Patents

Literature

91results about How to "Low cloud point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficiency hydrate inhibitive environment-friendly drilling fluid

ActiveCN104531106AGenerate good effectLow cloud pointDrilling compositionInorganic saltsSodium Bentonite

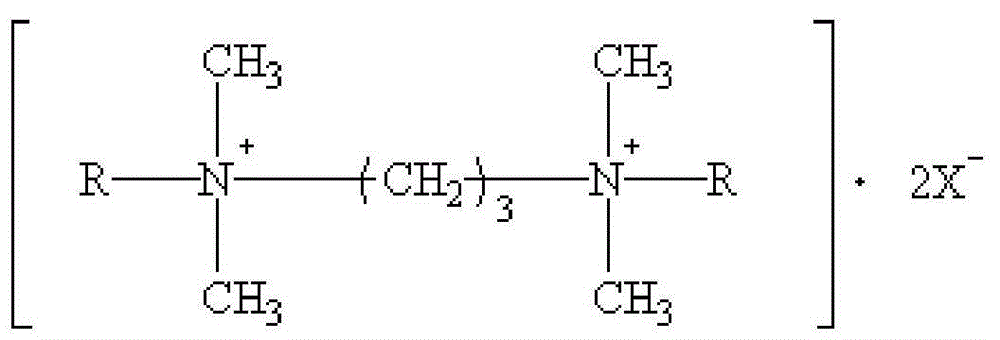

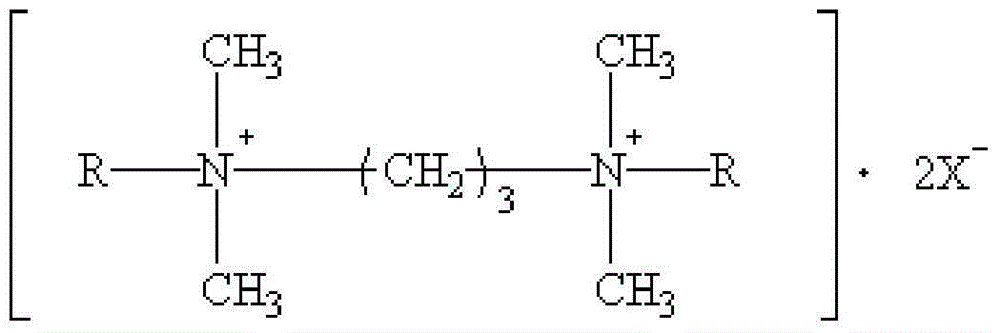

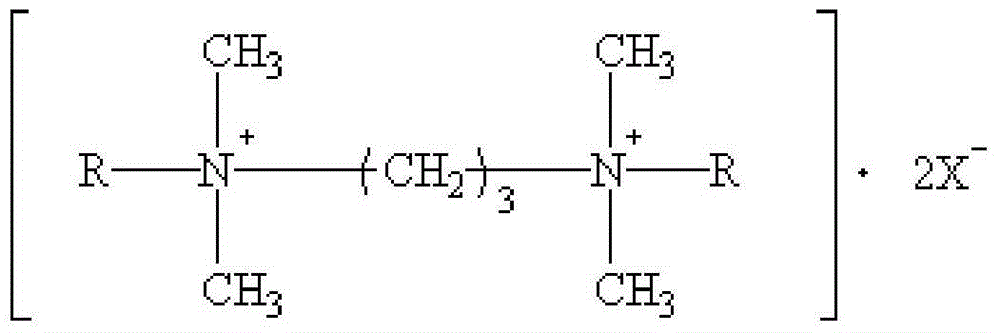

The invention relates to high-efficiency hydrate inhibitive environment-friendly drilling fluid, and particularly relates to the drilling fluid containing water, bentonite, hyamine dimeric surfactant, inorganic salt, sodium carboxymethyl starch, cationic polyacrylamide and solid anti-sloughing lubricating agent GFRH. The high-efficiency hydrate inhibitive environment-friendly drilling fluid can be used for exploiting continental or ocean oil-gas resources and can effectively inhibit the generation of hydrate; moreover, the components of the drilling fluid are small in environment harm, and the drilling fluid has the advantages of high efficiency and environmental protection.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Production of high quality lubricant bright stock

InactiveUS20050051463A1Low cloud pointImprove Oxidation StabilityHydrocarbon oil crackingTreatment with hydrotreatment processesIsomerizationDistillation

A process for producing a lubricant bright stock from a very heavy feed obtained from a petroleum crude is disclosed. The bright stock produced by the present process has a reduced cloud point and better oxidation stability relative to bright stocks prepared by conventional methods. The process comprises the steps of providing a petroleum residuum-derived stream; separating the residuum-derived stream at a distillation cut point in the range of 1150° F. to 1300° F., into a heavy fraction and at least one light fraction; hydrocracking the at least one light fraction under conditions to reduce the concentration of sulfur and nitrogen to suitable levels for hydroisomerization dewaxing; and dewaxing at least a portion of the hydrocracked stream under hydroisomerization conditions to produce a lubricant bright stock.

Owner:CHEVROU USA INC

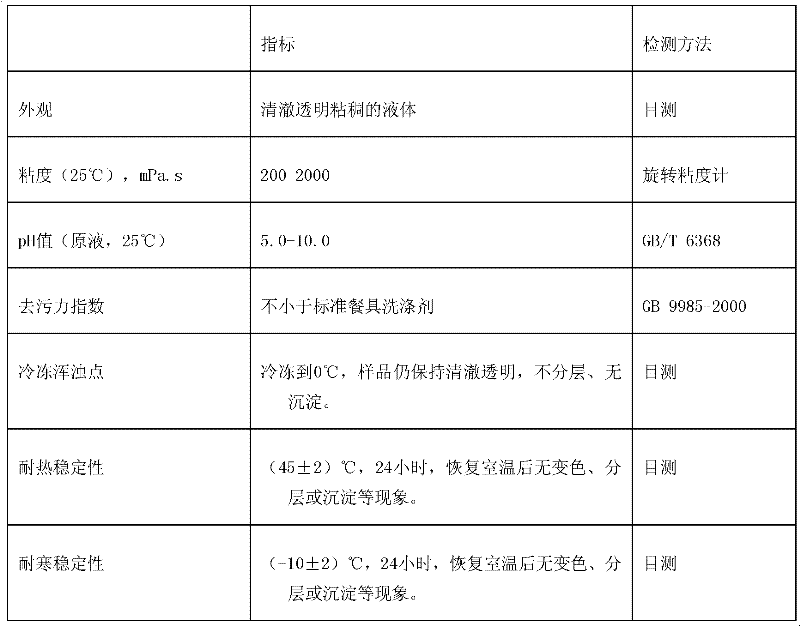

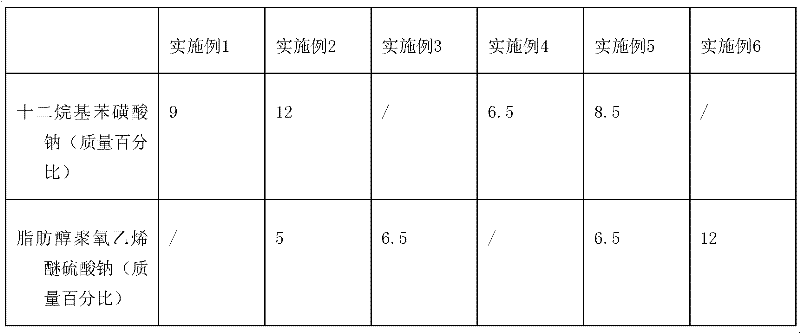

Compound type cleaning solution

InactiveCN102559406AExcellent decontamination synergisticGood thickeningAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsLiquid stateWater soluble

The invention relates to a compound type cleaning solution which comprises a component A, a component B and pure water, wherein the component A is composed of at least one amphoteric surfactant with 8 or more carbon atoms, and accounts for 0.1-15% of the cleaning solution by mass; the component B is at least one anionic surfactant, non-ionic surfactant or cationic surfactant with 8 or more carbon atoms, and accounts for 1-30% of the cleaning solution by mass; and the balance is pure water. In the invention, the amphoteric surfactant and other surfactants are compounded to prepare a dish hand-washing detergent which has excellent functions of cleaning, efficacy enhancing, thickening, foaming, foam stabilizing and the like and is very favorable for improving the performance of the product such as detergency, viscosity, storage stability and the like. Moreover, the amphoteric surfactant is generally in a water-soluble liquid state and can be easily mixed in a formula solution, thus the industrialization of the product provided by the invention can be easily realized.

Owner:WALCH GUANGZHOU COMMODITY

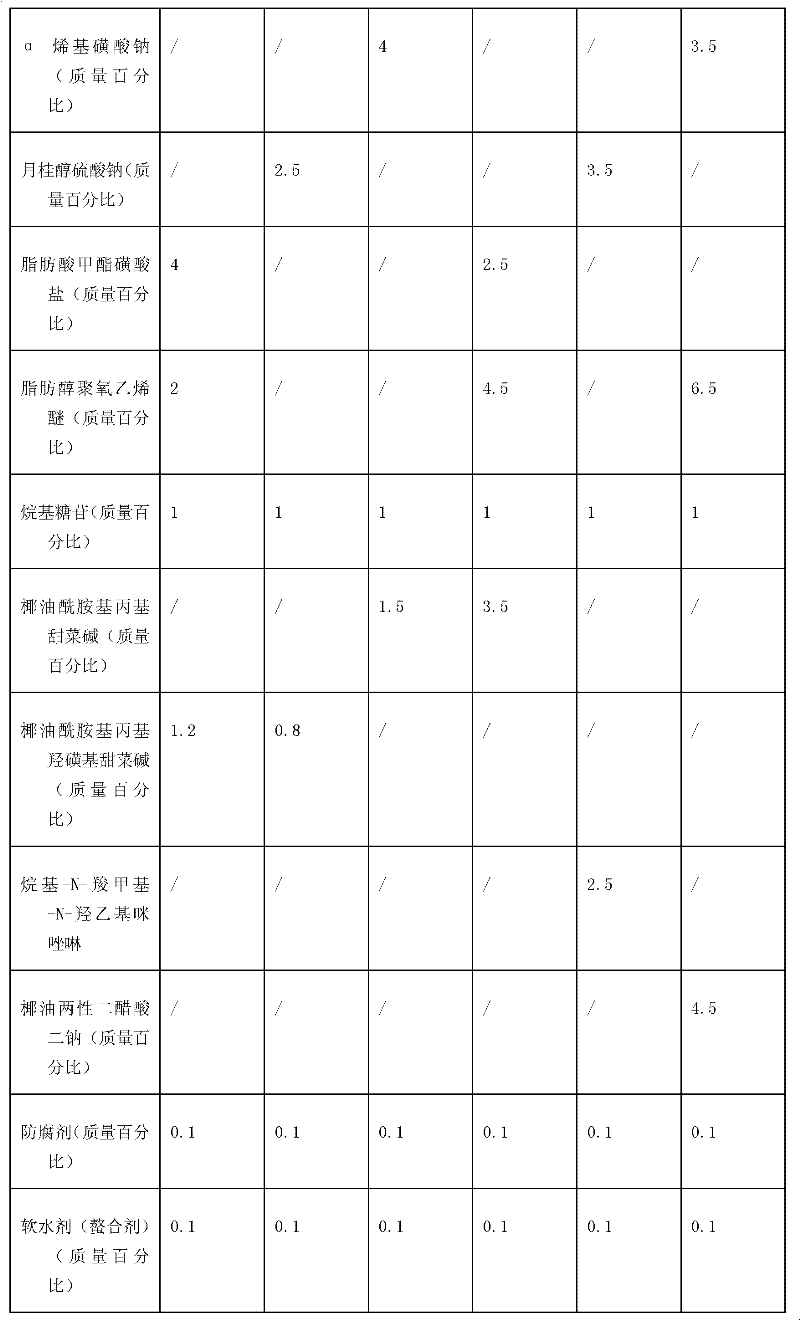

Process for making and composition of superior lubricant or lubricant blendstock

ActiveUS20070142685A1Reduce concentrationQuality improvementHydrocarbons from unsaturated hydrocarbon additionCatalystsAlkaneOligomer

A process for making and a composition of a superior lubricant or lubricant component by the oligomerization of a mixture comprising olefins and isoparaffins to produce an alkylated (“capped”) olefin oligomer having a very high VI and a low cloud point. The process preferably uses an acidic chloroaluminate ionic liquid catalyst system. Preferably the ionic liquid catalyst system comprises a Brönsted acid.

Owner:CHEVROU USA INC

Fatty acid composition, its production and use

InactiveUS20050268530A1Temperature stability is lowImprove the lubrication effectLiquid carbonaceous fuelsAdditivesTall oilMolecular biology

The present invention relates to a fatty acid composition which contains an effective amount of fatty acids providing improved low temperature stability of the composition. The present invention also relates to a process for producing a fatty acid composition wherein the process comprises the steps of selecting a crude tall oil having a fatty acid concentration and type capabld of providing low temperature stability, distilling said crude tall oil to provide a fatty acid composition containing an effective amount of tall oil fatty acids providing low temperature stability. The fatty acid composition of the present invention is used as a fuel additive.

Owner:ARIZONA CHEM CO

Nano-silver antibacterial agent and preparation method thereof

InactiveCN103999873AIncrease viscosityImprove antibacterial propertiesBiocideDisinfectantsEmulsionAntibacterial agent

The invention provides a nano-silver antibacterial agent which includes nano-silver antibacterial stock solutions. Nano-silver is included in the nano-silver antibacterial stock solutions, and the content of the nano-silver is 0.00025 mol / kg to 0.02 mol / kg. The invention further provides a preparation method of the nano-silver antibacterial agent. The nano-silver antibacterial agent can be foam emulsion and sprays in a flow state, can be used as washing-free sprays, and is convenient for people to use when cleaning with water is inconvenient in travel.

Owner:杜一挺

Low-permeability reservoir water-lock releasing agent and preparation method thereof

ActiveCN102899011ALow cloud pointGood water solubilityDrilling compositionFracturing fluidGlycol ethers

The invention discloses an oil field chemical agent used in petroleum gas oil-pumping operation construction, and particularly relates to a low-permeability reservoir water-lock releasing agent used in working fluid and a preparation method thereof. The low-permeability reservoir water-lock releasing agent consists of the following components in percentage by weight: 1 to 15 percent of glycol ether, 15 to 45 percent of didodecyl dicarboxylic sodium, 15 to 30 percent of ethylene glycol silicon ether and 30 to 60 percent of water. The preparation method comprises the following steps of: adding 30 to 60 percent of water into an enamel reaction kettle, starting a stirrer, and heating to raise the temperature to be between 30 and 40 DEG C; adding 1 to 15 percent of glycol ether and 15 to 45 percent of didodecyl dicarboxylic sodium into the reaction kettle, controlling the temperature and stirring for 1 hour; and adding 15 to 30 percent of ethylene glycol silicon ether into the reaction kettle, controlling the temperature to be between 40 and 80 DEG C, and reacting for 1 to 2 hours to obtain the water-lock releasing agent. The water-lock releasing agent is strong in surface activity and low in use level, can well maintain the permeability of a low-permeability reservoir and release water-lock damages, and is used in the working fluid such as fracturing fluid, perforating fluid, well control fluid and the like.

Owner:唐山冀油瑞丰化工有限公司 +1

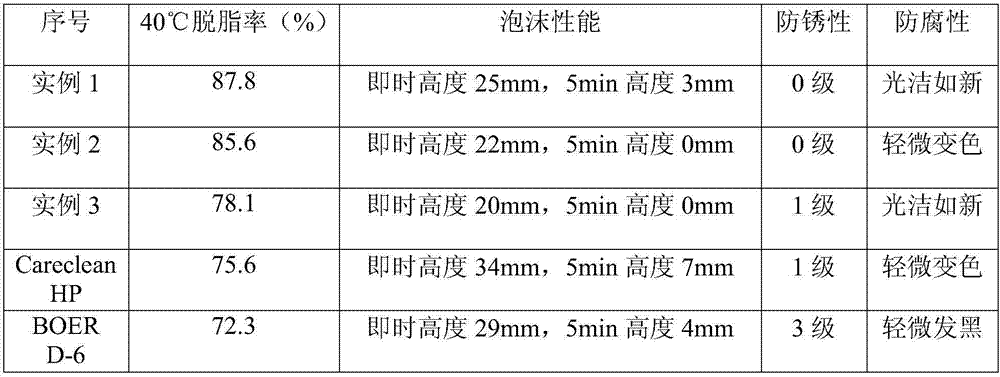

Water-based metal detergent and preparation method thereof

The invention discloses a water-based metal detergent which is composed of the following components in percentage by mass: 1-5% of anionic surfactant, 1-10% of nonionic surfactant I, 1-10% of nonionic surfactant II, 1-10% of nonionic surfactant III, 2-5% of corrosion inhibitor, 1.5-2.2% of assistant, 20-30.3% of organic alkali, 0.3-0.83% of defoaming agent and the balance of water. The higher-turbidity low-foam surfactants are introduced to effectively enhance the cleaning effect of the detergent. The oxidation-type corrosion inhibitor and adsorption-type corrosion inhibitor are compounded to enhance the corrosion inhibition effect. The organic phosphine is used instead of inorganic phosphorus, and thus, the detergent is safe and environment-friendly, thereby implementing zero addition of nitrites, silicates, ozonosphere-consuming substances and the like. The detergent has the advantages of favorable cleaning and corrosion inhibition effects, low foam, easy rinsing, stable performance and simple preparation technique, and has important practical application meanings.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Rapid detection method for nitrites in blood and urine

InactiveCN104280383APlay a separate rolePlay a role in high enrichmentMaterial analysis by observing effect on chemical indicatorCoupling reactionPharmacology

The invention discloses a rapid detection method for nitrites in blood and urine. The method comprises: utilizing a diazotization coupling reaction of nitrites and Griess reagent to form an azo compound, performing cloud point extraction, precipitating the colored azo compound at the bottom of a centrifuge tube, comparing the red color at the tube bottom with standard color gradation, and determining the content of the nitrite according to the color depth. Because the enriching multiple of cloud point extraction is large and blood and urine are subjected to decoloring and protein-removal processing, the interference is substantially eliminated, and the detection limit of nitrites in the system can reach 0.01 mu g / mL. The method has the characteristics of simpleness, rapidness, high sensitivity, on-site detection and the like.

Owner:云南健牛环境监测有限公司

Catalytic dewaxing catalyst and its preparation thereof

ActiveCN101134170AImproved dewaxing selectivityLow pour pointMolecular sieve catalystsPetroleum wax recoveryAqueous solutionMetal

The catalyst for catalyzing dewaxing process contains one carrier containing ZSM-5 molecular sieve and matrix, and one metal component with hydrogenating activity in the effective amount supported on the carrier. The preparation process of the catalyst includes one step of contacting the carrier containing ZSM-5 molecular sieve and matrix with mixed medium comprising water solution of organic amine and air, and one step of introducing metal component with hydrogenating activity to the carrier. The water solution of organic amine has organic amine content of 0.1-5 wt%, the ratio between the water solution and the carrier is 0.1-5 g / g.hr, and the ratio between the air and the carrier is 0.5-5 l / g.hr. The catalyst is especially suitable for catalyzing dewaxing process of lubricating oil fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for reducing the cloud point of a base oil

InactiveCN101223262ALow cloud pointRefining by heating/coolingPetroleum wax recoveryBase oilCloud point

The present invention relates to a method of reducing the cloud point of a base oil feedstock having a kinematic viscosity greater than 10 cSt at 100° C. by separating the molecules responsible for the high cloud point from the base oil by: (a) depositing the said molecules, (b) obtaining a base oil with a reduced cloud point, and (c) fusing the deposited molecules and detaching the molten molecules from said surface and reusing said surface to carry out step (a).

Owner:SHELL INT RES MAATSCHAPPIJ BV

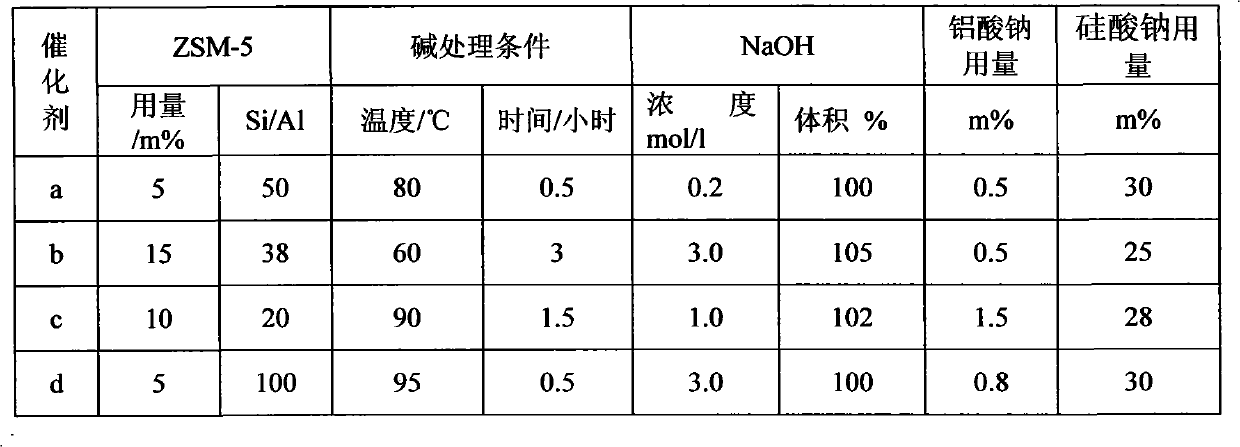

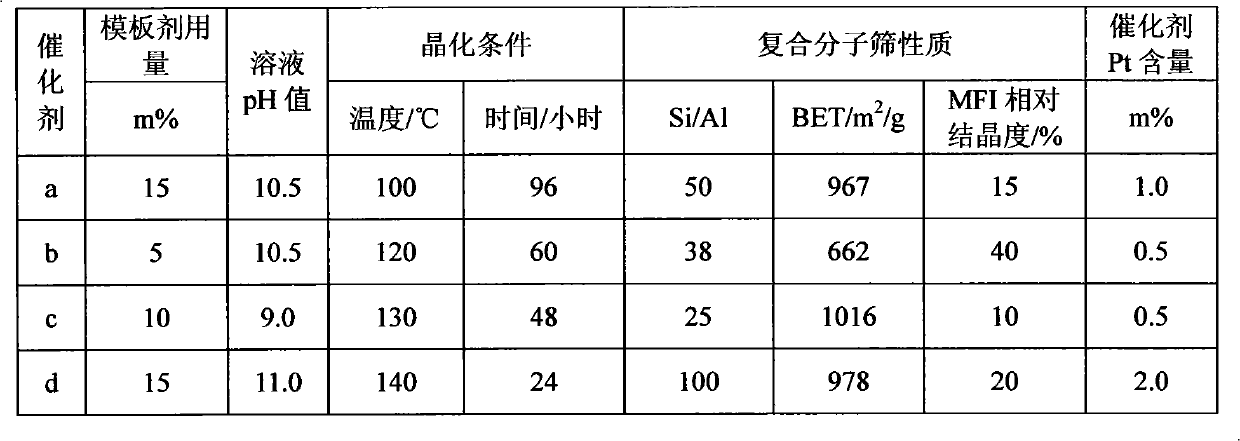

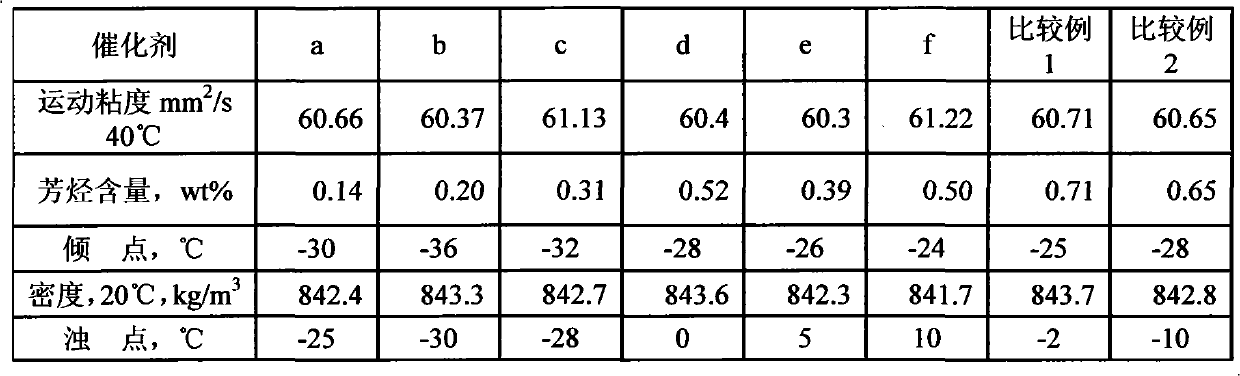

Catalyst for decreasing cloud point of lube base oil and preparation method thereof

The invention relates to a catalyst for decreasing the cloud point of lube base oil and a preparation method thereof. The catalyst comprises the following components in percentage by weight: (a) 0.05-2.0% of Pt or Pd or combination of Pt and Pd or non-precious metal or metal oxides of Pt or Pd, (b) 25.0-74.5% of a composite molecular sieve MFI-MCM of a microporous molecular sieve with an MFI topological structure and a mesporous molecular sieve MCM-41; and (c) 25-74.5% of alumina, wherein the composite molecular sieve MFI-MCM has the specific surface of 600-1100m<2> / g and the Si-Al molar ratio of 20-100, and the MFI-type microporous molecular sieve in the composite molecular sieve MFI-MCM is a molecular sieve ZSM-5 with the relative crystallinity of 10-40%. After lube base oil is processed with the catalyst provided by the invention, the cloud point is decreased by 15-55 DEG C, and a pour pint is decreased by 6-14 DEG C.

Owner:PETROCHINA CO LTD +1

Rapid detection method of nitrite in blood and urine with high sensitivity

InactiveCN104458712ALow cloud pointMild operating conditionsMaterial analysis by observing effect on chemical indicatorActive agentDioxyethylene Ether

The invention discloses a rapid detection method of nitrite in blood and urine with high sensitivity. Azo compound is formed through diazotization coupling reaction by nitrite and a Griess agent. A nonionic surfactant including fatty alcohol polyoxyethylene ether AEO series is used in cloud point extraction. The method has advantages such as mild operation condition, low cloud point temperature, short phase-separation time, high extraction efficiency and the like. The detection limit of nitrite in the system can reach 0.005 micrograms / mL. According to the invention, the method with high sensitivity is simple and fast and can be used on site.

Owner:云南健牛环境监测有限公司

Method for determining content of zinc in mung beans by using cloud point extraction-atomic spectrum method

InactiveCN103499537AHigh sensitivityImprove accuracyPreparing sample for investigationColor/spectral properties measurementsRelative standard deviationAlkylphenol

The invention provides a method for determining the content of zinc in mung beans by using a cloud point extraction-atomic spectrum method. The method is characterized by being comprising the flowing steps: pretreating mung bean samples by cold digestion and heating digestion through long-time soaking, combining 1-(2-pyridine azo)-2 naphthol (PAN) ethanol solution as a complexing agent with zinc to form a stable hydrophobic ionic associate after digestion, adding alkylphenol and ethylene oxide condensation compound to obtain a non-ionic surface active agent, extracting to obtain the non-ionic surface active agent organic phase, and determining the content of the zinc in the non-ionic surface active agent organic phase by using a flame atomic absorption spectrometry after dissolving and diluting of nitric acid and ethanol. The method solves the problems that a traditional method has low sensitivity to microelements and can be easily interfered by co-existing ions by using the flame atomic absorption spectrometry, and has the advantages of accuracy, reliability, high recovery rate, low relative standard deviation, high enrichment coefficient, rapidness and convenience.

Owner:SUZHOU GUOHUAN ENVIRONMENT DETECTION

Method for lowering lubricating oil fraction pour point and turbidity point

ActiveCN101134910AHigh activityHigh selectivityHydrocarbon oils refiningPetroleum wax recoveryWaxTurbidity

The method of lowering the pour point and cloud point of lube fraction oil includes contacting wax-containing lube fraction oil with catalytic dewaxing catalyst. The catalyst is prepared through introducing active hydrogenating component into carrier comprising ZSM-5 molecular sieve and matrix after the carrier is made to contact with mixed medium comprising organic amine aqua and air at 400-550 deg.c for 1-12 hr, where, the organic amine aqua contains organic amine in 0.1-5 wt%, the ratio between the aqua and the carrier is 0.1-5g / g.hr, and the ratio between air and the carrier is 0.5-5 l / g.hr. The method is especially suitable for producing lube fraction oil with low pour point and cloud point.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reducing cloud point of base oil of hydrogenation dewaxing lubricating-oil

ActiveCN1690175ALow cloud pointLow pour pointTreatment with plural serial refining stagesBase oilSolvent

A method for decreasing the cloud point of base oil of hydrotreated and dewaxed lubricating oil, mixing the raw material of base oil of hydrotreated and dewaxed lubricating oil with solvent and deflocculating agent, cooling, filtering in -5 to -30 Deg. C, and the filtrate being the cloud point decreased base oil of hydrotreated and dewaxed lubricating oil, thereinto, the content of deflocculating agent being the 0.002 to 5 percent of the raw material oil. With the method it can decrease obviously the cloud point and pour point of base oil, and increase the income ratio of base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

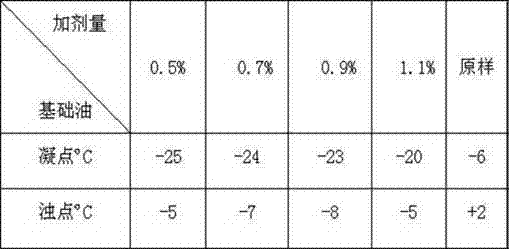

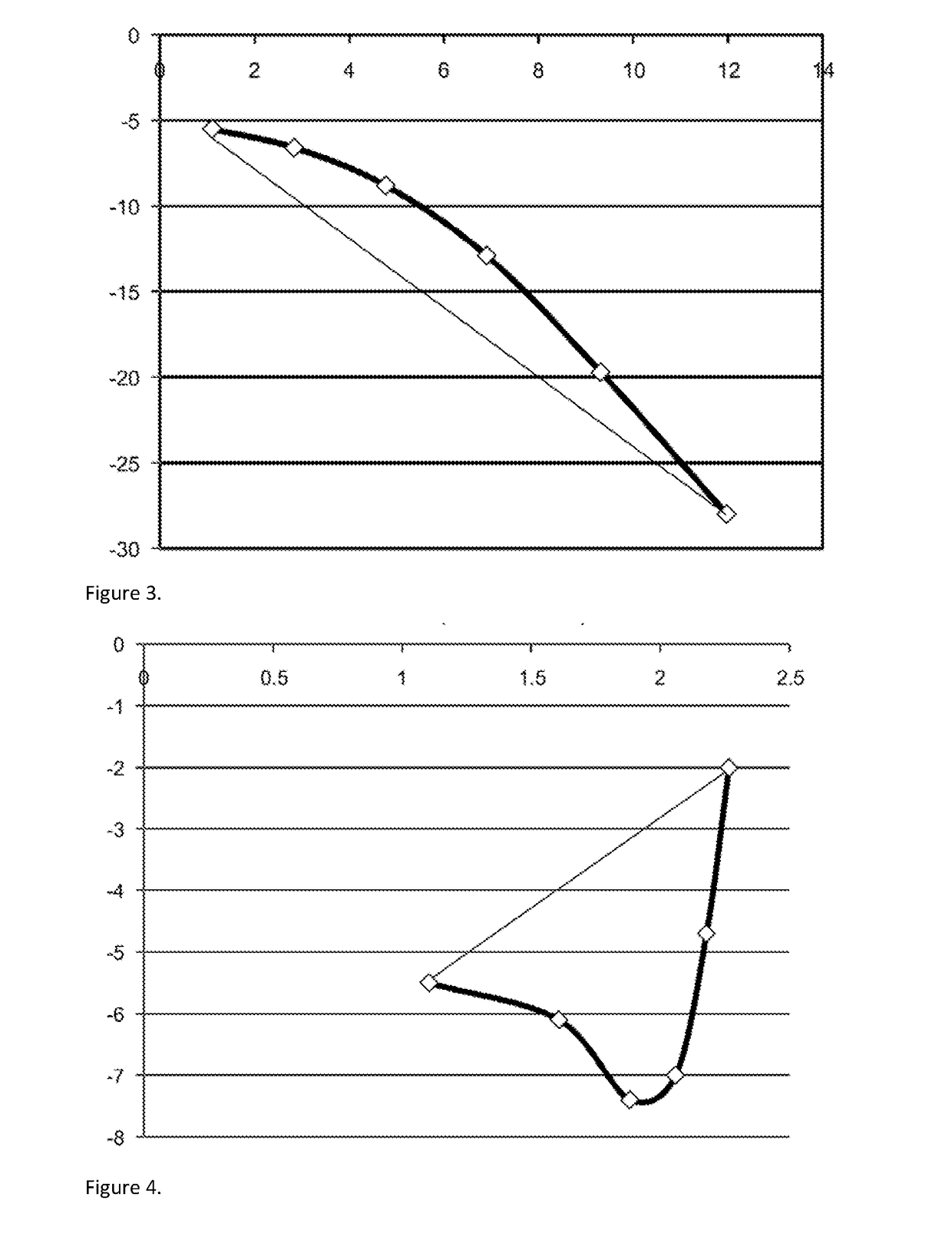

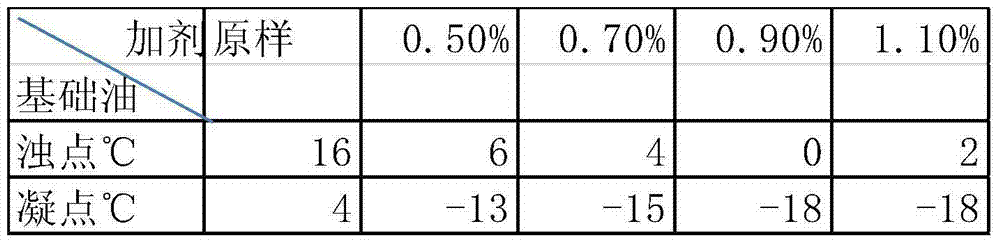

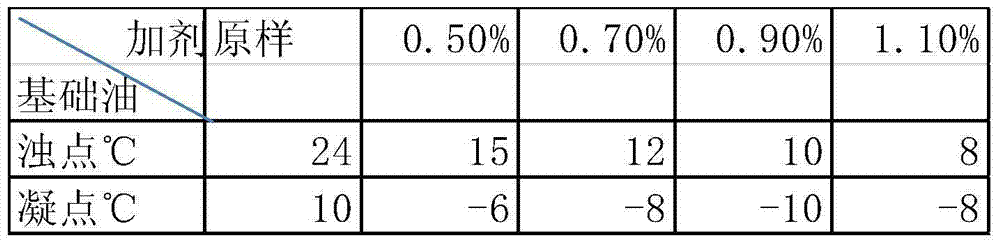

Preparation method of condensation point reducer with dual functions of reducing condensation point and turbidity point

InactiveCN103087235ALowering the freezing pointLow cloud pointLubricant compositionMethacrylateHigh carbon

The invention provides a preparation method of a condensation point reducer with dual functions of reducing condensation point and turbidity point, which comprises the following steps: (1) mixing C8-C18 straight-chain fatty alcohols and methacrylic acid in a mol ratio of (1.02-1.2):1, adding diluent oil as a solvent, adding a polymerization inhibitor hydroquinone and a catalyst p-methylbenzenesulfonic acid, and reacting at 100-140 DEG C for 2-8 hours under the catalytic action of acid to generate a high-carbon alcohol methacrylate crude product; (2) neutralizing the high-carbon alcohol methacrylate crude product obtained in the step (1) with alkali liquor until the pH value is 7, separating the organic layer, and dehydrating at 80-150 DEG C for 1-8 hours to obtain the high-carbon alcohol methacrylate; and (3) adding acid anhydride or ester and an initiator benzoperoxide into the high-carbon alcohol methacrylate obtained in the step (2), and reacting at 70-130 DEG C for 5-10 hours to obtain the polymer. The condensation point reducer provided by the invention has dual functions of reducing both condensation point and turbidity point of the base oil, thereby eliminating the hidden danger of flammability and explosiveness.

Owner:烟台市牟平区留德润滑油销售有限公司

Method for recovering polyether from waste metal processing liquid and application of polyether in concrete slump retaining agent

InactiveCN102174212ALow costGood collapsibilityPlastic recyclingMultistage water/sewage treatmentWater basedCloud point

The invention discloses a method for recovering polyether from waste metal processing liquid and application of the polyether in concrete slump retaining agent. The method for recovering the polyether from the waste metal processing liquid comprises the following steps: adding inorganic base to water-based waste metal processing liquid containing the polyether to adjust the pH value of the waste metal processing liquid to 10-12, standing the waste metal processing liquid for reaction, filtering, adding activated carbon and an inorganic acid to adjust the pH value of the waste metal processing liquid, heating to the temperature above the cloud point temperature, layering solution, standing at constant temperature, taking polyether phase on the upper layer, adding anti-oxidant to the polyether phase, and fully drying to remove water until the water content is 0.05 percent by weight or less to obtain the reaction product which is polyether. The following raw materials are needed when the polyether is applied to the concrete slump retaining agent: a catalyst, maleic anhydride, water, sulfonated styrene and an initiator in addition to the polyether. The polyether and the maleic anhydride are directly subjected to the esterification reaction under the heating condition without adding organic solvent and water and adopting a condensing and refluxing device, thus the equipment requirement and the production cost are reduced, and the production safety is improved. The prepared concrete slump retaining agent has good slump retaining performance, high water reducing rate and good compatibility with cement.

Owner:HOHAI UNIV +1

Neutral non-phosphorus degreasing agent and preparation method thereof

The invention discloses a neutral non-phosphorus degreasing agent and a preparation method thereof, and relates to the technical field of metal material surface cleaning agents. The neutral non-phosphorus degreasing agent consists of the following raw materials: 10-25 parts of a surfactant, 0.1-1 part of a de-foaming agent, 1-5 parts of a chelating agent, 5-15 parts of an inorganic detergent assistant, 0-3 parts of an additive and 100 parts of a mixed solvent. The raw materials are non-toxic, are good in water solubility, are small in harm to environment and an operator, and are free of damage to equipment; and the preparation method is simple, and the neutral non-phosphorus degreasing agent is strong in detergency power, is low in turbidity point and has the degreasing effect being 99%.

Owner:陈逸涵

Biodiesel with low temperature liquidity and preparation method of biodiesel

InactiveCN103834446AGood fluidity at low temperatureGood pour point depressing effectBiofuelsLiquid carbonaceous fuelsProcess engineeringOxidation stability

The invention discloses a biodiesel with low temperature liquidity and a preparation method of the biodiesel. The biodiesel with low temperature liquidity comprises 2.5-30 percent by volume of direct coal liquefaction hydro-upgraded modified full-fraction oil and 70-97.5 percent by volume of illegal cooling oil biodiesel. The preparation method of the biodiesel comprises the step: after mixing the illegal cooking oil biodiesel and the direct coal liquefaction hydro-upgraded modified full-fraction oil, and standing for 8-12 hours to obtain the biodiesel with low-temperature liquidity. According to the biodiesel with low temperature liquidity, the pour point, the cloud point, the flash point, the kinematic viscosity, the oxidation stability, the heat value, the density and the acid value of mixed oil are detected according to the GB_T20828-2007, and accord with relevant requirements of EN14214 and ASTMD6751 for the technical performance of the biodiesel through detection. Compared with the illegal cooking oil biodiesel, the biodiesel has the advantages that the cloud point is reduced by 1-8 DEG C, the pour point is reduced by 2-10 DEG C, namely, the low temperature liquidity is remarkably improved, and the preparation method is simple and effective.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

Phase formation agent for liquid-liquid-liquid tri-phase system

InactiveCN1806881AEasy to separateRealize recyclingLiquid solutions solvent extractionInorganic saltsPhase formation

The invention relates the phase former of liquid-liquid-liquid triple systems, comprising 7-20wt% copolymer of epoxyethane and epoxypropane, 7-20wt% inorganic salt and 10-40wt% organic solvent. The copolymer is block copolymer the weight average molecular weight of which is 1000-10000, comprising 40-85% epoxyethane block, or random copolymer the weight average molecular weight of which is 800-10000, comprising 50-85% epoxyethane. The invention can be used in separating filter liquor containing the biofermentation system, industrial waste water, and the complicated system containing the miscible liquids of organic synthesis product. The invention reaches the purification of phase-forming polyaromatics, reduces the cost, shortens the nature difference of organic phase and intermediate phase, and simplifies the technology.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

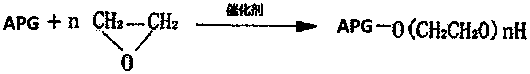

Low-temperature degreaser for chemical fiber fabrics and preparation method of low-temperature degreaser

InactiveCN110527601AReduce manufacturing costEasy to prepareNon-ionic surface-active compoundsDetergent solventsDispersityFiber

The invention discloses a low-temperature degreaser for chemical fiber fabrics and a preparation method of the low-temperature degreaser. The low-temperature degreaser is prepared from the componentsin parts by weight: 30-40 parts of fatty alcohol-polyoxyethylene ether containing alkyl polyglucoside (APG), 20-30 parts of fatty alcohol-polyoxyethylene ether phosphate containing APG, 20-30 parts offatty alcohol-polyoxyethylene ether sulphonate containing APG, 5-15 parts of a greasy dirt dispersant, 5-15 parts of a builder, 0.2-1.0 part of a pH value regulator and 30-50 parts of soft water, wherein the fatty alcohol-polyoxyethylene ether containing the APG, the fatty alcohol-polyoxyethylene ether phosphate containing the APG and the fatty alcohol-polyoxyethylene ether sulphonate containingthe APG are three main components of the low-temperature degreaser, and the proportion of the three components can be changed. Alcohol ether in a structure of the fatty alcohol-polyoxyethylene ether containing the APG has good decontaminability, degreasing performance and dispersity, the APG in the structure has the outstanding characteristic of good affinity to greasy dirt, thus the greasy dirt is better adsorbed, and the low-temperature degreaser is evenly dispersed in processing liquid, and is very suitable for a low-temperature degreasing process of the chemical fiber fabrics.

Owner:今冬科技(佛山)有限公司

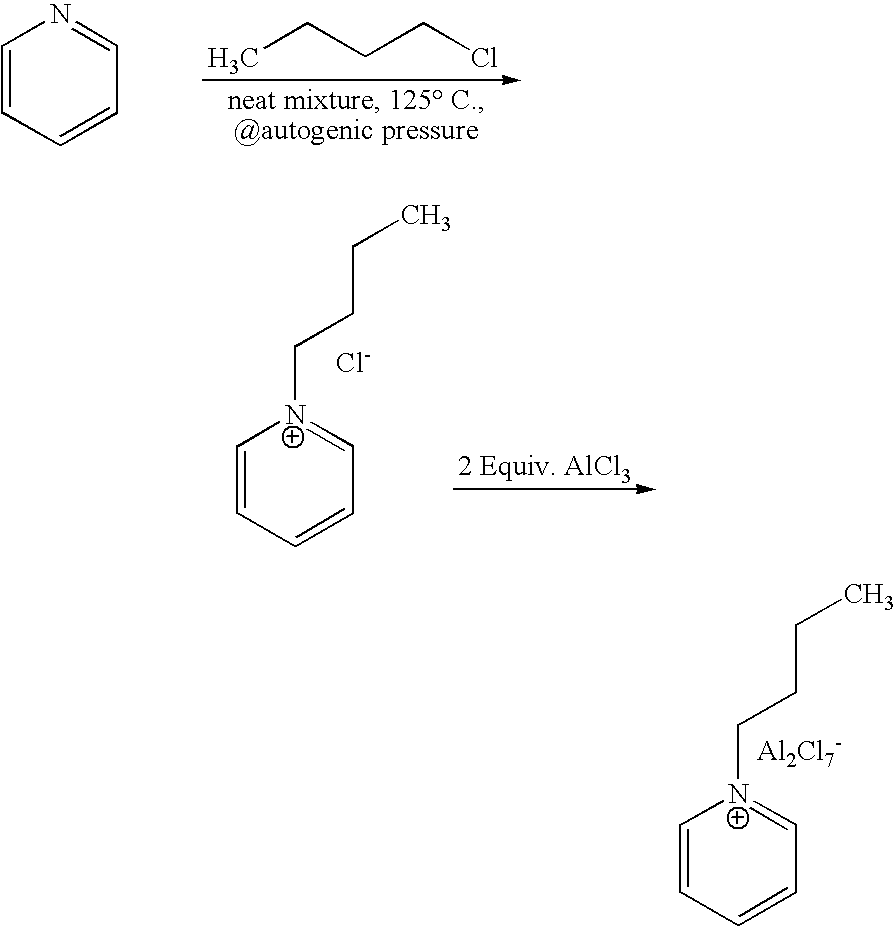

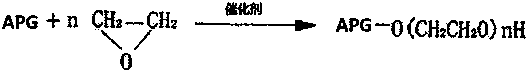

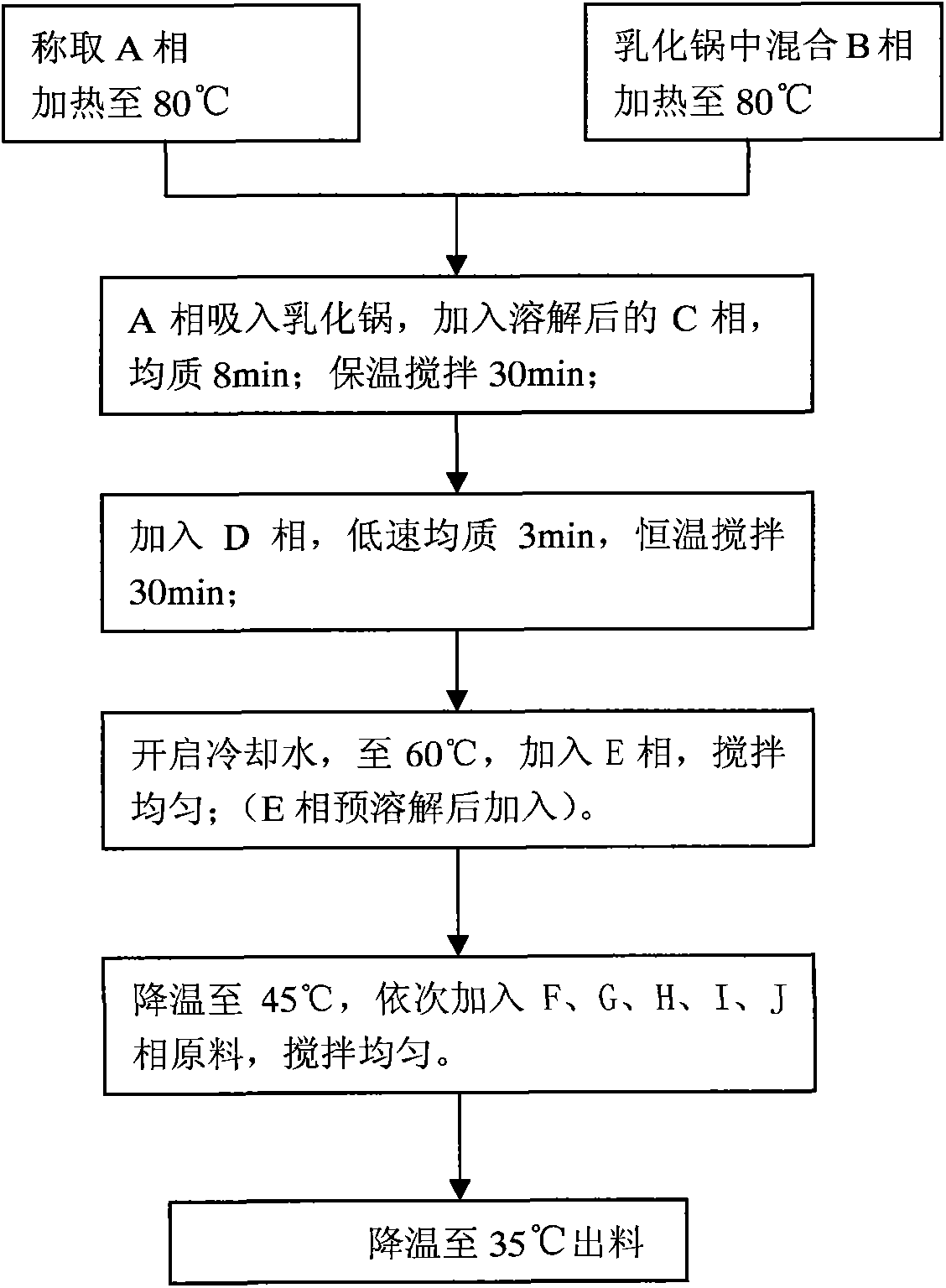

Post-foaming cleanser and preparation method thereof

ActiveCN109464300APromote degradationLow cloud pointCosmetic preparationsToilet preparationsChemistryTriethanolamine

The invention belongs to the technical field of cosmetics, and particularly relates to a post-foaming cleanser and a preparation method thereof. The post-foaming cleanser is prepared from the following components in percentage by mass: 10%-20% of a surfactant, 15%-20% of vaseline, 5%-10% of propylene glycol, 1%-2.5% of triethanolamine, 6%-14% of an acrylic copolymer, 3%-6% of a post-foaming agent,0.1%-0.5% of hydroxyethyl cellulose, 0.3%-0.7% of p-hydroxyacetophenone, 0.1%-0.5% of essence, 0.1%-1% of nitrogen and 35%-45% of water. The post-foaming cleanser can form foam without rubbing, has good foam stability, is convenient to use, has little irritation to skin and has good cleaning capability and good moisturizing performance.

Owner:中山市天图精细化工有限公司

Fuel compositions with enhanced cold properties and methods of making the same

ActiveUS20180216021A1Improve cold resistanceLess-expensive to productionBiofuelsLiquid carbonaceous fuelsDiesel fuelRenewable fuels

Methods of making a diesel fuel blend having enhanced cold properties; methods of lowering the cloud point of a mineral middle distillate fuel; and diesel fuel blends having a blend of a renewable fuel and a mineral middle distillate fuel.

Owner:NESTE OIL OY

A kind of low-permeability reservoir dewatering and locking agent and preparation method thereof

ActiveCN102899011BLow cloud pointGood water solubilityDrilling compositionFracturing fluidPhysical chemistry

The invention discloses an oil field chemical agent used in petroleum gas oil-pumping operation construction, and particularly relates to a low-permeability reservoir water-lock releasing agent used in working fluid and a preparation method thereof. The low-permeability reservoir water-lock releasing agent consists of the following components in percentage by weight: 1 to 15 percent of glycol ether, 15 to 45 percent of didodecyl dicarboxylic sodium, 15 to 30 percent of ethylene glycol silicon ether and 30 to 60 percent of water. The preparation method comprises the following steps of: adding 30 to 60 percent of water into an enamel reaction kettle, starting a stirrer, and heating to raise the temperature to be between 30 and 40 DEG C; adding 1 to 15 percent of glycol ether and 15 to 45 percent of didodecyl dicarboxylic sodium into the reaction kettle, controlling the temperature and stirring for 1 hour; and adding 15 to 30 percent of ethylene glycol silicon ether into the reaction kettle, controlling the temperature to be between 40 and 80 DEG C, and reacting for 1 to 2 hours to obtain the water-lock releasing agent. The water-lock releasing agent is strong in surface activity and low in use level, can well maintain the permeability of a low-permeability reservoir and release water-lock damages, and is used in the working fluid such as fracturing fluid, perforating fluid, well control fluid and the like.

Owner:唐山冀油瑞丰化工有限公司 +1

A kind of water-based metal cleaning agent and preparation method thereof

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Production of high quality lubricant bright stock

InactiveUS20090120838A1Low cloud pointImprove Oxidation StabilityTreatment with hydrotreatment processesBase-materialsDistillationSulfur

A process for producing a lubricant bright stock from a very heavy feed obtained from a petroleum crude is disclosed. The bright stock produced by the present process has a reduced cloud point and better oxidation stability relative to bright stocks prepared by conventional methods. The process comprises the steps of providing a petroleum residuum-derived stream; separating the residuum-derived stream at a distillation cut point in the range of 1150° F. to 1300° F., into a heavy fraction and at least one light fraction; hydrocracking the at least one light fraction under conditions to reduce the concentration of sulfur and nitrogen to suitable levels for hydroisomerization dewaxing; and dewaxing at least a portion of the hydrocracked stream under hydroisomerization conditions to produce a lubricant bright stock.

Owner:CHEVROU USA INC

Production method of sea-buckthorn transparency liquid facial soap

InactiveCN103966037ALow cloud pointImprove liquiditySurface-active non-soap compounds and soap mixture detergentsSkin careTurbidityGlycerol

The invention relates to a production method of a sea-buckthorn transparency liquid facial soap. The production method comprises the following steps: weighting dodecylic acid and myristic acid to be mixed and heated, adding glycerinum and acrylics, stirring, heating, and adding potassium hydroxide; adding cocamidopropyl, SLES (sodium laureth sulfate), cocamidopropyl betaine, lauramidopropyl hydroxy sulfobetaine, and homogenizing uniformly; cooling and lowering temperature, and sequentially adding EDTA(ethylene diamine tetraacetic acid) and potassium chloride; cooling down to a temperature of 45 DEG C, sequentially adding five groups of raw materials for mixing, then stirring uniformly. The production method provided by the invention has the benefits as follows: high content fatty acid and potassium hydroxide are adopted for neutralization, and through adding raw materials such as glycerol, a surfactant and the like, the turbidity point of the soap is lowered, so that the transparency liquid facial soap with excellent transparency and good fluidity at a temperature of 10-50 DEG C can be obtained; the stability is good, and a dry and rough feel cannot be caused after use.

Owner:上海梦之队国际贸易有限公司

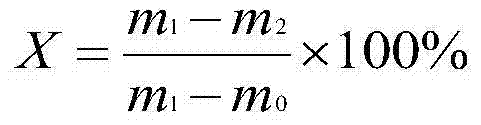

Preparation method of turbidity reducing agent

The invention relates to a preparation method of a turbidity reducing agent. The method comprises the steps: respectively mixing straight chain fatty alcohol of C12-14 and C14-18 with methacrylic acid; adding a polymerization inhibitor hydroquinol and a catalyst p-methylbenzene sulfonic acid and performing reaction under a nitrogen protection to produce a crude product of methacrylic acid higher alcohols ester; adding the crude product of methacrylic acid higher alcohols ester into an alkali liquid for neutralizing and stirring; separating an organic layer to obtain the methacrylic acid higher alcohols ester; mixing the two straight chain higher alcohols esters of C12-14 and C14-18; under the nitrogen protection, adding anhydride, ester or styrene and an initiating agent azo isobibutyronitrile for reacting to obtain a polymer, namely a target product. According to a solvent-free synthesizing method, solvent oil is eliminated, so that the cost is reduced, and the pollution is avoided.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

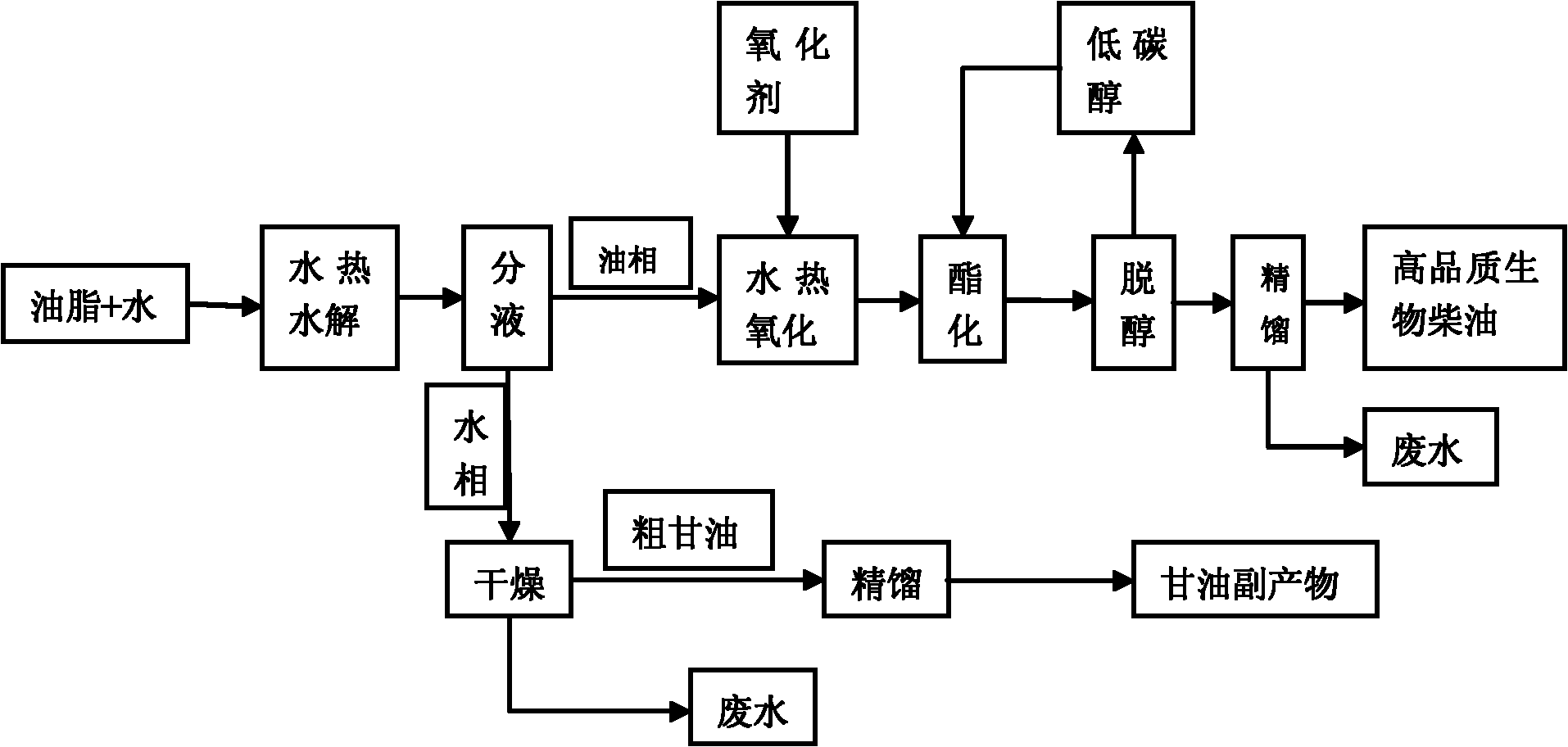

Method for preparing biodiesel

InactiveCN102061223AImprove low temperature fluidityImprove antioxidant capacityFatty acid esterificationFatty acids production/refiningBiodieselRenewable energy technology

The invention relates to the technical field of environmental engineering, oil chemistry and renewable energy sources, in particular to a method for preparing biodiesel. The method disclosed in the invention comprises the following steps of: conveying fatty acid and an oxidizing agent into a tubular hydrothermal reactor for carrying out selective oxidization treatment on the fatty acid to ensure that unsaturated bonds in the unsaturated fatty acid break to generate micromolecular saturated fatty acid; controlling the reaction conditions that the addition quantity of the oxidizing agent is 1-10 percent of oxygen quantity required for completing oxidizing raw material oil fat into CO2 and H2O, the temperature is 200-350 DEG C, the pressure is 5-30MPa, and the reaction time is 0.5-10min; directly mixing low carbon alcohol with micromolecular saturated fatty acid obtained from the step 1 for esterification to generate high-quality biodiesel with good low-temperature fluidity and strong anti-oxidization resistance; and controlling the reaction conditions that the temperature is 300-400 DEG C, the pressure is 20-35 MPa, the reaction time is 12-30min and the addition quantity of the lower carbon alcohol is 6-40 times that of the fatty acid. According to the method provided by the invention, the low-temperature fluidity and the anti-oxidization property of the biodiesel can be improved.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com