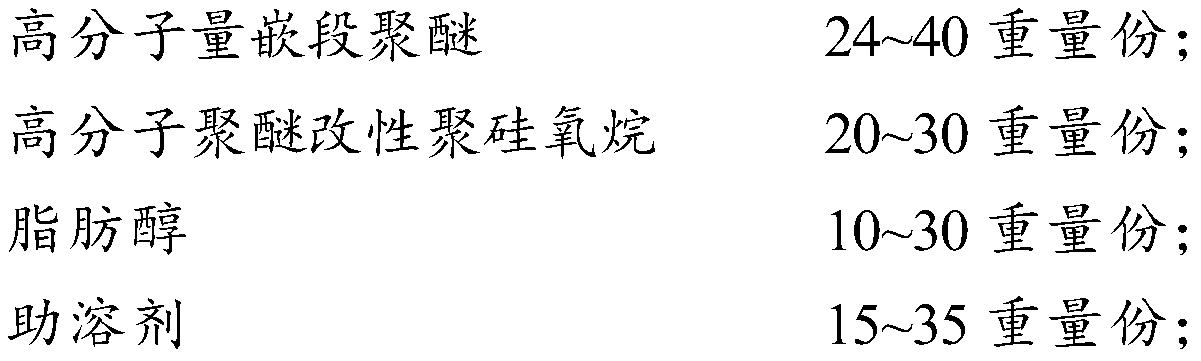

Preparation method of high-molecular-weight block polyether, silyl ether mixed defoaming agent and preparation method thereof

A high-molecular polyether and high-molecular-weight technology, which is applied in the preparation of high-molecular-weight block polyether, silicon ether mixed defoamer and its preparation field, can solve the problem of activity and service life, short coke generation time of coke tower, Energy and personnel waste and other issues, to achieve the effect of long foam suppression time, not easy to decompose, easy to burst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

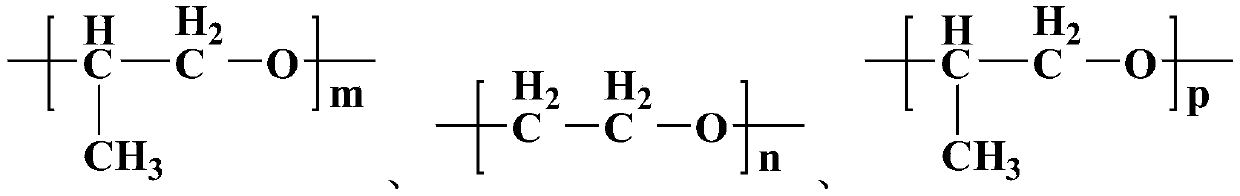

[0034] The invention provides a method for preparing a high molecular weight block polyether, comprising: using a polyhydric alcohol as an initiator, and performing ring-opening polymerization reaction with an alkylene oxide under the action of a catalyst to obtain a high molecular weight block polyether; The catalyst is an alkali metal catalyst and / or a high molecular weight block polyether.

[0035] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0036] The present invention uses polyalcohol as the initiator, which can increase the degree of esterification of the block polyether, increase the molecular weight of the block polyether in multiples, improve the high temperature stability of the block polyether, and the multi-block structure It can also improve the antifoam performance of block polyether. Described polyhydric alcohol in the invention is preferably one or more in glucose, fruc...

Embodiment 1

[0079]In parts by mass, add 1 part of glucose, 0.6 part of 120# solvent naphtha and 0.1 part of self-made polymer block polyether product in a dry autoclave (the preparation method and process are the same as in this example, except that the alkali metal hydrogen Potassium oxide as the catalyst) was used as the catalyst, and after being loaded into the autoclave, the air in the autoclave was replaced with nitrogen for 3 times, and the heating was started. The temperature in the kettle is 110°C, the pressure is 1.5MPa, add 150 parts of propylene oxide through the feed valve, close the feed valve, react for 3 hours, cool down to 40°C after the reaction, then add 100 parts of ethylene oxide, close the feed Valve, heat up to 100°C, react for 2.5h, cool down to 40°C after the reaction is over, then add 200 parts of propylene oxide, close the feed valve, heat up to 120°C, react for 2h, cool down to 40°C after the reaction, discharge, The product was washed and dried three times unde...

Embodiment 2

[0083] 2.1 End capping treatment of high molecular weight block polyether

[0084] Add the high molecular weight block polyether obtained in Example 1 and the end-blocking agent acetic anhydride into the reactor at a molar ratio of 1:6, raise the temperature to 140°C under the protection of nitrogen, and react for 3 hours. Nitrogen is vacuumed and purged to blow out the remaining acetic anhydride to obtain end-capped high molecular weight block polyether.

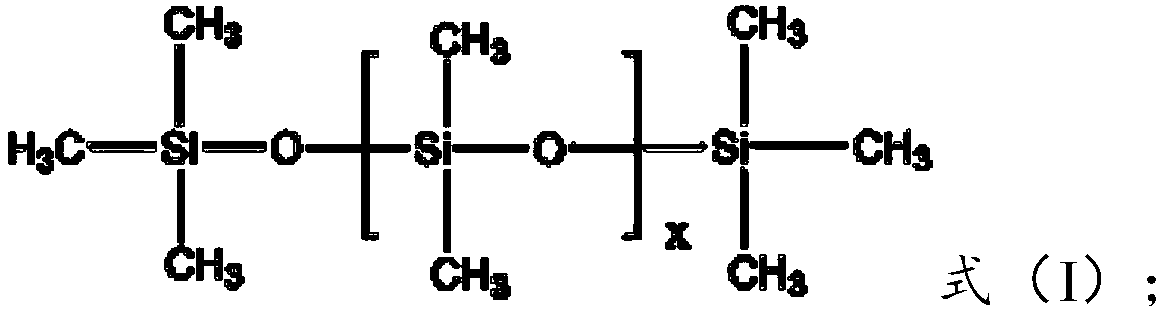

[0085] 2.1 Preparation of polymer polyether modified polysiloxane

[0086] In a 250mL three-necked flask equipped with a reflux condenser, a thermometer and a stirrer, add the end-blocked high molecular weight block polyether, polymethyl silicone oil (polymerization degree 80) prepared in 2.1, high molecular weight block polyether and polyformaldehyde The molar ratio of base siloxane is 1:1.1, add end-blocking high molecular weight block polyether and isoamyl alcohol with 10% of the total mass of polymethicone as solvent, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com