A kind of water-based environment-friendly metal welding base metal protective agent and preparation method thereof

A metal welding and environment-friendly technology, applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve the problems of anti-splash agent safety hazards, safety, and difficulty in cleaning, and achieve barrier welding slag and metal The effect of workpiece sticking, good wetting and spreading, and avoiding grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

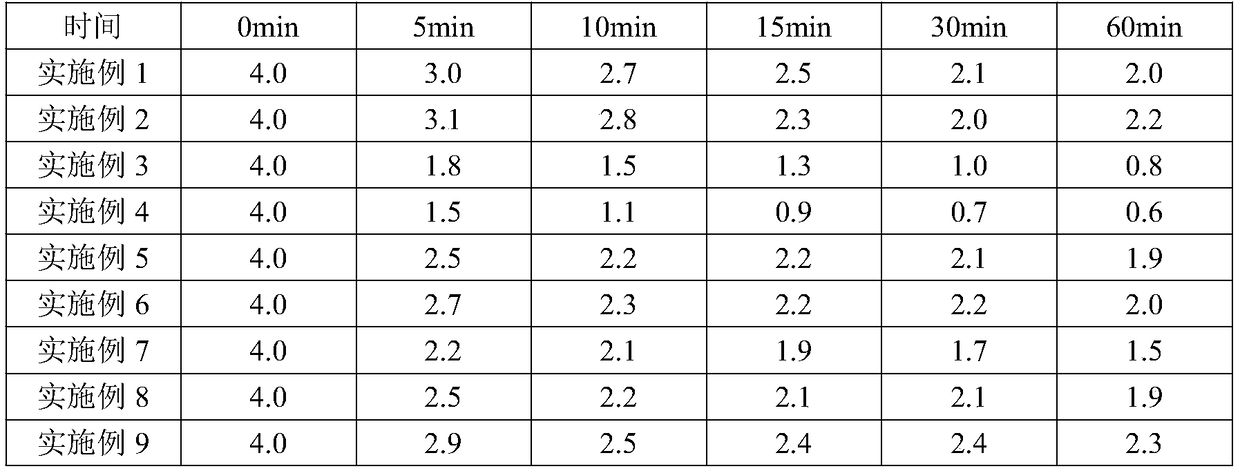

Embodiment 1

[0023] Raw materials: polyvinyl alcohol 1788 13%, alkyl glycoside APG1214 8%, alkylphenol polyoxyethylene ether OP-10 7%, benzotriazole 0.8%, triethanolamine oleic acid soap 2%, ethanol 14%, detox Ionized water 55.2%.

[0024] The preparation method is as follows:

[0025] (1) Take the raw material by weighing the raw material formula;

[0026] (2) Dissolving polyvinyl alcohol 1788 in ethanol and stirring for 30 minutes to obtain the first solution;

[0027] (3) Add alkyl glycoside APG1214, alkylphenol polyoxyethylene ether OP-10, benzotriazole, and triethanolamine oleic acid soap to deionized water in sequence, and stir for 50 minutes to obtain the second solution;

[0028] (4) Mix the two solutions obtained in step (2) and step (3), and stir for 30 minutes to obtain a metal welding base metal protective agent, which is filled into an aerosol can.

Embodiment 2

[0030] Raw materials: polyethylene glycol 2000 10%, alkyl glycoside APG1000 8%, sorbitan fatty acid ester S-808%, sodium molybdate 0.3%, triethanolamine oleic acid soap 3%, ethylene glycol 16%, Ionized water 54.7%.

[0031] The preparation method is as follows:

[0032] (1) Take the raw material by weighing the raw material formula;

[0033] (2) Polyethylene glycol 2000 was dissolved in ethylene glycol, and stirred for 40 minutes to obtain the first solution;

[0034] (3) Alkyl glucoside APG1000, sorbitan fatty acid ester S-80, sodium molybdate, and triethanolamine oleic acid soap were sequentially added to deionized water, and stirred for 60 minutes to obtain a second solution;

[0035] (4) Mix the two solutions obtained in step (2) and step (3), and stir for 40 minutes to obtain a metal welding base metal protective agent, which is filled into an aerosol can.

Embodiment 3

[0037] Raw materials: polyvinyl alcohol 1799 14%, sodium α-olefin sulfonate 9%, penetrant JFC-S 9%, benzotriazole 0.5%, sodium petroleum sulfonate 3%, ethanol 18%, deionized water 46.5 %.

[0038] The preparation method is as follows:

[0039] (1) Take the raw material by weighing the raw material formula;

[0040] (2) Dissolving polyvinyl alcohol 1799 in ethanol and stirring for 35 minutes to obtain the first solution;

[0041] (3) Add sodium α-alkenyl sulfonate, penetrant JFC-S, benzotriazole, and sodium petroleum sulfonate into deionized water in sequence, and stir for 55 minutes to obtain the second solution;

[0042] (4) Mix the two solutions obtained in step (2) and step (3), and stir for 35 minutes to obtain a metal welding base metal protective agent, which is filled into an aerosol can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com