Patents

Literature

275 results about "Silyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

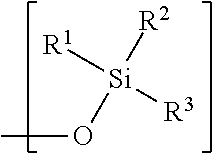

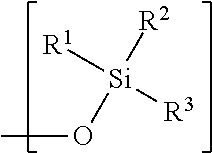

Silyl ethers are a group of chemical compounds which contain a silicon atom covalently bonded to an alkoxy group. The general structure is R¹R²R³Si−O−R⁴ where R⁴ is an alkyl group or an aryl group. Silyl ethers are usually used as protecting groups for alcohols in organic synthesis. Since R¹R²R³ can be combinations of differing groups which can be varied in order to provide a number of silyl ethers, this group of chemical compounds provides a wide spectrum of selectivity for protecting group chemistry. Common silyl ethers are: trimethylsilyl (TMS), tert-butyldiphenylsilyl (TBDPS), tert-butyldimethylsilyl (TBS/TBDMS) and triisopropylsilyl (TIPS). They are particularly useful because they can be installed and removed very selectively under mild conditions.

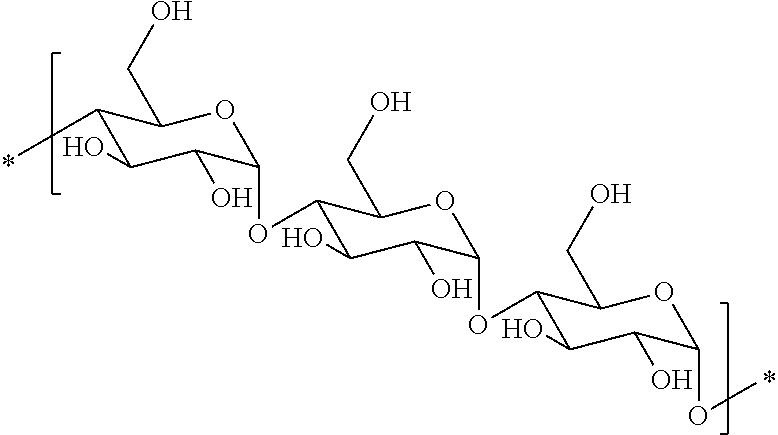

Hydrophobic polysaccharides with silyl ether linkages having enhanced degradation and medical articles made therefrom

ActiveUS8932616B2Improve degradation rateOvercome difficultiesBiocideOrganic active ingredientsPolymer scienceActive agent

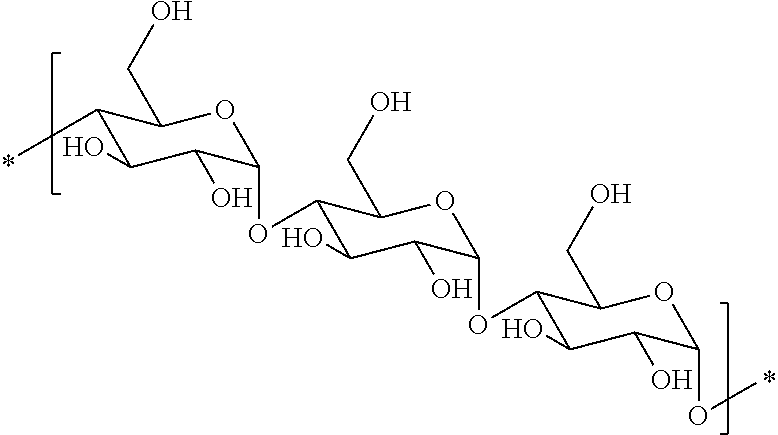

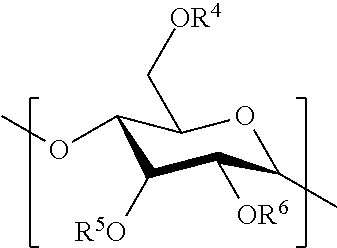

Hydrophobic α(1→4)glucopyranose polymers with enhanced degradation properties are described. Between the α(1→4)glucopyranose polymeric portion and the hydrophobic portion exists a linker portion having a silyl ether chemistry that facilitates degradation of the polymer. Biodegradable matrices can be formed from these polymers, and the matrices can be used for the preparation of implantable and injectable medical devices wherein the matrix is capable of degrading in vivo at an increased rate. Matrices including and capable of releasing a bioactive agent in vivo are also described.

Owner:SURMODICS INC

Compositions and methods for diverting injected fluids to achieve improved hydrocarbon fluid recovery

ActiveUS20090260819A1Increasing mobilizationImprove recovery rateFluid removalFlushingCross-linkMicroparticle

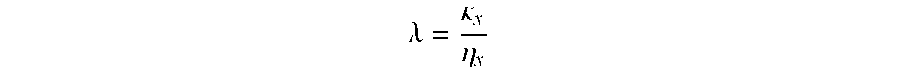

The present disclosure is directed to compositions and methods that may be used for enhanced oil recovery, for modifying the permeability of subterranean formations and for increasing the mobilization and / or recovery rate of hydrocarbon fluids present in the formations. The compositions may include, for example, expandable cross linked polymeric microparticles having an unexpanded volume average particle size diameter of from about 0.05 to about 5,000 microns and a cross linking agent content of from about 100 to about 200,000 ppm of hydrolytically labile silyl ester or silyl ether crosslinkers and from 0 to about 300 ppm of non-labile crosslinkers.

Owner:CHAMPIONX USA INC +1

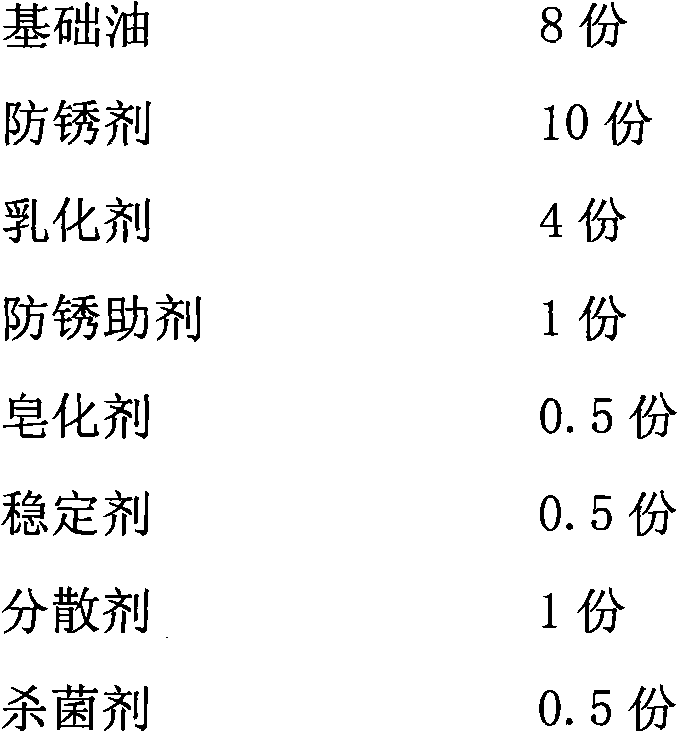

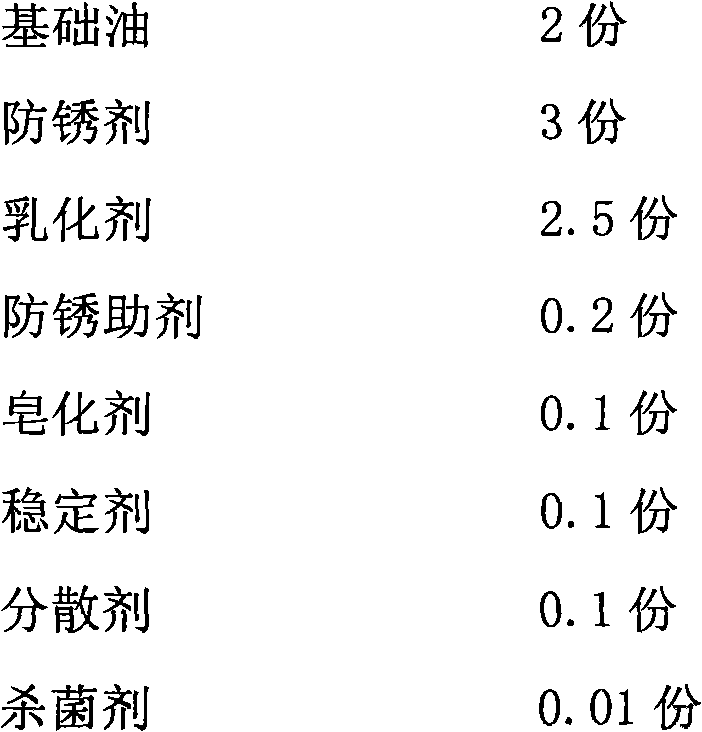

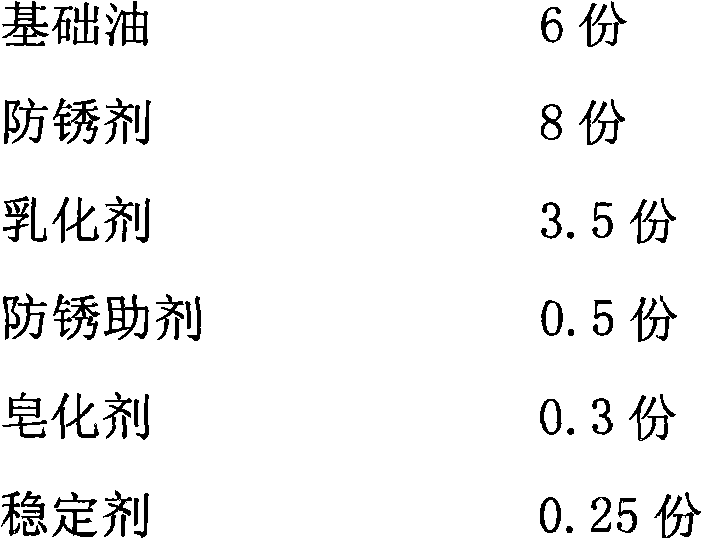

Water soluble antirusting fluid, and preparation method and using method thereof

The invention discloses a water soluble antirusting fluid, and a preparation method and a using method thereof. The antirusting fluid comprises the following components in part by mass: 2 to 8 parts of base oil, 3 to 10 parts of antirusting agent, 2.5 to 4 parts of emulsifier, 0.2 to 1 part of antirusting aid, 0.1 to 1 part of stabilizer, 0.1 to 1 part of dispersing agent, and 0.01 to 0.5 part of bacteriacide, wherein the base oil is No.10 light mechanical oil; the antirusting agent is a complex of different antirusting agents; the emulsifier is a complex of OP-10, peregal O and peregal 6501; the antirusting aid is a complex consisting of polyoxy silyl ether; the stabilizer is triethanolamine; the dispersing agent is one or more of glycerol, alcohol and kerosene; and the bacteriacide is sodium benzoate. The antirusting fluid is high in antirusting capacity, solution stability and treatment capacity, low in cost and environment-friendly; and the preparation method for the antirusting fluid is simple and does not require massive equipment investment, and the using method is simple and easy to implement.

Owner:ANHUI JIANGNAN MACHINERY

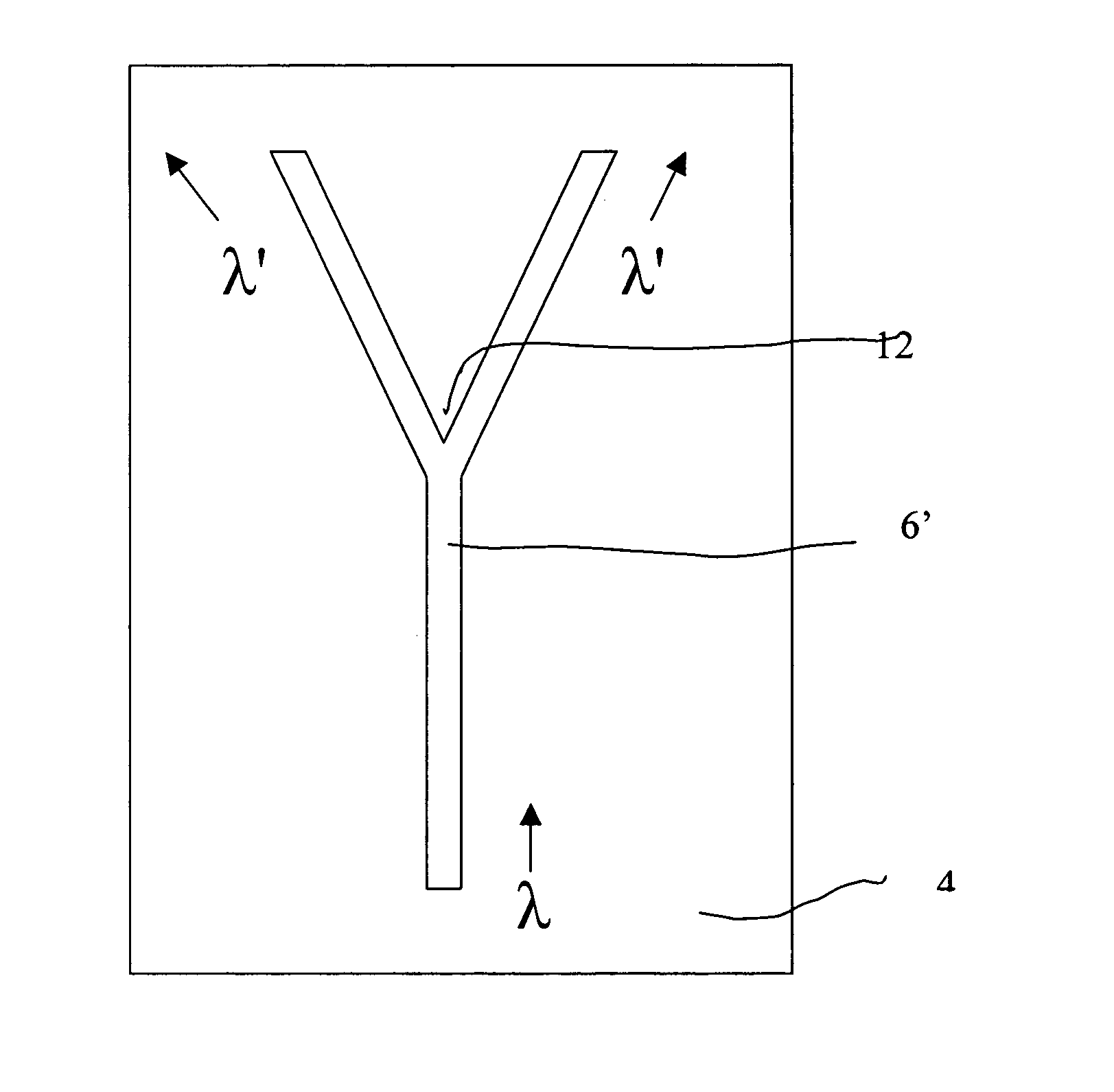

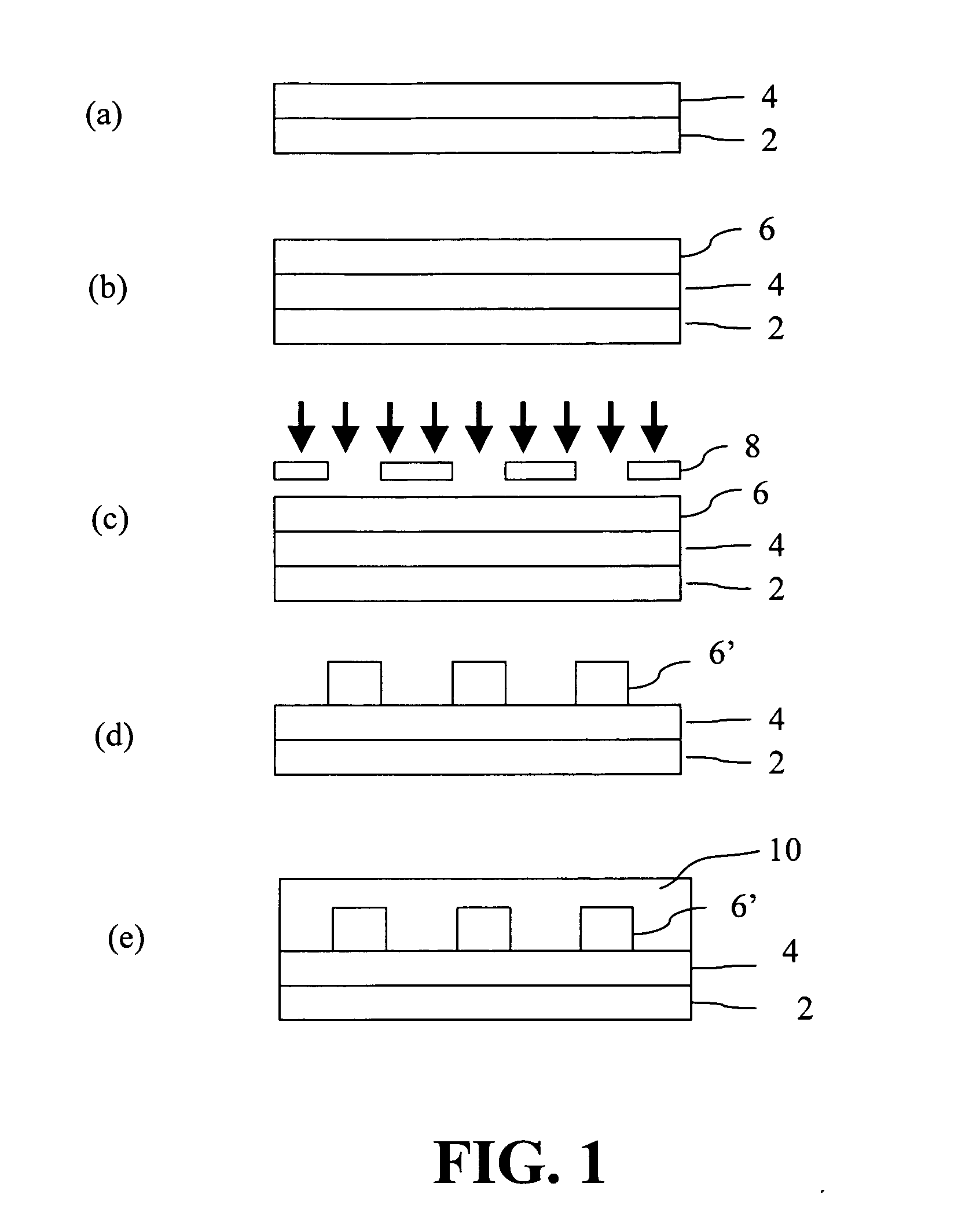

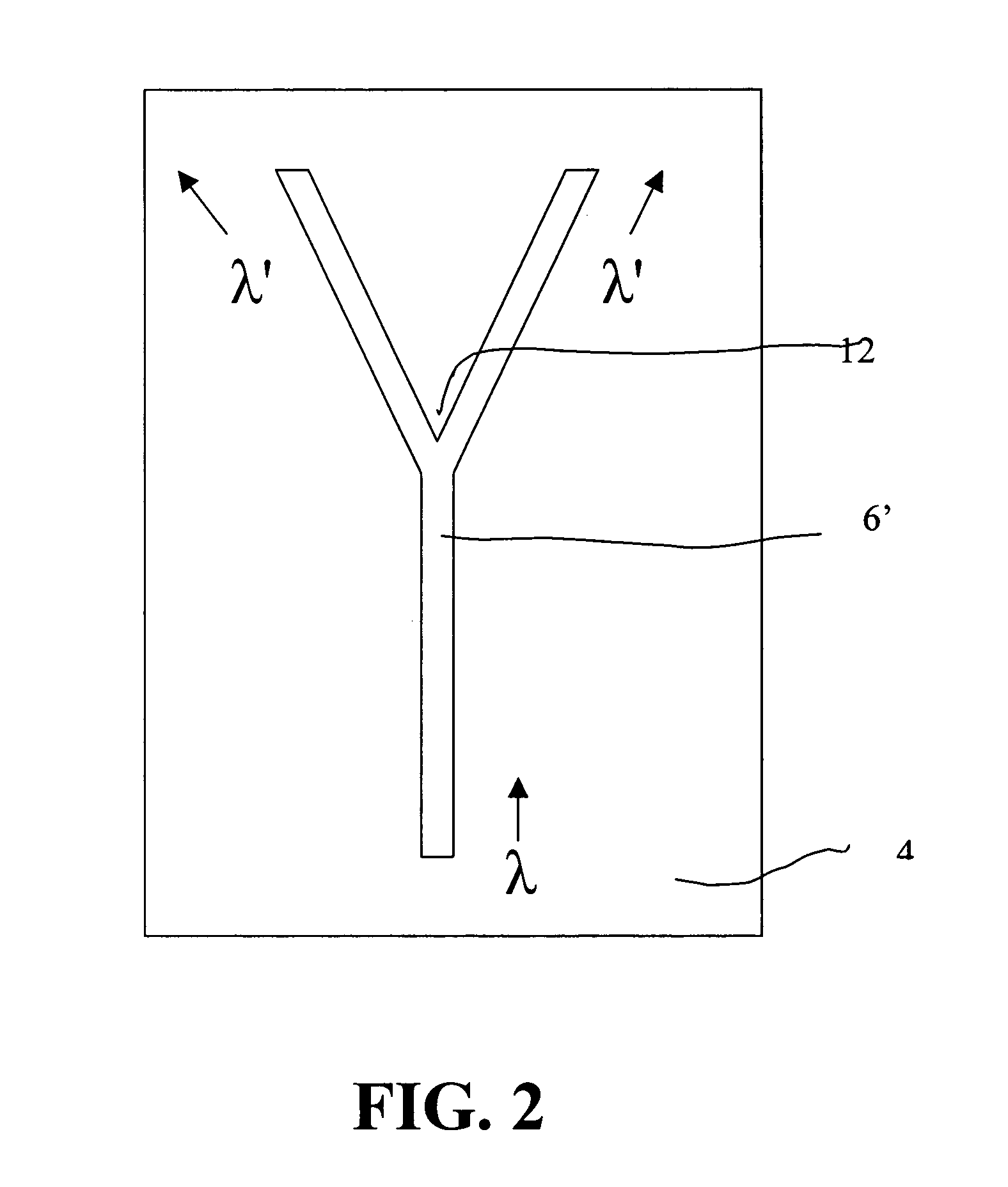

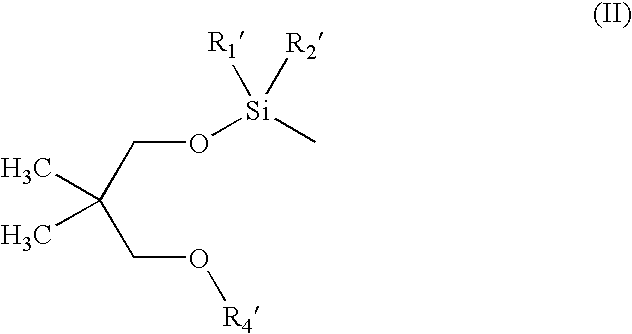

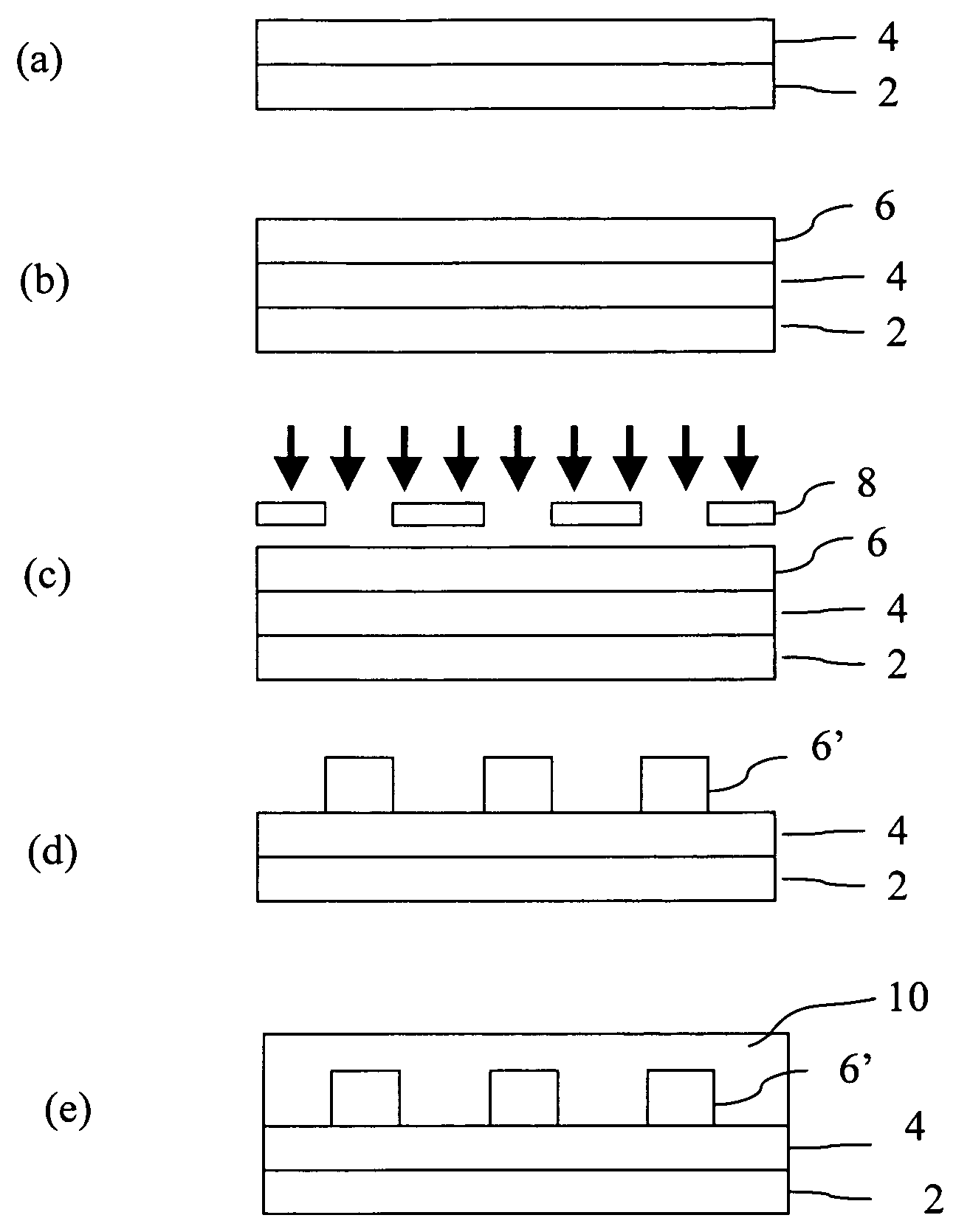

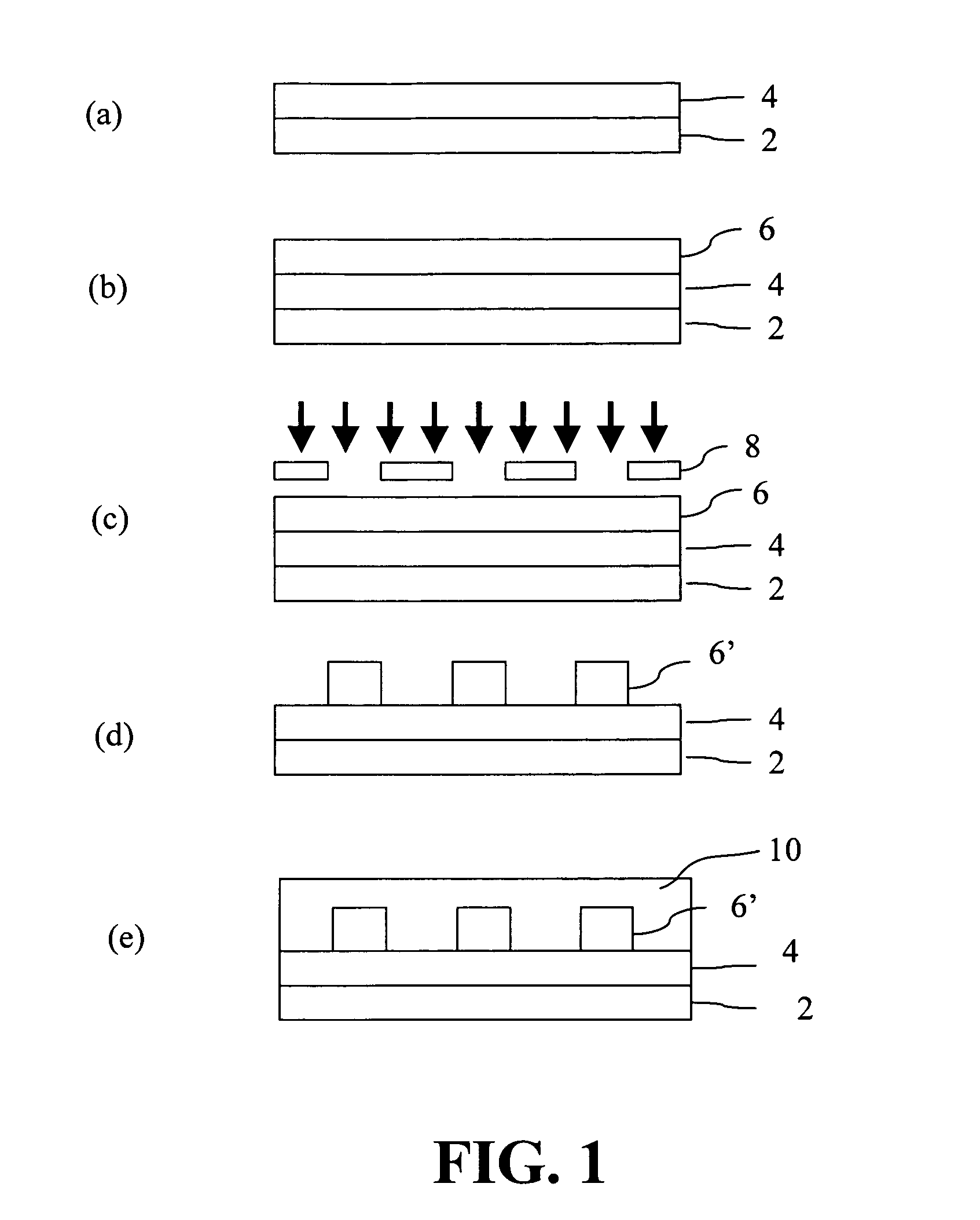

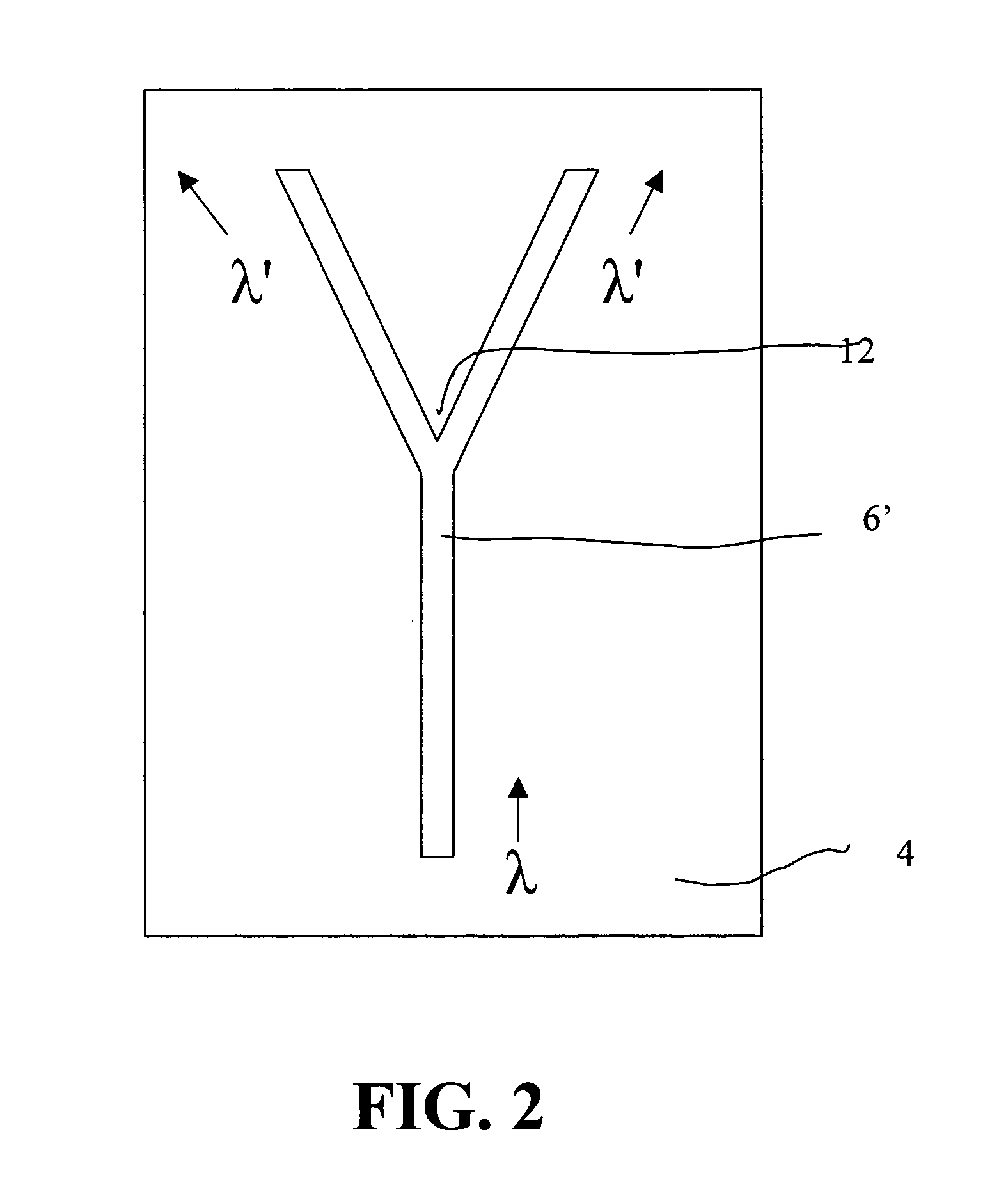

Waveguide compositions and waveguides formed therefrom

ActiveUS20050141839A1Altered solubilityIncrease flexibilityOptical fibre with graded refractive index core/claddingPhotosensitive materialsSolubilityThiol

Provided are compositions suitable for use in forming a flexible optical waveguide. The compositions include a polymer, having units of the formula (RSiO1.5), wherein R is a substituted or unsubstituted organic group, and a plurality of functional end groups. A first component is provided for altering the solubility of the composition in a dried state upon activation. A second component contains a plurality of functional groups chosen from hydroxy, amino, thiol, sulphonate ester, carboxylate ester, silyl ester, anhydride, aziridine, methylolmethyl, silyl ether, and combinations thereof. The second component is present in an effective amount to improve flexibility of the composition in a dried state before and after activation. Also provided are flexible optical waveguides, methods of forming flexible optical waveguides and electronic devices that include a flexible optical waveguide.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Low-permeability reservoir water-lock releasing agent and preparation method thereof

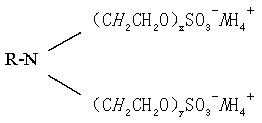

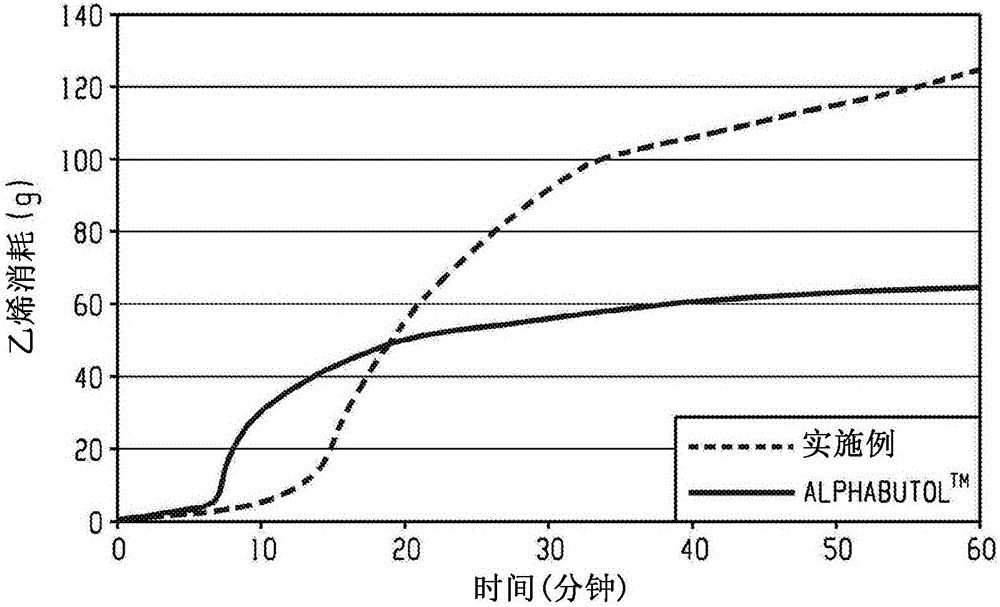

ActiveCN102899011ALow cloud pointGood water solubilityDrilling compositionFracturing fluidGlycol ethers

The invention discloses an oil field chemical agent used in petroleum gas oil-pumping operation construction, and particularly relates to a low-permeability reservoir water-lock releasing agent used in working fluid and a preparation method thereof. The low-permeability reservoir water-lock releasing agent consists of the following components in percentage by weight: 1 to 15 percent of glycol ether, 15 to 45 percent of didodecyl dicarboxylic sodium, 15 to 30 percent of ethylene glycol silicon ether and 30 to 60 percent of water. The preparation method comprises the following steps of: adding 30 to 60 percent of water into an enamel reaction kettle, starting a stirrer, and heating to raise the temperature to be between 30 and 40 DEG C; adding 1 to 15 percent of glycol ether and 15 to 45 percent of didodecyl dicarboxylic sodium into the reaction kettle, controlling the temperature and stirring for 1 hour; and adding 15 to 30 percent of ethylene glycol silicon ether into the reaction kettle, controlling the temperature to be between 40 and 80 DEG C, and reacting for 1 to 2 hours to obtain the water-lock releasing agent. The water-lock releasing agent is strong in surface activity and low in use level, can well maintain the permeability of a low-permeability reservoir and release water-lock damages, and is used in the working fluid such as fracturing fluid, perforating fluid, well control fluid and the like.

Owner:唐山冀油瑞丰化工有限公司 +1

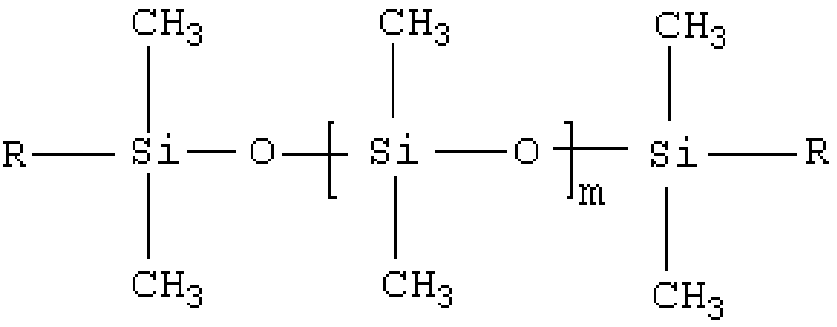

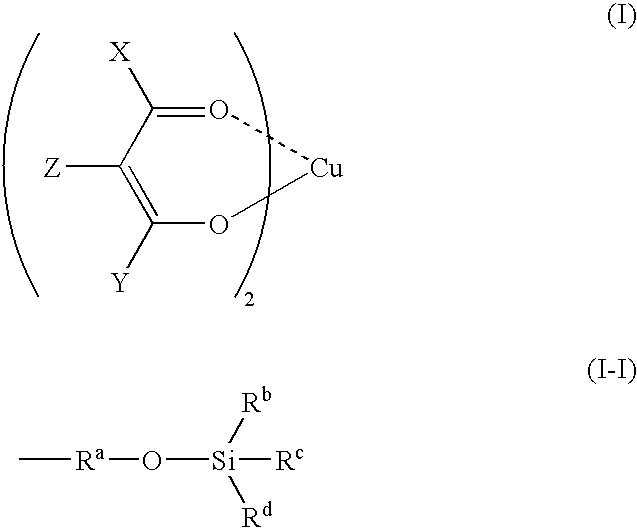

Silicon ether compounds and a method for the preparation thereof

ActiveUS7399812B2Silicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenElectron donor

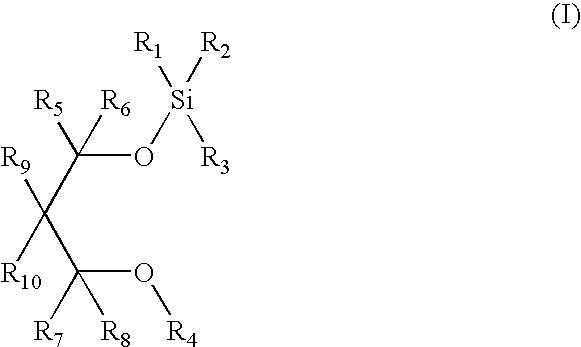

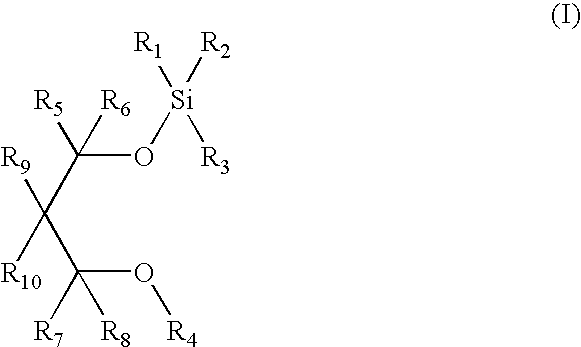

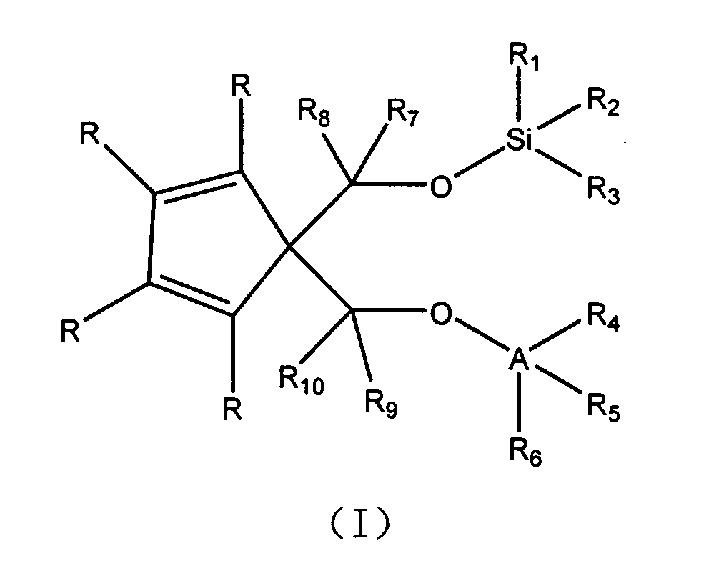

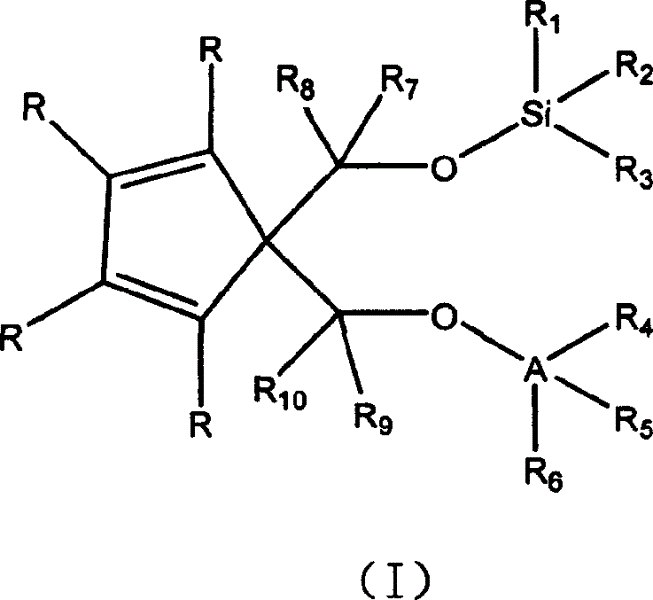

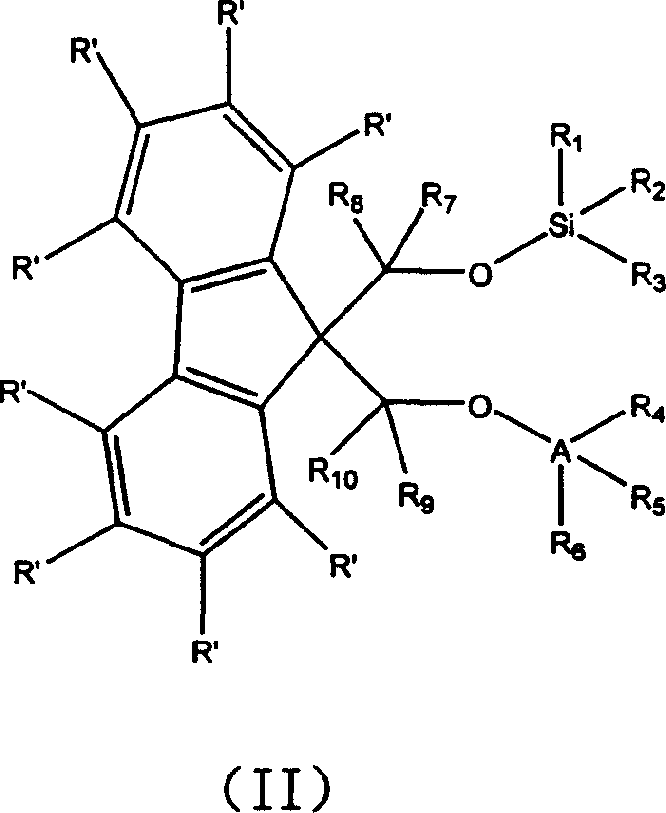

The present invention relates to silicon ether compounds having a general formula (I), a method for the preparation thereof and use thereof as a component of catalysts for polymerization of olefins. In particular, in propylene polymerization, catalyst systems comprising the silicon ether compounds as external electron donor component exhibit good hydrogen response, and can be used to prepare polymer having high isotacticity at high yield.wherein R1-R10 groups are as defined in the description.

Owner:CHINA PETROCHEMICAL CORP +1

Waveguide compositions and waveguides formed therefrom

ActiveUS7072563B2Altered solubilityIncrease flexibilityOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingSolubilitySilylene

Provided are compositions suitable for use in forming a flexible optical waveguide. The compositions include a polymer, having units of the formula (RSiO1.5), wherein R is a substituted or unsubstituted organic group, and a plurality of functional end groups. A first component is provided for altering the solubility of the composition in a dried state upon activation. A second component contains a plurality of functional groups chosen from hydroxy, amino, thiol, sulphonate ester, carboxylate ester, silyl ester, anhydride, aziridine, methylolmethyl, silyl ether, and combinations thereof. The second component is present in an effective amount to improve flexibility of the composition in a dried state before and after activation. Also provided are flexible optical waveguides, methods of forming flexible optical waveguides and electronic devices that include a flexible optical waveguide.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

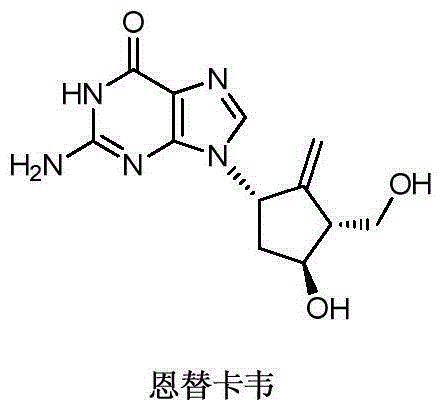

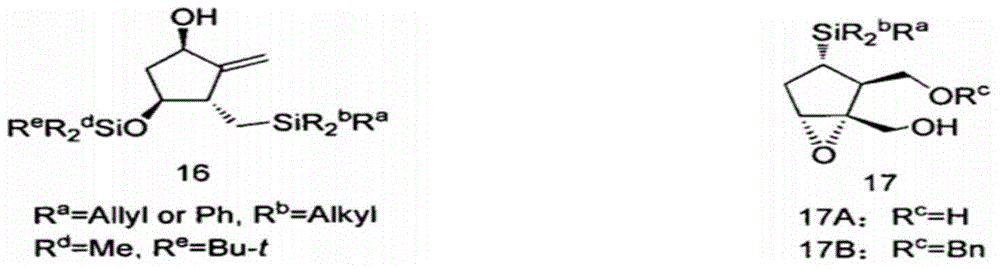

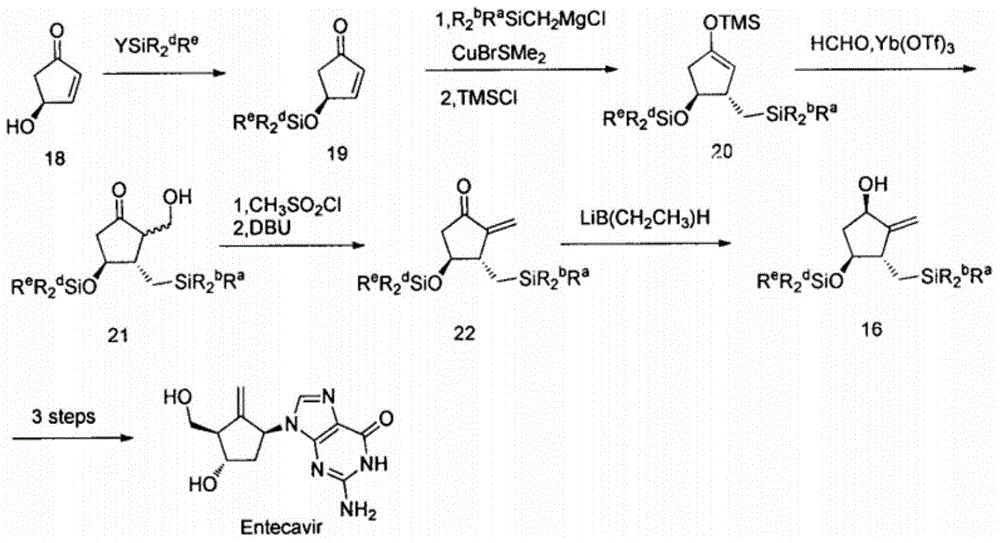

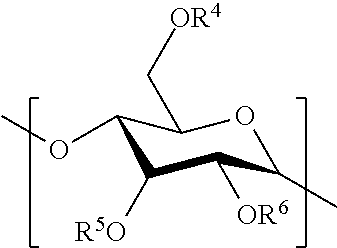

Novel synthetic method for entecavir compound

ActiveCN105037363ASolve rare problemsDosage controllableGroup 4/14 element organic compoundsKetoneAdipate

The invention belongs to the field of drug synthesis and relates to an entecavir compound and a synthetic method of an intermediate of the entecavir compound. The novel synthetic method comprises: by taking (S)-3-hydroxyl dimethyl adipate as an initial raw material, preparing an intermediate 9 through hydroxyl TBS protection, Dieckmann condensation reaction, ketone protection to ketal, ester group reduction to hydroxyl, hydroxyl protection, deprotection, ketone to silyl enol ether and Rubottom oxidizing reaction; and preparing entecavir from the intermediate 9 through wittig reaction, Mitsunobu reaction, silicon preventing radical group removal and basic hydrolysis. The novel synthetic method provided by the invention is mild and easily controllable in reaction condition, simple to operate, high in product yield, high in purity and suitable for industrialized mass production.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD +1

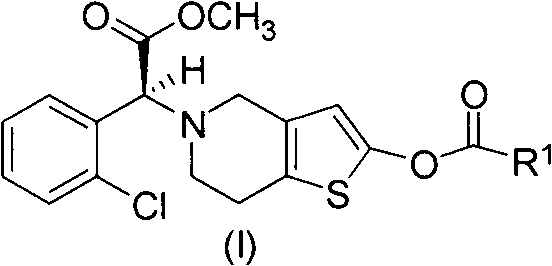

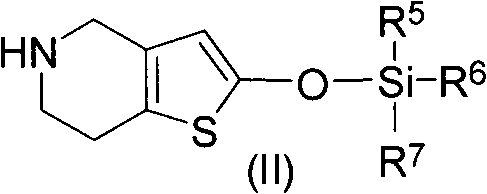

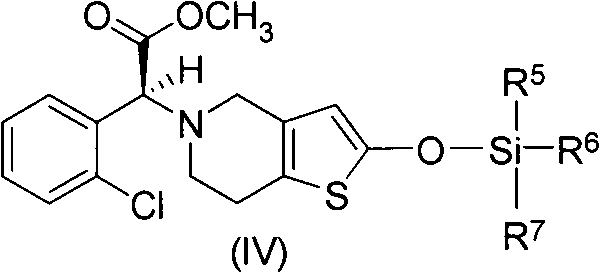

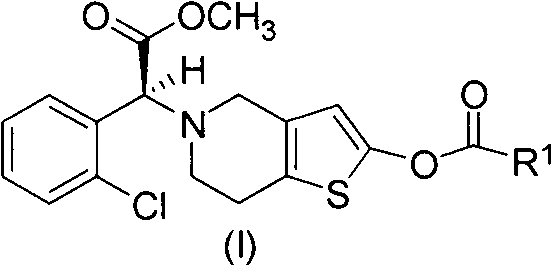

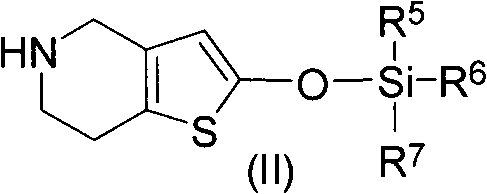

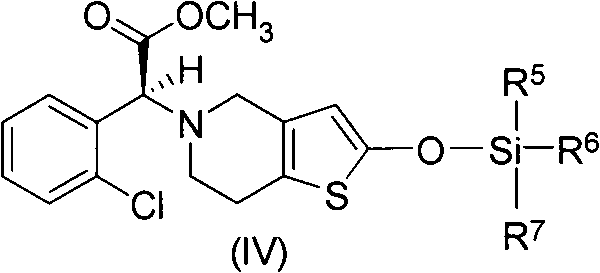

Method for preparing vicagrel and derivatives thereof

The invention relates to the pharmaceutical field, and concretely relates to a method for preparing vicagrel and derivatives thereof. The method comprises a step 1 of adopting optically-active alkyl sulfonate to carry out selective N-alkylation of 4,5,6,7-tetrahydrothieno[3,2-c]pyridine-2-ol silyl ether, and a step 2 of directly esterifying a product generated in step 1 to obtain vicagrel. The method has the advantages of less side reactions, high yield, high chemical purity and optical purity, low cost, simple operation, and suitableness for the industrialized production.

Owner:JIANGSU VCARE PHARMATECH

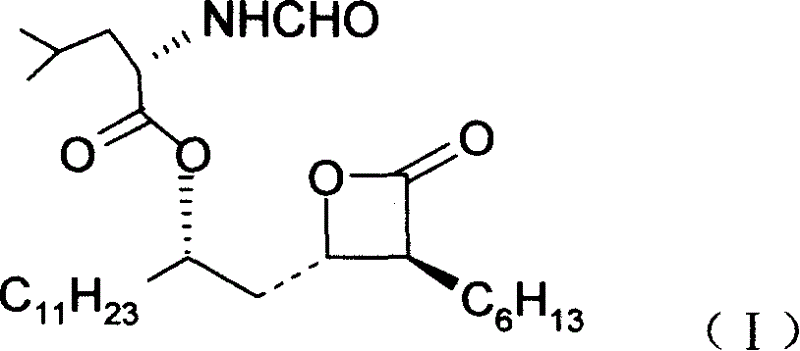

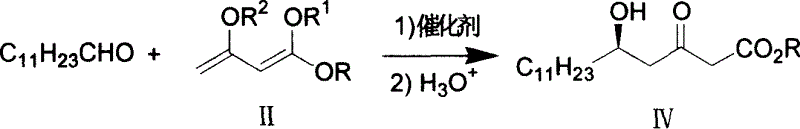

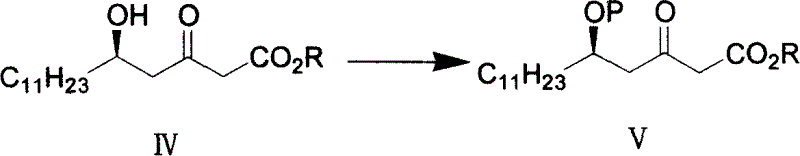

Orlistat preparation method

InactiveCN1765892AEasy to industrializeHigh utility valueOrganic chemistryPtru catalystCombinatorial chemistry

The invention relates to a preparation method for oleanstada, which comprises: on catalyst action, using enolsiliconether and lauraldehyde to condense directly and obtain chiral hydroxyl hexadeketo ester; after eight steps contained protecting hydroxyl group, reducing and cyclization, obtaining the objective product with chemical formula as (I) for efficient fat-reducing. This method needs low cost.

Owner:ARGUS PHARMA

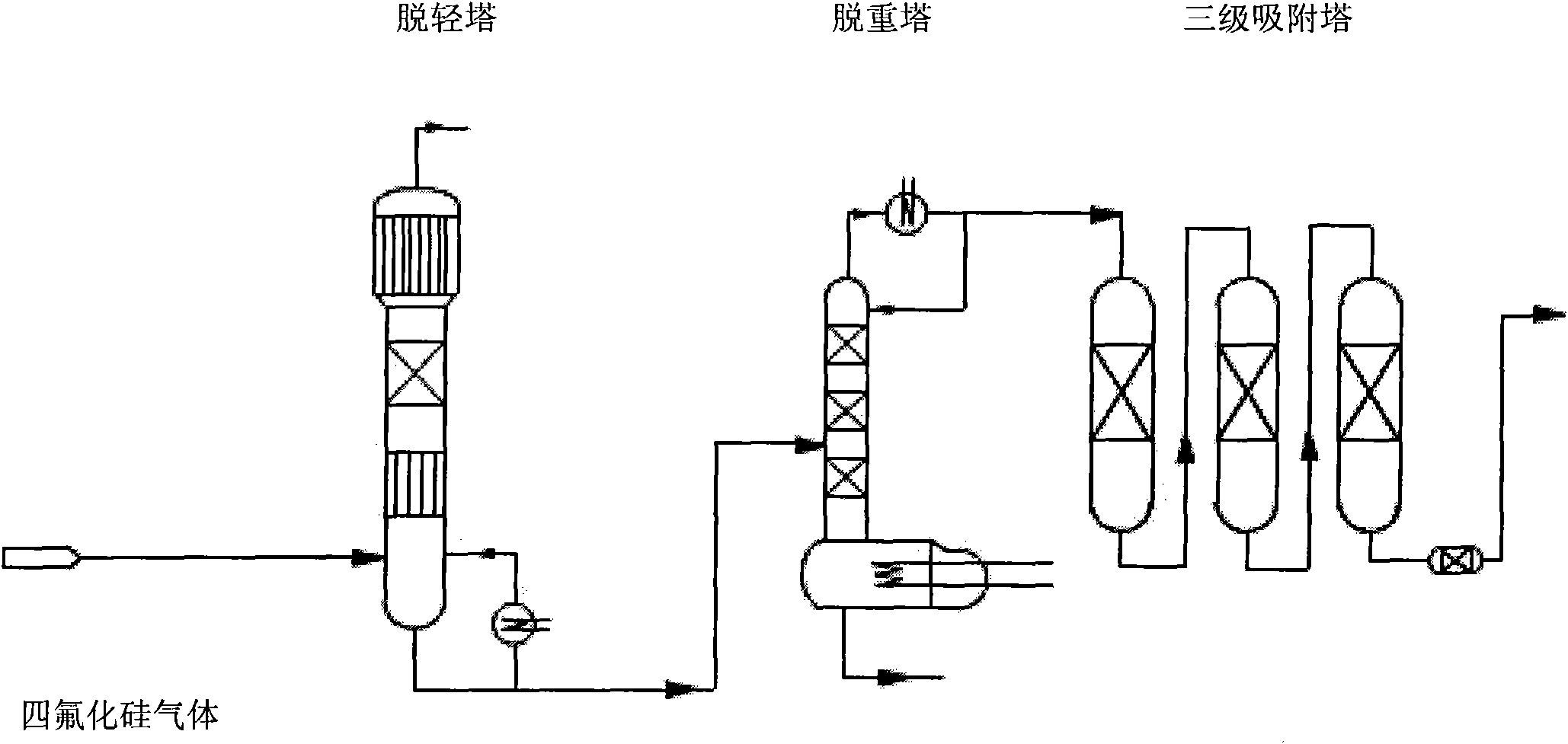

Purification method of silicon tetrafluoride prepared by using fluoride and silicon source power as raw materials

ActiveCN101774588AReduce concentrationMeet the use requirementsHalogenated silanesActivated carbonCarbon dioxide

The invention discloses a purification method of silicon tetrafluoride prepared by using fluoride and silicon source power as raw materials, which comprises the following steps: 1. removing nitrogen, oxygen and carbon dioxide in coarse silicon tetrafluoride produced by using the fluoride and the silicon source power as the raw materials through a lightness-removing column at the temperature of 150 DEG C below zero to 50 DEG C below zero, wherein the pressure of the lightness-removing column is 0.1 to 3MPa; 2. introducing a liquid-phase material at the bottom of the lightness-removing column into a weight-removing column, removing moisture and fluorine hydride from the column bottom at the temperature of 20 to 80 DEG C below zero, and discharging silicon tetrafluoride gas from the column top, wherein the pressure of the weight-removing column is 0.5 to 5MPa; 3. enabling the silicon tetrafluoride gas to pass through a triple-stage absorption column in which activated carbon is filled to absorb and remove dimethyl silicon ether hexafluoride; and 4. connecting the purified silicon tetrafluoride gas from the absorption column into a compressor pipeline and introducing into a storage tank for standby after being compressed to 2.5MPa. The coarse silicon tetrafluoride can be finally purified to the purity of more than 99.5% by the invention, thereby the use requirements of electron and semiconductor trades are completely satisfied.

Owner:ZHEJIANG ZHONGNING SILICON IND

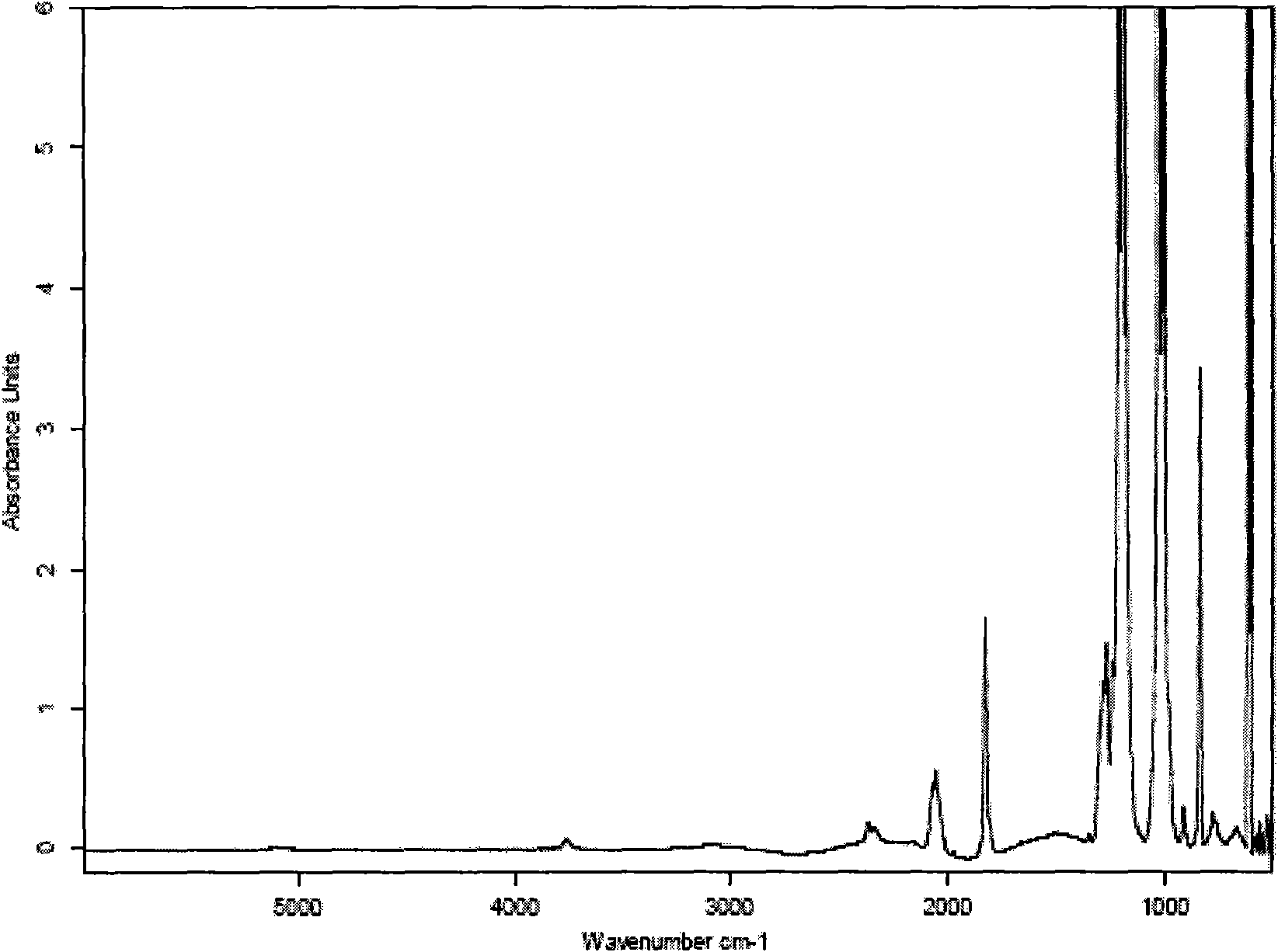

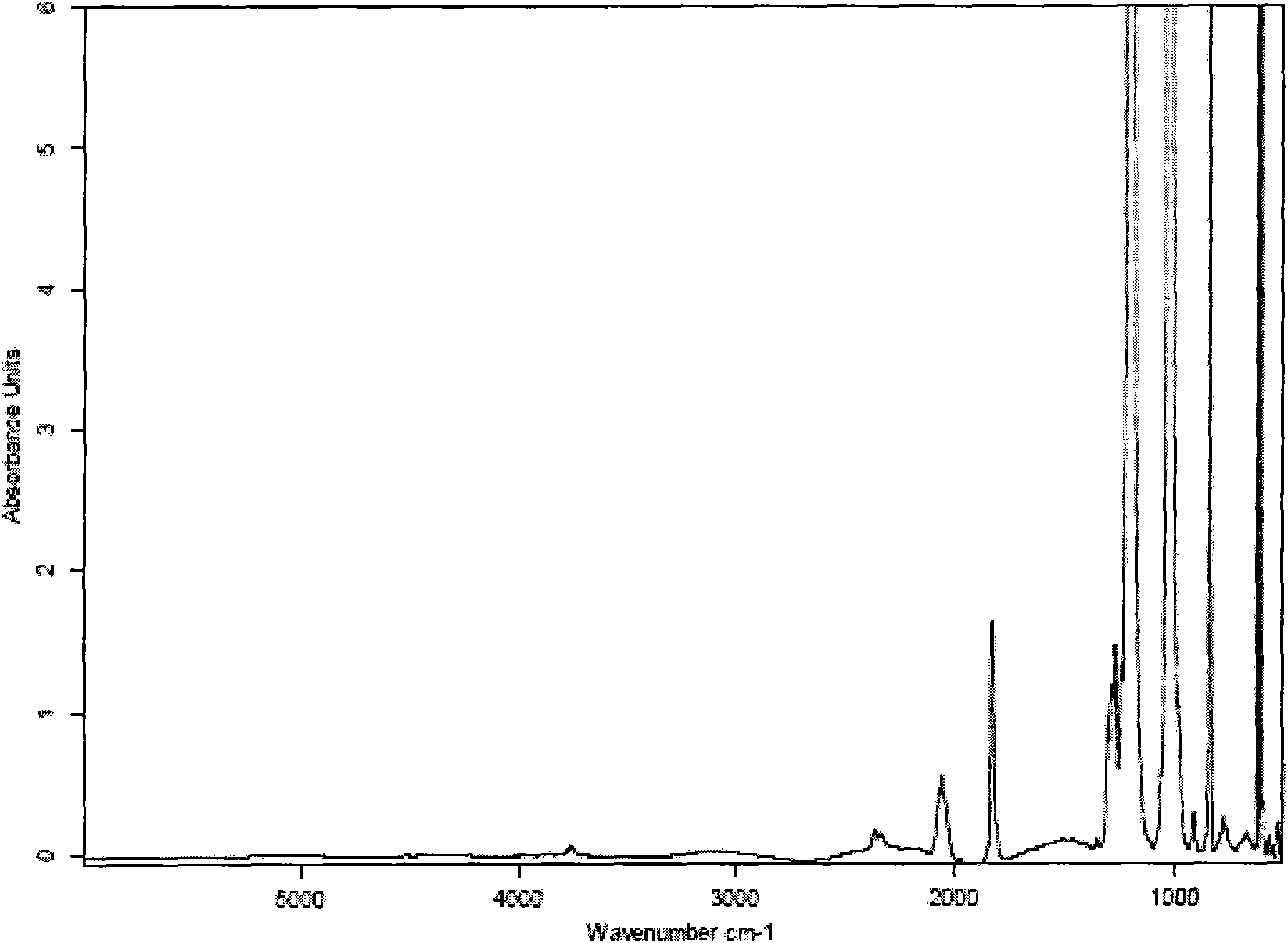

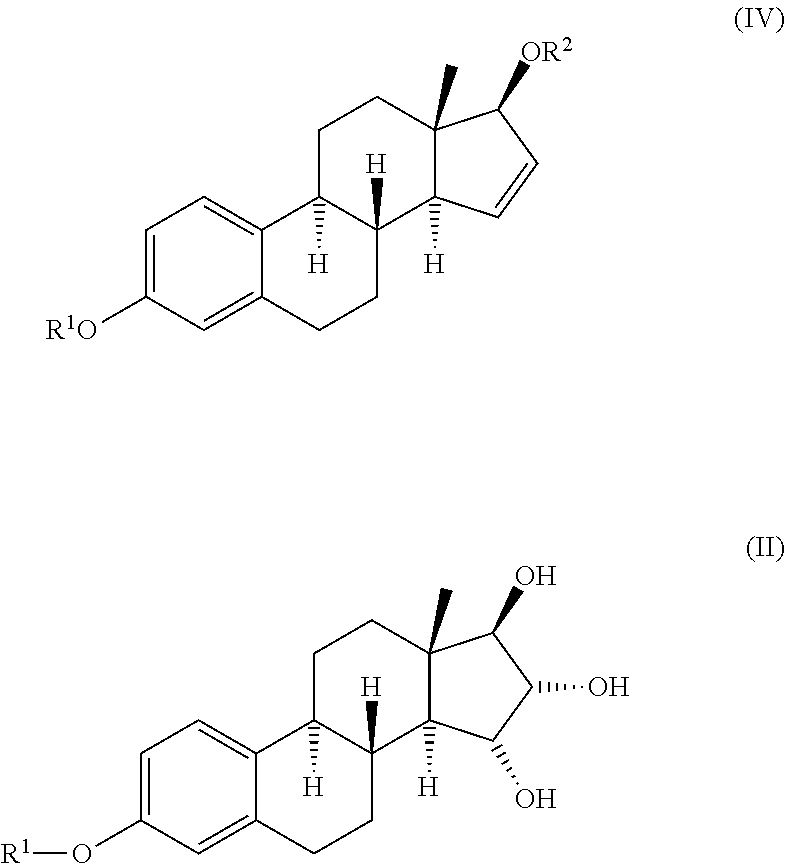

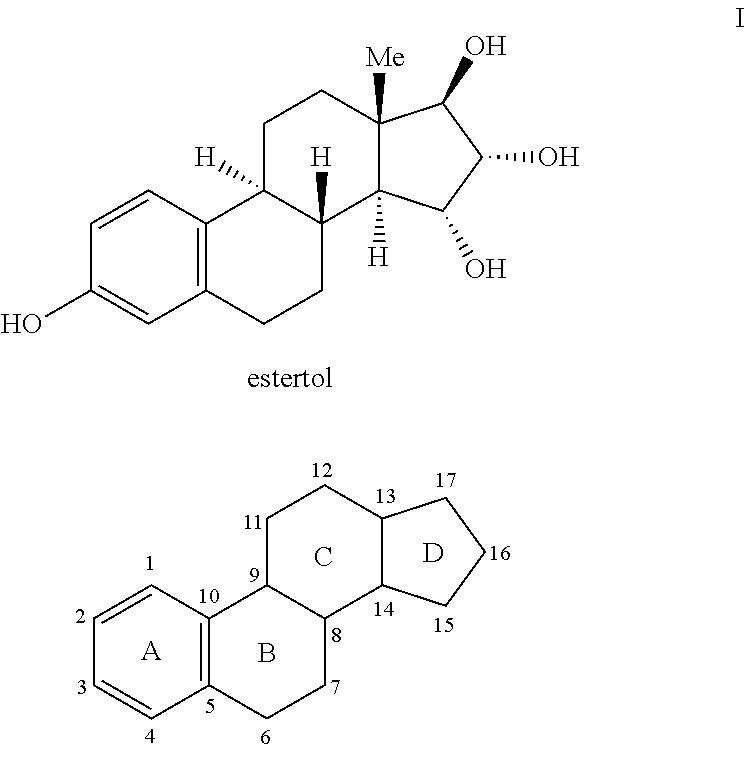

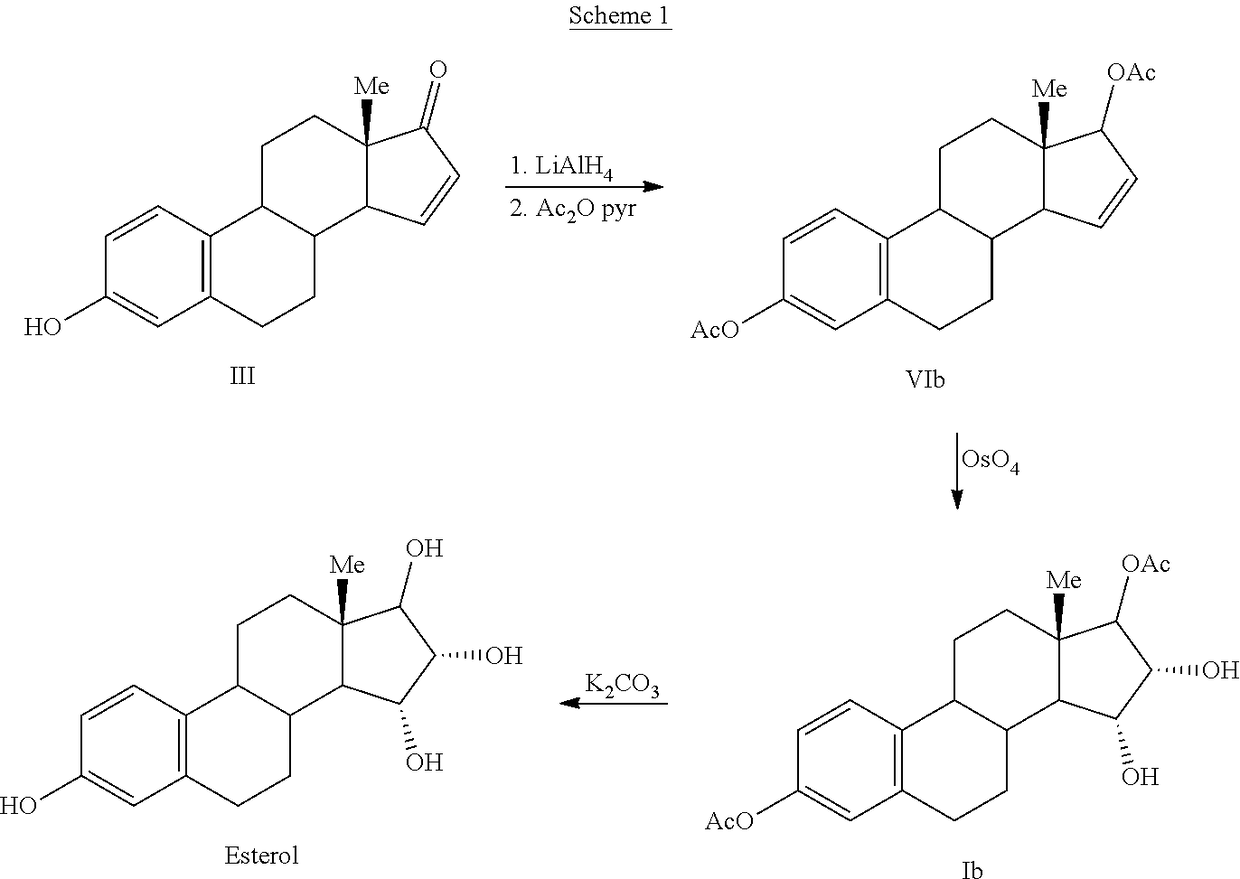

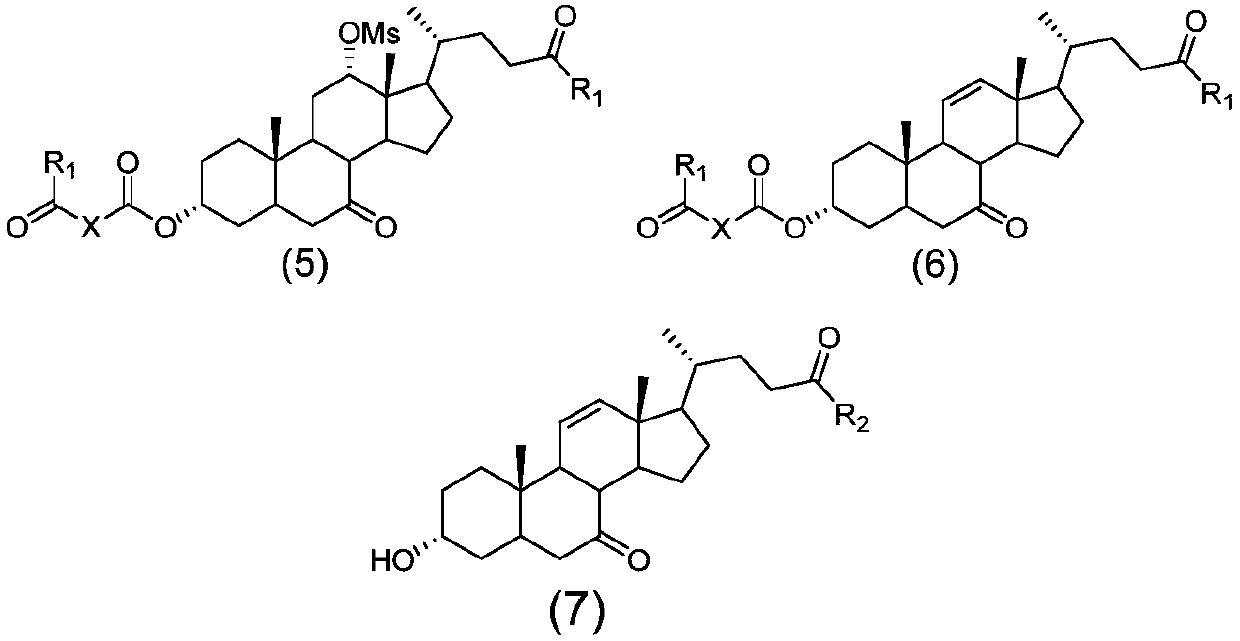

Process for the preparation of estetrol

The invention relates to a process for obtaining Estetrol or a salt or solvate thereof, the process comprising: a) reacting a compound of formula (IV) or a salt or solvate thereof, wherein R1 is a hydroxyl protecting group selected from a silyl ether, an ether, an ester, a carbamate and a carbonate, and R2 is a hydroxyl protecting group selected from an ether, with an oxidizing agent selected from OsO4 or a source of osmium tetroxide to produce Estetrol or a compound of formula (II) or a salt or solvate thereof wherein R1 is as defined previously; and b) if a compound of formula (II) is obtained in step a), deprotecting said compound to produce Estetrol.

Owner:CRYSTAL PHARMA SA

Hydrophobic polysaccharides with silyl ether linkages having enhanced degradation and medical articles made therefrom

ActiveUS20110076314A1Fast degradationShort period of implantationPowder deliveryOrganic active ingredientsSilyleneEnhanced degradation

Hydrophobic α(1→4)glucopyranose polymers with enhanced degradation properties are described. Between the α(1→4)glucopyranose polymeric portion and the hydrophobic portion exists a linker portion having a silyl ether chemistry that facilitates degradation of the polymer. Biodegradable matrices can be formed from these polymers, and the matrices can be used for the preparation of implantable and injectable medical devices wherein the matrix is capable of degrading in vivo at an increased rate. Matrices including and capable of releasing a bioactive agent in vivo are also described.

Owner:SURMODICS INC

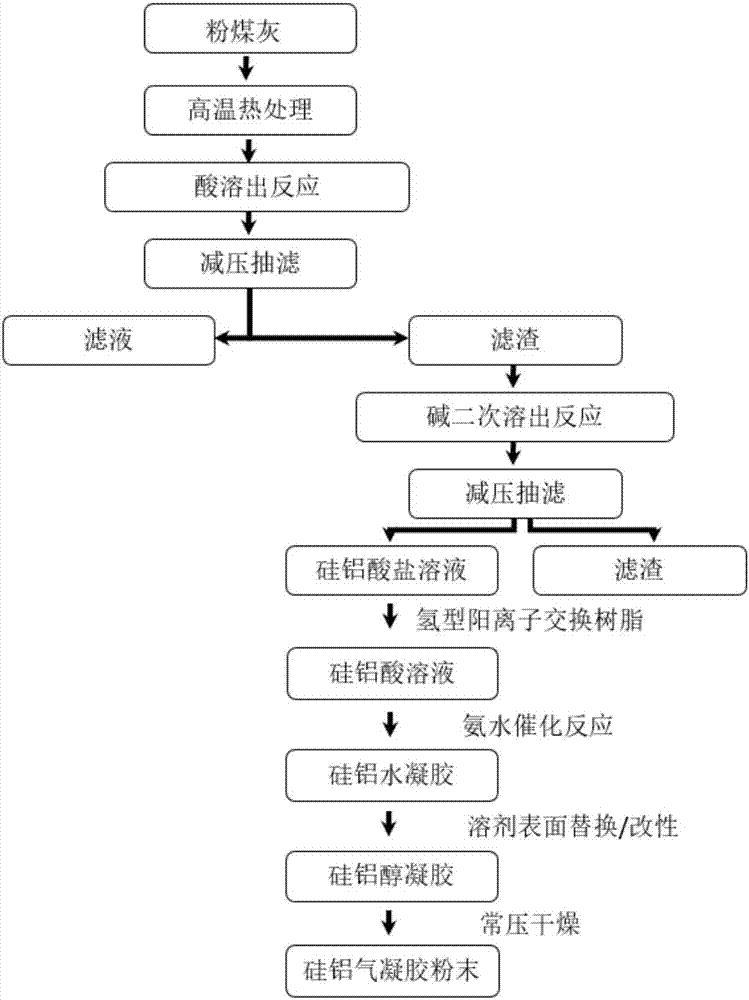

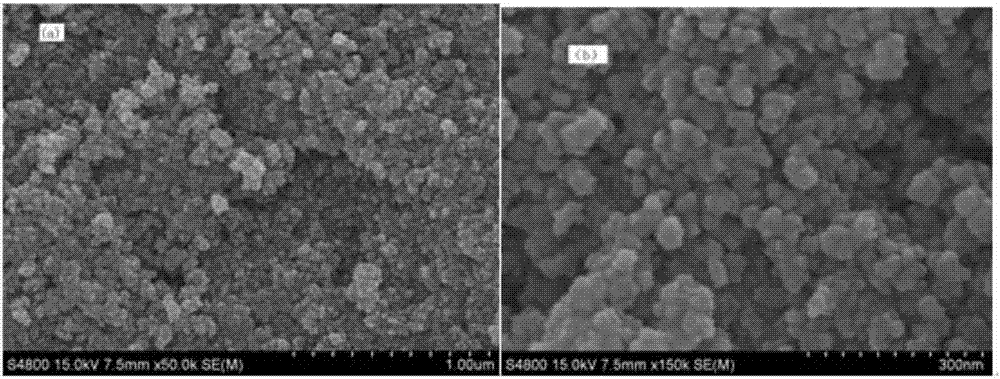

Preparation method of silicon-aluminum composite aerogel powder

ActiveCN107998996AAvoid introducingShorten the reaction process timeAerogel preparationSilicon compoundsFiltrationAmbient pressure

The invention discloses a preparation method of silicon-aluminum composite aerogel powder. The preparation method concretely comprises the following steps of (1) mixing coal ash subjected to high temperature activation treatment and a hydrochloric acid solution to perform acid dissolution reaction, performing suction filtration on an obtained reaction solution, mixing obtained filter residues andan inorganic alkaline solution to perform alkaline dissolution reaction, and performing suction filtration; (2) adopting hydrogen-type cation exchange resin to perform exchange on an obtained silicoaluminate salt solution until a pH value of the solution is 2-3, then adopting ammonia water to catalyze an obtained silicoaluminate solution to perform catalysis until a pH value is 5-7, and then performing ageing; (3) adopting ethanol to perform solvent replacement on obtained silicon-aluminum hydrogel to obtain silicon-aluminum alcogel; (4) adopting a mixed solution of hexamethyldisiloxane and the ethanol to perform surface modification on the silicon-aluminum alcogel; and (5) performing ambient pressure drying, crushing and screening on the silicon-aluminum gel with the hydrophobic surface to obtain the silicon-aluminum composite aerogel powder. The preparation method has the advantages of wide source of raw materials, low cost, simpleness in preparation technology, suitability for industrial production in large scale and the like.

Owner:UNIV OF SCI & TECH LIAONING

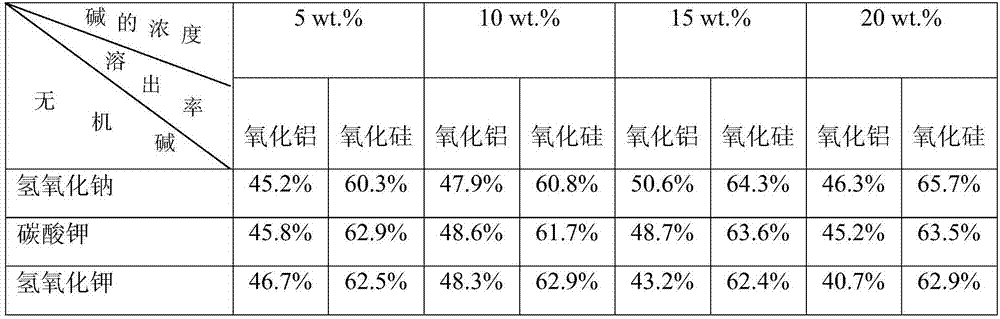

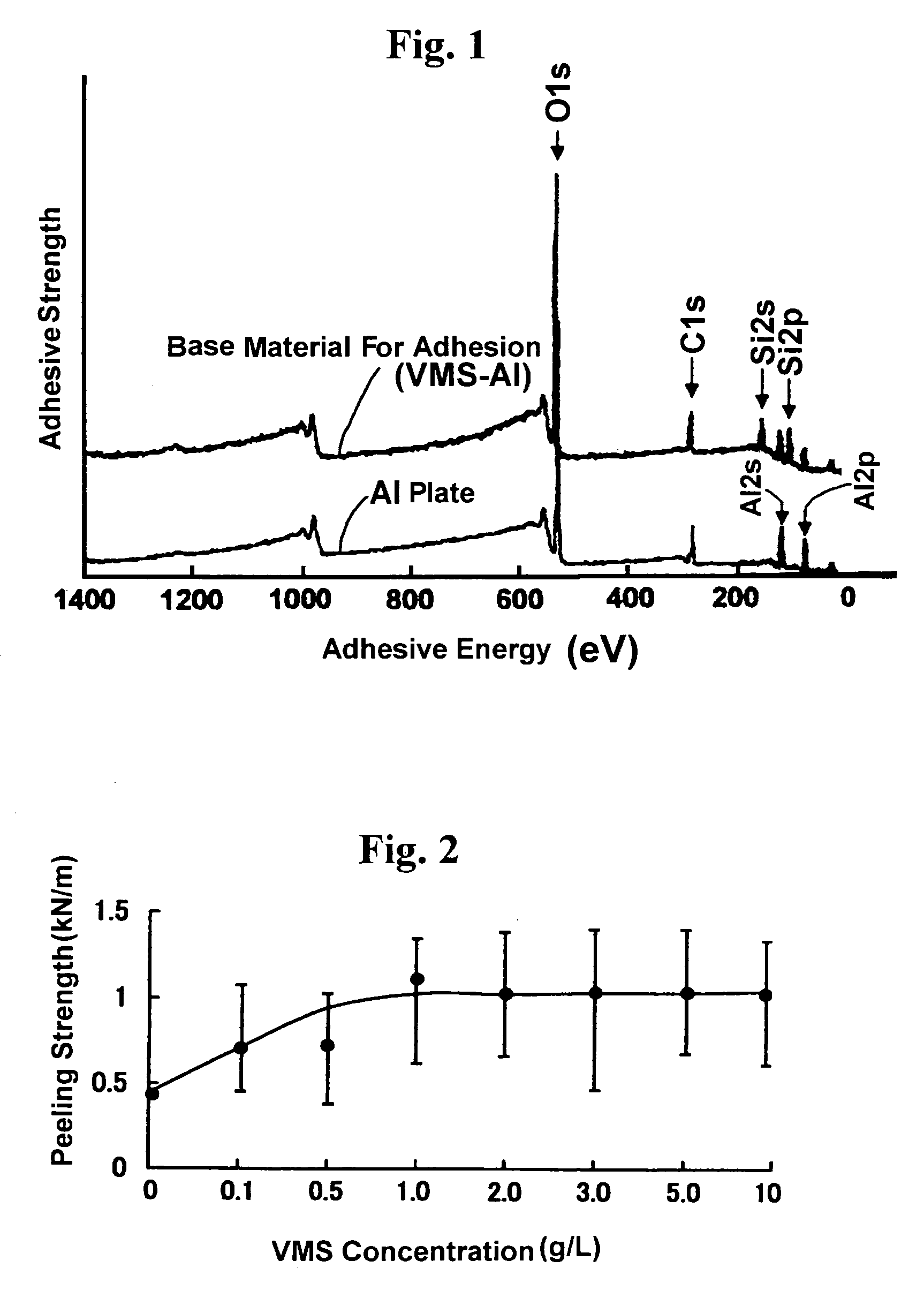

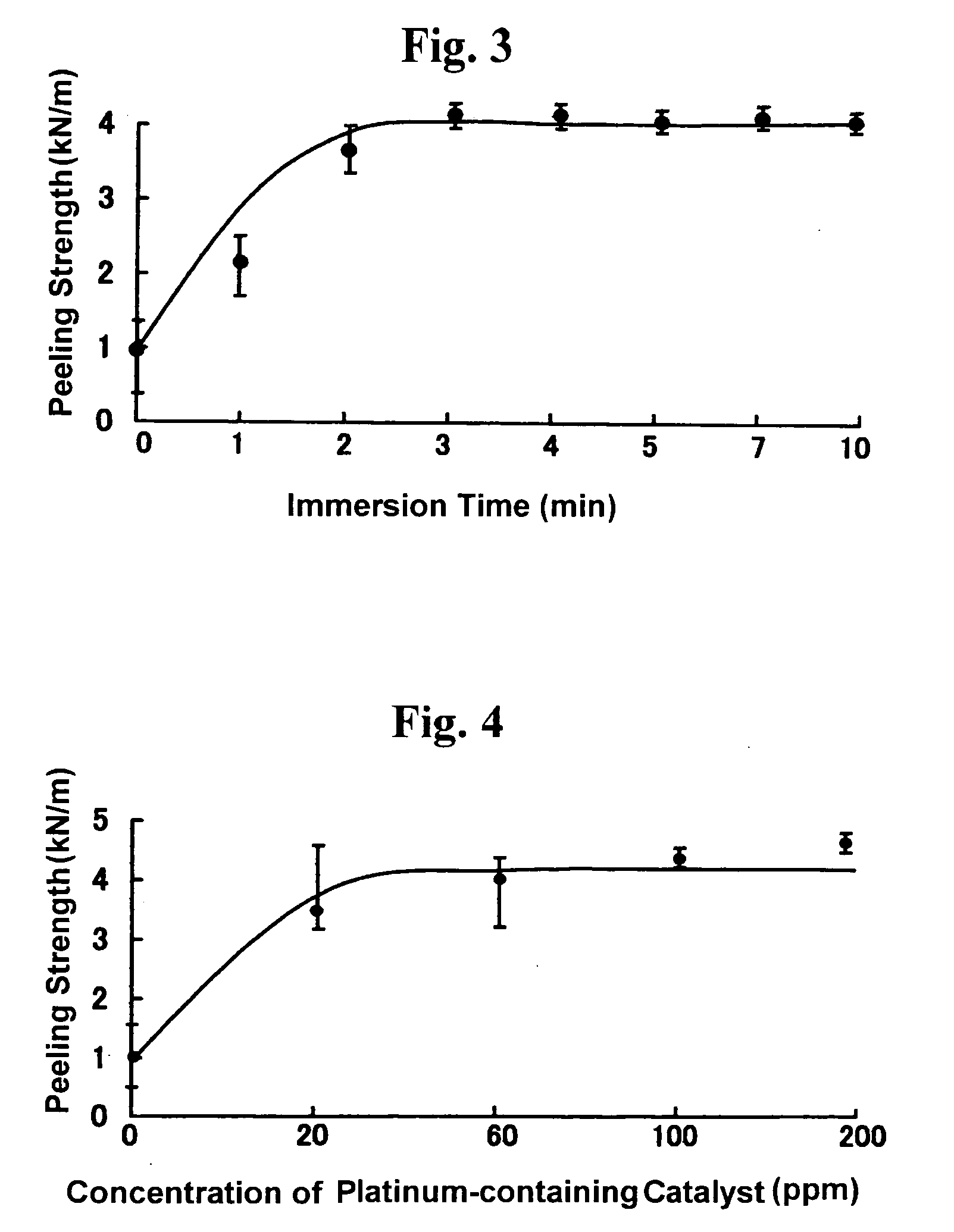

Base material for adhesion and silicone rubber-adhered article using thereof

ActiveUS20090277581A1Simple processSimple materialAdhesive processesThin material handlingCeramicSilyl ether

A base material for adhesion to be adhered to a solid body comprising;a substrate made from metal, polymer resin, glass or ceramics whose surface is adhesive to the solid body by silyl-ether-linkage that at least one active silyl group selected from the group consisting of a hydrosilyl-containing silyl group, a vinyl-containing silyl group, an alkoxysilyl-containing silyl group and a hydrolytic group-containing silyl group having reactivity with a reactive group on the surface of the solid body is bound to a dehydrogenated residue of hydroxyl group on the surface of the substrate.

Owner:ASAHI RUBBER

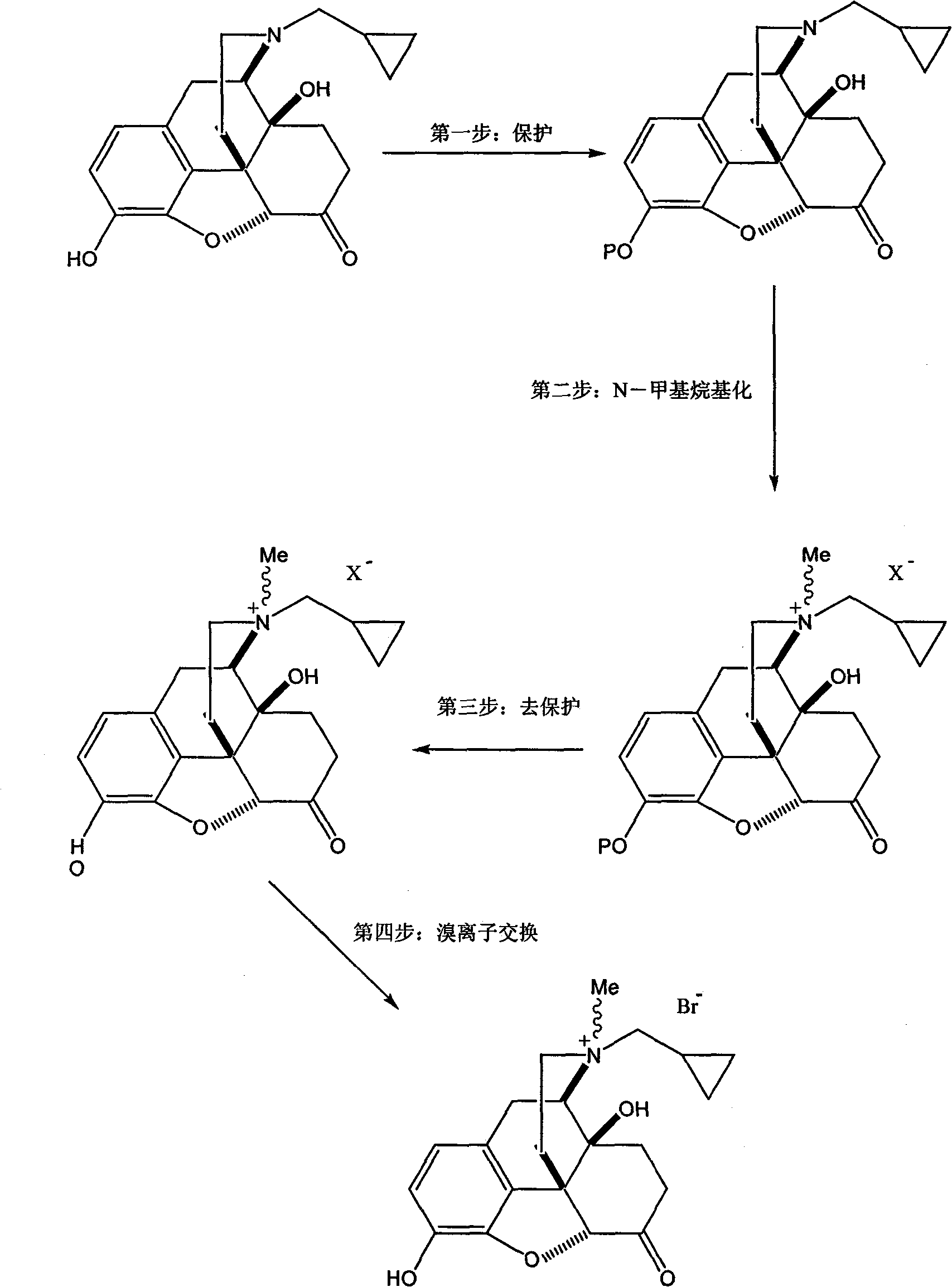

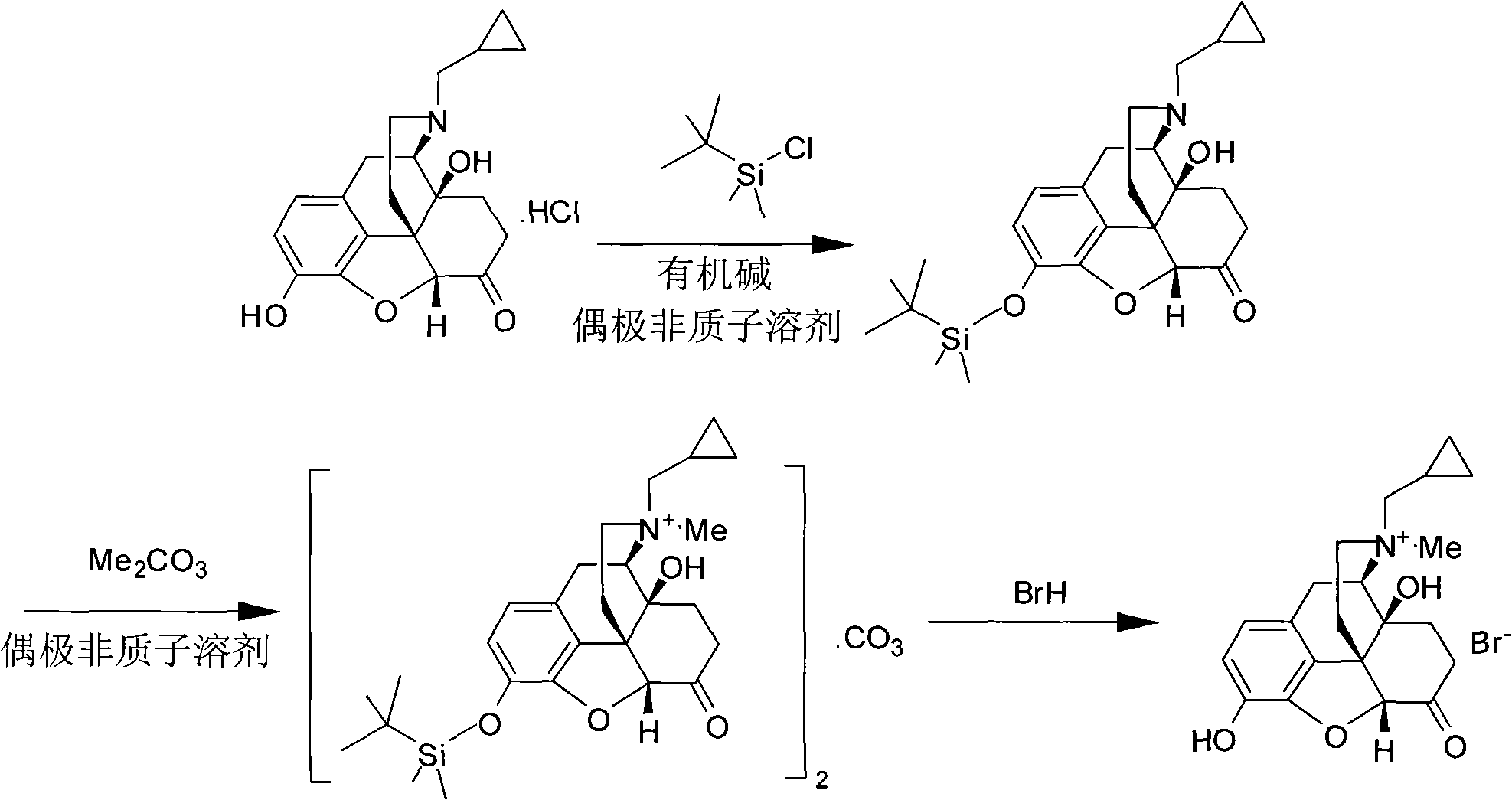

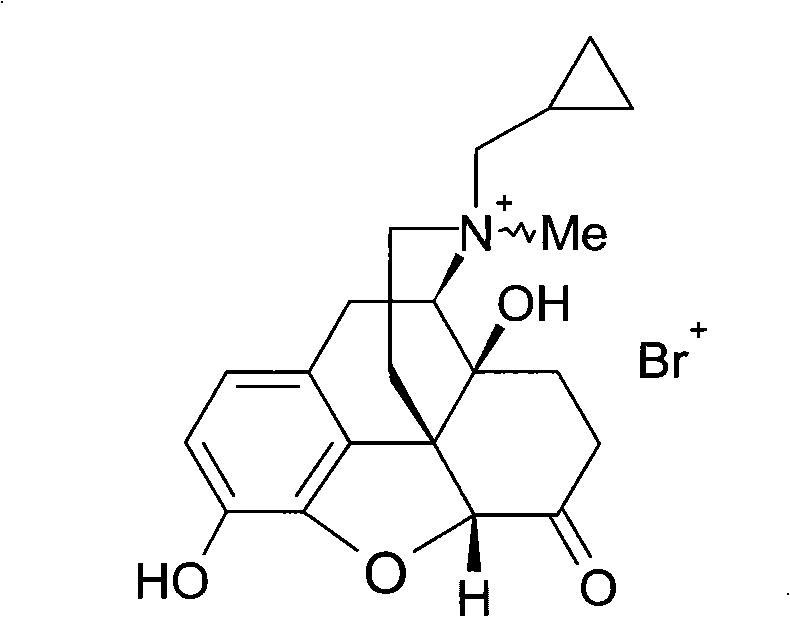

Method for preparing methylnaltrexone bromide

ActiveCN101845047ANo irritating smellHigh reaction yieldOrganic chemistryBulk chemical productionMethylating AgentOrganic base

Owner:NANJING CHENGONG PHARM CO LTD

Methyl MQ resin and preparation method thereof

The invention discloses a methyl MQ resin preparation method, which comprises: adding an organic solvent 1 to a sodium silicate aqueous solution in a dropwise manner under stirring, stirring at a temperature of 25+ / -2 DEG C, standing, generating precipitate at the bottom portion of the sodium silicate aqueous solution, taking out the sodium silicate aqueous solution, and adding corresponding waterto obtain a refined sodium silicate aqueous solution; carrying out a reaction on an acid and the refined sodium silicate aqueous solution, adding an organic solvent 2 and silyl ether, and carrying out a reflux reaction; separating the reaction product, and purifying; and carrying out spray drying on the obtained purified product to obtain the methyl MQ resin. According to the present invention, the methyl MQ resin prepared from the refined sodium silicate aqueous solution has high molecular weight compared with the methyl MQ resin prepared from the non-refined sodium silicate aqueous solution, and further has narrow molecular weight distribution; the excess silyl ether can be used as both the reaction material and the extractant for the reaction product; and during the post-treatment, thewater washing is avoided so as to prevent the emulsification. The present invention further provides a high molecular weight methyl MQ resin having a molecular weight of greater than 10000 g / mol.

Owner:济南雅达新材料科技有限公司

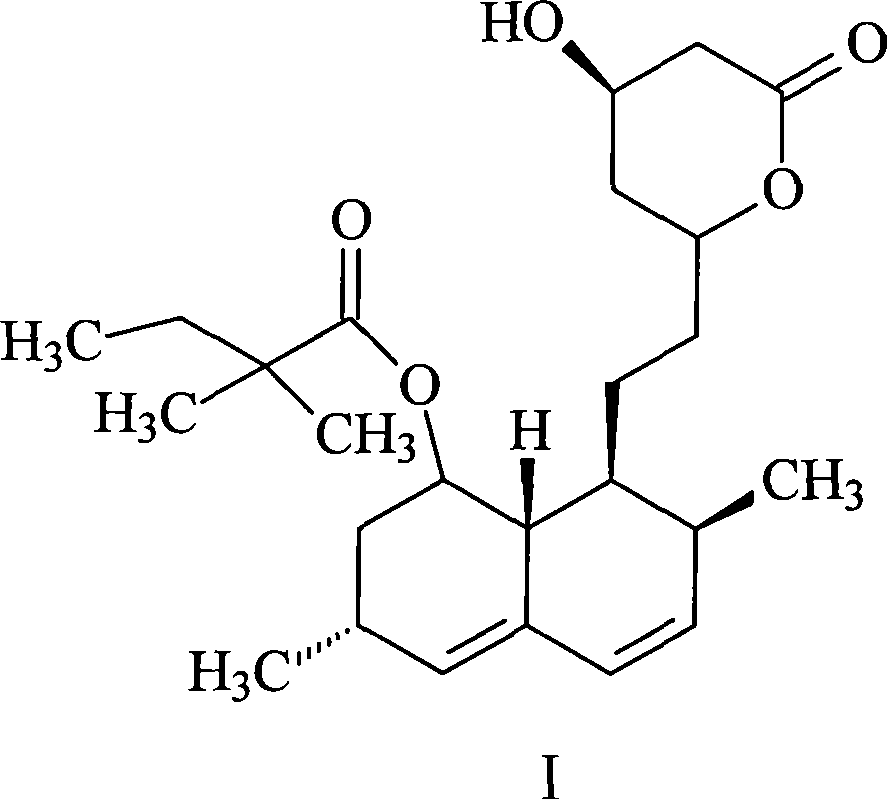

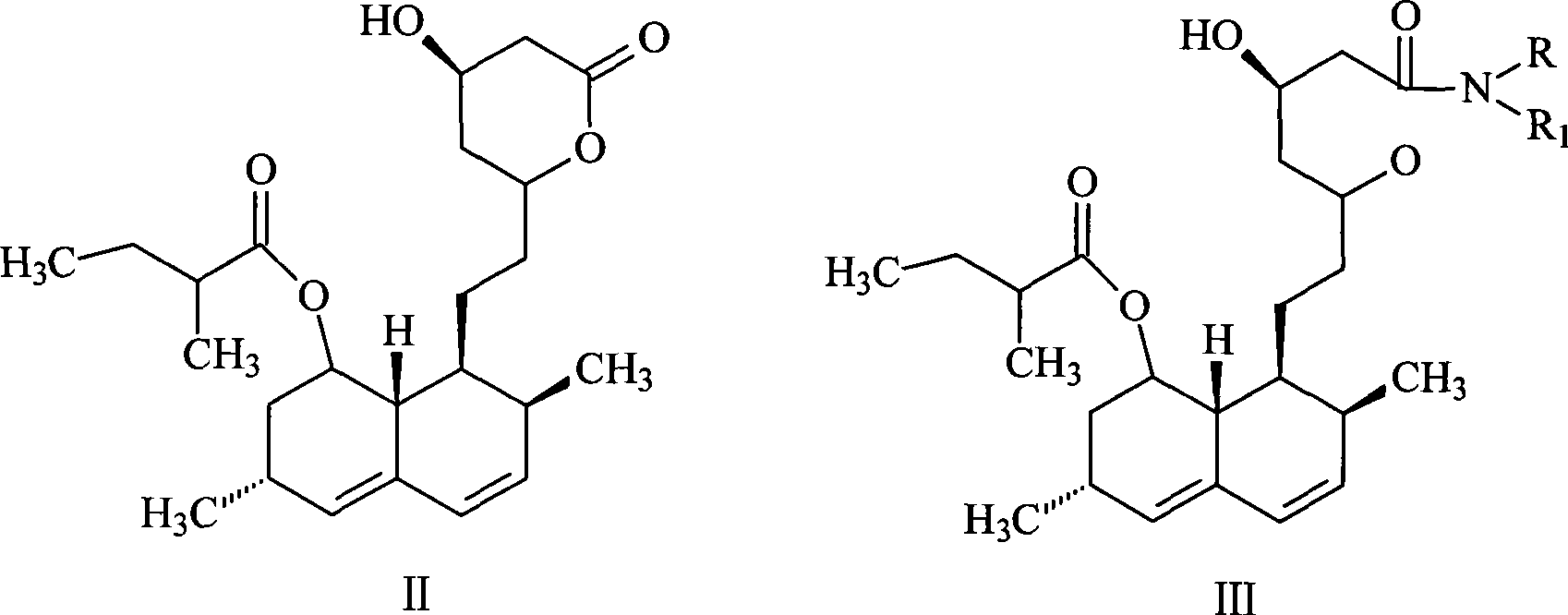

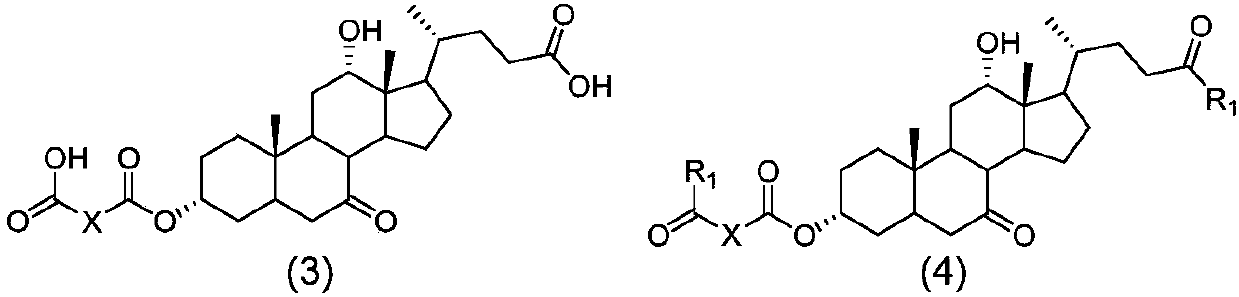

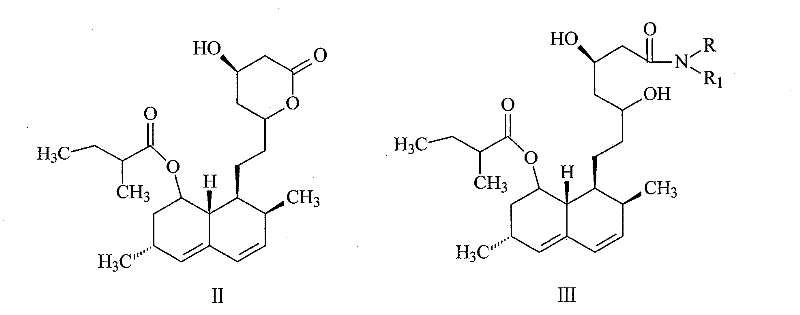

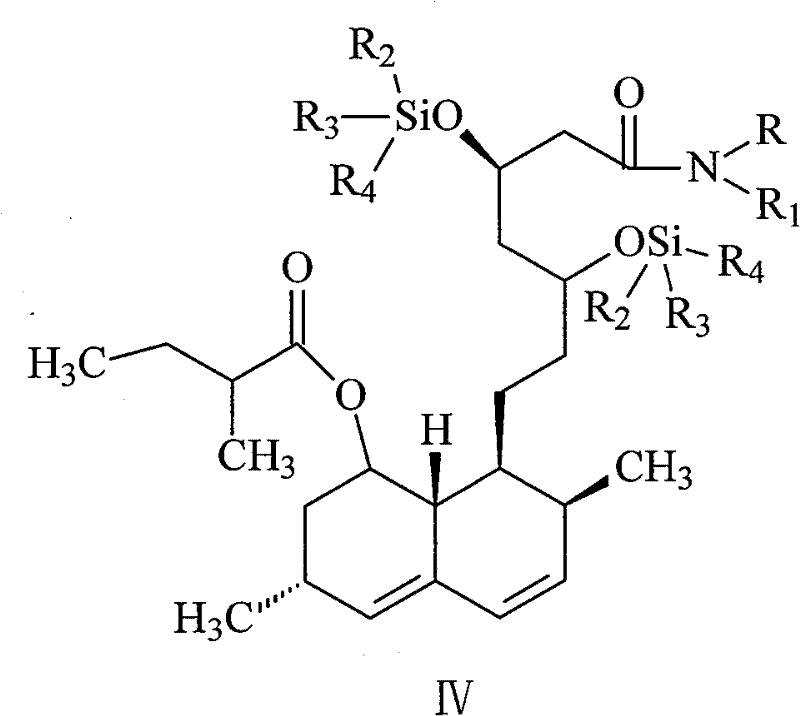

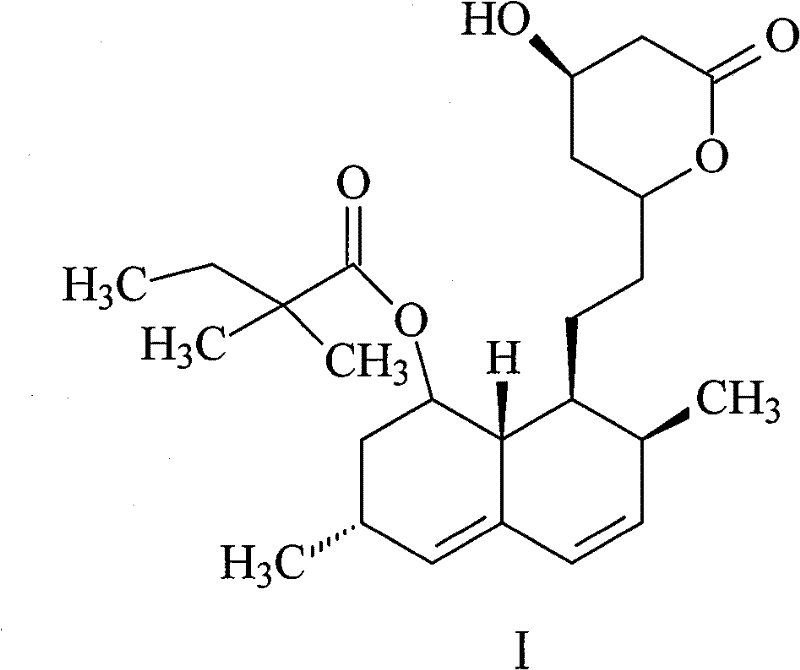

Preparation method of simvastatin

ActiveCN101381356AReduce manufacturing costSimple production processOrganic chemistryMetabolism disorderLovastatinHydrolysis

The invention discloses a method for preparing simvastatin. The method is as follows: a. lovastatin and alkylamine are prepared into lovastatin amide; b. hydroxyl groups in lovastatin amide molecules are protected, and lovastatin amide di-(trimethyl) silyl ether is generated; c. the lovastatin amide dimethyl (trimethyl) silyl ether is subjected to methylation, so as to obtain simvastatin amide di-silyl ether; d. the simvastatin amide di-silyl ether is protected, and simvastatin amide is generated; e. the simvastatin amide is subjected to hydrolysis and is added with ammonia gas, and simvastatin ammonium salt is obtained; and f. the simvastatin ammonium salt is subjected to ring closure to generate the simvastatin. The method takes a composite solvent of tetrahydrofuran and cyclonexane as a solvent for the protective reaction; the lovastatin amide di-(trimethyl) silyl ether can directly perform methylation reaction without alkaline washing and water scrubbing; after water scrubbing of methylate, protective groups are automatically fallen off, thereby the reaction for removing the protective groups is saved and the products can directly perform ammonium salt reaction. The method simplifies the synthesis technique of the simvastatin.

Owner:HEBEI GUOLONG PHARMA CO LTD

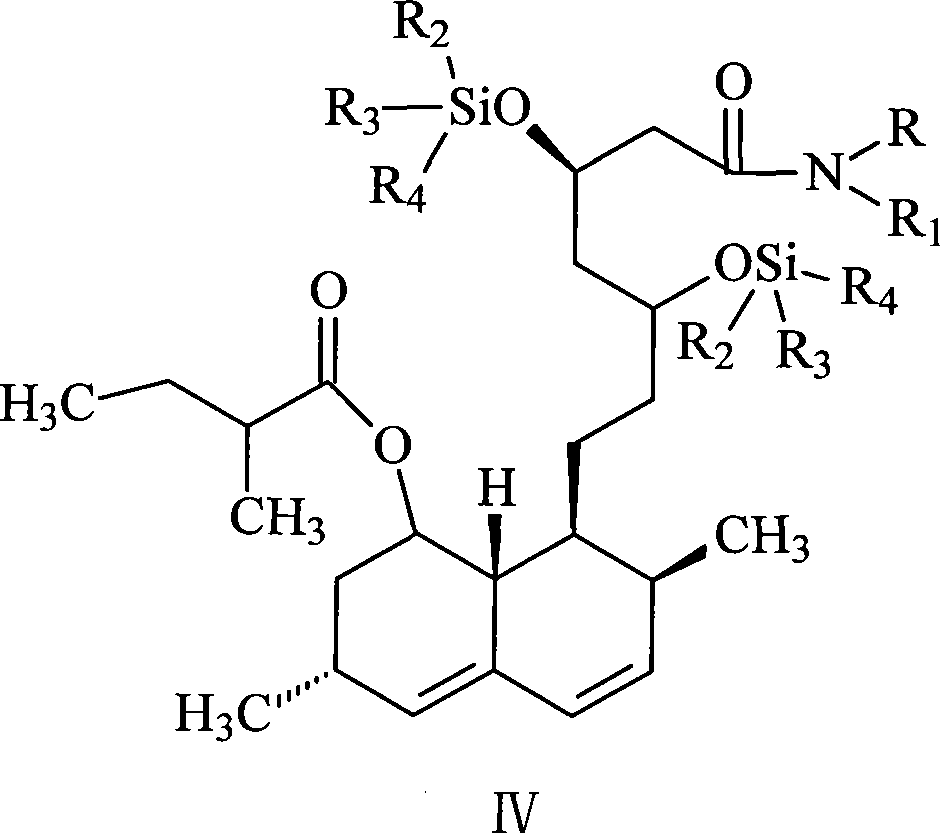

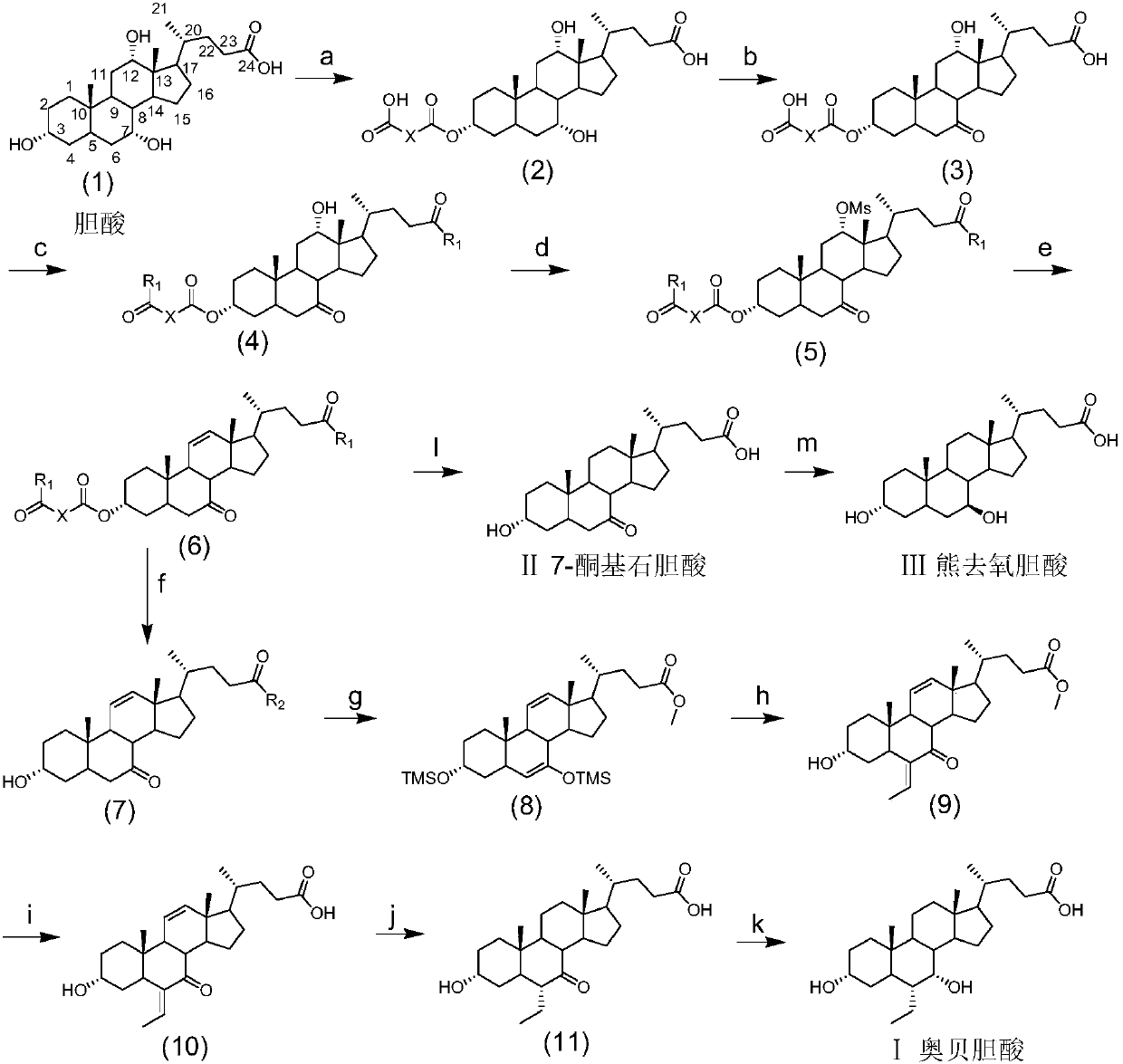

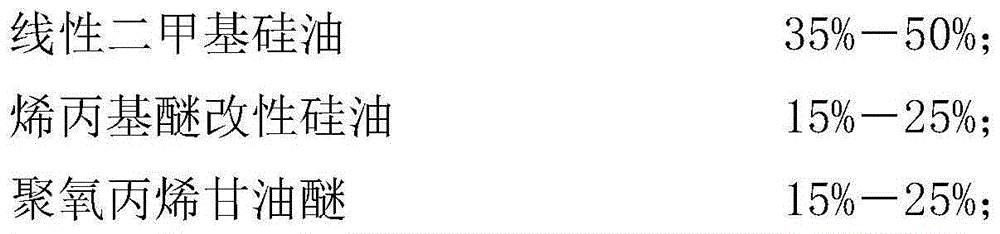

Method for preparing obeticholic acid, ursodeoxycholic acid and 7-ketolithocholicacid

InactiveCN108676049AEasy to manufactureHigh yieldSteroidsBulk chemical productionCholic acidSynthesis methods

The invention discloses a method for preparing obeticholic acid, 7-ketolithocholicacid and ursodeoxycholic acid. Cholic acid is used as a raw material for preparing obeticholic acid through selectiveprotection by a 3-alpha-hydroxyl group, selective oxidation of a 7-alpha-hydroxyl group, esterification of a 24th carboxyl group, methanesulfonation of a 12-alpha-hydroxyl group, elimination, hydrolysis, silylation, condensation, hydrolysis, catalytic hydrogenation, carbonyl reduction and other reactions; an intermediate is subjected to catalytic hydrogenation to prepare the 7-ketolithocholicacidand then is reduced to prepare the ursodeoxycholic acid. The method provided by the invention uses cheap cholic acid as the raw material, and has advantages of novel synthesis method, low cost, high yield, mild reaction condition, high simplicity in operation, environmental friendliness and high convenience in industrial production.

Owner:EAST CHINA NORMAL UNIV

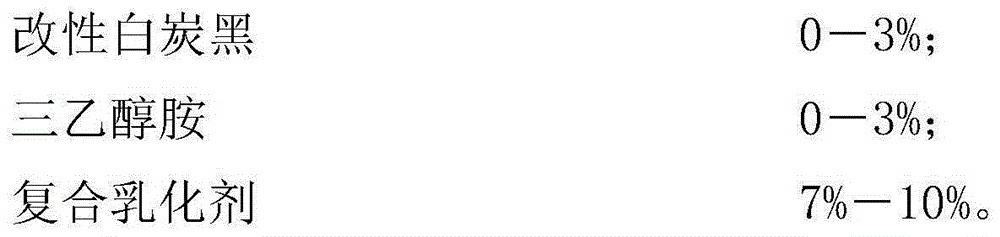

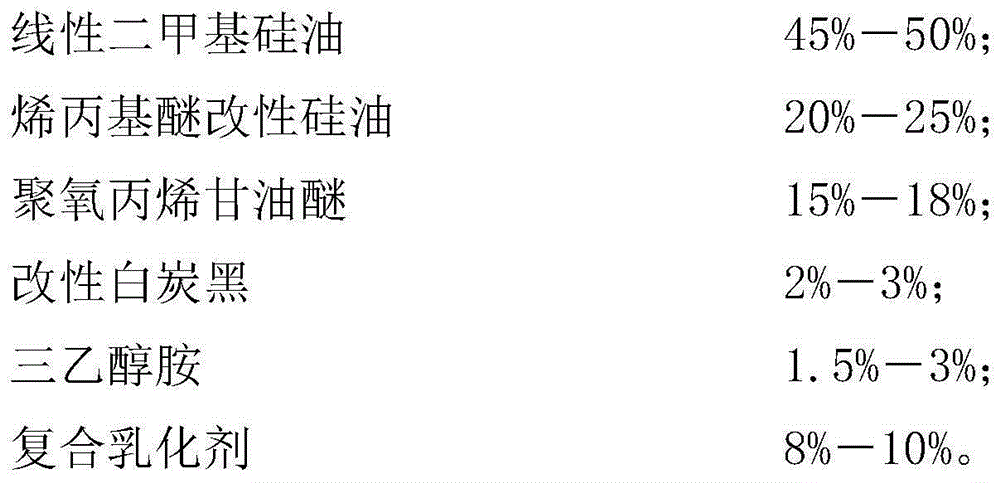

Silyl ether mixed defoaming agent emulsion and preparation method thereof

InactiveCN105031978AEasy to operatePromote fermentationFoam dispersion/preventionEmulsionFermentation

The invention discloses silyl ether mixed defoaming agent emulsion and a preparation method thereof. The silyl ether mixed defoaming agent emulsion is prepared from the following components: linear simethicone, allyl ether modified polysiloxane, polyoxypropylene glyceryl ether, modified white carbon black, triethanolamine and a compound emulsifier. The preparation method comprises the following steps: uniformly mixing the linear simethicone and the modified white carbon black, and heating to obtain a mixture I; adding triethanolamine into the mixture I, stirring and cooling to obtain a mixture II; adding the allyl ether modified polysiloxane and the polyoxypropylene glyceryl ether, and further stirring to obtain a mixture III; adding the compound emulsifier into the mixture III, and stirring at high speed to obtain coarse emulsion; adding thickening water into the coarse emulsion, and preparing raw emulsion; and pouring the raw emulsion into a high-speed homogenizer for stirring to obtain the fine-smooth and stable emulsion. The defoaming agent easily dissolves in water, and is small in specific surface area, high in defoaming speed, lasting in foam inhibition and small in use amount; the preparation method is convenient and easy to operate; the defoaming agent has no toxic effects on microorganisms, has an effect of promoting the growth of mycelia, is beneficial to microbial fermentation and is relatively environmentally friendly.

Owner:杭州彤诚新材料技术有限公司

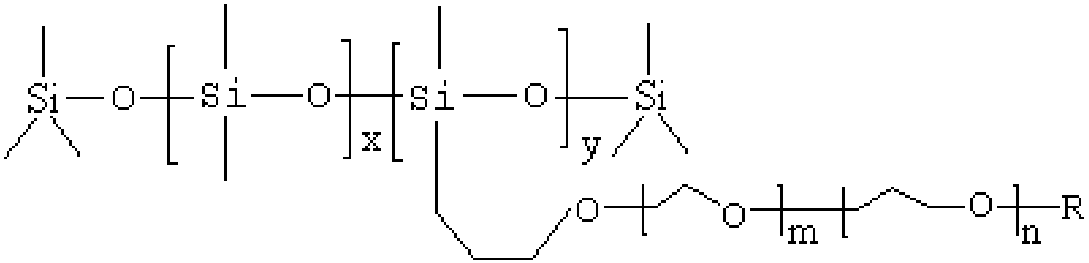

Silicon ether compound and preparation method and application thereof

InactiveCN1542014AHigh catalytic activityHydrogen sensitivityGroup 4/14 element organic compoundsHydrogen atomEther

The present invention relates to one new kind o silyl-ether compound and its preparation and application. The compound has the structure shown in the general expression (I).

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthetic leather water-based mist-surface skin-feeling high-temperature-resistant pretreatment agent and preparation process thereof

A synthetic leather water-based mist-surface skin-feeling high-temperature-resistant pretreatment agent and a preparation process thereof are disclosed. The synthetic leather water-based mist-surface skin-feeling high-temperature-resistant pretreatment agent comprises the following raw materials by weight: 30-40% of waterborne polyurethane, 10-15% of an emulsifier, 1-3% of polyether modified amino silicone oil, 0.5-1% of a polyether polyester modified organo-siloxane leveling agent, 2-5% of a silicon ether copolymer defoaming agent, 5-10% of light extinction powder, 0.5-2% of a waterborne polyurethane associative thickener and 40-60% of water. The waterborne polyurethane is prepared from diisocyanate, a polyol, an extender, a catalyst and a neutralizer by an acetone method. The synthetic leather water-based mist-surface skin-feeling high-temperature-resistant pretreatment agent uses the water as a solvent for replacement of a poisonous solvent, has the propertied of being non-burning, safe, environmentally-friendly and cost-saving, and has the advantages of good film forming property, solvent resistance, cold resistance, hydrolysis resistance, high temperature resistance and embossing. The synthetic leather prepared by the synthetic leather water-based mist-surface skin-feeling high-temperature-resistant pretreatment agent has the advantages of no change in hand feeling before and after the embossing, fullness, fineness and good permeability, and the like.

Owner:嘉兴禾大科技有限公司

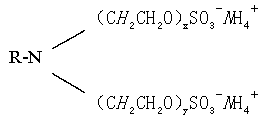

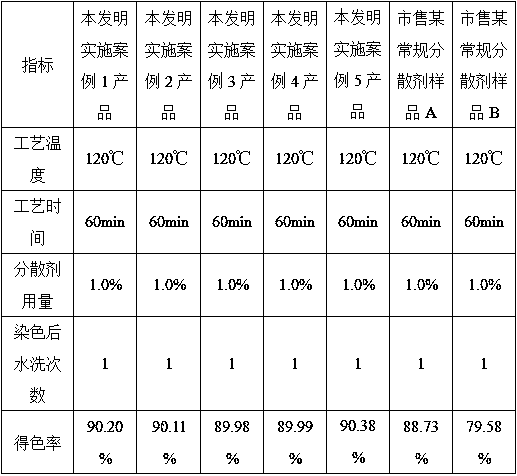

Degreasing agent used for dyeing in one bath and with multiple functions

The invention relates to a degreasing agent used for dyeing in one bath and with multiple functions. The degreasing agent is characterized by being composed of the following ingredients by mass percent: 5-20% of fatty alcohol polyoxyethylene ether, 5-20% of modified fatty amine polyoxyethylene ether, 2-10% of a dispersing agent, 5-10% of a solvent, 0.3-1% of polyether modified silyl ether ester and the balance of water. The degreasing agent used for dyeing in one bath and with multiple functions is easy in application and simplified in operation, and only one auxiliary is added. In the aspectof effect, dye dispersing and uniform dyeing effects are better during textile dyeing; besides, the degreasing agent has low foaming property and is easy to clean, degreasing is thorough during one-bath process dyeing of multiple fiber fabrics, removed grease stains are dispersed in dye liquor and can not touch a cloth cover and the inner wall of a dye vat, so that the problems of color tone, color spot, nonuniform dyeing and the like can be effectively avoided, deposition of cation and anion dyes also can be avoided, time, electricity and water are saved at the same time, energy conservationand emission reduction are realized, and economic benefit is effectively improved, so that energy-saving and environmental requirements can be better met.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

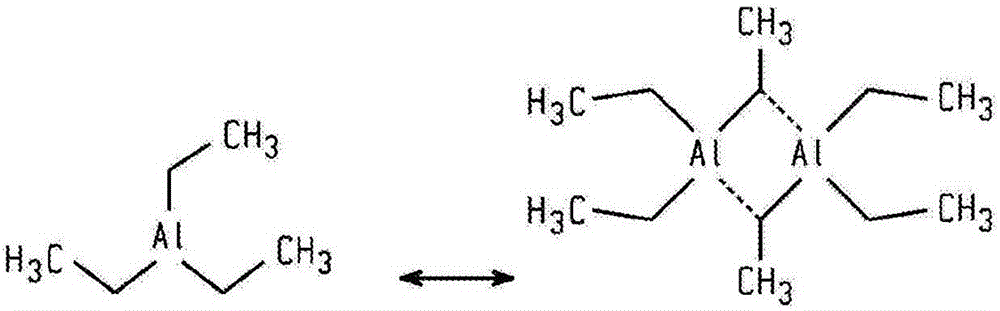

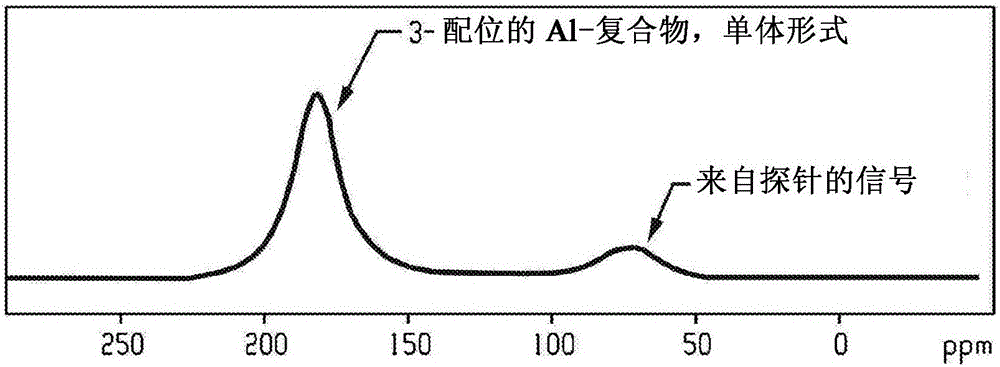

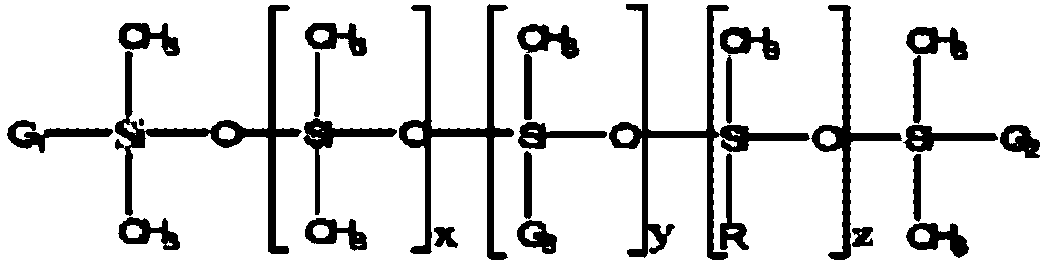

Modifying organoaluminum co-catalysts for improved performance

ActiveCN105980053AOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsCarbamateSilylene

The invention provides modifying organoaluminum co-catalysts for improved performance. Processes of making catalyst compositions are provided. In an exemplary embodiment, the processes include modifying an organoaluminum compound with a modifier that decreases the initial reducing strength of the organoaluminum compound, where the modifier can be an ether, an anhydride, an amine, an amide, a silicate, a silyl ether, a siloxane, an ester, a carbonate, a urea, a carbamate, a sulfoxide, a sulfone, a phosphoramide, or a combination thereof. The processes further include adding a transition metal complex to the mixture of the organoaluminum compound and the modifier; and obtaining a catalyst composition including the organoaluminum compound and the transition metal complex.

Owner:SABIC GLOBAL TECH BV

Ultra-high-molecular-weight polyether modified polysiloxane for flatting agent and preparation method and application of polyether modified polysiloxane

The invention provides ultra-high-molecular-weight polyether modified polysiloxane for a flatting agent and a preparation method and application of polyether modified polysiloxane. The preparation method of the polyether modified polysiloxane comprises the steps that allyl polyether and dichloromethylsilane are subjected to a hydrosilylation reaction in a solvent under catalysis of a platinum catalyst, and silyl ether is obtained; alkyl silane and obtained silyl ether are mixed and dropwise added to water for a hydrolysis reaction, and a hydrolysate is obtained; under catalysis of a basic catalyst, a cyclosiloxane monomer and the hydrolysate are subjected to a copolymerization reaction, and ultra-high-molecular-weight polyether modified polysiloxane is obtained through a neutral reaction.According to the preparation method, the smooth characteristic of ultra-high-molecular-weight polysiloxane is sufficiently used, the dispersibility of modified polysiloxane is excellent, and the smoothness and luster of water-based ink and paint are effectively improved; adopted polyether is easy to acquire, high in selectivity and low in cost.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

A method for preparing vicagrelor and derivatives thereof

The invention relates to the pharmaceutical field, and concretely relates to a method for preparing vicagrel and derivatives thereof. The method comprises a step 1 of adopting optically-active alkyl sulfonate to carry out selective N-alkylation of 4,5,6,7-tetrahydrothieno[3,2-c]pyridine-2-ol silyl ether, and a step 2 of directly esterifying a product generated in step 1 to obtain vicagrel. The method has the advantages of less side reactions, high yield, high chemical purity and optical purity, low cost, simple operation, and suitableness for the industrialized production.

Owner:JIANGSU VCARE PHARMATECH

Preparation method of simvastatin

ActiveCN101381356BReduce manufacturing costSimple production processOrganic chemistryMetabolism disorderLovastatinHydrolysis

Owner:HEBEI GUOLONG PHARMA CO LTD

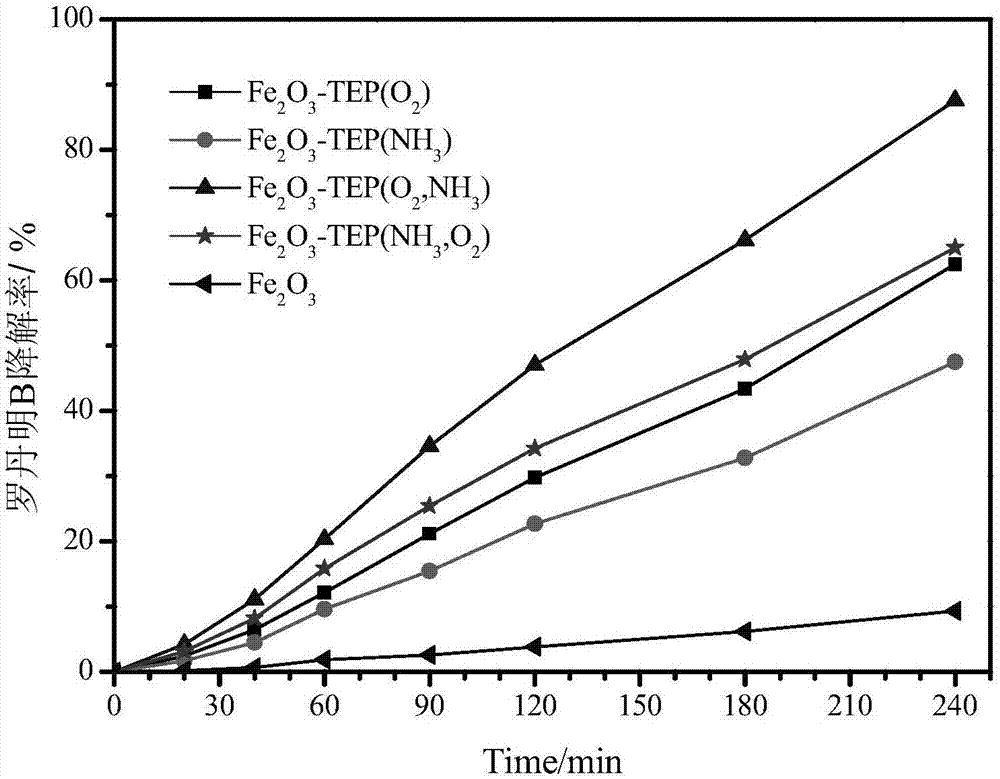

Floating environmental restoration material of Fe2O3-doped TiO2 loaded expanded perlite and preparation method of floating environmental restoration materials

ActiveCN107096537AThe synthesis process is simpleReduce manufacturing costWater/sewage treatment by irradiationWater treatment compoundsEnvironmental remediationLow density

The invention discloses a floating environmental restoration material of Fe2O3-doped TiO2 loaded expanded perlite and a preparation method of the floating environmental restoration materials. According to the conditions that the expanded perlite is a low-density porous material, and has the characteristics of being free of toxicity and high in acid and alkali resistance and adsorptivity, a lot of silanol groups and silyl-ether groups exist on the surface and are combined with the photocatalysis ability of TiO2, and the photocatalysis ability is further improved by using Fe2O3 doping and calcination in oxygen and / or ammonia gas to prepare the easy-to-recover environmental restoration material. The environmental restoration material can be applied to removal of organic pollutants in the environment.

Owner:YANGZHOU UNIV

Halogen-free flame-retardant electronic material and preparation method thereof

The invention provides a halogen-free flame-retardant electronic material and a preparation method thereof. The preparation method comprises the following steps: adding a fullerene derivative into a cyanate chlorobenzene solution, adding diethylbenzene phosphate and enol silyl ether, carrying out reflux reaction for 80 minutes, adding dicarboxyl phthalimide, reacting for 75 minutes, and simultaneously carrying out rotary evaporation and drying to remove a solvent, so as to obtain a cyanate prepolymer; mixing the cyanate prepolymer with N-4-hydroxyphenyl maleic anhydride alkylamine, naphthol phenolic resin and tetraglycidyl diaminomethylene, stirring at 120 DEG C for 45 minutes, adding silicon carbide short fibers and 1,8-octane dithiol, continuing to stir for 20 minutes, and naturally cooling, so as to obtain a cyanate modified matter; crushing the cyanate modified matter, adding the crushed cyanate modified matter, polyphenylene sulfide and hollow aluminum oxide into an extruder, carrying out extrusion at 155 DEG C, so as to obtain halogen-free flame-retardant particles; and carrying out hot-pressing on the halogen-free flame-retardant particles, so as to obtain the halogen-free flame-retardant electronic material. The prepared halogen-free flame-retardant electronic material has excellent flame retardance and very good dielectric property and thermal performance.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

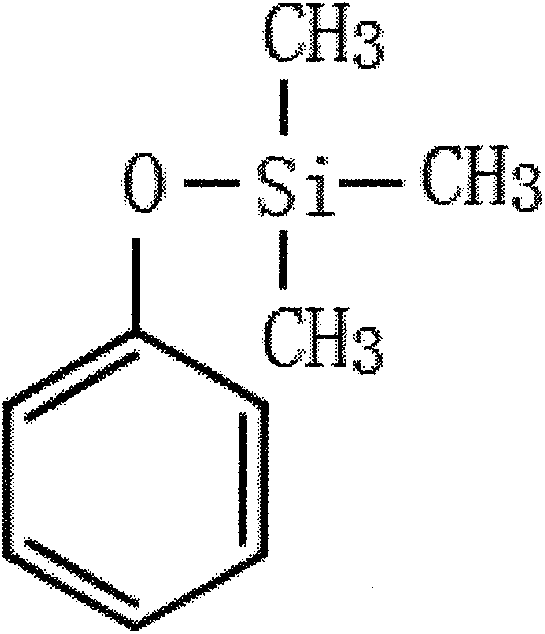

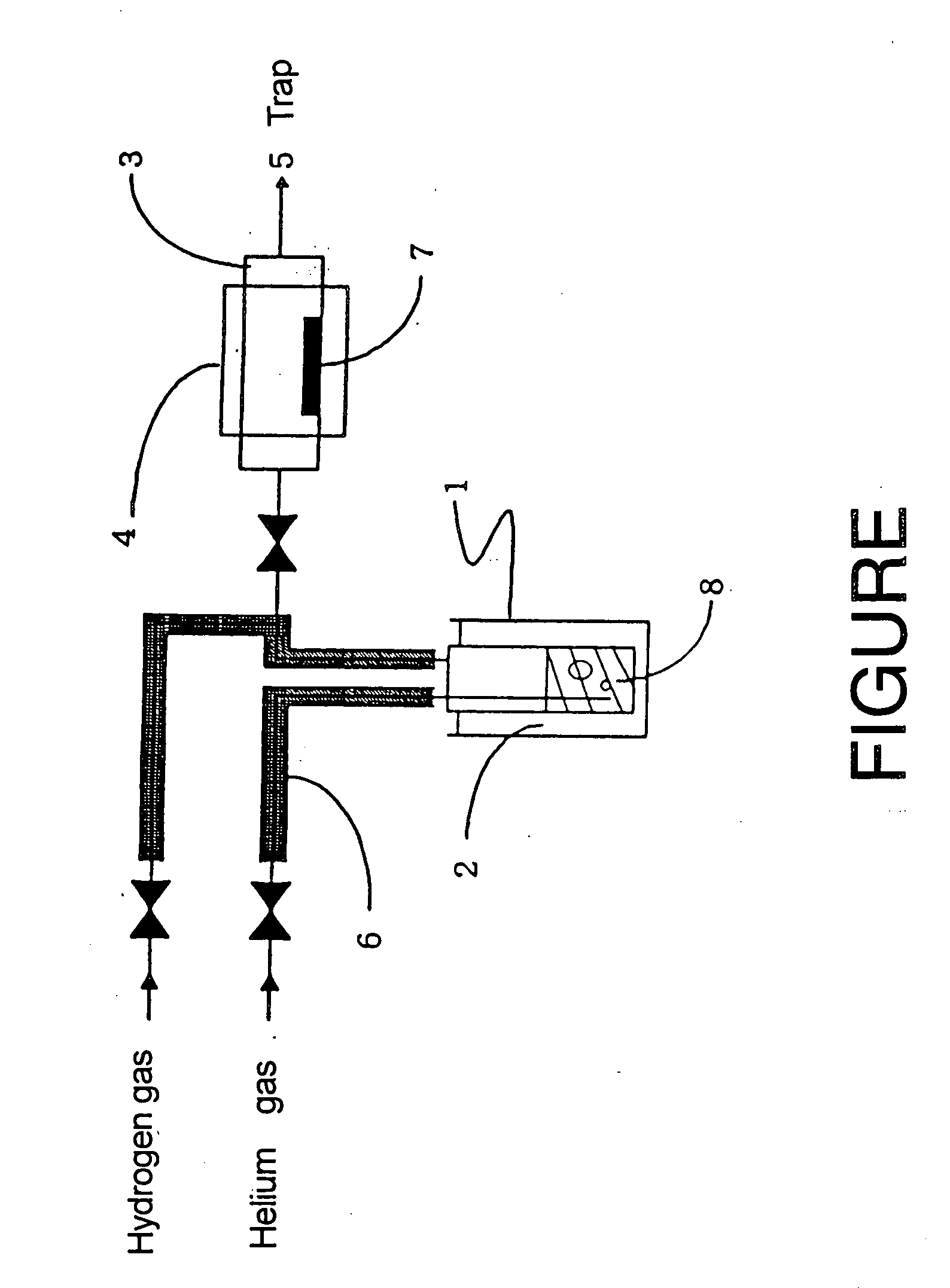

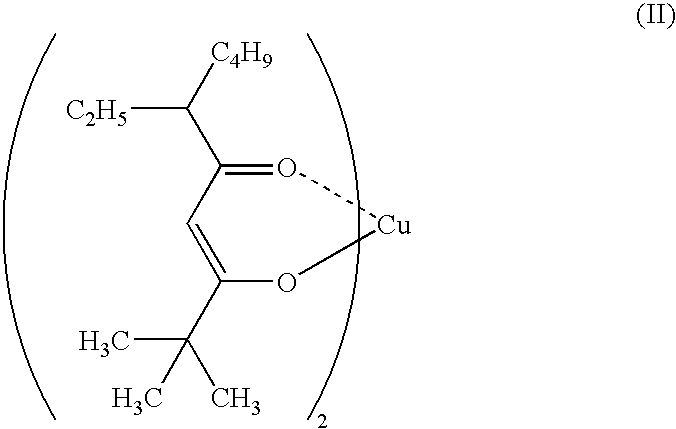

Copper complexes and process for formatiom of copper-containing thin films by using the same

InactiveUS20050080282A1Low melting pointThermally stableFurnaces without endless coreSilicon organic compoundsSilyleneHydrogen

Copper-containing thin films can be industrially advantageously formed by chemical vapor deposition using as the copper source a divalent copper complex bearing β-diketonato ligands having silyl ether linkage. A representative example of the divalent copper complex is represented by the formula (I): wherein Z is hydrogen or alkyl; X is a group represented by the formula (I-I), in which Ra is alkylene, and each of Rb, Rc and Rd is alkyl; and Y is an alkyl group or a group represented by the formula (I-I), in which Ra is alkylene, and each of Rb, Rc and Rd is alkyl.

Owner:UBE IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com