Plastic baking oven pad and manufacturing process thereof

A technology of plasticity and preparation process, applied in the field of oven mats, can solve problems such as food contamination, troublesome cleaning, etc., and achieve the effects of avoiding pollution, good environmental protection, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

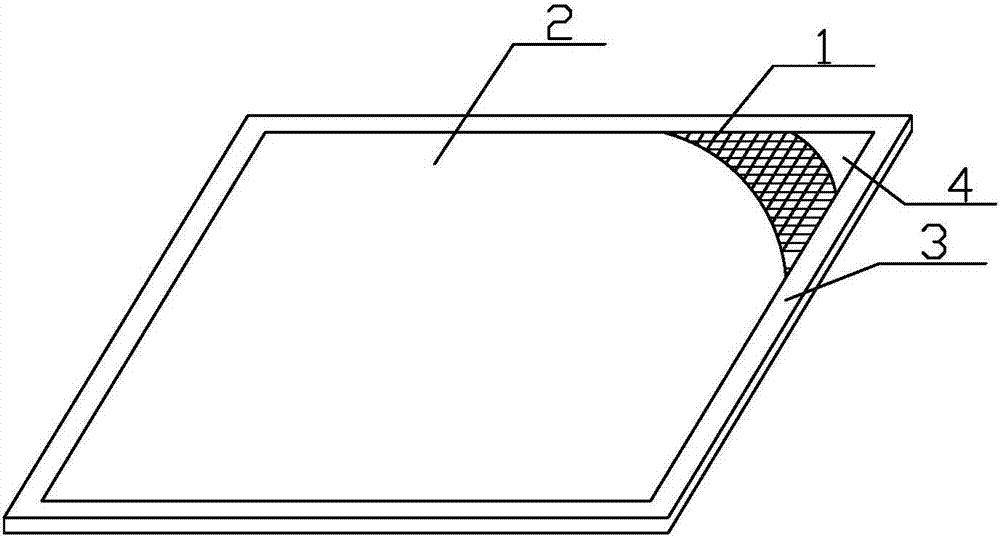

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] Such as figure 1 Shown, the technical scheme that the present invention takes is as follows:

[0026] A plastic oven mat, comprising a steel wire mesh 1, a silicone rubber layer 2, an edge wrapping 3, and a glass fiber base cloth 4; a steel wire mesh 1 is laid on the upper surface of the glass fiber base cloth 4, and a silicon rubber layer 2 is laid on the upper surface of the steel wire mesh 1 , the edges of the silicone rubber layer 2 are wrapped with hemming 3 .

[0027] Further, the steel wire mesh 1 is braided by thin steel wires, the mesh of the steel mesh 1 is square, and the side length of the mesh is one centimeter.

[0028] Further, the surface of the silicone rubber layer is smooth.

[0029] The manufacturing process of the plastic oven mat provided by the present invention comprises the following steps:

[0030] a) select silicone rubber slurry for us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com