Water-based metal detergent and preparation method thereof

A metal cleaning agent, water-based technology, applied in the field of cleaning agents, can solve the problems of incomparable cleaning effects of difficult-to-solvent cleaning agents, oxidation rust or corrosion, difficulty in waste liquid treatment, etc., to improve the corrosion inhibition effect and reduce raw materials. Cost, effect of excellent emulsifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A water-based metal cleaning agent, the mass percent of each component is: sodium dodecylbenzene sulfonate 1.8%, SIMULSOL OX1309L 8.5%, RHODOCLEAN MSC 1.5%, Rhodafac H66 2.5%, corrosion inhibitor (molybdenum Sodium Acetate 4.5%, PE1198LA 0.25%), Disodium EDTA 2.0%, Triethanolamine 28.75%, C740 water-based defoamer 0.82%, distilled water surplus, the specific preparation steps are as follows:

[0034] Weigh each raw material according to the above ratio, add anionic surfactant, nonionic surfactant Ⅰ (SIMULSOL OX1309L), nonionic surfactant Ⅱ (RHODOCLEAN MSC) and nonionic surfactant Ⅲ (Rhodafac H66) in sequence, and then Add corrosion inhibitor, ethylenediaminetetraacetic acid disodium salt (auxiliary), triethanolamine (organic base) and distilled water, and finally add defoamer (based on a total of 100g), and stir at room temperature for 30 minutes until the solution is clear and transparent. The water-based metal cleaning agent.

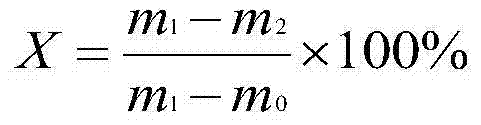

[0035]The water-based metal cleaning ag...

Embodiment 2

[0037] A water-based metal cleaning agent, the mass percentage of each component is: alkyl alkoxy ether fatty acid potassium 1.5%, SIMULSOL OX1309L 2.5%, fatty alcohol EO-PO block copolymer 5.5%, Rhodafac H662.0 %, sodium molybdate 4.5%, PE1198 LA 0.25%, disodium edetate 1.75%, triethanolamine 27.5%, C740 water-based defoamer 0.52%, distilled water surplus, its preparation method is the same as embodiment 1.

[0038] The water-based metal cleaning agent prepared in this example was tested for degreasing rate, foam performance, anti-rust performance and anti-corrosion performance, and the results are shown in Table 1.

Embodiment 3

[0040] A water-based metal cleaning agent, the mass percentage of each component is: sodium dodecylbenzene sulfonate 1.8%, SIMULSOL OX1309L 1.0%, ethylenediamine EO-PO block copolymer surfactant 7.8% , Rhodafac H66 2.5%, sodium molybdate 4.5%, PE1198 LA 0.375%, EDTA disodium 2.125%, triethanolamine 30.25%, C740 water-based defoamer 0.56%, distilled water surplus, its preparation method is the same as the implementation example 1.

[0041] The water-based metal cleaning agent prepared in this example was tested for degreasing rate, foam performance, anti-rust performance and anti-corrosion performance, and the results are shown in Table 1.

[0042] Table 1

[0043] The above results show that the water-based metal cleaning agent prepared by the present invention has good cleaning effect, excellent anti-corrosion and anti-rust effect, low foaming and easy rinsing, and high stability.

[0044] The water-based metal cleaning agent prepared by the present invention has ideal cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com