ALow costSimple processWelding/cutting media/materialsSoldering mediaWater basedFilm-forming agent

The invention discloses a water-based environment-friendly metal welding base metal protective agent. The water-based environment-friendly metal welding base metal protective agent is prepared from, by weight percent, 9%-15% of a polymer film-forming agent, 8%-16% of a spreading agent, 5%-10% of a wetting flatting agent, 0.5%-5% of a rust-inhibiting additive, 12%-18% of a cosolvent and 45%-65% of deionized water. The raw materials adopted in the protective agent are environment-friendly, non-poisonous and degradable components; the prepared metal welding base metal protective agent can effectively avoid welding splash adhesion, is easy to clean and moderate in viscosity, and has excellent antirust performance; and the protective agent is suitable for multiple welding positions of flat welding, transverse welding, vertical welding, overhead welding and the like. The invention further discloses a preparation method of the water-based environment-friendly metal welding base metal protective agent. According to the preparation method, no heating is needed, operation is easy, the application range is wide, and cost is low.

Owner:南京尚易环保科技有限公司

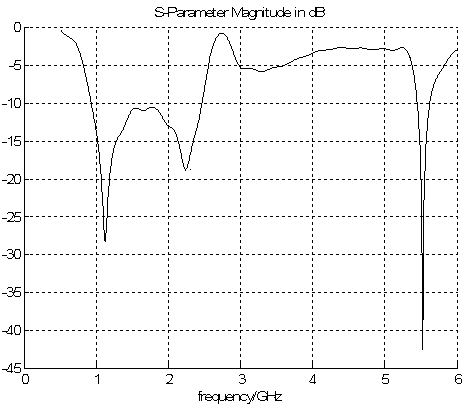

Flexible dual-band planar microstrip antenna

InactiveCN103457030AEasy to bendHigh temperature resistantSimultaneous aerial operationsResonant antennasUltra-widebandSoftware engineering

Owner:EAST CHINA JIAOTONG UNIVERSITY

Extraction method of lincomycin

ActiveCN103724380AHigh strengthExtended service lifeSugar derivativesSugar derivatives preparationChemical oxygen demandUltrafiltration

The invention provides an extraction method of lincomycin. The extraction method mainly comprises the following steps: adjusting acidity of fermentation liquor, filtering by using a ceramic ultrafiltration membrane, then adjusting alkalinity, then filtering by using a ceramic ultrafiltration membrane again, then carrying out primary sec-octyl alcohol extraction and hydrochloric acid back-extraction, adjusting alkalinity of the primary back extraction liquor and then filtering by using a ceramic ultrafiltration membrane again; carrying out secondary sec-octyl alcohol extraction and hydrochloric acid back-extraction and adding acetone to the secondary back extraction liquor to carry out evaporative crystallization. According to the extraction method provided by the invention, the yield of the lincomycin is high, the color grade of the lincomycin can be improved, and the B component content in the lincomycin is reduced. According to the extraction method of the lincomycin, the feed liquid quality of other extraction technologies can be improved by a membrane treatment process, the integral extraction efficiency is further improved, the residual volume of sec-octyl in raffinate in the extraction procedure is reduced, the product quality is improved, and meanwhile, the COD (Chemical Oxygen Demand) in produced wastewater is reduced. The extraction method has certain economic benefit and environmental benefit.

Owner:JIANGSU JIUWU HITECH

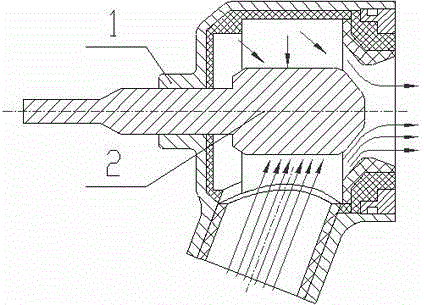

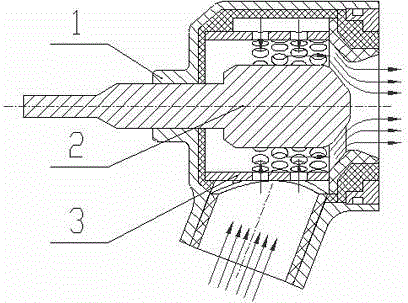

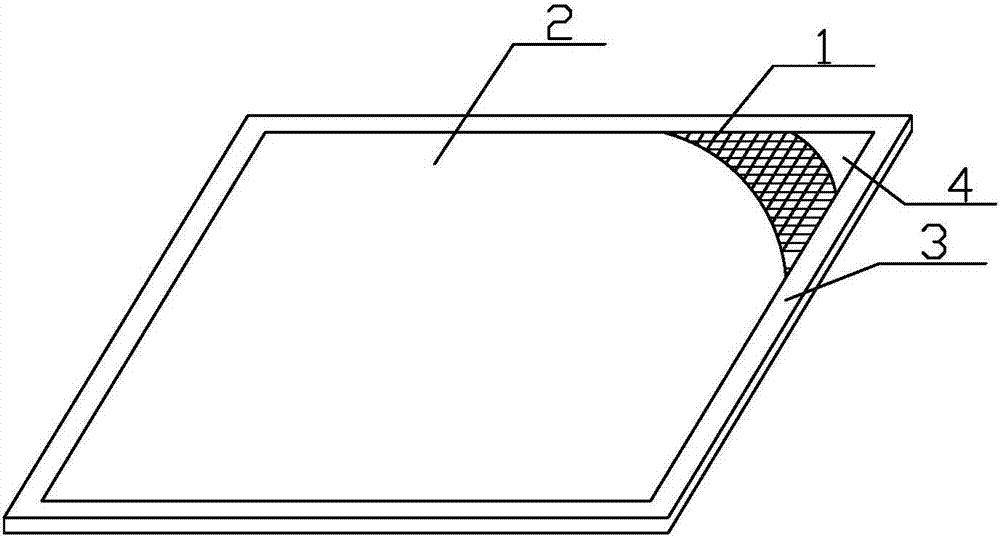

Gradual-change cavity microperforated broad band sound absorption type sound barrier

ActiveCN101139822AImprove the sound absorption coefficientSound absorption frequency bandwidthNoise reduction constructionSound barrierAbsorption factor

The invention belongs to the acoustical technical field and relates in specific to a novel non-fiber type and micropunched sound absorption type sound barrier body with transition cavity. The invention comprises a micropunched panel, a top face, a bottom face, a left end face, a right end face and a back plate; the micropunched panel, the top face, the bottom face, the left end face, the right end face and the back plate are connected to form a closed cavity; the cavity depth appears in a linear transition; the maximum depth is 2.5 to 3.5 times as the minimum depth. The micropunched panel is arranged with micropores with total occupied area of 0.5 percent to 3 percent of the panel area; the micropore aperture is 0.6 to 1.2mm. In actual use, it is only necessary to mount the invented device into a sound barrier vertical column or other places for sound absorption process. The invented device is characterized in being simple, easy and convenient manufacturing, thin shape and being light and having perfect sound absorption performances. Sound absorption band width with sound absorption factor higher than 0.4 exceeds 2 octaves. Therefore, the invention has advantages of broad application scope, easy purging, high-temperature resistance, and superior weather ability. Besides, the invented device can be completely recycled for use to thoroughly avoid the problem of secondary pollution, for which the invention has superior environmental protection function.

Owner:SHAZC GRP CORP LTD

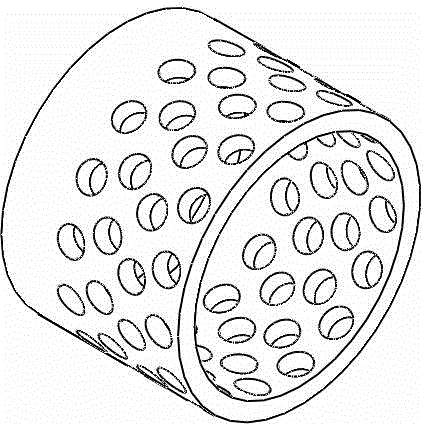

Annular porous flow disturbing structure of gas flow adjusting device of solid rocket engine

The invention proposes an annular porous gas turbulence structure of a solid rocket motor gas flow regulating device, which premixes and evenly distributes the high-temperature and high-speed incoming gas, reduces the uneven erosion and aerodynamic impact of the gas on the valve core of the flow regulating device, and can also be used To filter some of the bulky debris entrained in solid rocket motor gases. The annular porous gas turbulence structure can process multiple air holes on the annular turbulence structure according to the incoming flow direction. The shape and number of air holes can be adjusted according to the area of the gas inlet and nozzle outlet. The periphery of the spool of the regulating device is fixed between the gas inlet and the spool of the flow regulating device through mechanical and adhesive means. The invention not only has the characteristics of simple structure, compactness, easy molding, convenient assembly, high temperature resistance, reliable operation, etc.; it also plays the role of premixed gas flow, uniform distribution of gas, and reduces local erosion and ablation of high-temperature and high-speed gas on the gas flow adjustment device. .

Owner:SHANGHAI XINLI POWER EQUIP RES INST

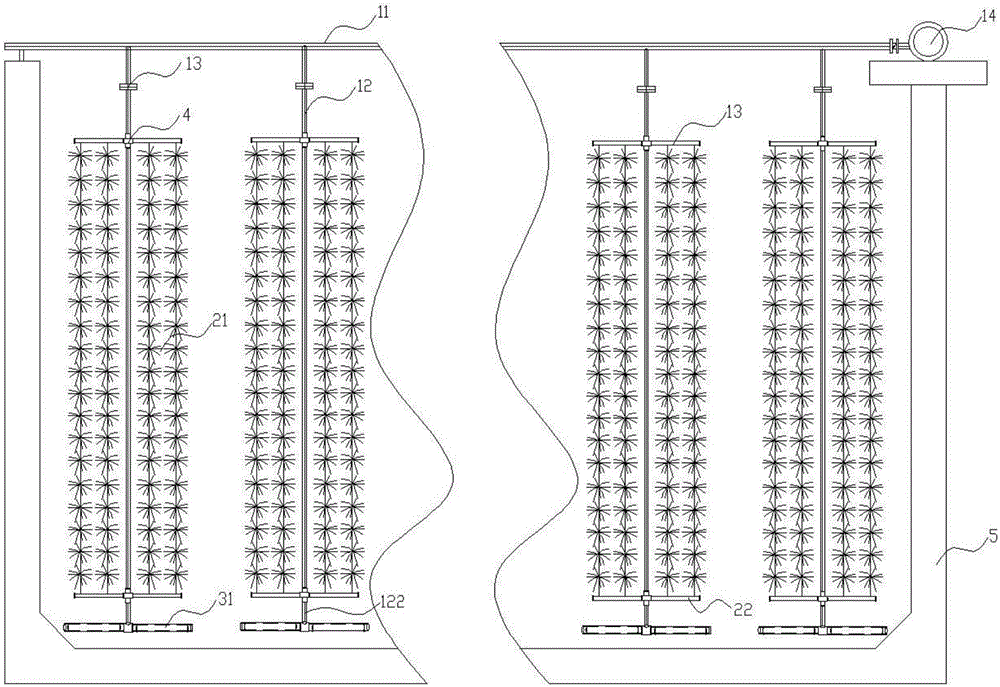

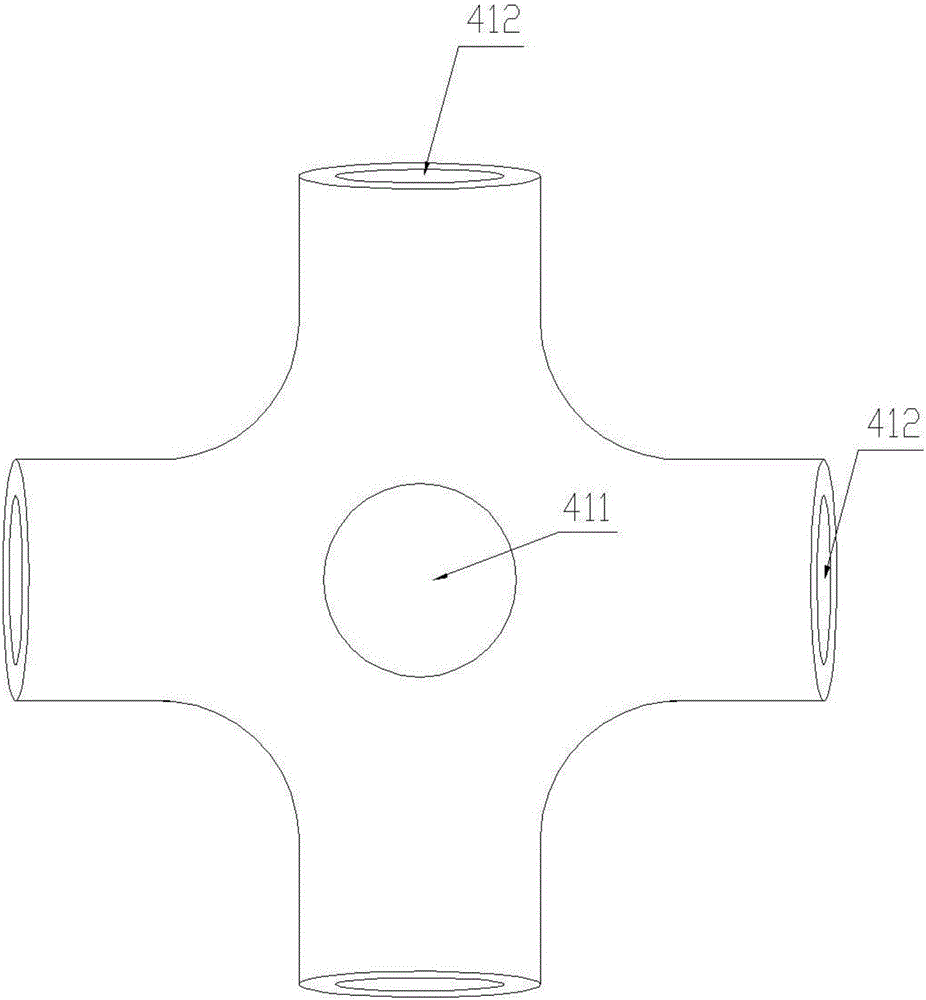

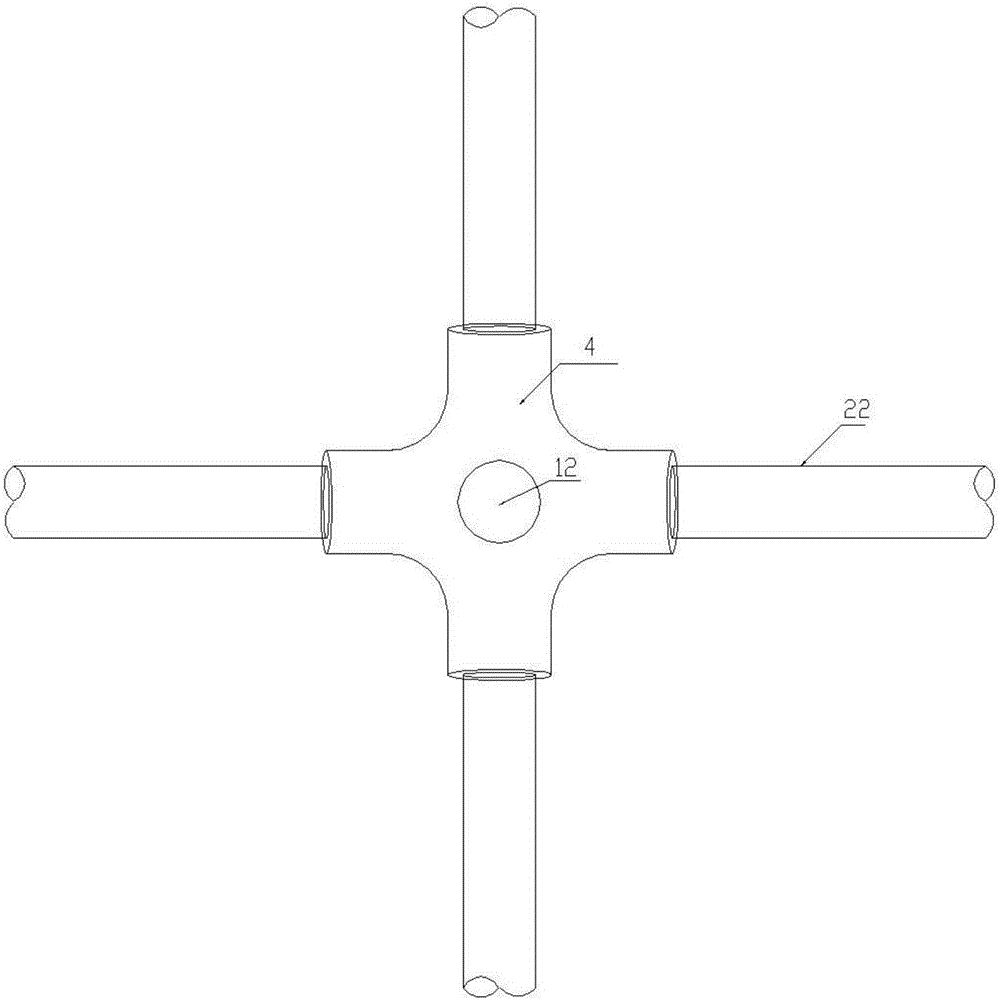

Aeration and filler integrated suspended lift mounting system

PendingCN106186291AOutstanding and Beneficial Technical EffectsCut costsBiological treatment apparatusSustainable biological treatmentAeration systemWastewater

The invention belongs to the technical field of wastewater treatment, and particularly relates to an aeration and filler integrated suspended lift mounting system. The system comprises an air intake system, a filler system and an aeration system; the air intake system is mounted over a water tank and comprises a plurality of air intake branches and a plurality of air intake branching tubes, and each air intake branch is connected with a plurality of the air intake branching tubes; the filler system is arranged inside the water tank and comprises biological filler and filler connecting tubes, and the biological filler is fixed between the air intake system and the aeration system through the filler connecting tubes; the aeration system is mounted at the bottom of the tank and connected with the air intake system through the air intake branching tubes. Aeration and filler are integrated to be applied to urban sewage treatment and treatment of many kinds of industrial wastewater, the aeration and filler systems are mounted in a supportless manner, and a short way which is simple, easy and good in treatment effect is provided for effective treatment of various types of wastewater.

Owner:余昕

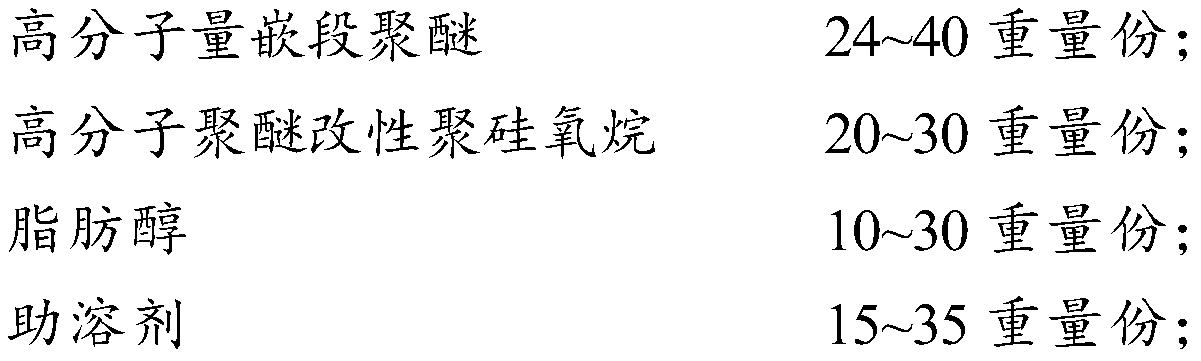

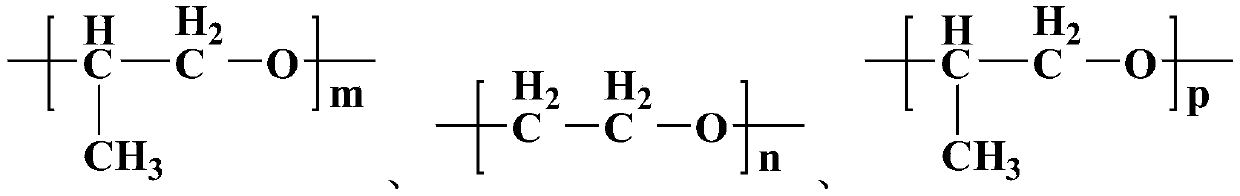

Preparation method of high-molecular-weight block polyether, silyl ether mixed defoaming agent and preparation method thereof

PendingCN111019116ANot easy to decomposeLong foam suppression timeFoam dispersion/preventionAlkanePolymer science

The invention provides a silyl ether mixed defoaming agent. The silyl ether mixed defoaming agent comprises the following components in parts by weight: 24-40 parts of high molecular weight block polyether; 20-30 parts of polymer polyether modified polysiloxane; 10-30 parts of fatty alcohol; and 15-35 parts by weight of a cosolvent; wherein the high-molecular-weight block polyether is obtained bypolymerizing polyol and alkylene oxide; wherein the high-molecular silyl ether modified polysiloxane is prepared from high-molecular-weight block polyether modified polysiloxane. Compared with the prior art, the polyether chain segment with hydrophilicity is grafted to the polysiloxane chain segment with hydrophobicity, so that the formed silyl-ether copolymer has the advantages of two defoaming agents, namely silicon and ether; the high molecular polyether modified polysiloxane and the high molecular weight block polyether are compounded for use, so that the good defoaming effect of the highmolecular polyether modified polysiloxane and the good foam inhibition effect of the high molecular weight block polyether have a synergistic effect, the reduction of the foam amount is effectively ensured, and meanwhile, the fatty alcohol with high surface activity is matched, so that the improvement of the defoaming efficiency is promoted.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

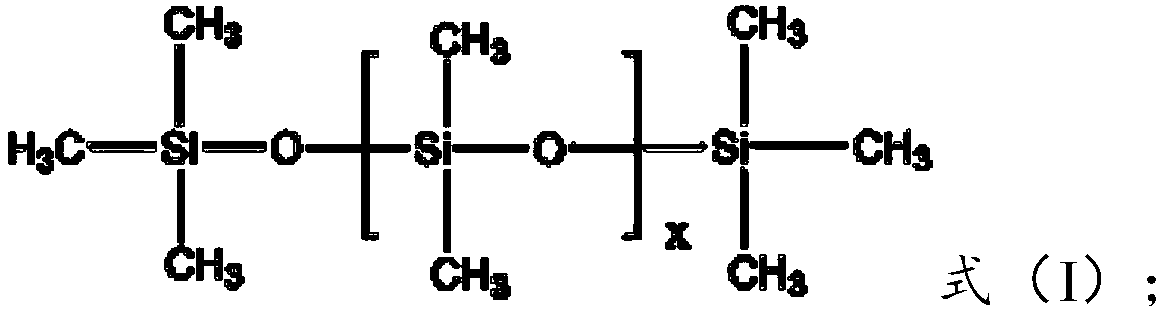

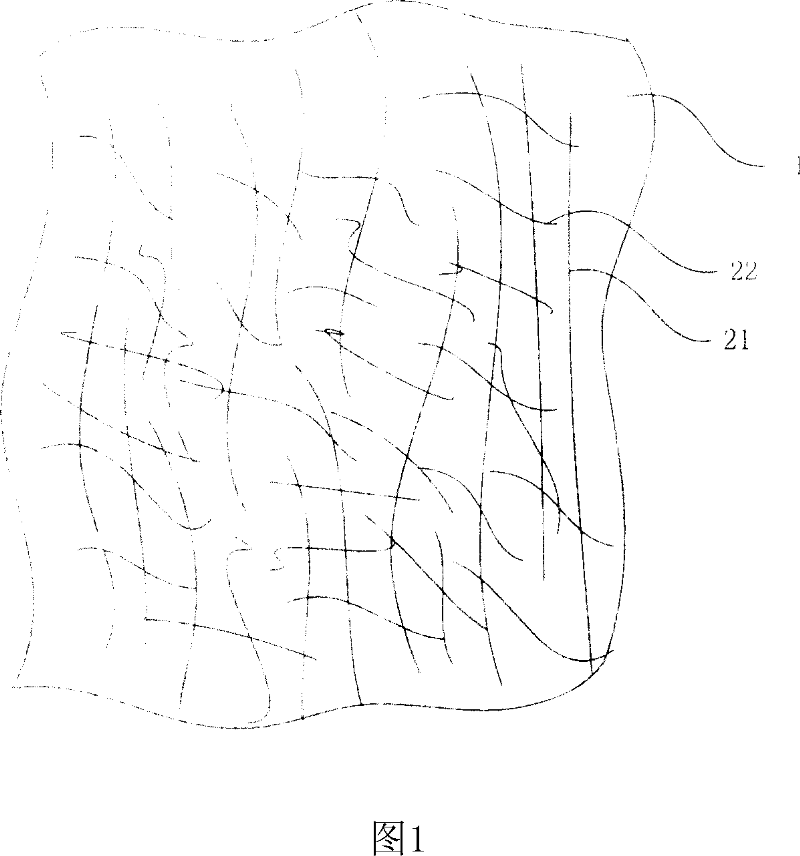

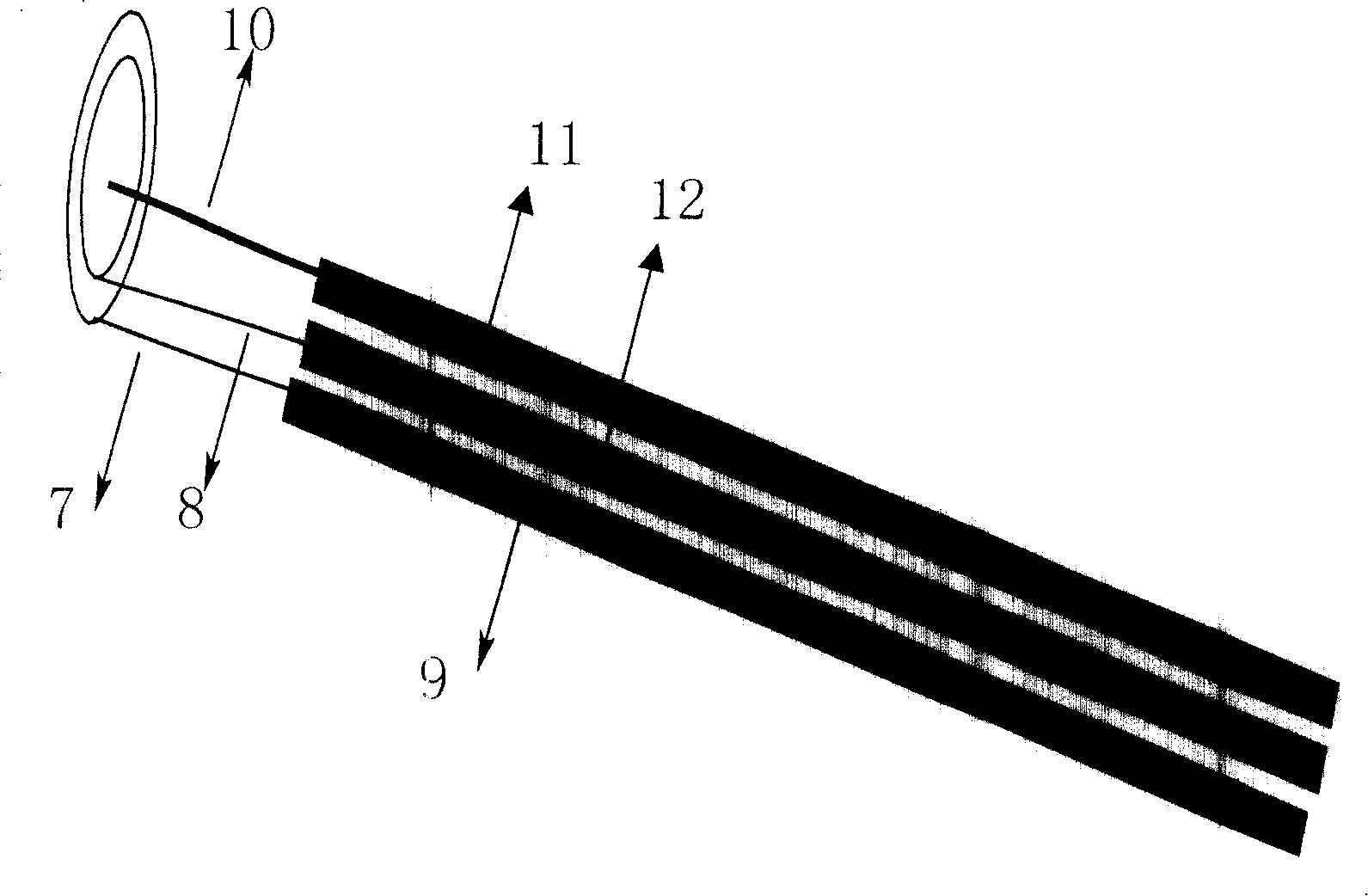

Conductive plastic and its processing method and apparatus

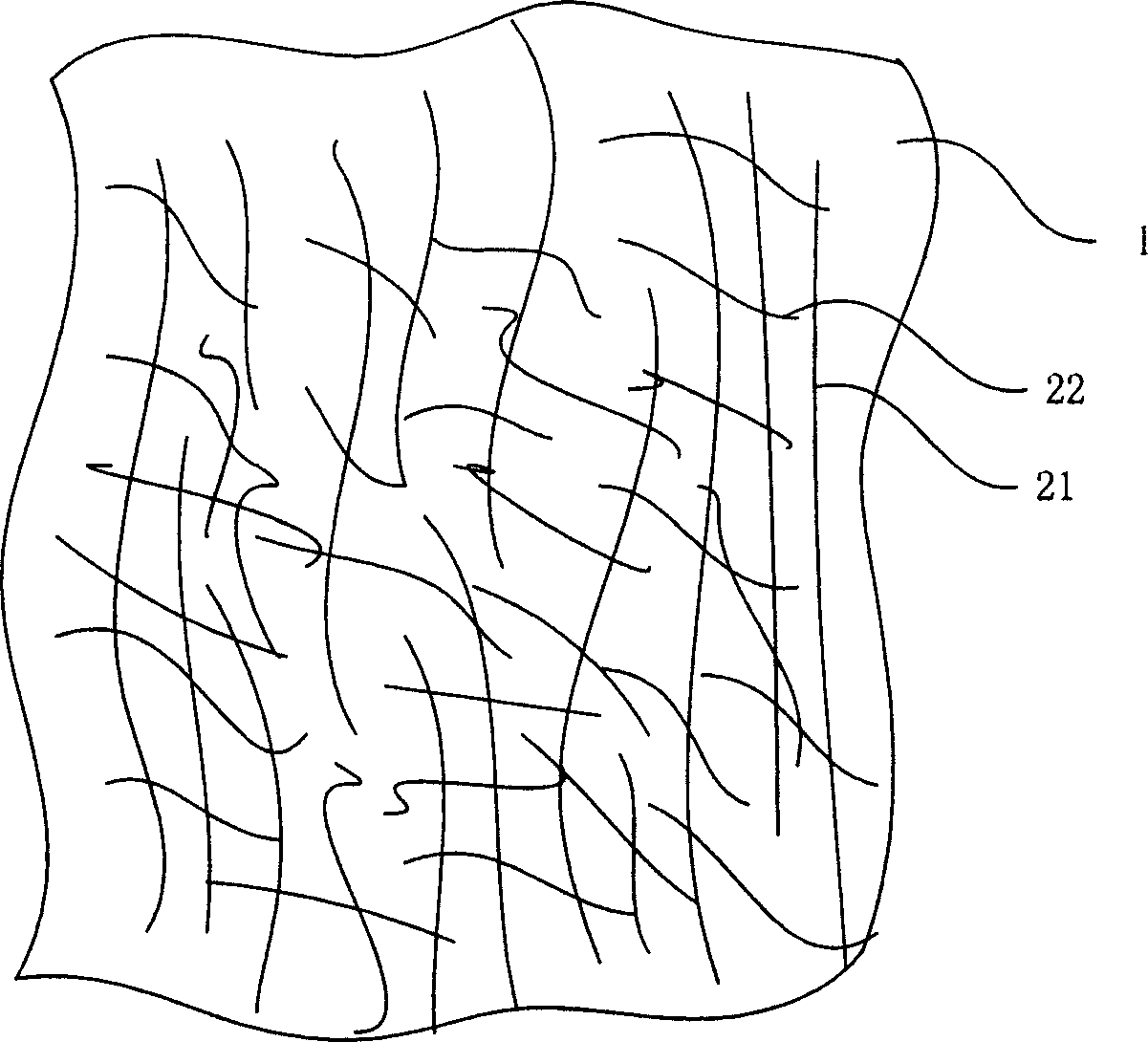

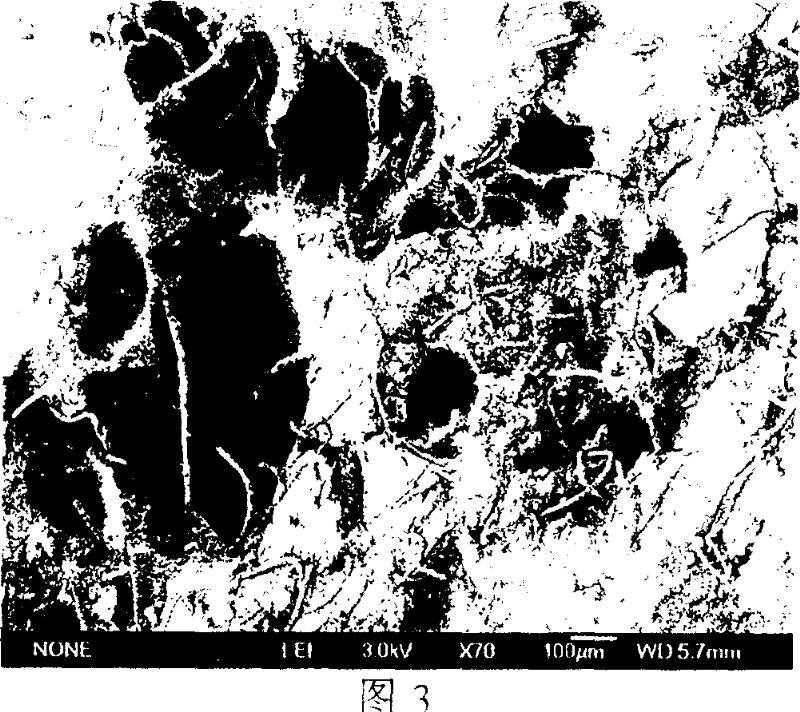

InactiveCN100338130CVolume resistivity is stableImprove antistatic performanceFiberElectrical resistance and conductance

The present invention discloses one kind of conductive plastic and its processing method and apparatus. The conductive plastic includes conductive fiber 0.1-45 vol%, thermoplastic plastic 55-99 vol% and machining assistant 0-3 vol%. The conductive fiber is arranged in 3D netted form homogeneously with multiple joining points, and the conductive plastic has high conductivity, high antistatic and electromagnetic shielding effect, and low surface resistance and volumetric resistivity, and may be injected, extruded and molded like common plastic.

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

A kind of extraction method of lincomycin

ActiveCN103724380BHigh strengthExtended service lifeSugar derivativesSugar derivatives preparationBiotechnologyChemical oxygen demand

The invention provides an extraction method of lincomycin. The extraction method mainly comprises the following steps: adjusting acidity of fermentation liquor, filtering by using a ceramic ultrafiltration membrane, then adjusting alkalinity, then filtering by using a ceramic ultrafiltration membrane again, then carrying out primary sec-octyl alcohol extraction and hydrochloric acid back-extraction, adjusting alkalinity of the primary back extraction liquor and then filtering by using a ceramic ultrafiltration membrane again; carrying out secondary sec-octyl alcohol extraction and hydrochloric acid back-extraction and adding acetone to the secondary back extraction liquor to carry out evaporative crystallization. According to the extraction method provided by the invention, the yield of the lincomycin is high, the color grade of the lincomycin can be improved, and the B component content in the lincomycin is reduced. According to the extraction method of the lincomycin, the feed liquid quality of other extraction technologies can be improved by a membrane treatment process, the integral extraction efficiency is further improved, the residual volume of sec-octyl in raffinate in the extraction procedure is reduced, the product quality is improved, and meanwhile, the COD (Chemical Oxygen Demand) in produced wastewater is reduced. The extraction method has certain economic benefit and environmental benefit.

Owner:JIANGSU JIUWU HITECH

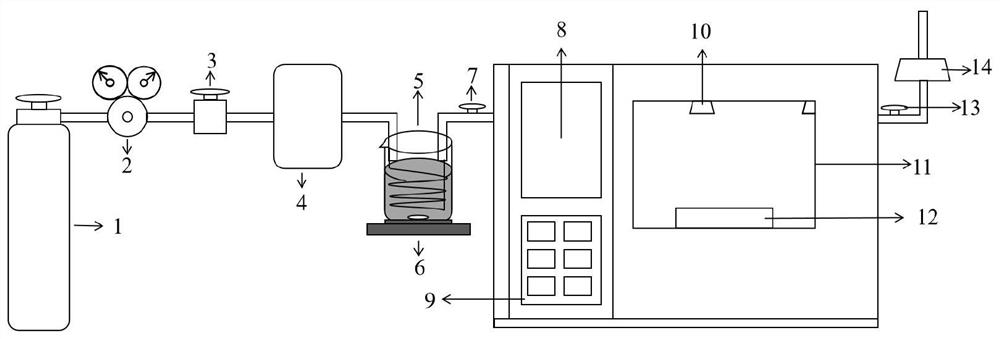

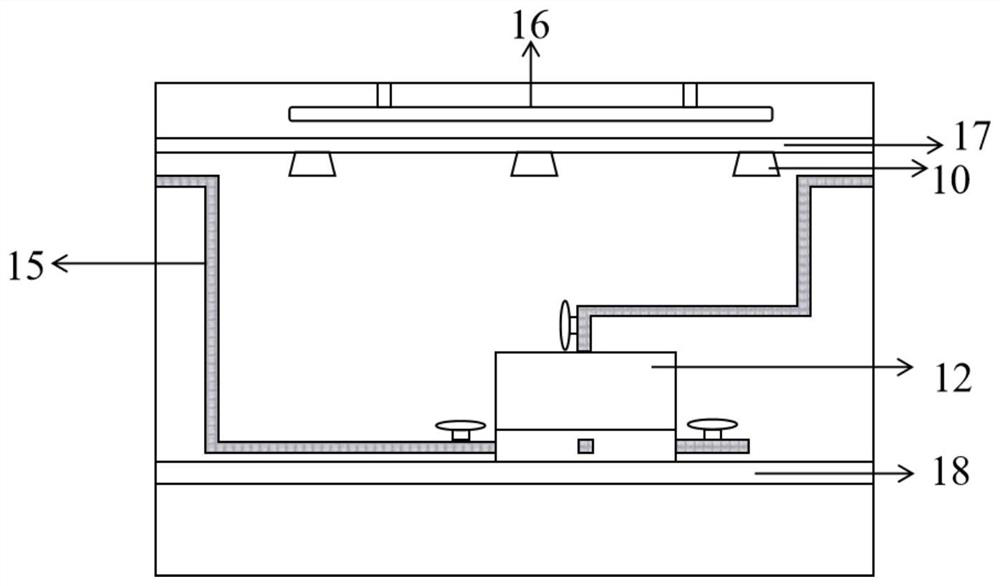

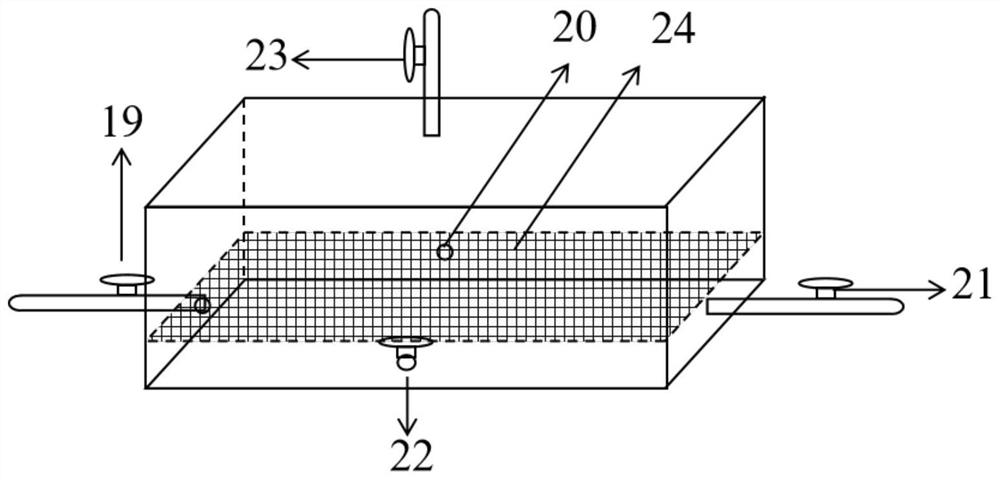

Asphalt accelerated aging test device for simulating all-weather multi-environment coupling effect

PendingCN113109241AWide applicabilityImprove economyWeather/light/corrosion resistanceMagnetic stirrerBeaker

The invention discloses an asphalt accelerated aging test device for simulating an all-weather multi-environment coupling effect. The device comprises a synthetic air bottle, a pressure regulator, a flow valve, an ozone generator, a beaker, a heatable magnetic stirrer, an air inlet valve, a display screen, a control panel, a spraying device, an observation window, a small test box, an air outlet valve, an exhaust hood, an internal pipeline, an ultraviolet radiation device, a water pipe, a sample rack, a small test box air inlet valve, a small test box air outlet valve and a screen. Gas factors are utilized to accelerate simulation of long-term thermo-oxidative aging of the asphalt binder, the aging process of the asphalt binder is accelerated, and trace active oxygen existing in reality is added in a high-concentration form. The device can simultaneously reflect the influence of environmental factors such as temperature, ultraviolet rays, rainfall, oxygen, ozone and nitrogen oxides in the nature to accurately simulate the asphalt aging behavior in all weathers, so that the indoor test result is more in line with the actual service condition of the asphalt pavement.

Owner:BEIJING UNIV OF TECH

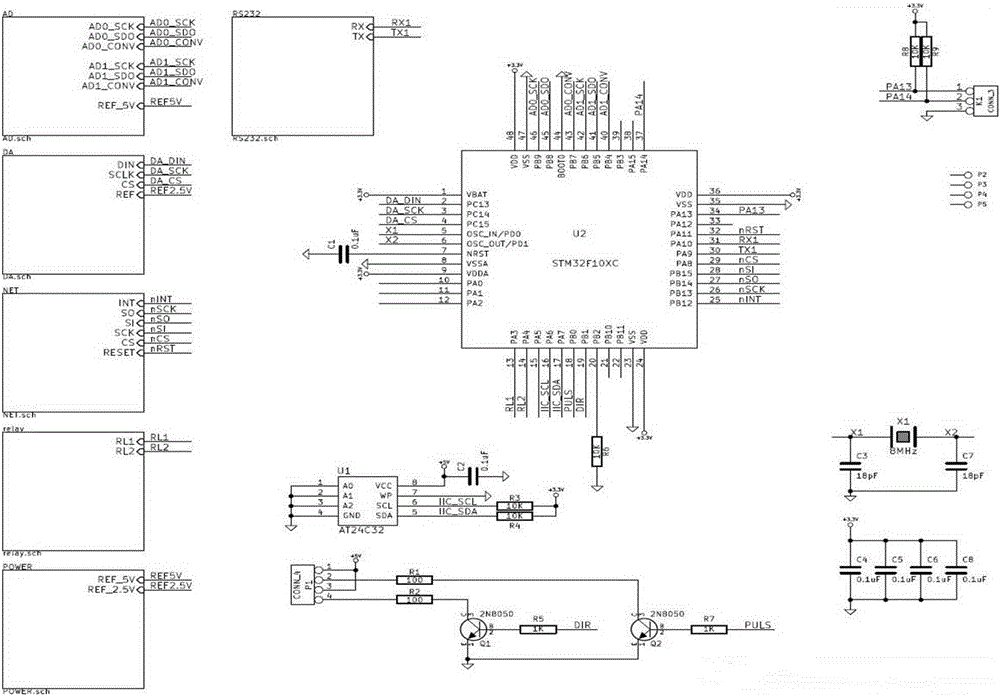

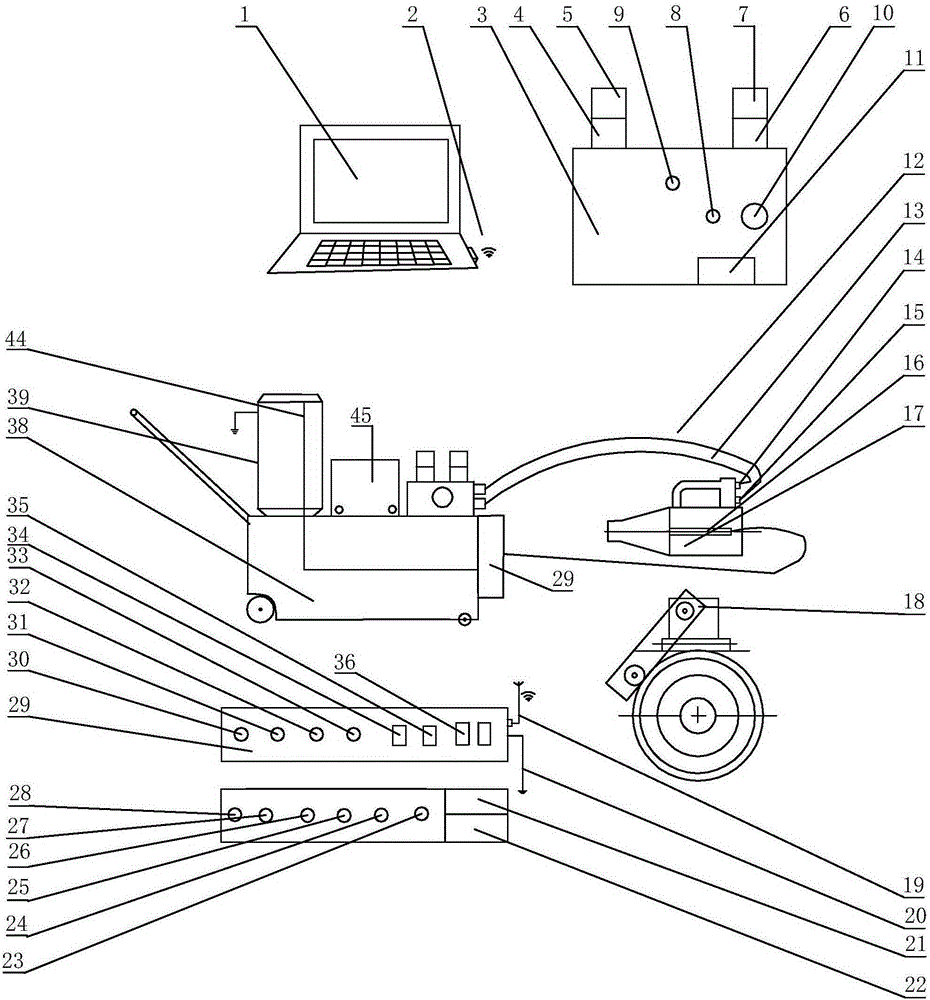

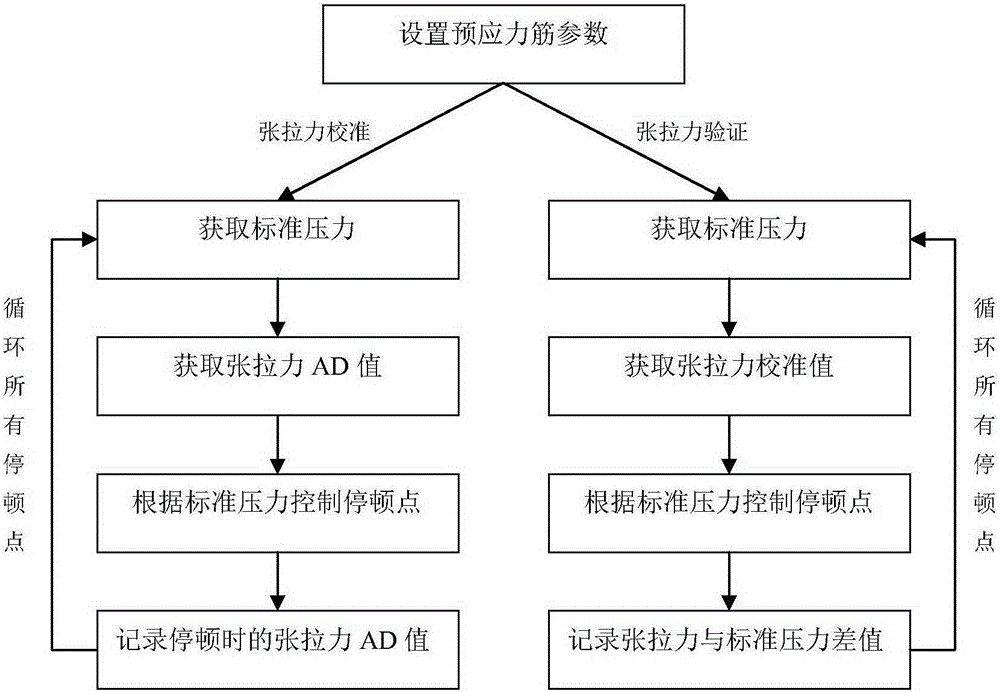

Servo-type reverse-pulling pre-stress detector

The invention discloses a servo-type reverse-pulling pre-stress detector, and the detector comprises an oil tank, a displacement sensor, a centre hole jack, a control box, a combined valve body, a motor, and an intelligent terminal. The motor serves as a servo motor and a servo driver. The intelligent terminal and an industrial level wireless router integrated with a control circuit in the control box form a wireless local network. A pressure transmitter and the displacement sensor respectively transmit a pressure signal and a displacement signal to the control box, and an Ethernet communication module in the control box transmits the signals to the router. The signals are transmitted to the intelligent terminal through the router, and an instruction signal for hydraulic control is transmitted to the router in a wireless manner after processing. The instruction signal is transmitted to the Ethernet communication module in the control box through the router, and then is transmitted to the servo driver after processing, so as to control the servo motor to operate and to carry out hydraulic lifting and descending for pre-stress detection. The detector employs a servo motor, so the system can guarantee the detection precision, is good in adaptability, improves the detection efficiency, and prolongs the service life. Wireless communication is employed between the intelligent terminal and the control box, so the detector is good in operation flexibility.

Owner:GUANGDONG HELI CIVIL ENG CO LTD +1

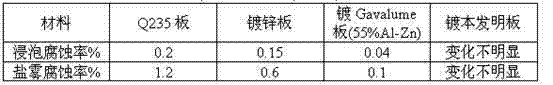

Be and multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material and preparation method thereof

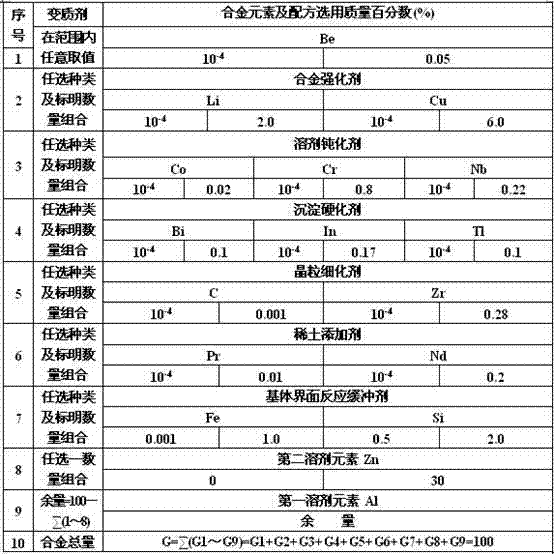

InactiveCN102650026AOrganizational structure optimizationAchieving resistance to acid, alkali and salt corrosionHot-dipping/immersion processesAlloy coatingUltimate tensile strength

The invention discloses a Be and multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material and a preparation method thereof. The alloy comprises the following components in weight percentage: not greater than 30 percent of Zn, 10<-4>-0.05 percent of Be, 10<-4>-6.0 percent of alloy enhancer, 10<-4>-1.0 percent of solvent passivator, 10<-4>-0.5 percent of sediment hardening agent, 10<-4>-1.0 percent of grain refiner, 10<-4>-1.0 percent of rare earth addition, 0.001-2.0 percent of matrix interface reaction buffering agent and the balance Al and unavoidable trace impurities. The aluminum alloy coating material produced according to the technical scheme provided by the invention can be used for forming light and thin high-quality coatings on the surfaces of steel and iron alloy, wherein the light and thin high-quality coatings are attractive and are high in corrosion resistance, abrasion resistance, strength and ductility and good in matrix metallurgical bonding. The aluminum alloy coating material can be used for anti-corrosion coatings on the surfaces of steel and iron alloy products. Production equipment for the aluminum alloy coating material does not need to be specially made; the source of the raw material is rich; the starting cost is low; and the industrial waste can be conveniently and cyclically utilized.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

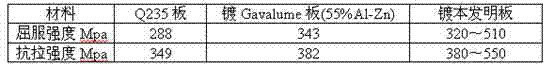

Plastic baking oven pad and manufacturing process thereof

InactiveCN107081944AEasy to cleanEasy to withstand high temperatureLamination ancillary operationsLaminationFiberGlass fiber

The invention discloses a plastic oven mat, which comprises a steel wire mesh, a silicon rubber layer, wrapping, and a glass fiber base cloth; a steel wire mesh is laid on the upper surface of the glass fiber base cloth, a silicon rubber layer is laid on the surface of the steel wire mesh, and the edge of the silicon rubber layer is Package has binding. The invention provides a plastic oven mat. The plastic oven mat is easy to clean, high temperature resistant, and environmentally friendly. At the same time, it has good plasticity. When baking food, the edge of the plastic oven mat can be folded and placed in a baking tray. The food that needs to be baked is placed in the baking tray for baking, and the oil stains on the food can be collected by the plastic oven mat folded at the edge, so as to avoid the oil stains from contaminating the oven.

Owner:江苏东剑材料科技有限公司

Preparation method of electrochemical combined electrode

This invention relates to a method for processing electrochemical combination electrodes sealed by the nm flexible epoxy resin material including: 1, inserting a working electrode matrix material into a conductive support copper rod wrapped with an insulation pyrocondensed tube, a hole Ag reference electrode is welded to the support copper rod, the bottom of a hole Pt counter-electrode is welded to the support copper rod, the hole Ag reference electrode, the hole Pt counter-electrode and the working electrode matrix are arrayed from inside to outside with the working electrode at the middle, the tops of which are at a same plane, the support copper rods of them are fixed by a pyrocondensed tube and put into a die set and fixed, 2, casting the nm flexible epoxy resin material onto the die set to deaerate and cure it, 3, taking out the electrode after cooling it and polishing it.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

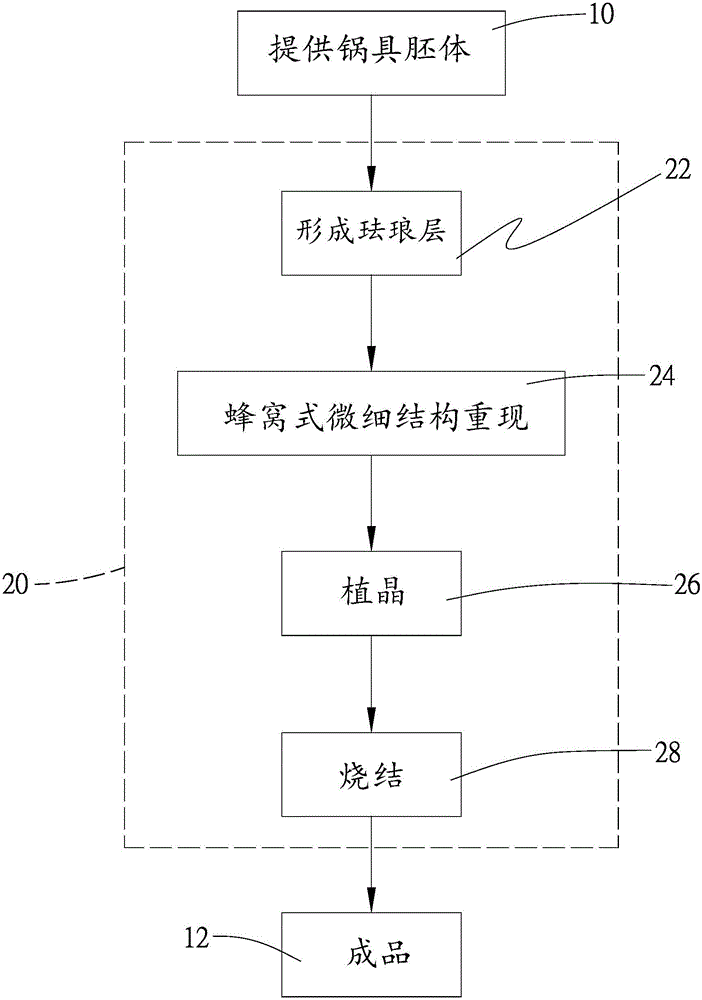

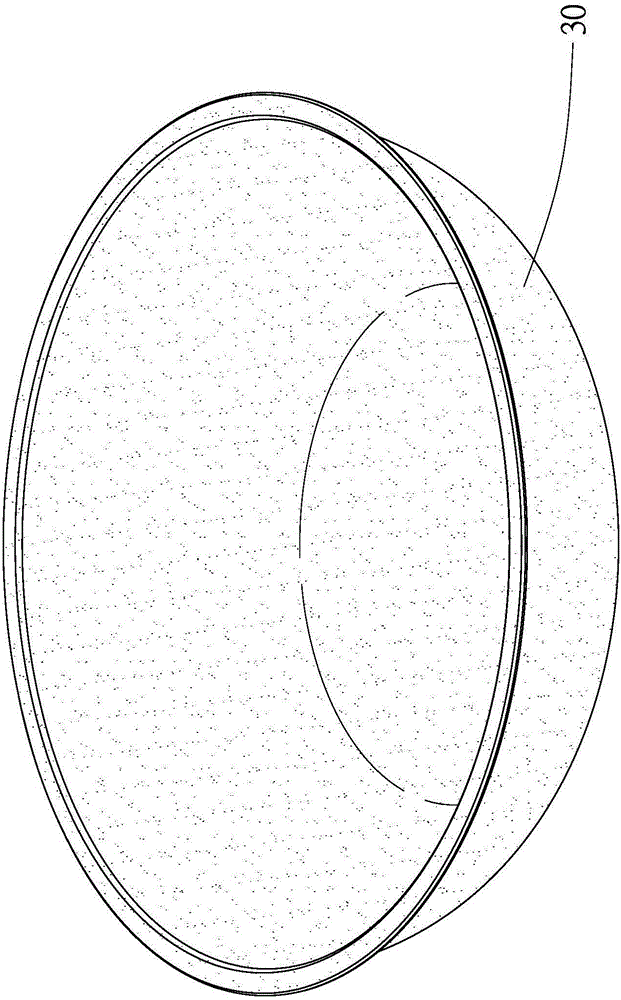

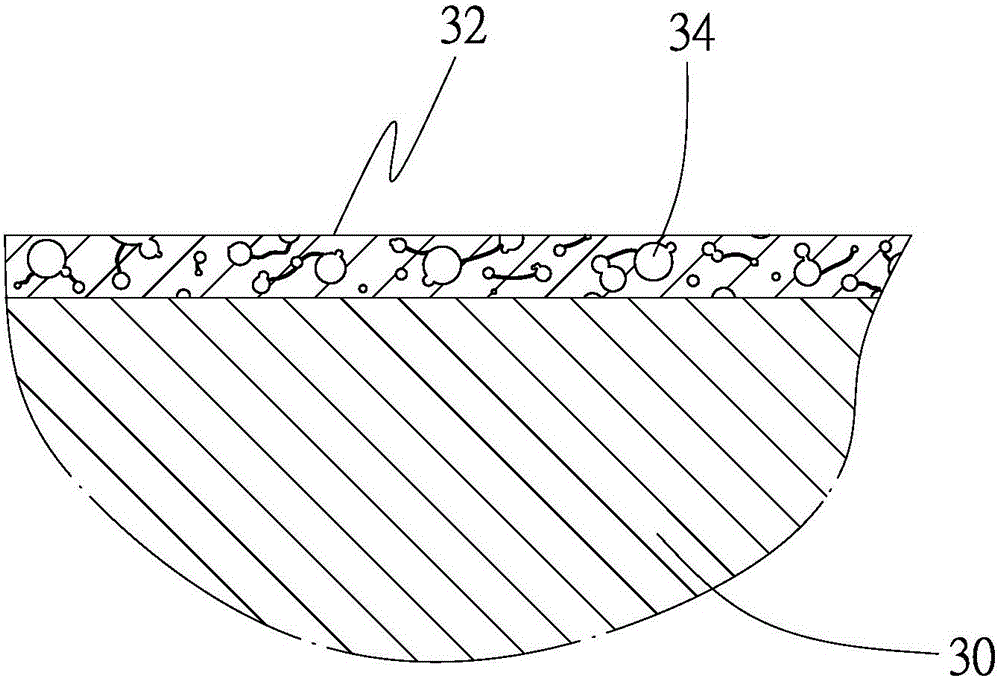

Preparing method and structure for cookware with lotus effect surface

ActiveCN107433331AWith oil absorption/drainage effectDoes not reduce lifespanMaterial nanotechnologySilicaFine structureDeep frying

The invention provides a preparing method and a structure for cookware with a lotus effect surface. The preparing method for the pot comprises the steps that surface treatment such as forming an enamel layer, repeating a honeycomb fine structure, crystal planting and sintering is performed on a pot blank body, so that nano Si-O-Si molecules are attached to the pot blank body, and a surface of a non-stick cookware is made. Therefore, the cookware made by the method has the structure that a lotus stone carrier is attached to the surface of the pot blank body, and some fine structures are arranged on the surface of the lotus stone carrier; the fine structures are combined with the required nano Si-O-Si molecules, so that the cookware has the advantages of easy cleaning, good hardness, non-stickness and long service life, and is suitable for the surface of comprehensive cooking operations such as cooking, steaming, frying, boiling, frying, deep frying.

Owner:王崇哲

Three-dimensional multi-cavity micro-perforated periodical ultra-wideband sound-absorbing structure

PendingCN108154875AImprove the sound absorption coefficientSound absorption frequency bandwidthSound producing devicesUltra-widebandPeak value

The invention relates to a three-dimensional multi-cavity micro-perforated periodical ultra-wideband sound-absorbing structure, comprising a micro-perforated panel, parallel-arrangement cross sectionsin periodical structure, parallel-arrangement vertical sections in periodical structure and a unit bottom plate are connected to form two, preferably three or four, closed cavities periodically arranged in two orthogonal directions, having maxium depth that is 1.5-5 times as great as minimum depth; the micro-perforated panel is provided with micropores having an area that is 0.2-5% of that of themicro-perforated panel, the micropores are 0.2-1.2 mm in pore diameter, with unit width and length not exceeding 0.15 m. The three-dimensional multi-cavity micro-perforated periodical ultra-widebandsound-absorbing structure is just fixed to a wall in the place requiring sound absorption. The three-dimensional multi-cavity micro-perforated periodical ultra-wideband sound-absorbing structure is simple, is convenient to process, is thin and portable and has good sound-absorbing property, low-frequency sound absorption coefficient is not lower than 0.8, the peak value reaches 1.0, the sound absorption is flat, and the structure is widely applicable, is easy to wash and tolerant to high temperatures, has excellent weatherability and is suitable for complete recycling.

Owner:TONGJI UNIV +1

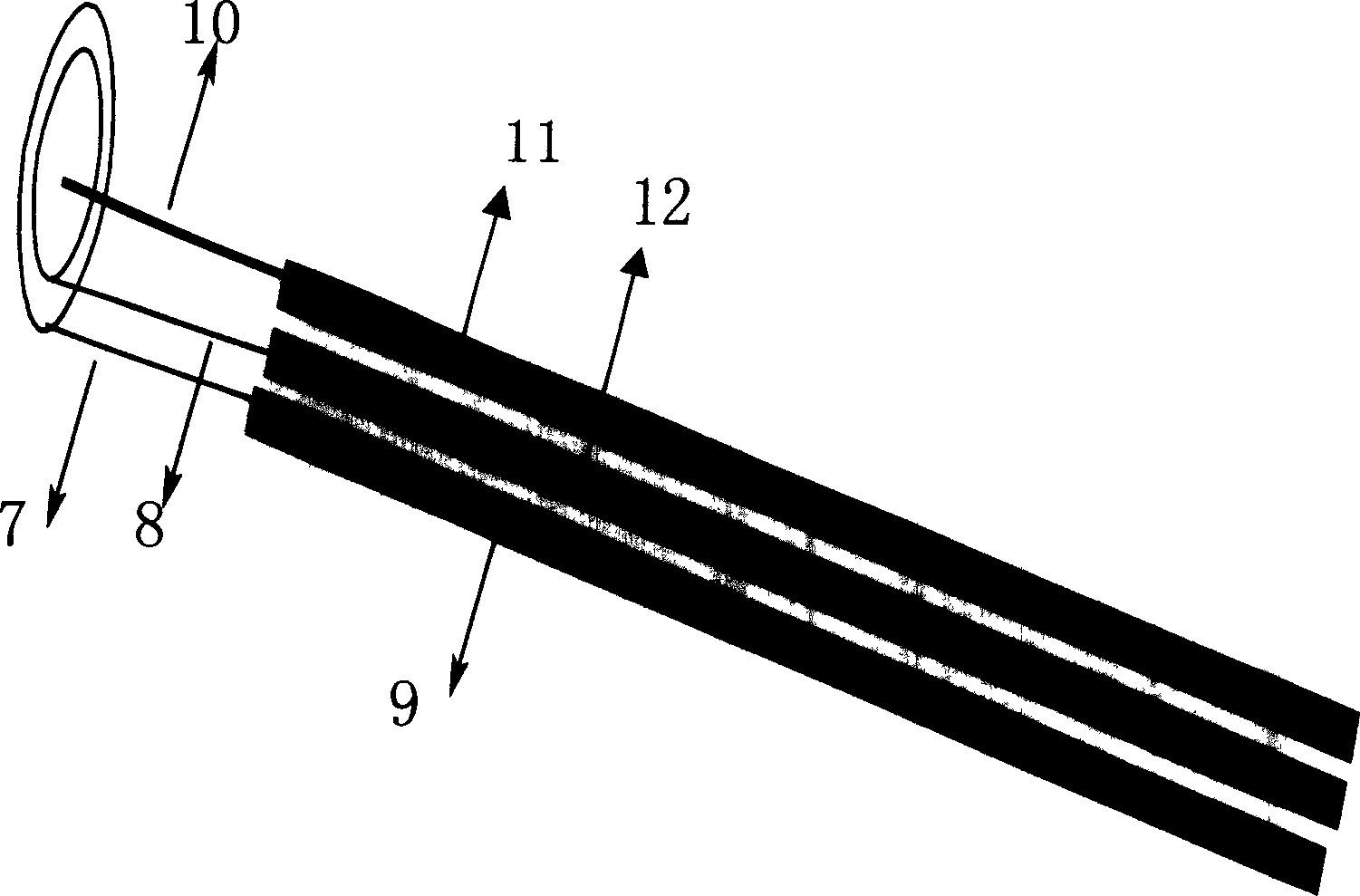

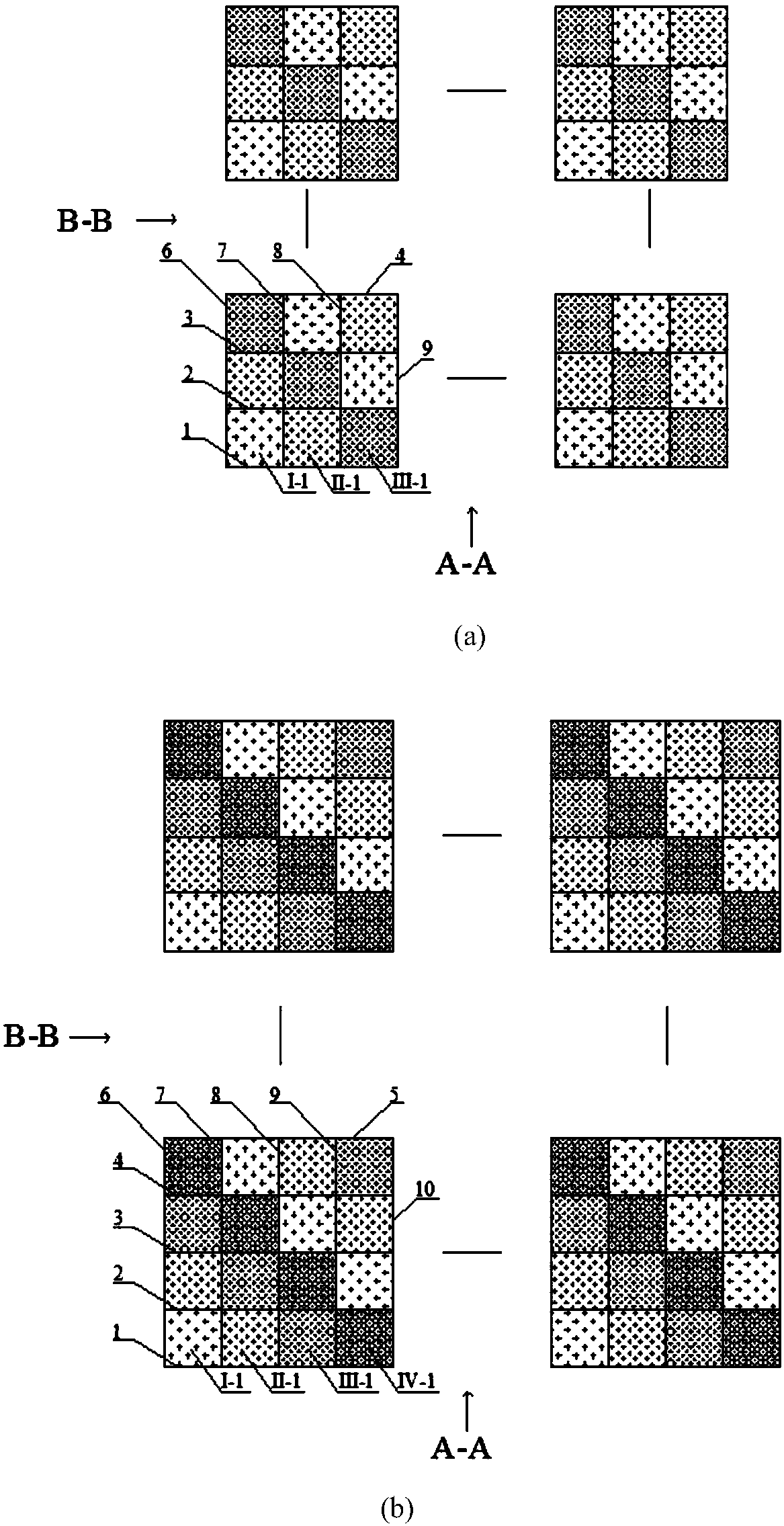

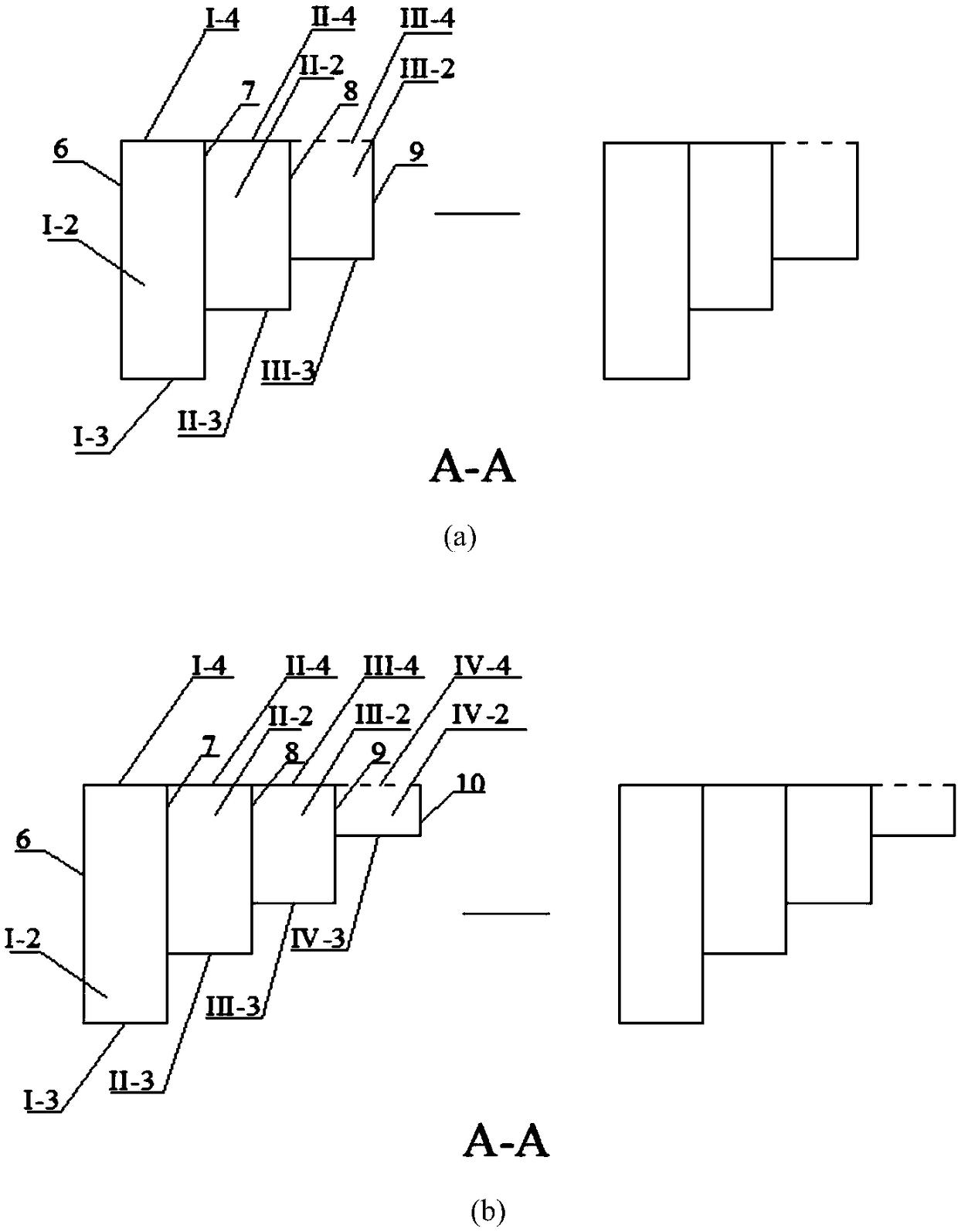

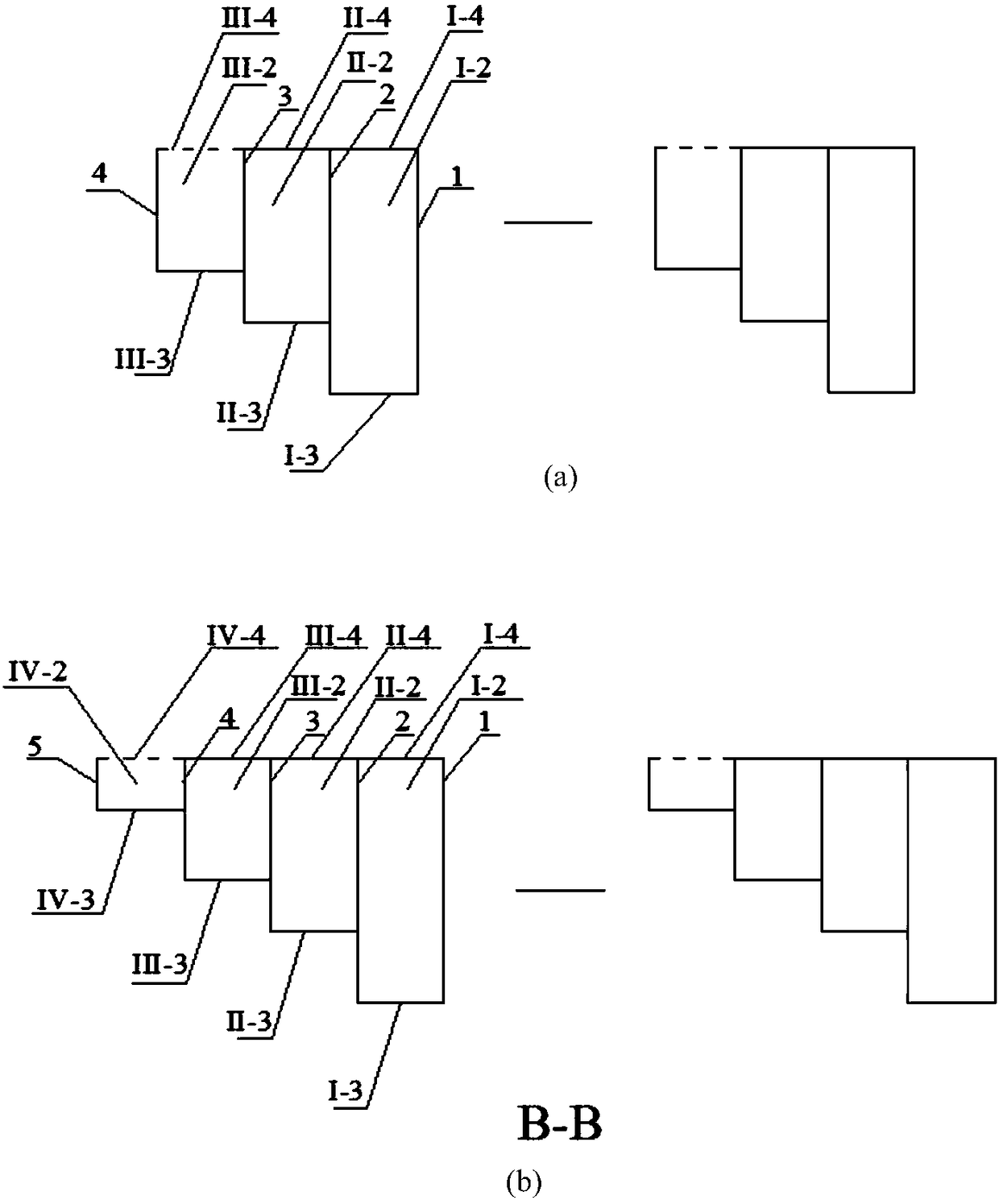

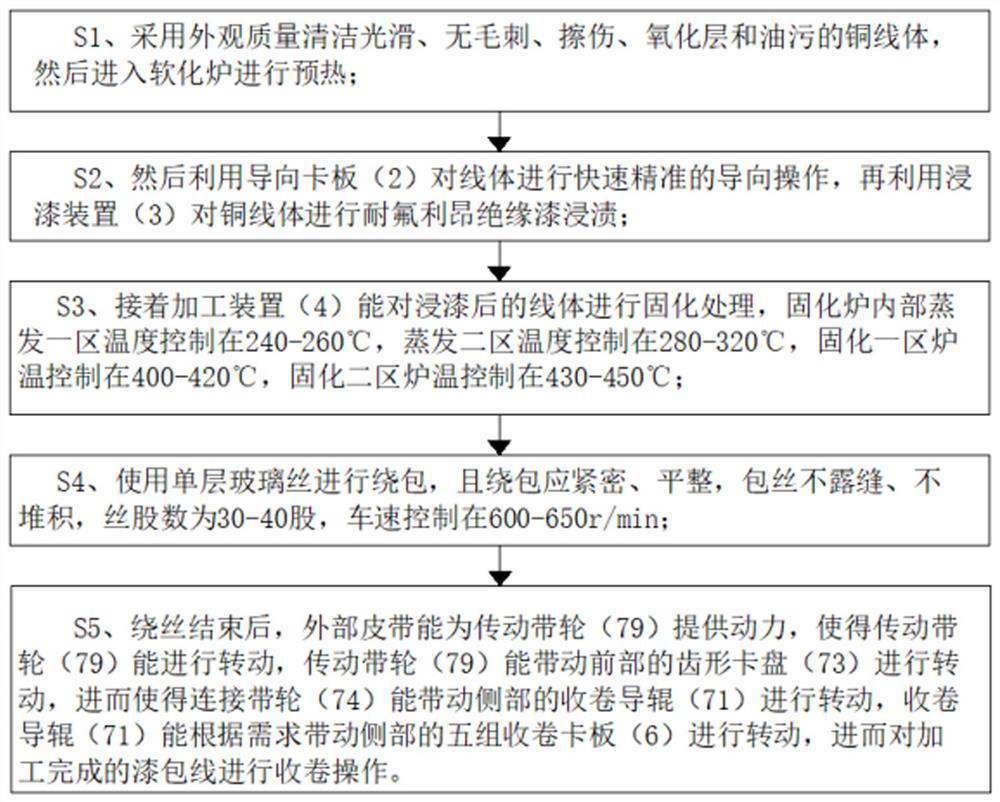

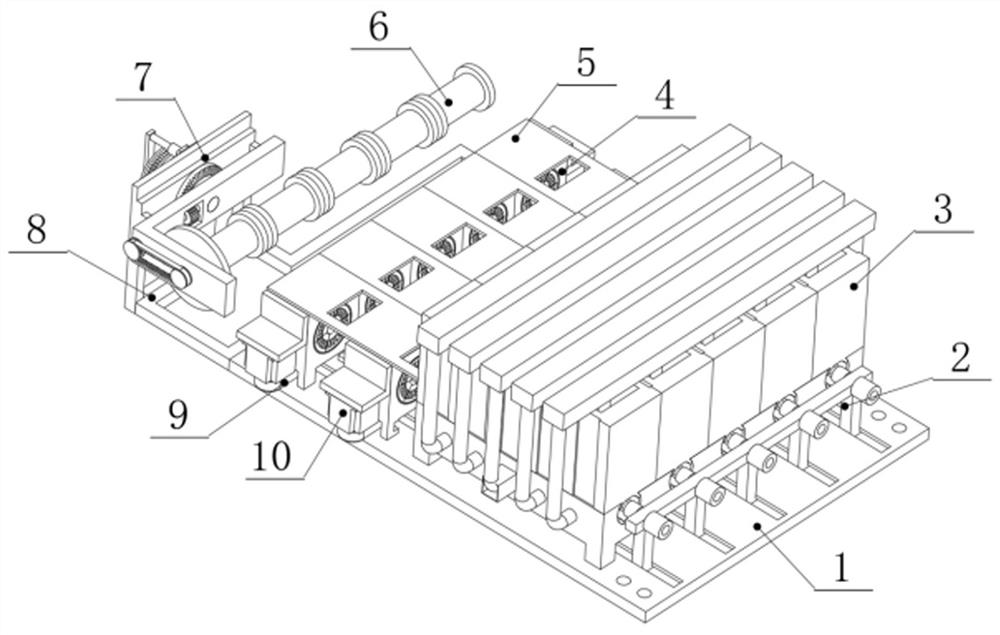

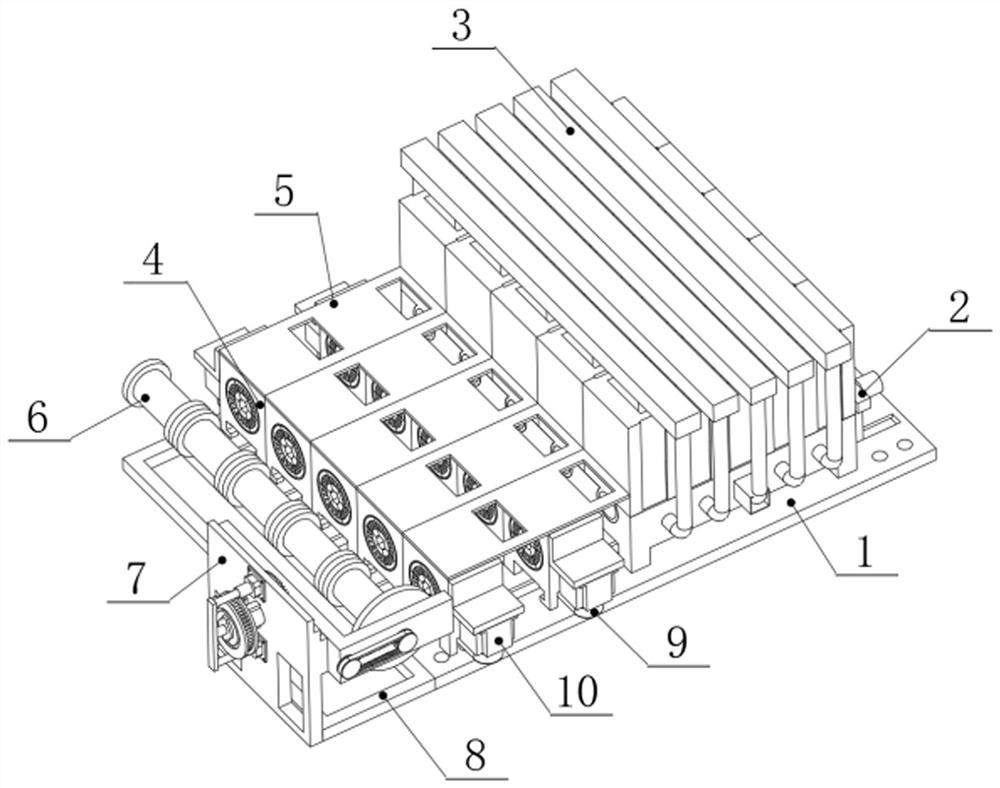

Production process and equipment of Freon-resistant composite enameled wire with glass fiber wrapping

ActiveCN114520083AImprove winding efficiencyImprove processing efficiencyFilament handlingInsulating conductors/cablesGlass fiberFiber

The invention relates to the technical field of composite enameled wire production, in particular to a production process and equipment of a Freon-resistant composite enameled wire wrapped with glass fiber, and the process comprises the following steps: a copper wire body which is clean and smooth in appearance quality and free of burrs, scratches, oxidation layers and oil stains is adopted and then enters a softening furnace to be preheated; then, the wire body is quickly and accurately guided, and the copper wire body is subjected to Freon-resistant insulating paint dipping by using a paint dipping device; then the processing device can carry out curing treatment on the wire body subjected to paint dipping; single-layer glass fibers are used for wrapping, wrapping needs to be tight and flat, and the wrapping fibers are free of seam exposure and accumulation; winding operation is carried out after wire winding is finished; the equipment comprises a supporting bottom plate, a guiding clamping plate, a paint dipping device, a machining device, a connecting clamping plate, a winding clamping plate, a winding device, a connecting bottom frame, a tooth-shaped belt and a servo motor. The preparation method is reasonable in design, simple in process and clear in process route, and the prepared finished product has excellent performance of high temperature resistance, high pressure resistance and corrosion resistance.

Owner:湘潭市霞城电工有限公司

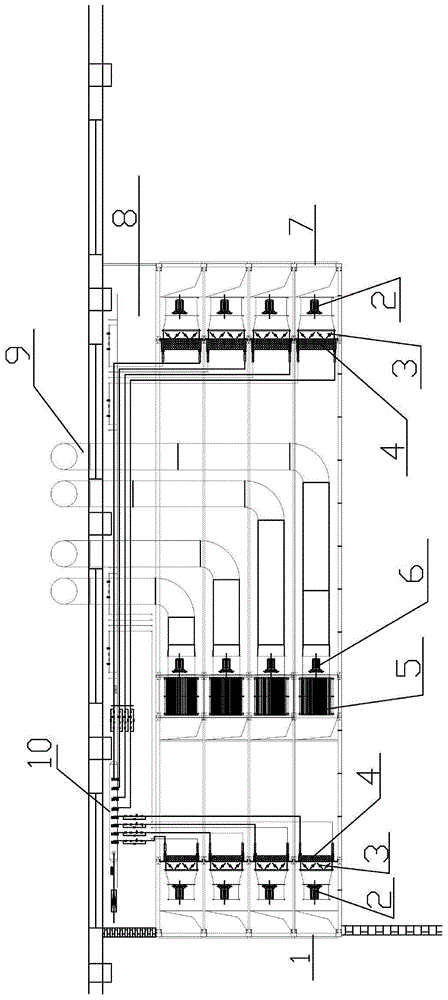

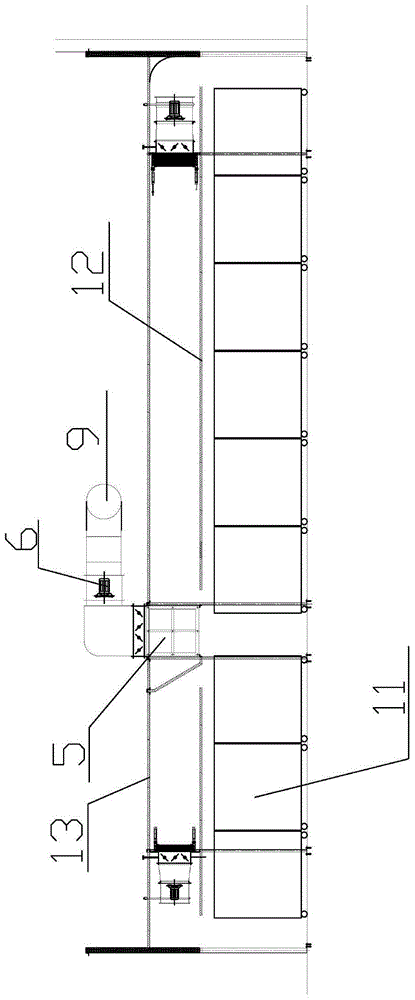

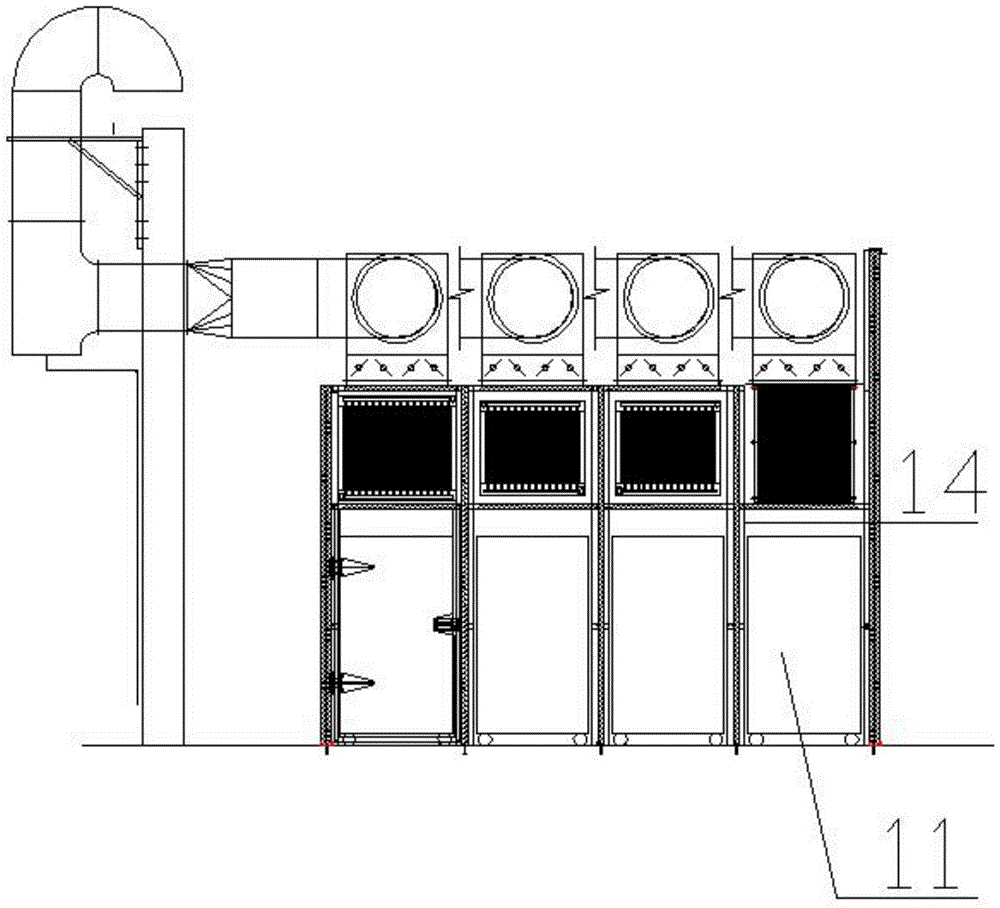

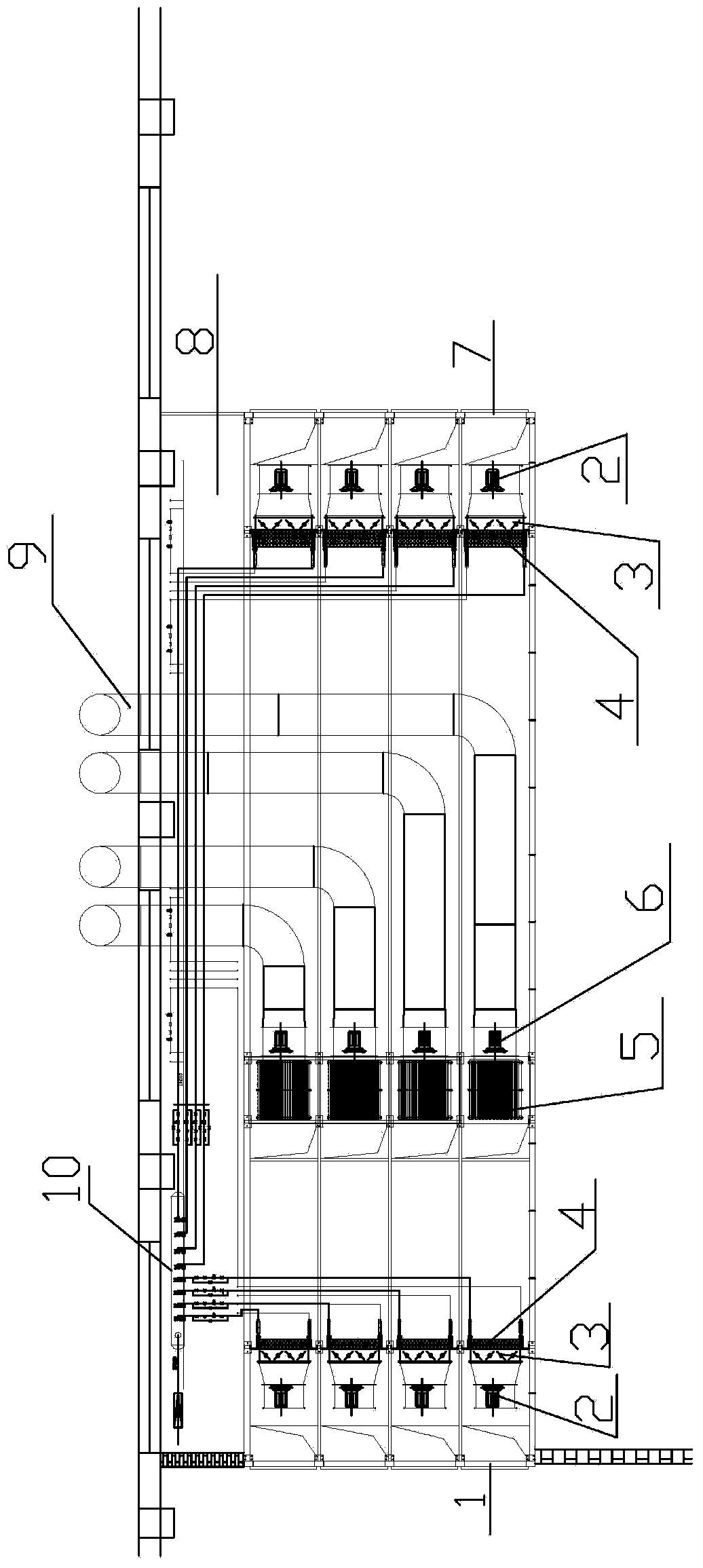

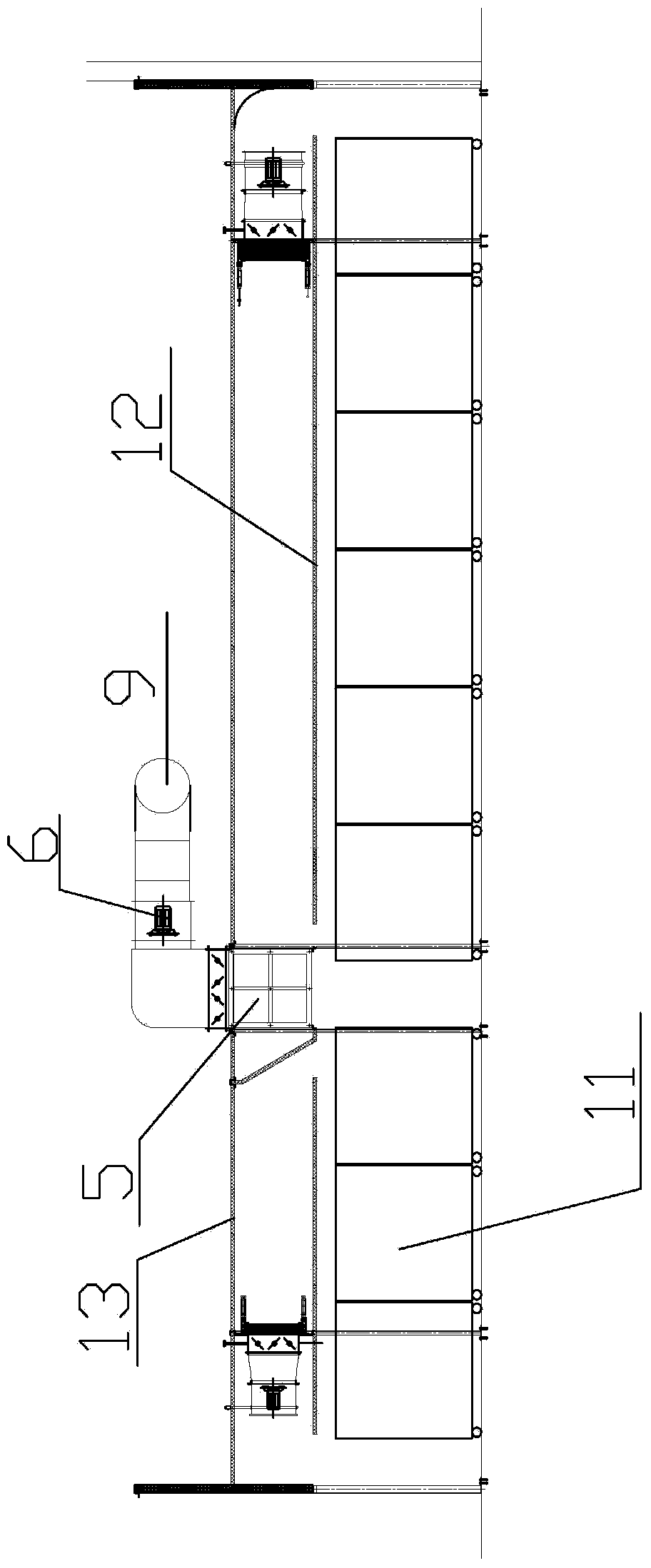

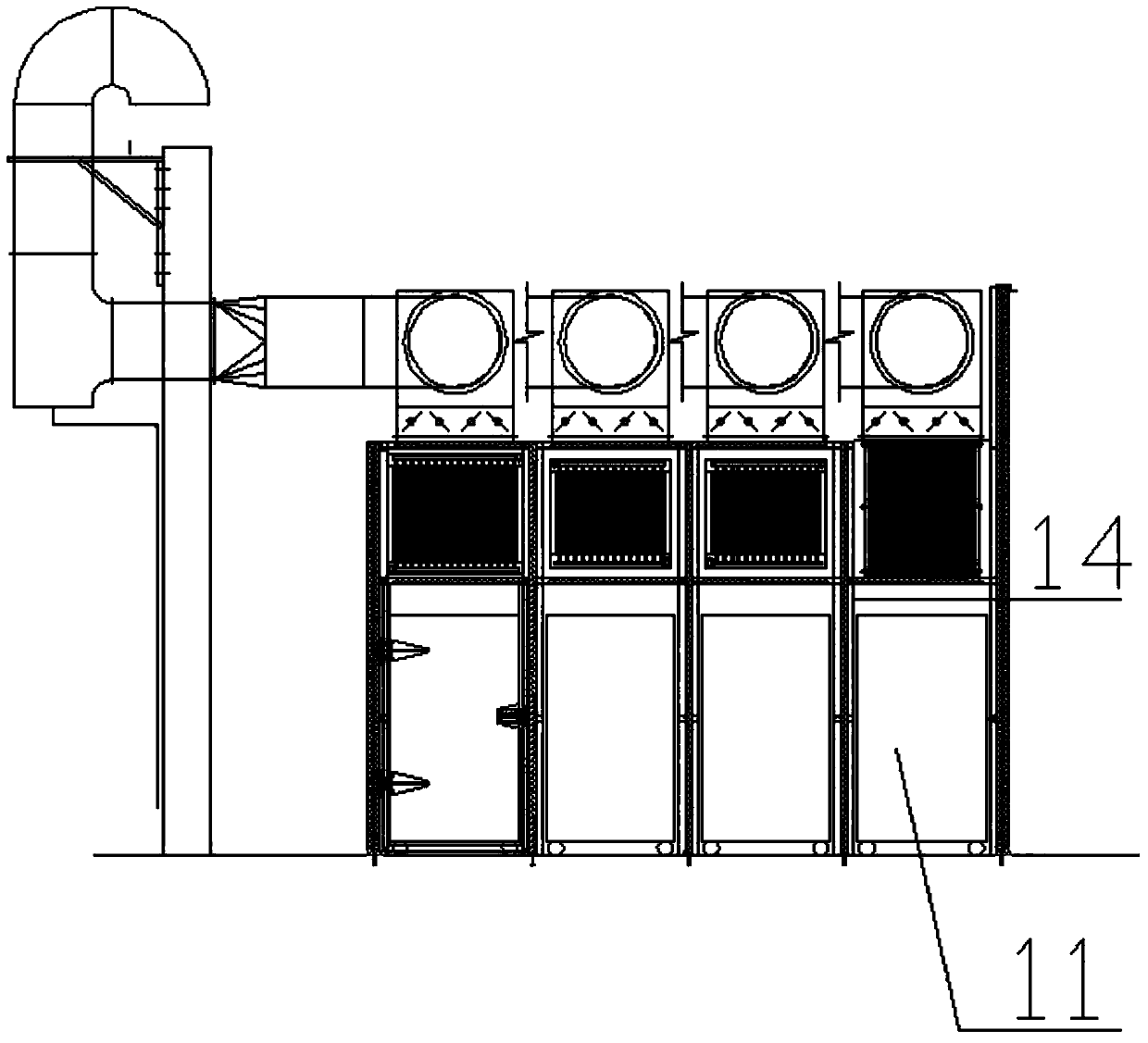

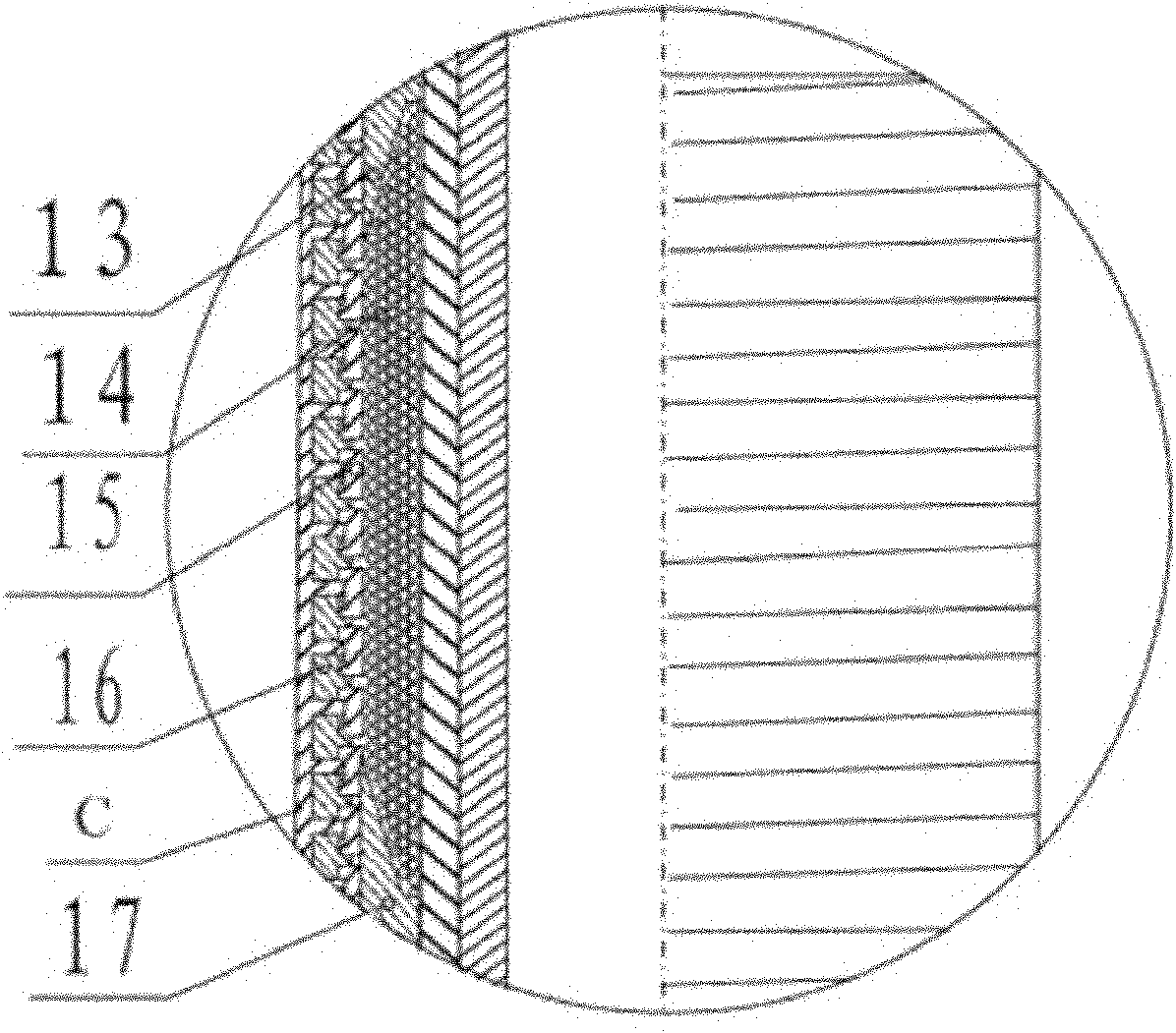

A food drying system

ActiveCN104197653BUniform temperatureClean airDrying gas arrangementsFood preservationAutomatic controlAgricultural engineering

A food drying system includes: a plurality of drying chambers, a steam system, a front chamber door, a rear chamber door, a control panel and a plurality of trolleys; the drying chamber includes: an exhaust system and two There are two circulation systems, and the exhaust system is placed in the middle of the two circulation systems; the exhaust system includes: a fresh air heat exchanger, an exhaust fan, a damper and an exhaust duct, and the fresh air heat exchanger and the exhaust duct The air valve and the exhaust fan are arranged in sequence between them; the circulation system includes: a circulation fan, a manual air valve and a heat exchanger, and the manual air valve is placed between the circulation fan and the heat exchanger; the steam System, including: steam pressure reducing valve, sub-cylinder, pipeline, steam coil, steam trap and control valve group, the control valve group is connected with the control panel, the pipeline is connected with the heat exchanger in the circulation system, and the steam system is placed in the equipment room The system is suitable for drying a large number of drying products, and the drying speed is fast and intelligent automatic control can be realized.

Owner:MEGAUNITY ENVIRONMENTAL SOLUTIONS CO LTD

A kind of water-based environment-friendly metal welding base metal protective agent and preparation method thereof

ActiveCN106141501BLow costSimple processWelding/cutting media/materialsSoldering mediaWater basedFilm-forming agent

The invention discloses a water-based environment-friendly metal welding base metal protective agent. The water-based environment-friendly metal welding base metal protective agent is prepared from, by weight percent, 9%-15% of a polymer film-forming agent, 8%-16% of a spreading agent, 5%-10% of a wetting flatting agent, 0.5%-5% of a rust-inhibiting additive, 12%-18% of a cosolvent and 45%-65% of deionized water. The raw materials adopted in the protective agent are environment-friendly, non-poisonous and degradable components; the prepared metal welding base metal protective agent can effectively avoid welding splash adhesion, is easy to clean and moderate in viscosity, and has excellent antirust performance; and the protective agent is suitable for multiple welding positions of flat welding, transverse welding, vertical welding, overhead welding and the like. The invention further discloses a preparation method of the water-based environment-friendly metal welding base metal protective agent. According to the preparation method, no heating is needed, operation is easy, the application range is wide, and cost is low.

Owner:南京尚易环保科技有限公司

Glass fiber sintering filter cartridge and preparing method thereof

InactiveCN109647028AGuaranteed StrengthStable chemical propertiesGravity filtersStationary filtering element filtersGlass fiberFiltration

The invention relates to a glass fiber sintering filter cartridge and a preparing method thereof, and belongs to the technical field of glass fiber materials. In the method, a suction filter with a peripheral cylindrical metal net is mainly used, a wet filter cartridge is prepared through suction filtration, the prepared wet filter cartridge is subjected to hot-press sizing through a male die anda female die, and finally the glass fiber sintering filter cartridge is prepared through drying. The glass fiber sintering filter cartridge has the advantages of being stable in chemical performance,resistant to high temperature, resistant to corrosion, high in dust holding capacity, good in filtering performance and the like and is a filtering system widely used in the fields of industry, agriculture, national defense, scientific research and the like; the requirements for the glass fiber sintering filter cartridge are increased daily in all the fields; the preparing method of the filter cartridge is simple, easy to operate, low in cost and suitable for industrial production.

Owner:CHONGQING FIBER RES & DESIGN INST CO LTD

Production process of freon resistant, double glass fiber covered enamelled wire

ActiveCN101615451BHigh temperature resistantEasy to withstand high temperatureFurnace typesHeat treatment furnacesGlass fiberOperational costs

The invention relates to a production process of a freon resistant, double glass fiber covered enamelled wire, which solves problems of lag in an existing production process of glass fiber covered enamelled wires, large waste of raw materials, high energy consumption, environmental pollution and quality instability. The production process ensures quality of finished products and work efficiency by the following steps: strictly selecting the raw materials, taking the raw materials into a softening furnace for solidifying treatment by freon resistant insulating impregnating varnish; covering with conductor glass fiber, wherein, two layers of the glass fiber are covered in reverse directions to prevent single cladding; and controlling temperature of a baking furnace and the like. The production process has rational design, simple process, low manufacturing cost, low operating cost, reliable work, high efficiency, stable quality and strong workability, can help manufacture a plurality of different single and double glass fiber, paper covered and enamelled flat copper wires, round copper wires and irregular copper wires, and various electromagnetic wires for different uses, and the production process has wide market prospect.

Owner:湘潭市霞城电工有限公司

Food drying system

ActiveCN104197653AUniform temperatureClean airDrying gas arrangementsFood preservationSteam pressureAutomatic control

A food drying system comprises multiple drying box channels, a steam system, a front box channel door, a rear box channel door, a control plate and multiple trolleys. Each drying box channel comprises an exhaust system and two circulating systems, wherein the exhaust system is arranged between the two circulating systems. Each exhaust system comprises a fresh air heat exchanger, an exhaust fan, an air valve and an exhaust pipeline, wherein the air valve and the exhaust fan are sequentially arranged between fresh air heat exchanger and the exhaust pipeline. Each circulating system comprises a circulating fan, a manual air valve and a heat exchanger, wherein the manual air valve is arranged between the circulating fan and the heat exchanger. The steam system comprises a steam pressure reducing valve, a steam header, pipelines, a steam coil pipe, a steam trap and a control valve set, wherein the control valve set is connected with the control plate, the pipelines are connected with the heat exchangers in the circulating systems, and the steam system is arranged in a device chamber. The food drying system is suitable for drying a large number of products needing to be dried, is high in drying speed and can achieve intelligent automatic control.

Owner:MEGAUNITY ENVIRONMENTAL SOLUTIONS CO LTD

Sealing device and mechanical sealing packer

ActiveCN102094593BLarge amount of expansionPlay a protective effectSealing/packingEngineeringTemperature resistance

The invention provides a sealing device and a mechanical sealing packer, the sealing device comprises an upper open block, a hydraulic medium, a bimetal convex-concave spring and a lower open block, wherein the bimetal convex-concave spring comprises red copper and a convex-concave spring, the red copper is laid and welded on the surface and the side surface of the convex-concave spring, the bimetal convex-concave spring is arranged vertically, the hydraulic medium is placed in the bimetal convex-concave spring, and the upper open block and the lower open block for extruding and closing the hydraulic medium are respectively connected above and below the hydraulic medium; the mechanical sealing packer is provided with the sealing device; and the sealing device and the mechanical sealing packer provided with the sealing device have the characteristics of high temperature resistance and high pressure resistance, and have very important production practical significance in exploitation process of thick oil.

Owner:通化红光石油机械有限责任公司

Oil and water well sealing and plugging agent and preparation method thereof

ActiveCN102504781BSatisfy the requirements of sealing blow-byEasy to prepareDrilling compositionCuring (chemistry)Oil field

The invention relates to the technical field of oilfield chemistry, in particular to an oil and water well sealing and plugging agent and a preparation method of the oil and water well sealing and plugging agent. The oil and water well sealing and plugging agent is suitable for sealing and plugging an oil and water well. The oil and water well sealing and plugging agent consists of the following raw materials: XP lost circulation additive, G-class oil-well cement, blast furnace KZ micro powder, borax and water. The oil and water well sealing and plugging agent has the beneficial effects that the oil and water well sealing and plugging agent is simple to prepare, is convenient to construct, is safe and reliable and has high plugging strength; the oil and water well sealing and plugging agent has the characteristics of excellent suspension stability, low initial viscosity, easiness for pumping, high temperature resistance, high curing strength and the like and is mainly applied to non-corresponding production layers caused by poor cementing quality or damage to a sleeve above and below a perforated section of the oil and water well; the requirements on sealing and plugging of the oil and water well can be met; and currently, the oil and water well sealing and plugging agent is accumulatively implemented for over 90 well times, good sealing and plugging effects are obtained and the water injection efficiency is also improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com