Floating environmental restoration material of Fe2O3-doped TiO2 loaded expanded perlite and preparation method of floating environmental restoration materials

A technology of expanded perlite and repair materials, applied in the field of environmental restoration, can solve problems such as difficult separation, unfavorable recycling, easy aggregation, etc., and achieve the effects of controllable hydrolysis degree, improved visible light adsorption, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

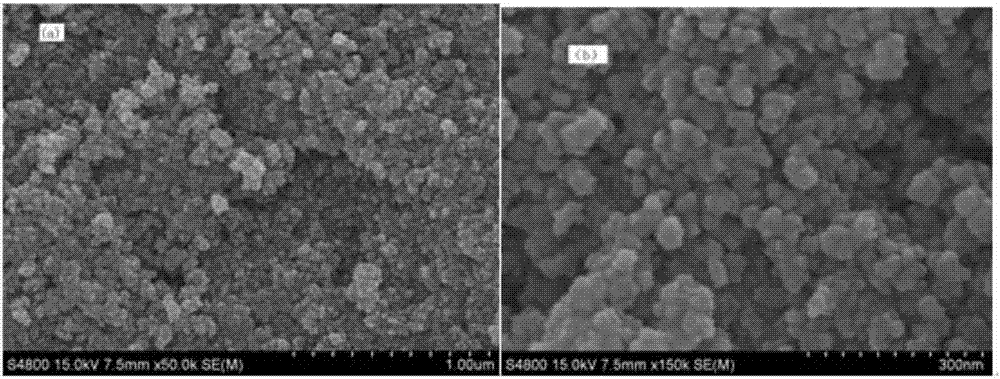

[0028] Take a certain amount of FeCl 3 ·6H 2 O was dissolved in oleic acid to form a mixture A; A was vigorously stirred and lauryl alcohol was added to form a mixture B; B was transferred to a microwave reactor for 30 minutes; the temperature was lowered, centrifuged, washed, ultrasonicated, and centrifuged again to obtain Fe 2 o 3 . Its scanning electron microscope picture is as figure 1 As shown, Fe 2 o 3 It is a spherical particle, and the diameter of the material is between 20 and 30 nm.

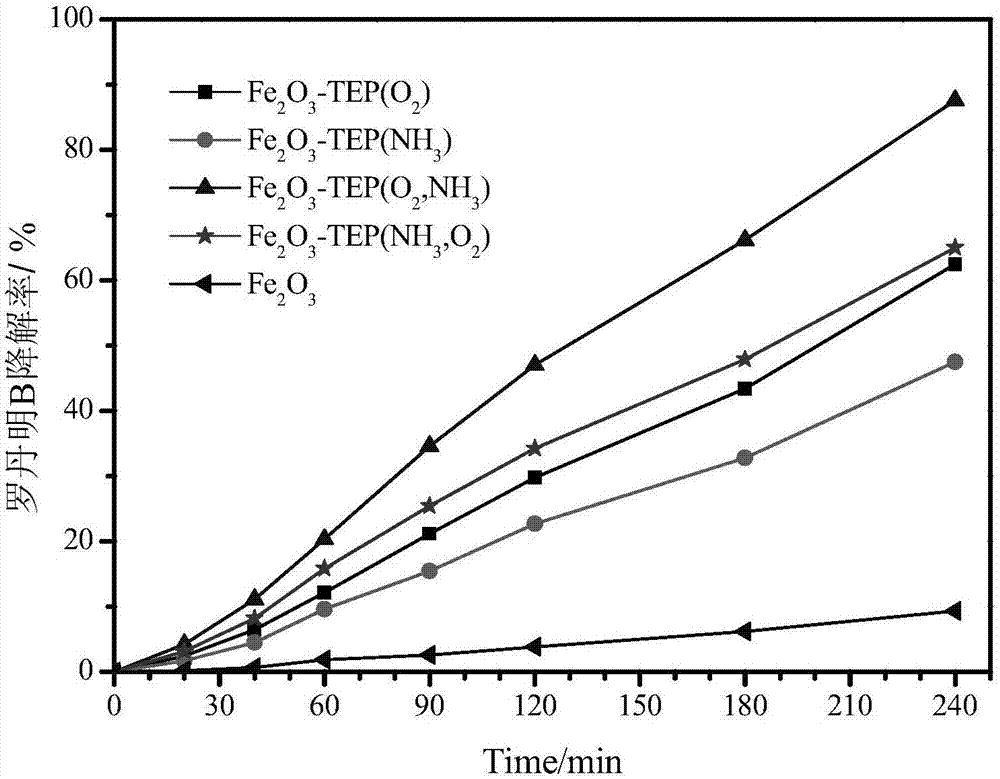

[0029] Take 0.1g of Fe 2 o 3 Add 50mL rhodamine B solution to a 50mL quartz tube, absorb in dark for 1.5 h, and illuminate with 500w xenon lamp for 4h. Rhodamine B solution concentration: 10mg / L. Such as image 3 As shown, the experimental measurement of the degradation rate of Rhodamine B was 9.32%.

example 2

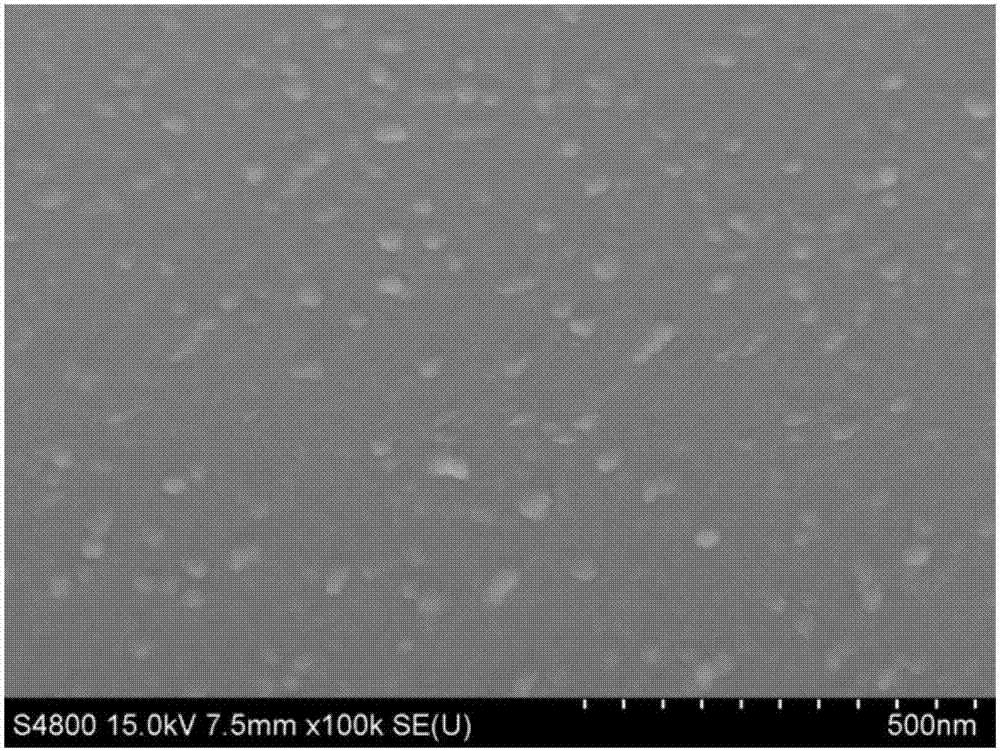

[0031] Take 10ml of absolute ethanol, 5~7ml of tetraisopropyl titanate, pour into a beaker and stir to obtain solution A, 0.01g of Fe 2 o 3 Add a certain amount of water and 5-7ml of acetic acid to obtain solution B, and stir with a magnetic stirrer at room temperature. Put the 10-20 mesh expanded perlite particles that are washed, air-dried, sieved, and etched with NaOH into solution A, and solution B is added dropwise to the mixture of solution A and expanded perlite to obtain Stable and homogeneous transparent sol, aged at room temperature for 24 hours; dried perlite and calcined in a tube furnace at 450°C for 10 minutes in an oxygen atmosphere (300~400ml / min) to obtain Fe 2 o 3 -TEP(O 2 ) environmental remediation materials, whose appearance is as follows figure 2 shown.

[0032] Take 0.1g of Fe 2 o 3 -TEP(O 2 ) and 50mL rhodamine B solution were added to a 50mL quartz tube, darkly adsorbed for 1.5 h, and irradiated with a 500w xenon lamp for 4h. Rhodamine B solu...

example 3

[0034] Take 10ml of absolute ethanol, 5~7ml of tetraisopropyl titanate, pour into a beaker and stir to obtain solution A, 0.01g of Fe 2 o 3 Add a certain amount of water and 5-7ml of acetic acid to obtain solution B, and stir with a magnetic stirrer at room temperature. Put the 10-20 mesh expanded perlite particles that are washed, air-dried, sieved, and etched with NaOH into solution A, and solution B is added dropwise to the mixture of solution A and expanded perlite to obtain Stable and homogeneous transparent sol, aged at room temperature for 24 hours; dried perlite and then calcined in a tube furnace at 450°C for 10 minutes in an ammonia atmosphere (300~400ml / min) to obtain Fe 2 o 3 -TEP(NH 3 ) Environmental restoration materials.

[0035] Take 0.1g of Fe 2 o 3 -TEP(NH 3 ) and 50mL rhodamine B solution were added to a 50mL quartz tube, darkly adsorbed for 1.5h, and irradiated with a 500w xenon lamp for 4h. Rhodamine B solution concentration: 10mg / L. Such as ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com