Low-temperature degreaser for chemical fiber fabrics and preparation method of low-temperature degreaser

A technology for chemical fiber fabrics and degreasers, which is applied in chemical instruments and methods, solvents for cleaning compositions, nonionic surface active compounds, etc. The effect of low production cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]The object of the invention of the present invention is achieved like this: a kind of low-temperature degreasing agent used in the dyeing and finishing of chemical fiber fabrics, comprises the fatty alcohol polyoxyethylene ether that contains alkyl glucoside in parts by weight 40 parts, the alkane containing glycoside-containing fatty alcohol polyoxyethylene ether phosphate, 30 parts of fatty alcohol polyoxyethylene ether sulfonate containing alkyl glycoside, 5 parts of oil stain dispersant, 15 parts of builder, 1.0 part of pH adjustment agent and 40 parts soft water.

[0048] The preparation method of medium and low temperature degreaser of the present invention is characterized in that comprising the following steps:

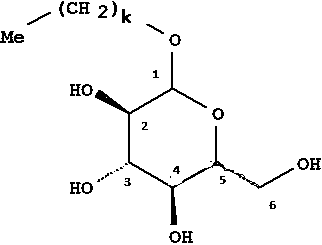

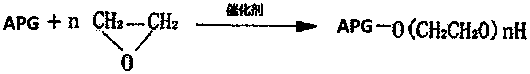

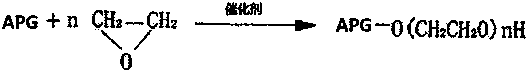

[0049] Step (1) Preparation of fatty alcohol polyoxyethylene ether containing alkyl glycoside

[0050] Step (2) Preparation of fatty alcohol polyoxyethylene ether phosphate containing alkyl glycoside

[0051] Step (3) Preparation of fatty alcohol polyo...

Embodiment 2

[0071] The object of the invention of the present invention is achieved like this: a kind of low-temperature degreasing agent used in the dyeing and finishing of chemical fiber fabrics, comprises the fatty alcohol polyoxyethylene ether containing alkyl glycoside of 30 parts by weight, the fatty alcohol polyoxyethylene ether containing alkyl glycoside of 30 parts, glycoside-containing fatty alcohol polyoxyethylene ether phosphate, 20 parts of fatty alcohol polyoxyethylene ether sulfonate containing alkyl glycoside, 15 parts of oil stain dispersant, 15 parts of builder, 0.2-1.0 parts of pH value conditioner and 40 parts soft water.

[0072] The preparation method of medium and low temperature degreaser of the present invention is characterized in that comprising the following steps:

[0073] Step (1) Preparation of fatty alcohol polyoxyethylene ether containing alkyl glycoside

[0074] Step (2) Preparation of fatty alcohol polyoxyethylene ether phosphate containing alkyl glycos...

Embodiment 3

[0095] The object of the invention of the present invention is achieved like this: a kind of low-temperature degreasing agent used in the dyeing and finishing of chemical fiber fabrics, comprises the fatty alcohol polyoxyethylene ether that contains alkyl glucoside 35 parts by weight, 25 parts by weight glycoside-containing fatty alcohol polyoxyethylene ether phosphate, 25 parts of fatty alcohol polyoxyethylene ether sulfonate containing alkyl glycoside, 10 parts of oil stain dispersant, 10 parts of builder, 0.2-1.0 parts of pH value conditioner and 40 parts soft water.

[0096] The preparation method of medium and low temperature degreaser of the present invention is characterized in that comprising the following steps:

[0097] Step (1) Preparation of fatty alcohol polyoxyethylene ether containing alkyl glycoside

[0098] Step (2) Preparation of fatty alcohol polyoxyethylene ether phosphate containing alkyl glycoside

[0099] Step (3) Preparation of fatty alcohol polyoxyet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com