Patents

Literature

92results about How to "High cloud point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

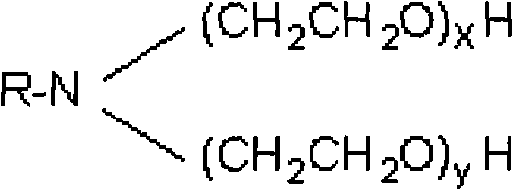

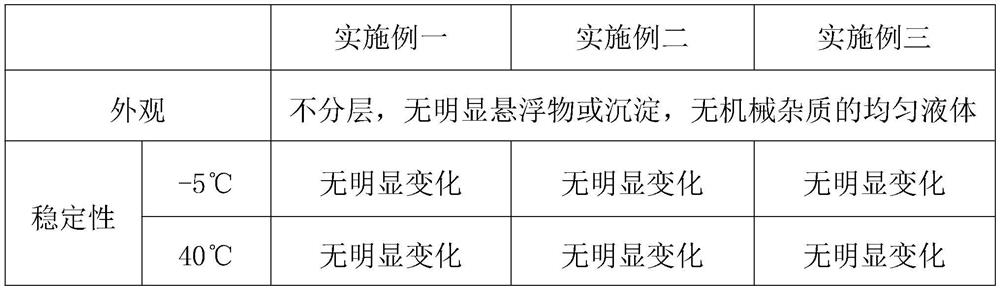

Fabric one-bath deoiling agent

ActiveCN101629130AHigh affinityGood emulsificationNon-ionic surface-active compoundsDry-cleaning apparatus for textilesFiberPolymer science

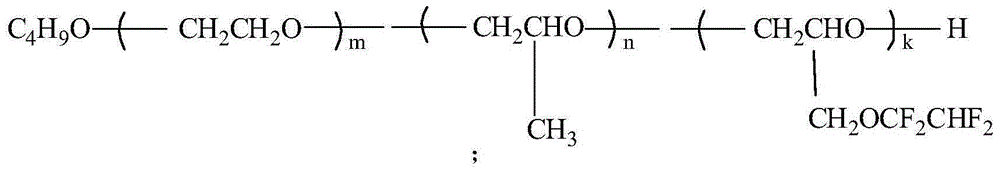

The invention relates to a fabric deoiling agent, in particular to a fabric one-bath deoiling agent not only suitable for the single deoiling treatment of fabrics, such as terylene, chinlon, cotton, and the like, but also particularly suitable for treating chemical fiber fabrics, such as the terylene, the chinlon, and the like by a deoiling dyeing one-bath method. The invention provides the fabric one-bath deoiling agent with favorable deoiling effect under acidic conditions and an application thereof. The fabric one-bath deoiling agent comprises the following ingredients in percentage by weight: 10-60 polyoxyethylene alkyl amine, 5-40 alkyl sulfonate, 10-50 sulfate surface active agent or / and phosphate salt surface active agent and the balance of water. The fabric one-bath deoiling agent can be used for treating the fabrics of the terylene, the chinlon, the cotton, and the like by the deoiling dyeing one-bath method.

Owner:福建省晋江新德美化工有限公司

Heavy oil cleaning agent

InactiveCN1844342AHarm reductionEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPetroleumEther

The invention relates to a heavy oil cleaning agent comprising the following constituents (by weight percent): (1) Tetrasodium EDTA 1-5, (2) sodium nitrite 0.1-1, (3) sodium carbonate 0.5-2, (4) polyoxythylene fatty alcohol ether 2-10, (5) polyoxythylene fatty alcohol ether sodium sulfate 1-5, (6) triethanolamine 0.2-1, (9) balancing water.

Owner:CHINA NAT OFFSHORE OIL CORP +1

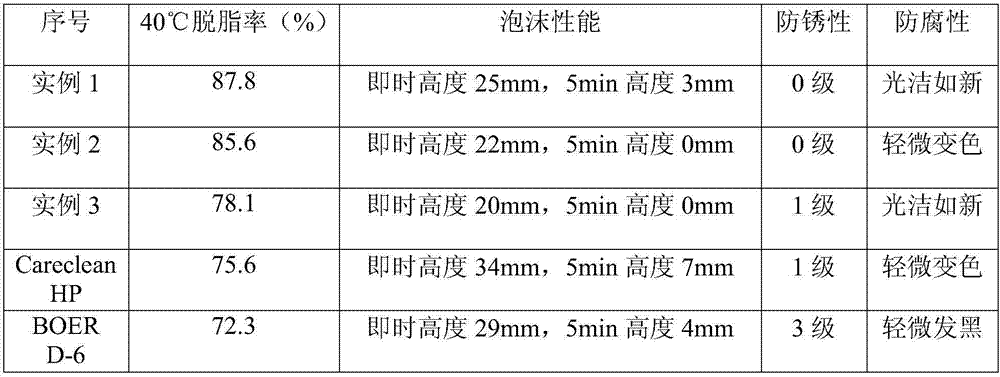

Low-foam middle-cloud-point environment-friendly water base metal cleaner composition and preparing method thereof

The invention provides a low-foam middle-cloud-point environment-friendly water base metal cleaner composition and a preparing method thereof, and belongs to the field of metal cleaners. The low-foam middle-cloud-point environment-friendly water base metal cleaner composition is composed of low-foam low-cloud-point nonionic surface active agents, low-foam anion surface active agents, triethanolamine oleic soap, triethanolamine, styrene acrylic three azole nitrogen, ethylene diamine tetraacetic acid, sodium carbonate, polyether, organosilicone, sodium hydroxide and deionized water, wherein solid-phase raw material and liquid-phase raw material are sequentially added to a reaction container according to a formulation and metering, the organosilicone and the deionized water are finally added to the reaction container, stirring is conducted for 10min to 20min under the condition of indoor temperature, and clear products with a pH value ranging from 9 to 10 are obtained. The triethanolamine oleic soap is a cloud point improving agent, good water solubility is achieved after the triethanolamine oleic soap and the triethanolamine are re-compounded according to the ratio, solubilizing ability of the low-foam low-cloud-point nonionic surface active agents is enhanced, therefore the temperature of the solution cloud point of the cleaner is improved to 45 DEG C, cleaning efficiency of the cleaner is improved, and the low-foam middle-cloud-point environment-friendly water base metal cleaner particularly suitable for high-pressure spraying cleaning is obtained.

Owner:BOER TECH WUHAN

Glass wax solvent and adhesive wax cleaning method

PendingCN109370801AHigh cloud pointImprove emulsificationInorganic/elemental detergent compounding agentsCationic surface-active compoundsInorganic saltsAdhesive

The invention provides a glass wax solvent which comprises 2-6wt% of weakly alkaline inorganic salt, 3-6wt% of chelating agents, 10-25wt% of surfactants, 2-10wt% of cosolvents and the balance water. The surfactants are anionic surfactants and nonionic surfactants, and the weight ratio of the anionic surfactants to the nonionic surfactants is (2-8):(10-20). The glass wax solvent is designed according to characteristics of adhesive wax, a formula of the glass wax solvent is free from strongly alkaline auxiliaries such as sodium hydroxide and potassium hydroxide, the anionic surfactants and the nonionic surfactants are compounded, the turbidity point of the wax solvent can be increased under the combined action of the components of the wax solvent, and the emulsifying and cleaning capacity ofthe wax solvent can be improved. The invention further provides an adhesive wax cleaning method.

Owner:LENS TECH CHANGSHA

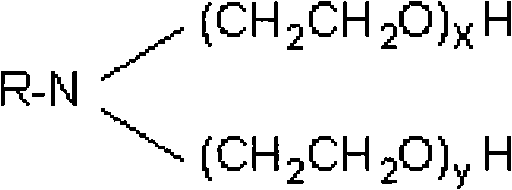

Water-based metal detergent and preparation method thereof

The invention discloses a water-based metal detergent which is composed of the following components in percentage by mass: 1-5% of anionic surfactant, 1-10% of nonionic surfactant I, 1-10% of nonionic surfactant II, 1-10% of nonionic surfactant III, 2-5% of corrosion inhibitor, 1.5-2.2% of assistant, 20-30.3% of organic alkali, 0.3-0.83% of defoaming agent and the balance of water. The higher-turbidity low-foam surfactants are introduced to effectively enhance the cleaning effect of the detergent. The oxidation-type corrosion inhibitor and adsorption-type corrosion inhibitor are compounded to enhance the corrosion inhibition effect. The organic phosphine is used instead of inorganic phosphorus, and thus, the detergent is safe and environment-friendly, thereby implementing zero addition of nitrites, silicates, ozonosphere-consuming substances and the like. The detergent has the advantages of favorable cleaning and corrosion inhibition effects, low foam, easy rinsing, stable performance and simple preparation technique, and has important practical application meanings.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

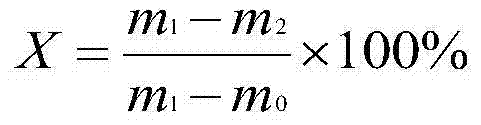

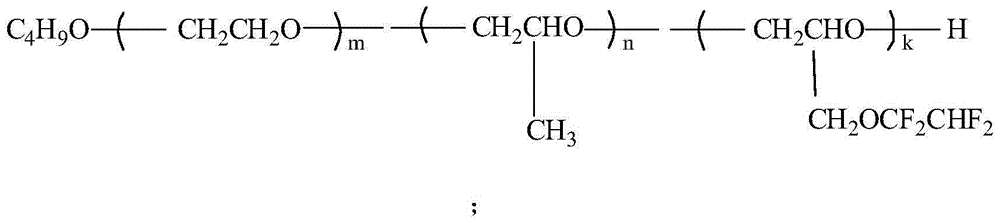

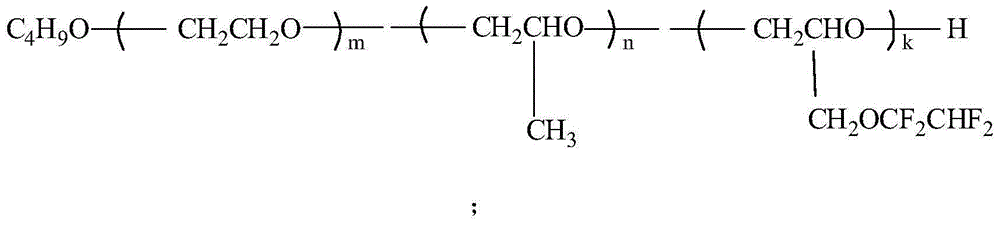

Super-fine-denier polyester fiber and manufacturing method thereof

ActiveCN105002603ASoft and delicateConvenient careArtificial thread manufacturing machinesFibre typesPolyesterEthylene oxide

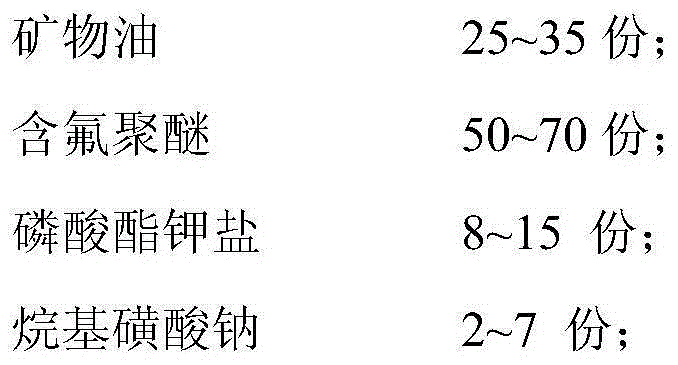

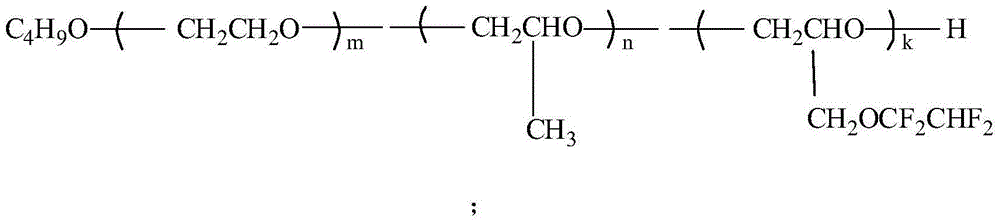

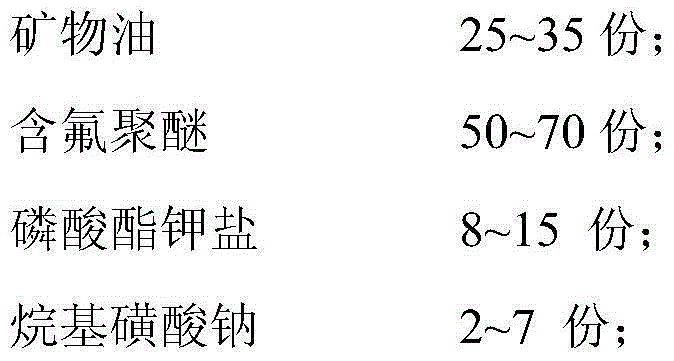

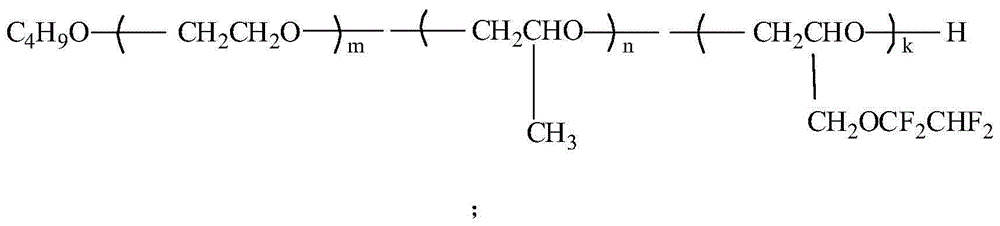

The invention relates to a super-fine-denier polyester fiber and a manufacturing method thereof. The super-fine-denier polyester fiber is mainly made of polyester through spinneret orifice melt spinning and high-speed coiling by the adoption of a grazing agent. The grazing agent at least comprises fluorine-containing polyether, and the mass of the fluorine-containing polyether is larger than or equal to 45% of the mass of the grazing agent. The fluorine-containing polyether is a random copolymer of ethylene oxide, oxirane,2-[(1,1,2,2-tetrafluoroethoxy)methyl] and epoxypropane. The structural formula of the fluorine-containing polyether is as shown in the specification. The manufacturing method of the super-fine-denier polyester fiber comprises the steps of conducting measuring, extrusion, cooling, grazing, stretching and thermal shaping on the polyester and then conducting high-speed winding, and then the super-fine-denier polyester fiber is manufactured. The super-fine-denier polyester fiber has the advantages of being soft in hand feel, high in flexibility, gentle in gloss, high in water absorbing and oil absorbing performance, density, specific surface area and heat preservation performance and the like. The development of the weaving technology and the printing and dyeing technology enables more potential features of the super-fine-denier polyester fiber to be explored gradually.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

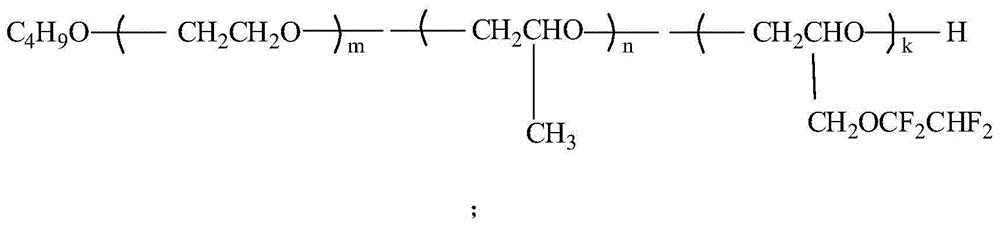

Developing solution composition

InactiveCN101290480AHigh cloud pointIncrease concentrationPhotosensitive material processingCarbon numberAlkaline earth metal

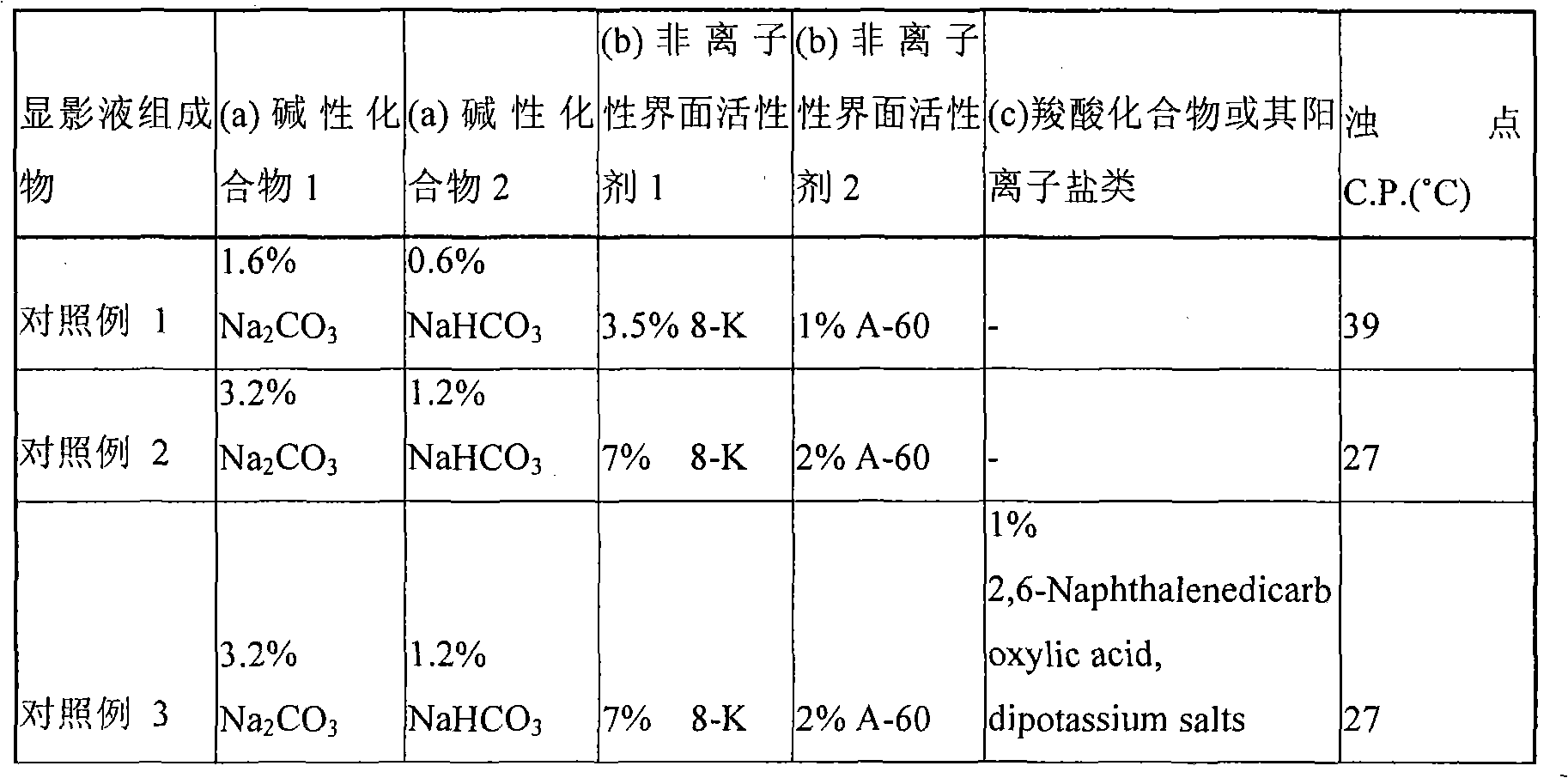

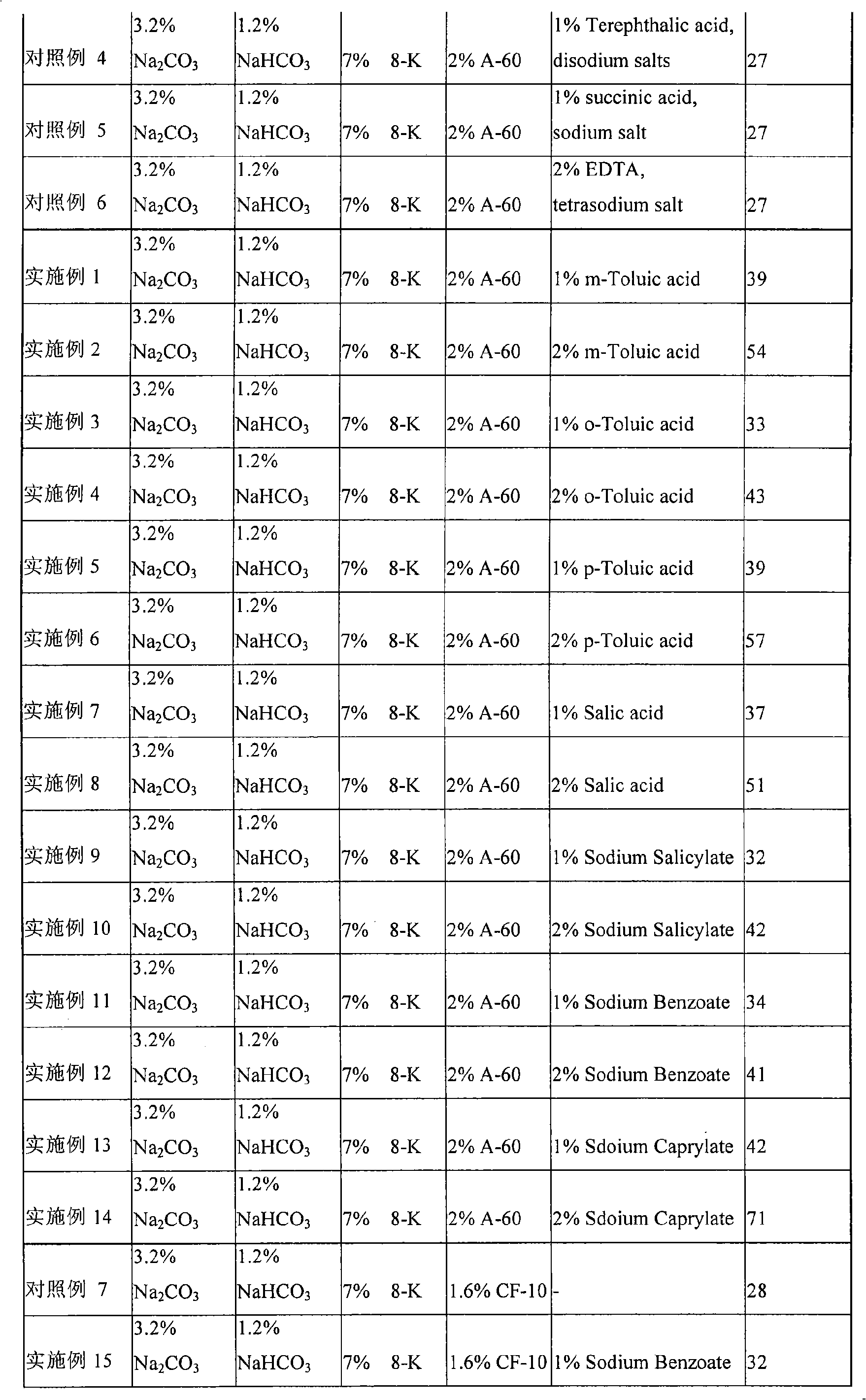

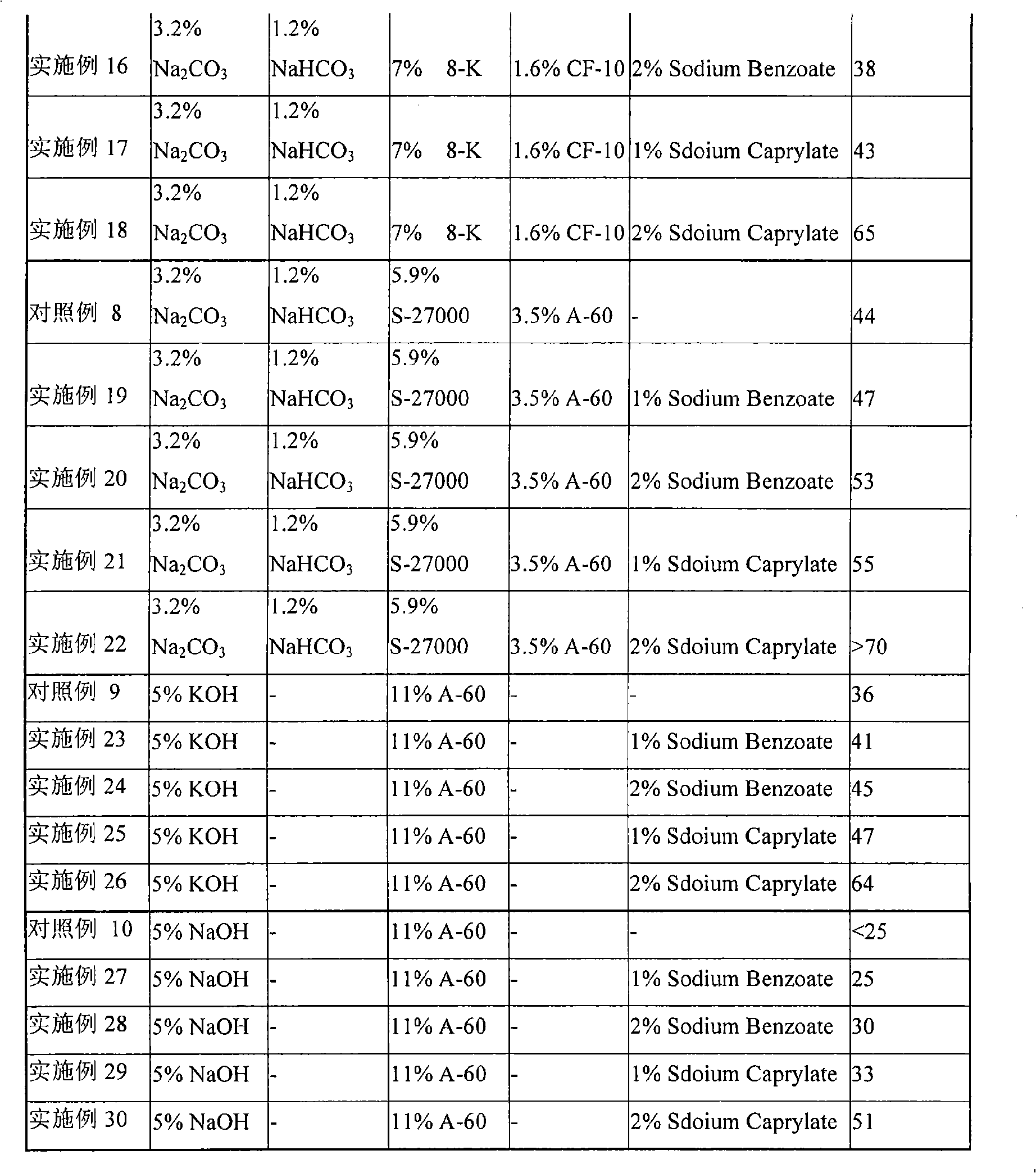

The invention relates to developing solution constituent. The compositions by weight portion of the developing solution constituent are: (a), 0.1 to 20 portions of alkaline compounds; (b), 0.1 to 20 portions of non-ionic surface active agent; (c), 0.1 to 10 portions of monocarboxylic acid compounds with the structure of (I): RCOOR', wherein, R refers to fatty groups or aromatic series which contain 5 to 12 carbon numbers and R' refers to hydrogen, alkali metals or alkaline-earth metal cations; and (d), the balance being water. The weight is calculated based on 100 portions of the developing solution constituent.

Owner:ETHICAL INT WAREHOUSING TRADING SHANGHAI

Method for preparing modified magnesium hydroxide flame retardant

ActiveCN103965656AGood compatibilitySimple processPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsEmulsionActive agent

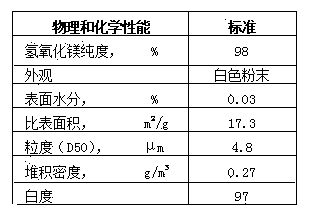

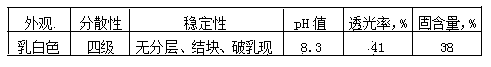

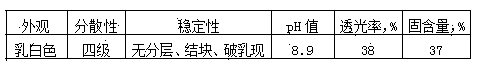

The invention discloses a method for preparing a modified magnesium hydroxide flame retardant. The method comprises the following steps: preparing a compound emulsifier; dissolving sodium lauryl sulfate and triethanolamine in water to prepare a transparent solution, adding the compound emulsifier and an auxiliary emulsifier in oxidized polyethlene wax, adding the transparent solution after the oxidized polyethlene wax is melted, and agitating to obtain an emulsion; adding an ammonia water solution into the emulsion to obtain an organic modified emulsion; adding an anionic surfactant water solution into magnesium hydroxide, and agitating to obtain powder; drying to obtain magnesium hydroxide powder; adding the organic modified emulsion into the magnesium hydroxide powder, adding a dispersant, cooling to a room temperature, and obtaining magnesium hydroxide modified by the organic emulsion. The modified magnesium hydroxide flame retardant has great dispersibility and great compatibility with organic substances, can be uniformly dispersed in a base material, and cannot cause agglomeration. After the modified magnesium hydroxide flame retardant is added to an organic material, the mechanical property losses of the material can be effectively reduced. The method has the advantages of simple preparing technology, easiness in operation, strong controllability and simple equipment. As no pollution is caused in the whole technical process, energy-saving and environment-friendly requirements are met.

Owner:山东大耀特种材料有限公司

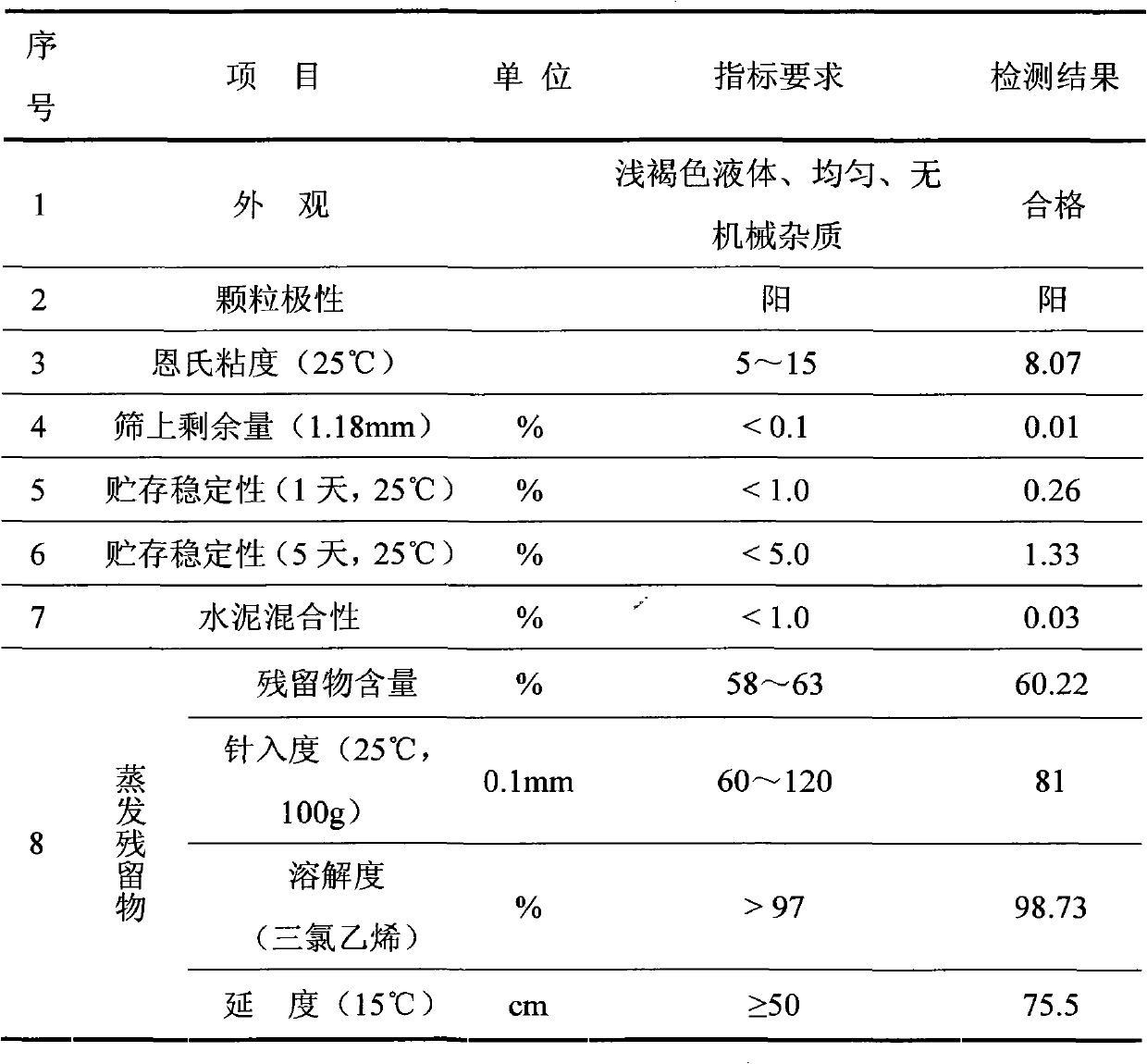

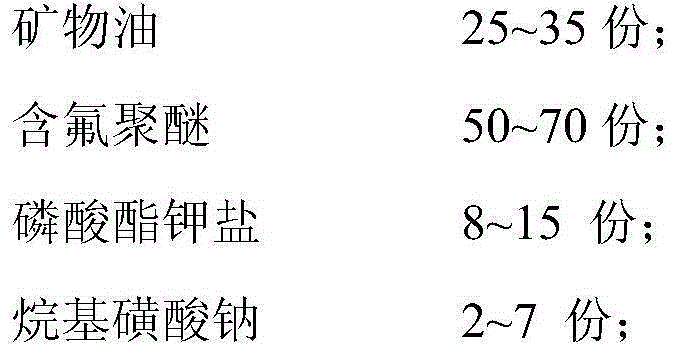

Emulsifier for high-iron emulsified asphalt and preparation method thereof

ActiveCN102002244AExtend the construction time limitSolve impossible puzzlesBuilding insulationsEmulsionAlkylphenol

The invention relates to an emulsifier for high-iron emulsified asphalt and a preparation method thereof. The emulsifier comprises the following raw materials in part by weight: 35.6 to 63.0 parts of alkylamine emulsifier, 20.2 to 38.3 parts of polyxyethylated alkylphenol emulsifier, 0.3 to 1.1 parts of aid 1, 0 to 1.0 part of aid 2 and 5.0 to 8.0 parts of aid 3. The emulsified asphalt prepared from the emulsifier can be used in a relatively wide temperature range and can be cooled rapidly without breaking emulsion. The emulsifier has the outstanding characteristics that: an emulsifier which is suitable for different temperature environments can be compounded by adjusting the composition proportion of the emulsifier and the problems of poor thermal stability of the high-iron emulsified asphalt and easy emulsion breaking are solved; and the emulsifier has high thermal stability, a small using amount and a wide application range, is easy and convenient to operate during use, can be prepared into high-stability high-iron emulsified asphalt and can lower the cost of an emulsion additive by about 20 percent.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

Coarse-denier porous polyester fiber and preparation method thereof

ActiveCN105019245AFiber feels softGood drapabilityFibre typesDyeing processPolyesterOptical property

The invention relates to a coarse-denier porous polyester fiber and a preparation method thereof. The coarse-denier porous polyester fiber is mainly prepared by the steps of melt spinning of polyester through multiple spinneret holes, application of an oiling agent, stretching and winding, wherein the oiling agent at least comprises fluorine-containing polyether, the mass of which is more than or equal to 45% of that of the oiling agent, the fluorine-containing polyether is a random copolymer of ethylene oxide, [(1,1,2,2-tetrafluoroethoxy) methyl] oxirane and propylene oxide, and the structural formula of the random copolymer is shown in the specification. The preparation method comprises the steps of metering, extruding, cooling, oiling and high-speed winding of polyester, thereby obtaining the coarse-denier porous polyester fiber. The coarse-denier porous polyester fiber is endowed with soft and elegant silk light sensation. Not only does the porous polyester fiber have excellent optical property, but also a fabric has effect of thick hand feeling and good fluffiness and breathability since a large quantity of fibers cannot be arranged closely and interspaces are correspondingly enlarged.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

Laundry condensate bead with 8 times of cleaning power and preparation method thereof

ActiveCN111704965AHigh cloud pointDissolve fastOrganic detergent compounding agentsNon-ionic surface-active compoundsSolventLaundry

The invention relates to the technical field of daily chemical detergents, and provides laundry condensate bead with 8 times of cleaning power and a preparation method thereof. The laundry condensatebead comprises the following components in percentage by mass: 8-20% of dodecylbenzene sulfonic acid, 10-20% of sodium alcohol ether sulphate, 7-24% of fatty acid methyl ester ethoxylate, 5-12% of isomeric alcohol ether, 6-18% of AEO-9, 10-20% of a solubilizing agent, 5-15% of triethanolamine, 5-15% of trisodium N,N-dicarboxymethyl alaninate, 0.5-3% of anti-redeposition agent, 0.5-2.5% of protease, 0.3-2% of Kathon, 0.2-2% of DMDM hydantoin and 0.5-3% of daily essence. The laundry condensate bead prepared by the invention has 8 times of cleaning power on carbon black, protein and sebum stains,and solves the problem that a laundry condensate bead formula in the prior art only has 8 times of cleaning effect on a certain stain selected from the carbon black, protein and sebum stains.

Owner:FUJIAN HENGAN HLDG CO LTD +1

Bright warm-keeping lightness type fibers and preparation method thereof

ActiveCN105063809AImprove breathabilityImprove thermal insulationFilament/thread formingSynthetic polymer filament chemical after-treatmentThermal insulationPolyester

The present invention relates to bright warm-keeping lightness type fibers and a preparation method thereof, wherein mainly a polyester is subjected to special-shaped spinning hole melt spinning, oil agent feeding and winding so as to prepare the bright warm-keeping lightness type fibers, wherein the oil agent at least comprises a fluorine-containing polyether, the mass of the fluorine-containing polyether is more than or equal to 45% of the mass of the oil agent, the fluorine-containing polyether is a random copolymer of ethylene oxide, [(1,1,2,2-tetrafluoroethoxy)methyl]ethylene oxide and propylene oxide, and the structure formula is defined in the specification. The preparation method comprises: metering a polyester, extruding, cooling, oiling, stretching, carrying out thermal shaping, and winding so as to prepare the bright warm-keeping lightness type fibers. According to the bright warm-keeping lightness type fibers of the present invention, the fiber cross section shape is changed by the spinning while the fibers have the hollowness, the air permeability and the thermal insulation property are increased, and with the special cross section shape of the fibers, the bright surface light refraction effect is provided so as to make the fabric bright and gorgeous; and the fibers further have characteristics of lightness, light weight, and soft touch feeling.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

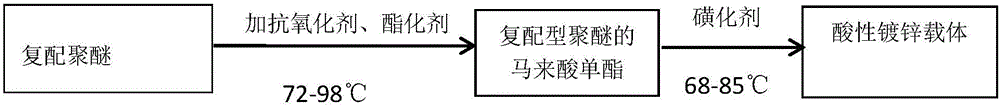

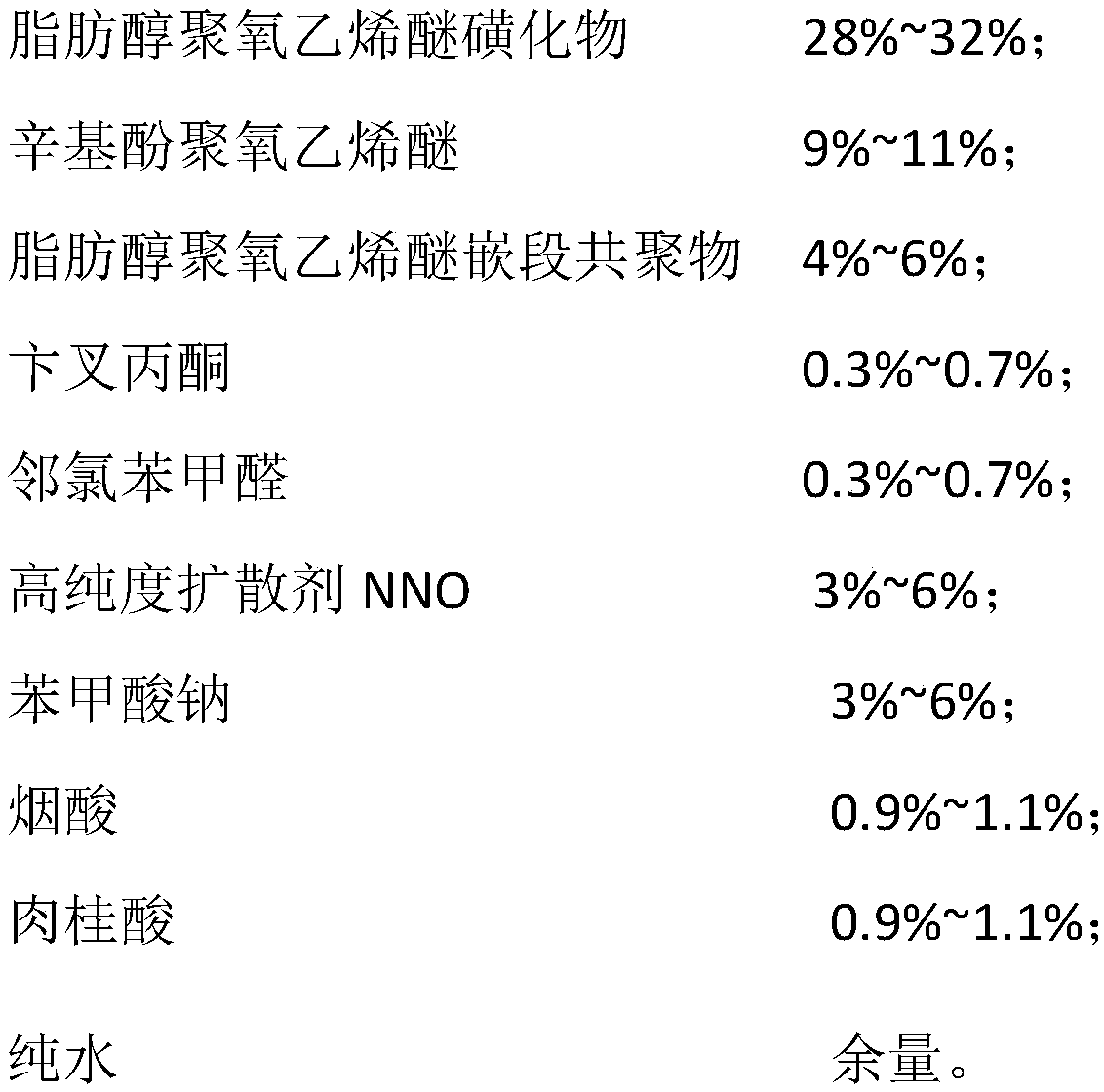

Acidic zinc-plated carrier and a preparation method and application thereof

The invention discloses an acidic zinc-plated carrier and a preparation method and application thereof. The preparation method of the acidic zinc-plated carrier includes the following steps that an antioxidant and maleic anhydride are added to compound polyether under the temperature condition of 72-98 DEG C, heat preservation and esterification are performed for 2.5-5.5 hours to obtain maleic monoester of the compound polyether, and sulfonation is performed under the temperature condition of 68-85 DEG C to obtain the acidic zinc-plated carrier. The naphthol blocked polyether with a special structure is used as a main raw material and is supplemented with isomeric alcohol ethoxylates, linear alcohol ethoxylates and alkylphenol ethoxylates, and the obtained acidic zinc-plated carrier is free-cloud-point and low-foam and has strong blocking capability.

Owner:WUHAN OXIRAN SPECIALTY CHEM CO

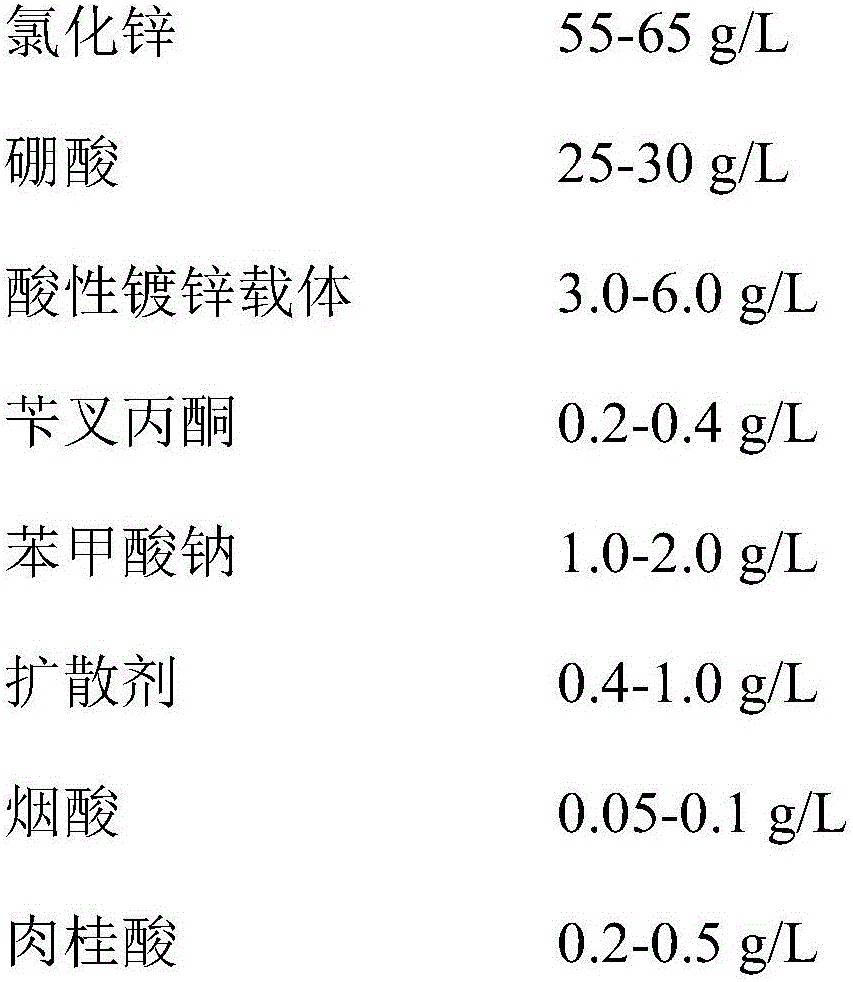

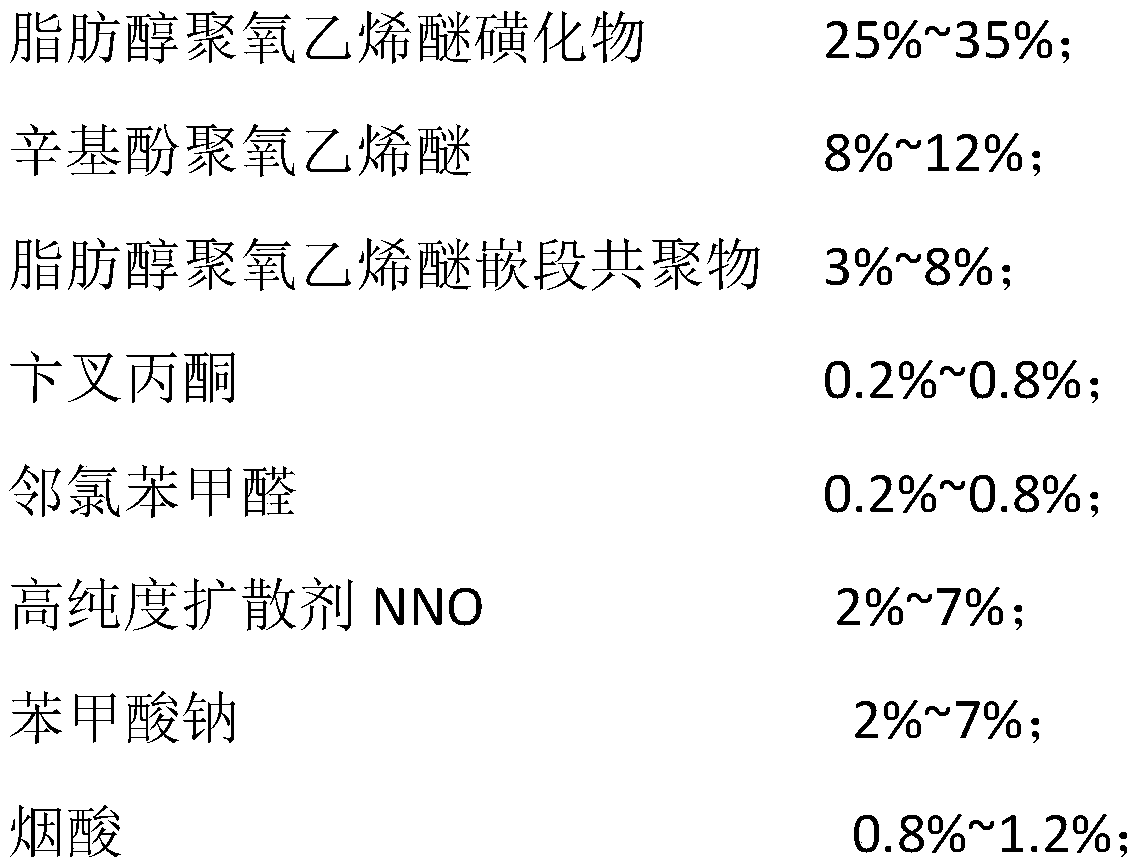

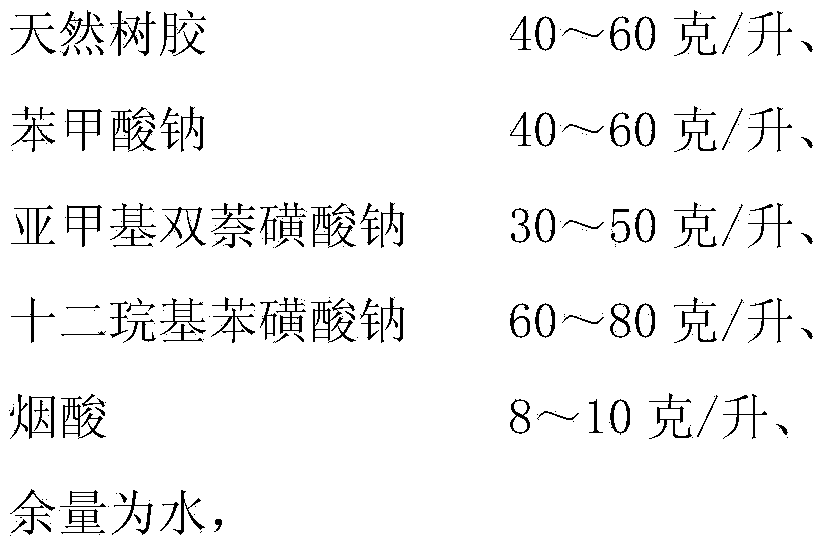

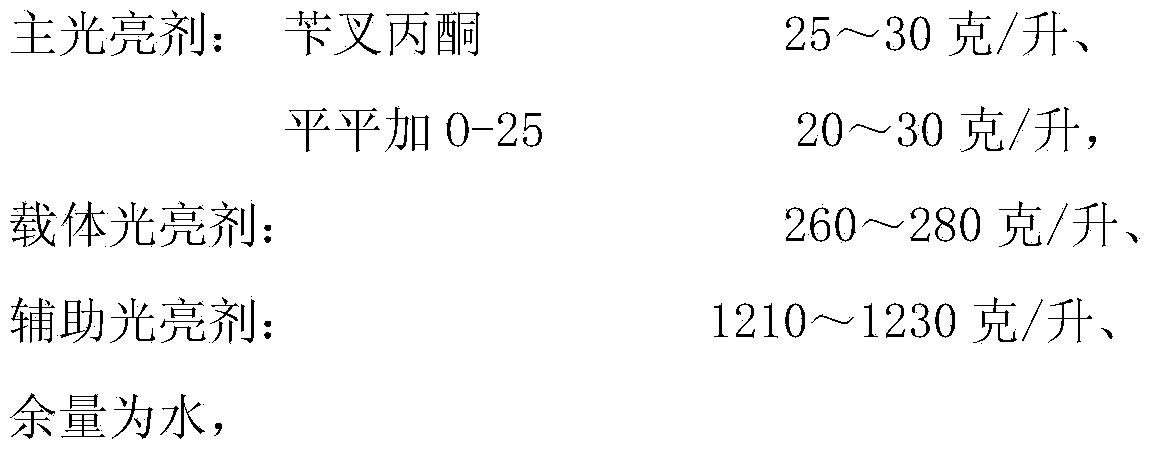

Novel acidic zinc-plating additive

The invention discloses a novel acidic zinc-plating additive. The additive comprises the following components of, in percentage by weight, 25%-35% of fatty alcohol-polyoxyethylene ether sulphonate, 8%-12% of octyl phenol polyoxyethylene ether; 3%-8% of fatty alcohol-polyoxyethylene ether block copolymer, 0.2%-0.8% of benzyl fork acetone, 0.2%-0.8% of o-chlorobenzaldehyde, 2%-7% of high-purity diffusant NNO, 2%-7% of sodium benzoate, 0.8%-1.2% of nicotinic acid, 0.8%-1.2% of cinnamic acid and the balance pure water. According to the additive, a zinc-plated layer with good brightness, leveling and ductility can be rapidly obtained in acid zinc-plating; the cloud point is high, the temperature resistance is good, the current efficiency is high, the light emitting speed is fast, throwing is good, the efficiency is high, and the zinc-plated layer is suitable for rolling plating and hanging plating; the zinc-plated layer is compact in crystallization, non-brittle of zinc and free of foaming,various blue-white and colorful passivation treatment can be easily accepted, and the corrosion-resistant performance is excellent; and the consumption of the additive is less in the plating liquid,supplement and maintenance are convenient, and the additive is economical and practical.

Owner:宁波市鄞州艾博化工科技有限公司

Cleaning solution for cleaning metal surfaces

ActiveUS20200140782A1Improve wettabilityEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsActive agentPolyethylene glycol

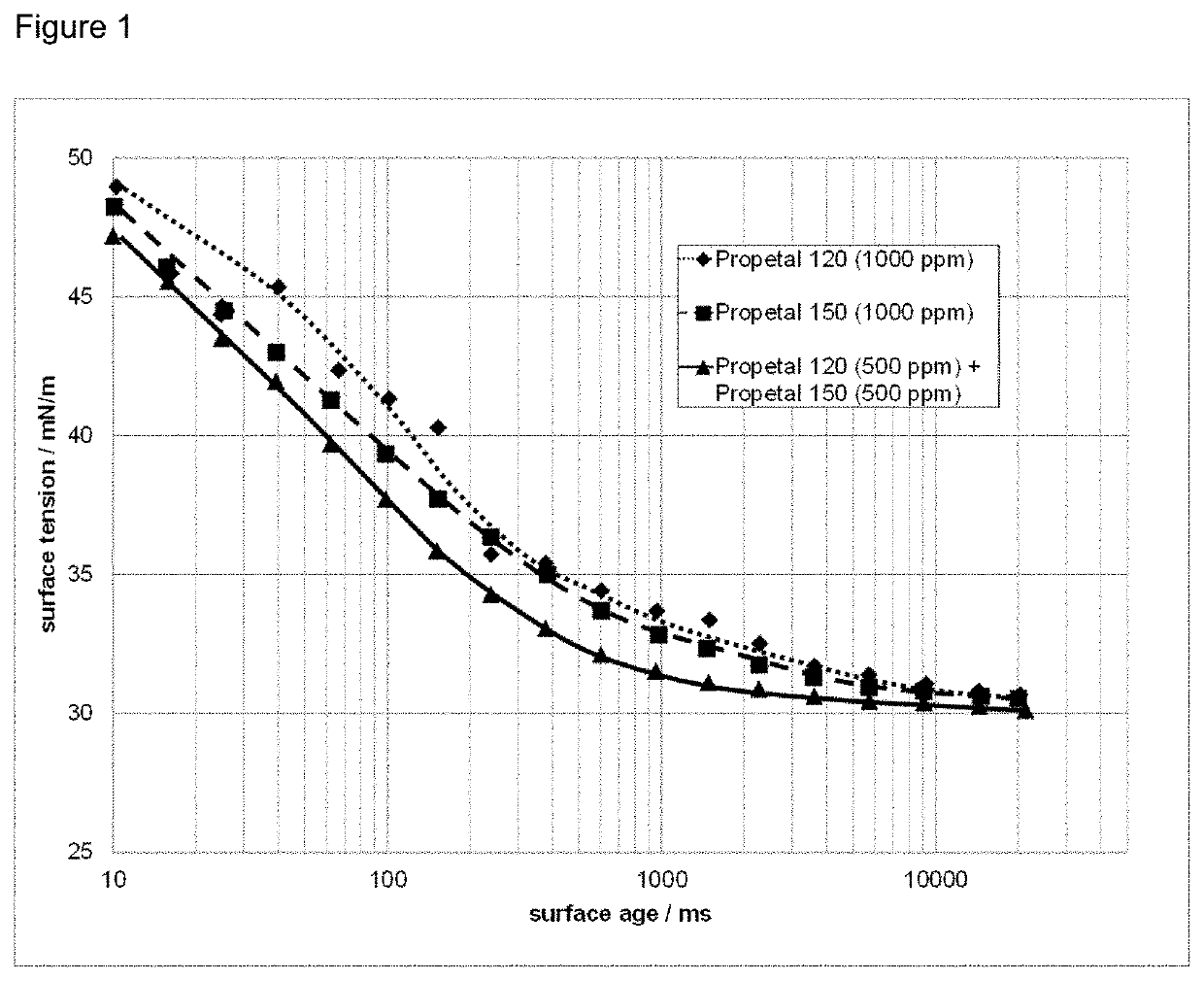

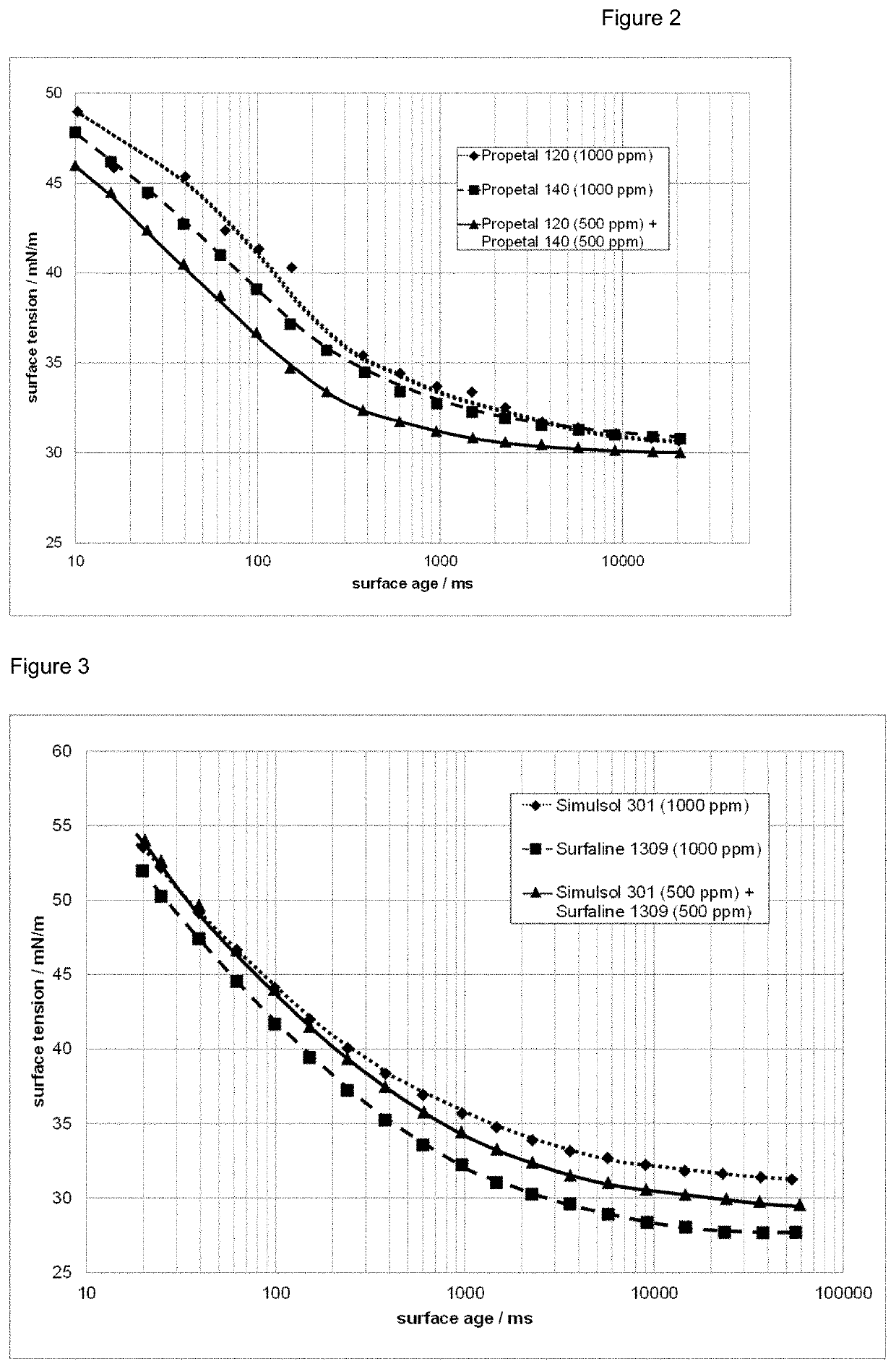

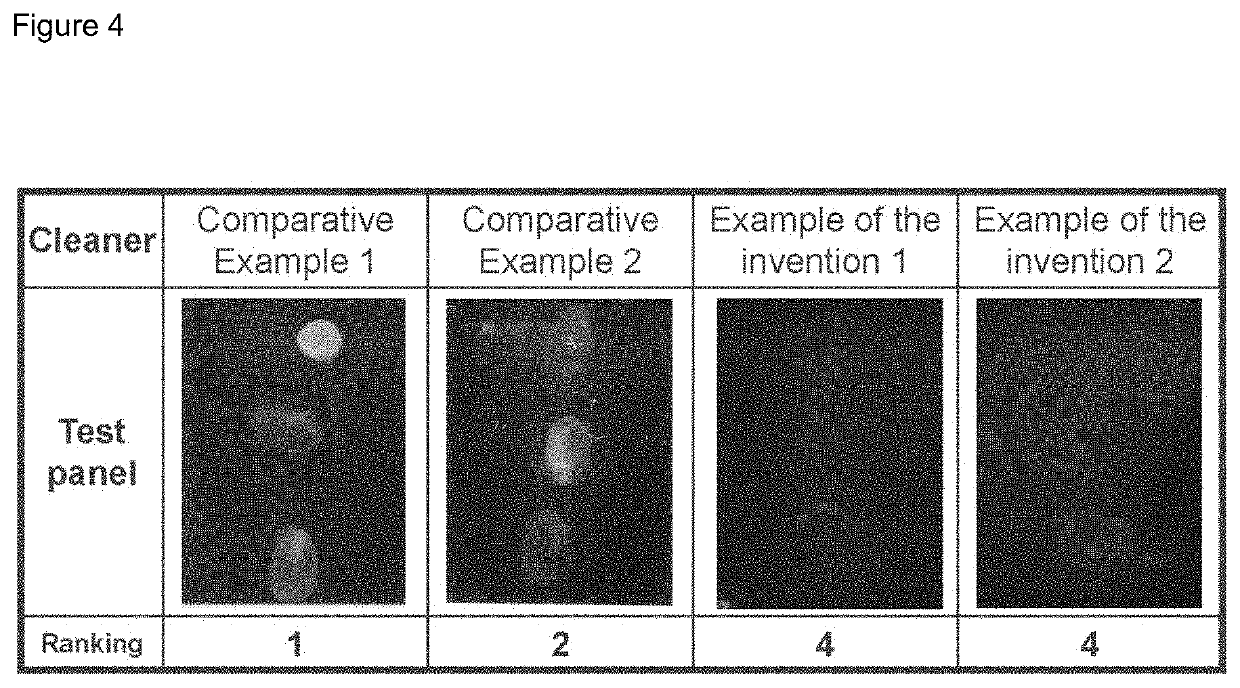

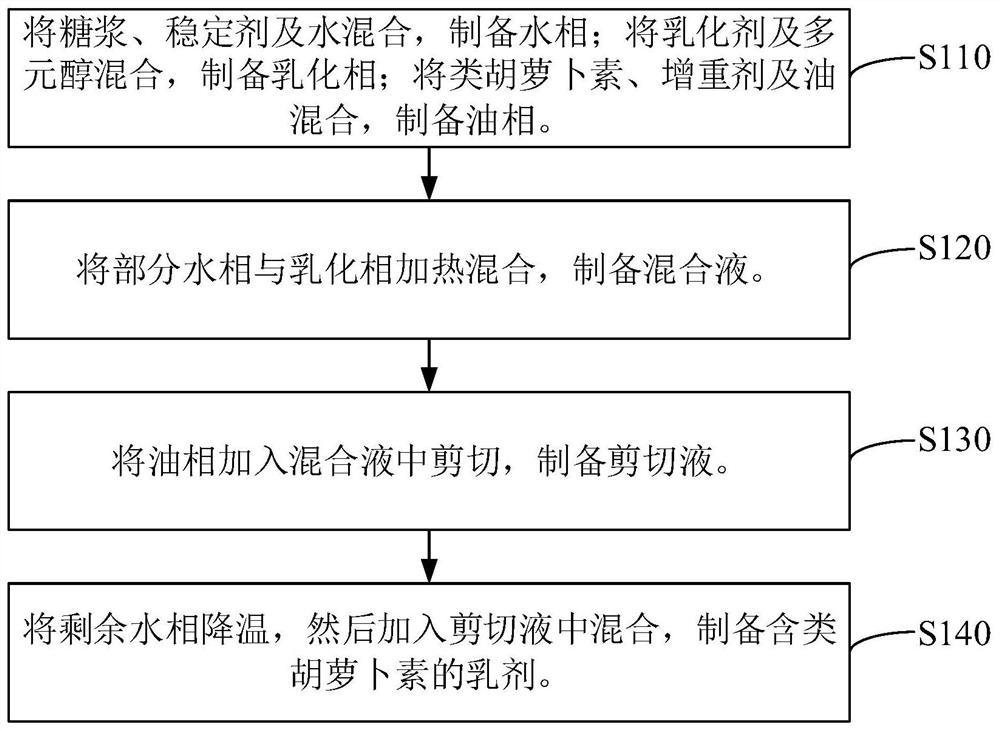

Cleaning solution for cleaning and / or wetting metal surfaces, comprisingat least one acid,a first surfactant, which is an alkyl-poly(ethyleneglycol-co-propyleneglycol)-ether having a cloud point of ≤25° C.,a second surfactant, which is selected from the group consisting ofi) an alkyl-poly(ethyleneglycol-co-propyleneglycol)-ether having a cloud point of ≥30° C.,ii) an alkyl-polyethyleneglycol-ether having a cloud point of ≥45° C.wherein the cloud points are determined according to European Standard EN 1890:2006, item 8.2 of German Version, with the modification that 10 wt % H2SO4 is used as solvent and that the concentration of the surfactant is 1000 mg / L.

Owner:ATOTECH DEUT GMBH

Carotenoid-containing emulsion and preparation method, application and beverage thereof

ActiveCN111789216ASmall particle sizeThickenCosmetic preparationsFood ingredient as thickening agentPolymer sciencePolyol

The invention relates to a carotenoid-containing emulsion and a preparation method, application and beverage thereof. The preparation method of the carotenoid-containing emulsion comprises the following steps: mixing syrup, a stabilizer and water to prepare an aqueous phase; mixing an emulsifier and polyol to prepare an emulsified phase; mixing carotenoid, a weighting agent and oil to prepare an oil phase; heating and mixing part of the aqueous phase with the emulsified phase to prepare a mixed solution; adding the oil phase into the mixed solution for shearing to prepare shearing liquid; andcooling the residual aqueous phase, and then adding the mixture into a shearing solution for mixing to prepare the carotenoid-containing emulsion. The preparation method can prepare an emulsion with good stability, which does not delaminate after being placed in an environment of 55 DEG C for a long time.

Owner:DONGGUAN BOTON FLAVORS & FRAGRANCES

Cleaning compositions

InactiveUS20150111803A1Point becomes highLow foam levelOrganic detergent compounding agentsSurface-active detergent compositionsGlycosideFatty alcohol

A cleaning composition comprises A) a fatty alcohol-alkylene oxide copolymer, B) a glycoside, and C) a benzene sulfonate, wherein, the weight ratio of the component B and the component C is less than or equal to 5:1. The cleaning composition can be used as a detergent for cleaning medical appliances.

Owner:3M INNOVATIVE PROPERTIES CO

A kind of water-based metal cleaning agent and preparation method thereof

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparing technology for organic coating of zinc-sulfide long-afterglow luminescent powder

The invention discloses a preparing technology for organic coating of zinc-sulfide long-afterglow luminescent powder. The preparing technology includes the steps that a compound emulsifier is prepared; lauryl sodium sulfate and triethanolamine are dissolved into water and prepared into a transparent solution, the compound emulsifier and an emulsifying assistant are added into high-density oxidized polyethlene wax, the mixture is subjected to high temperature and high pressure and emulsified, then the transparent solution is added, the mixture is stirred, and emulsion is obtained; an ammonia water solution is added into the emulsion, and organic modified emulsion is obtained; an anionic surfactant water solution is added into zinc-sulfide luminescent powder, the mixture is stirred, and slurry is obtained; the organic modified emulsion is added into the zinc-sulfide luminescent powder slurry, a dispersing agent is added, the mixture is cooled to be the room temperature, filtered and dried, and the zinc-sulfide luminescent powder after being coated with the organic emulsion is obtained. The zinc-sulfide long-afterglow luminescent powder is good in dispersity and organic compatibility, and can be evenly dispersed into a base material, the agglomeration phenomenon cannot be generated, and if the zinc-sulfide long-afterglow luminescent powder is added into an organic material, damage to mechanical performance of the material can be effectively reduced.

Owner:潍坊科澜新材料有限公司

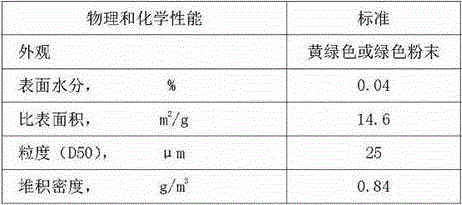

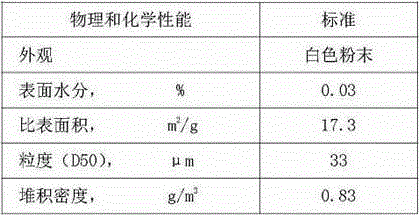

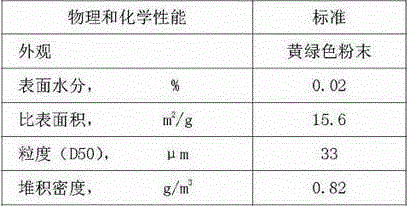

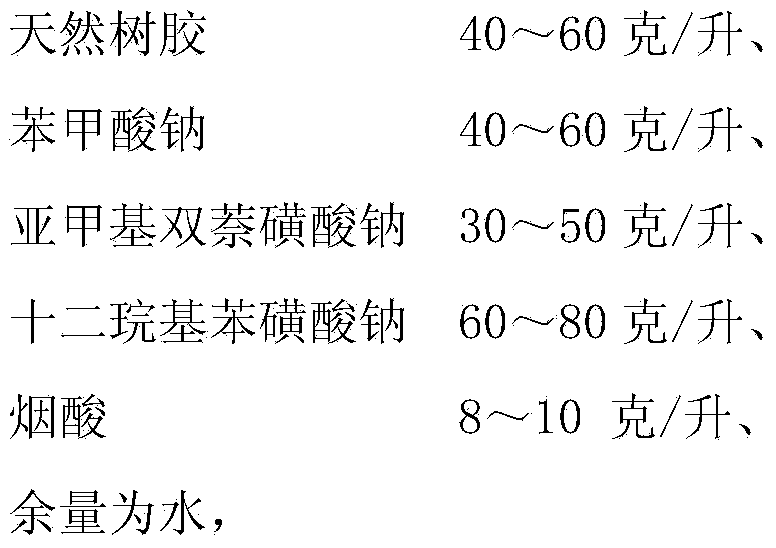

Auxiliary brightening agent for potassium chloride galvanizing and preparation method and use of auxiliary brightening agent

The invention provides an auxiliary brightening agent for potassium chloride galvanizing. The auxiliary brightening agent is combined with a main brightening agent and a carrier brightening agent for application, and is characterized in that the formula of the auxiliary brightening agent comprises natural gum, wherein the natural gum is crushed into powder, the powder is dissolved in hot water, impurities are filtered from the powder through a filter, and the powder is added into the auxiliary brightening agent for uniform stirring. According to the auxiliary brightening agent, the cathodic polarization of a high-current density area can be improved, the dispersion capability of a plating solution can be improved, and plated layer crystals are delicate and bright; the plating solution is high in covering power, and a plated layer is clear, smooth and high in deposition speed, the binding force of the plated layer can meet requirements, high current efficiency is ensured, and a plated part is prevented from being scorched and blackened; the auxiliary brightening agent is easy to prepare, stable, low in cost, pollution-free and environmentally friendly.

Owner:王维福

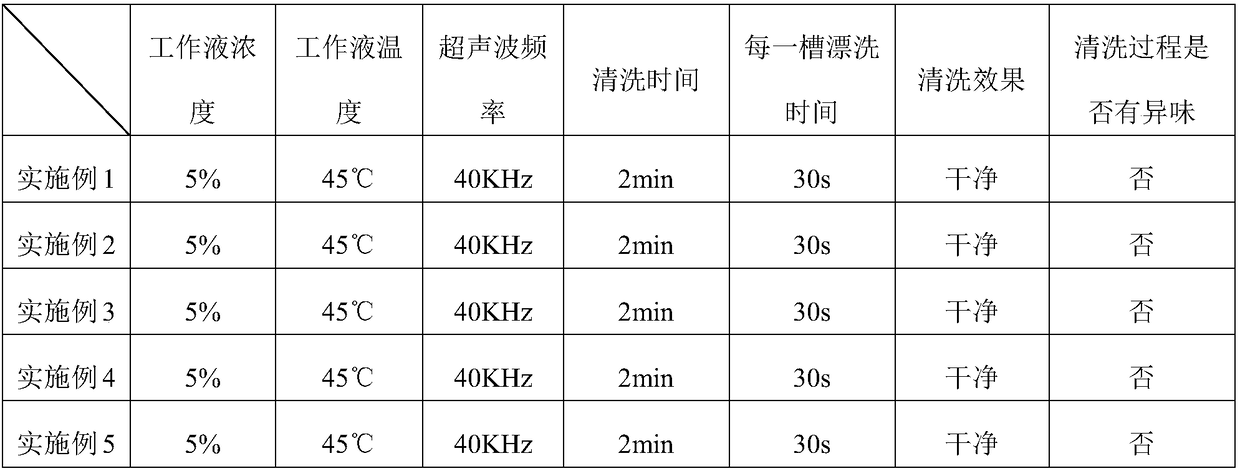

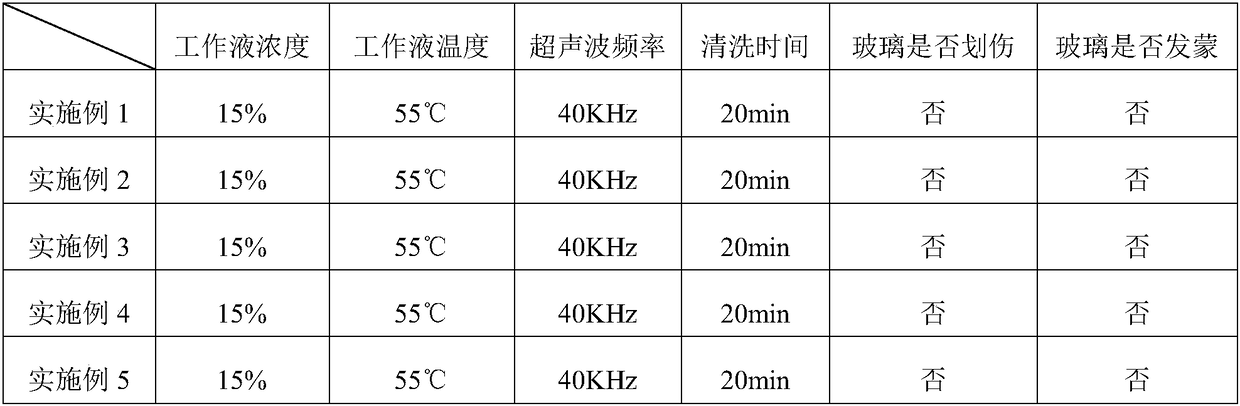

Antibacterial glass cleaning agent as well as preparation method and application thereof

ActiveCN108559650AImprove decontamination abilityImprove solubilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSolventCleansing Agents

The invention belongs to the field of industrial cleaning, and specifically relates to a cleaning agent as well as a preparation method and an the application thereof, in particular to the applicationin cleaning antibacterial glass. The cleaning agent comprises a complexing agent, an auxiliary agent, a solvent, a surfactant, a defoaming agent and water, and when the cleaning agent is applied, theconcentration of working liquid is 5-15%, the temperature is 40-55 degree Celsius, and the cleaning time is 2-5min. The cleaning agent provided by the invention has an excellent cleaning effect on antibacterial glass without damaging the glass, has no peculiar smell generated in a cleaning process, avoids harms to operators, and greatly improves the industrial production efficiency.

Owner:广东山之风环保科技有限公司

A hydrate kinetic inhibitor

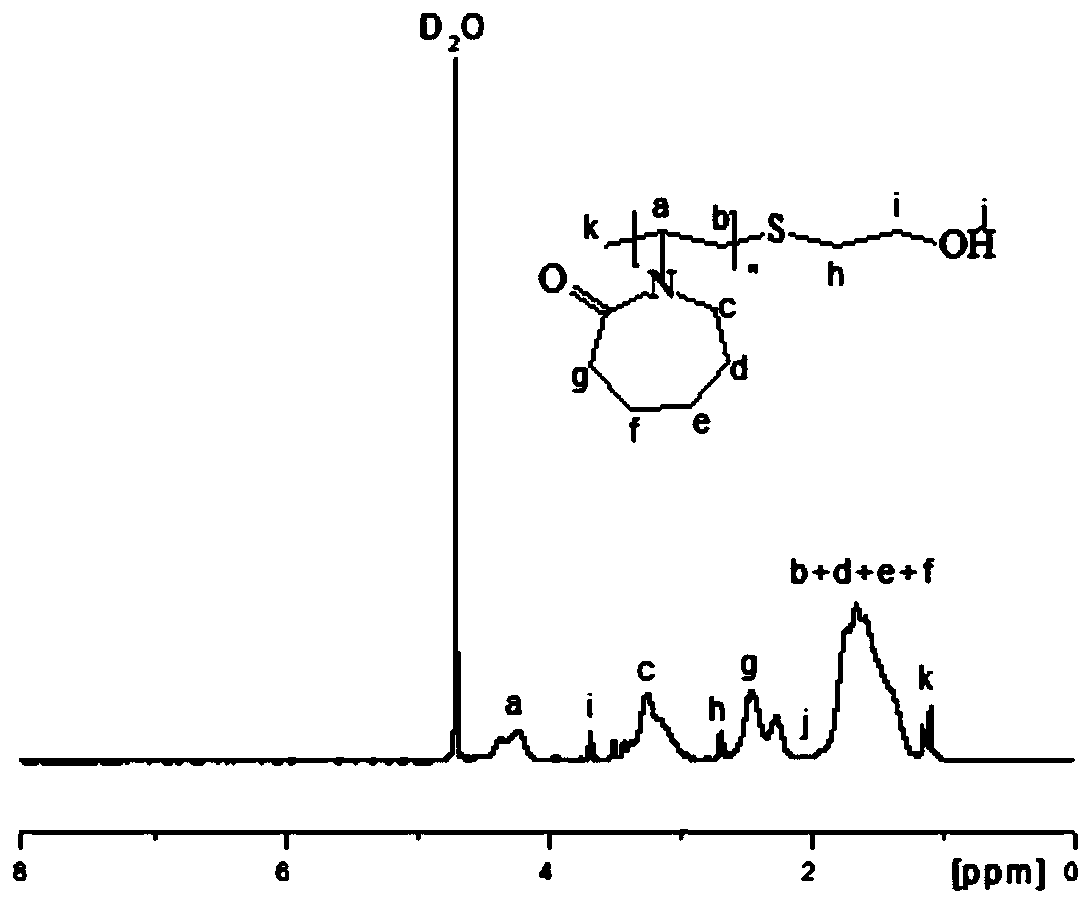

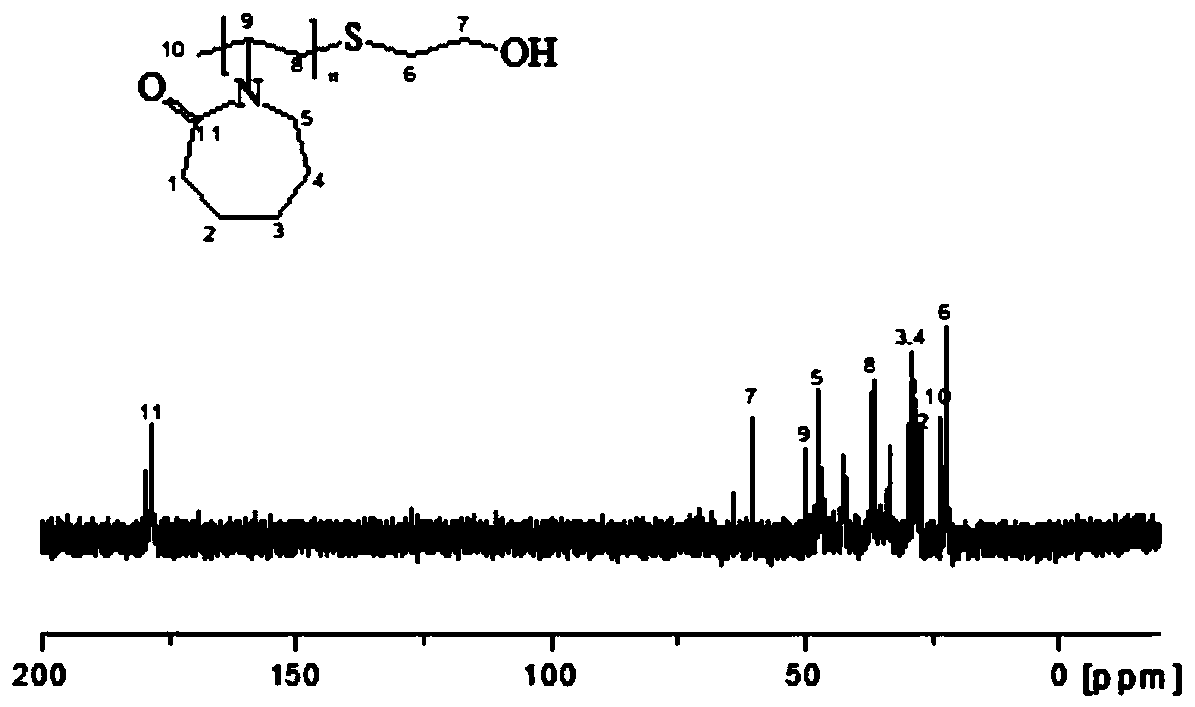

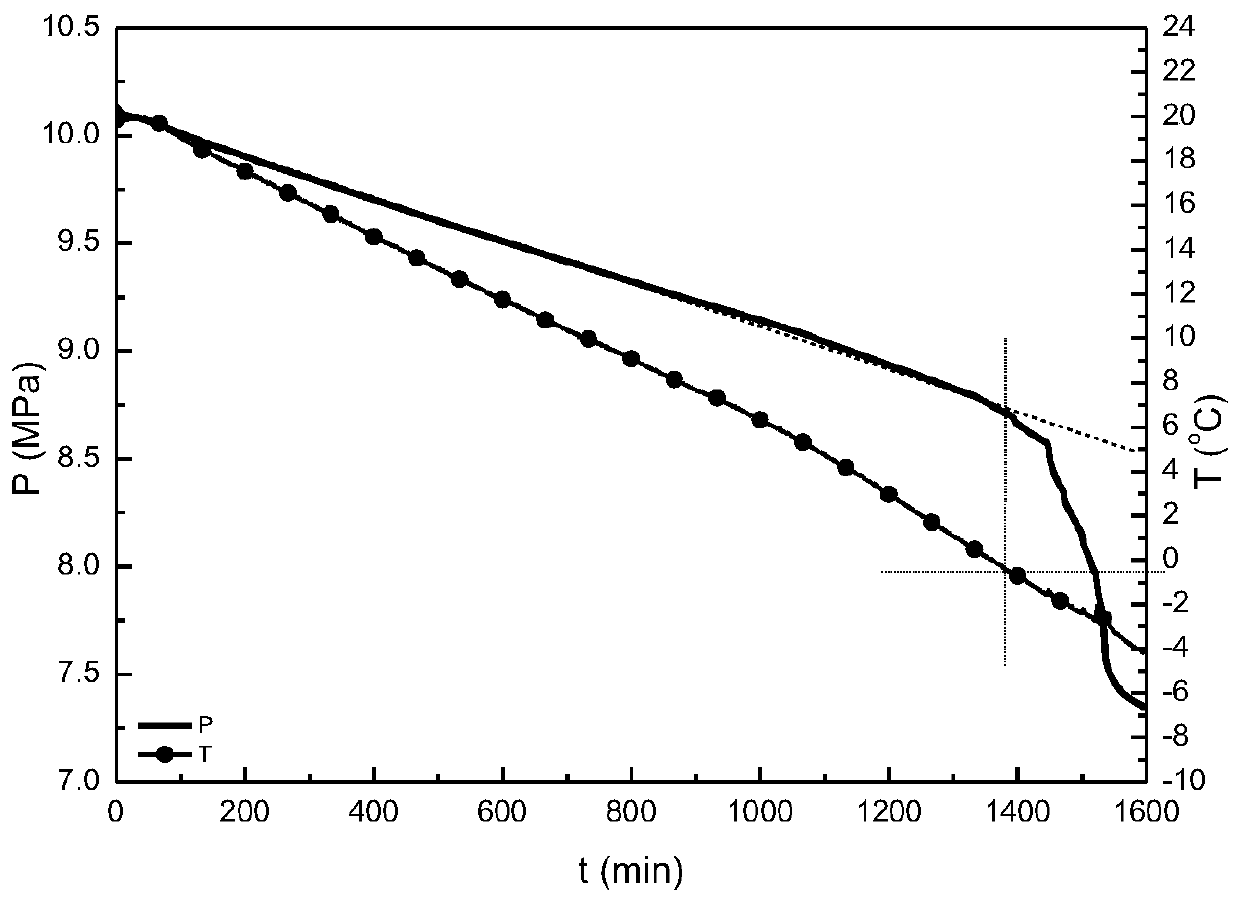

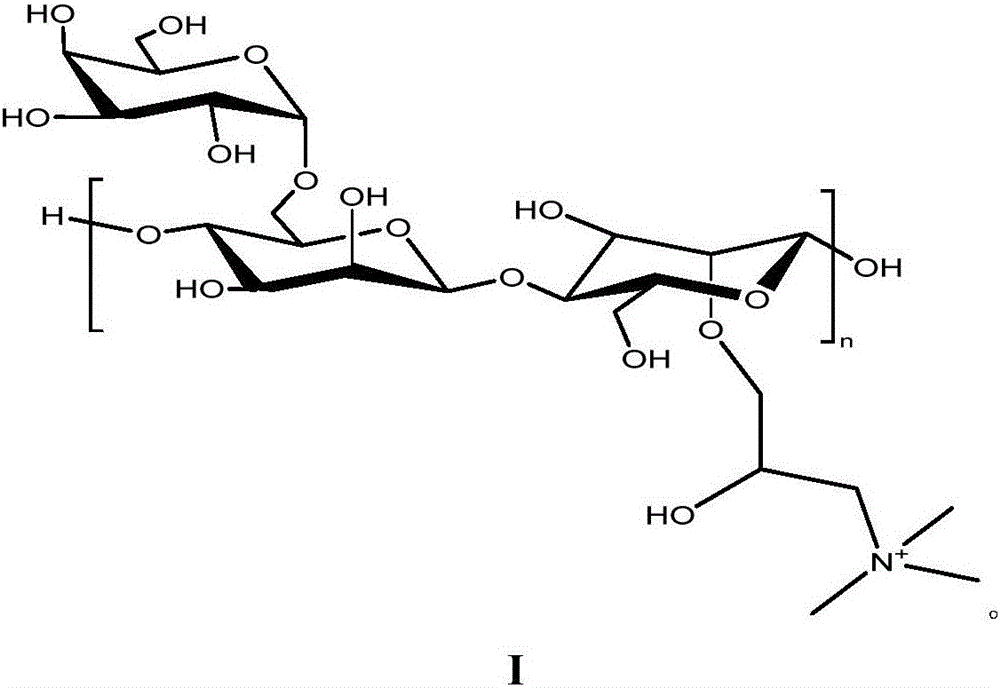

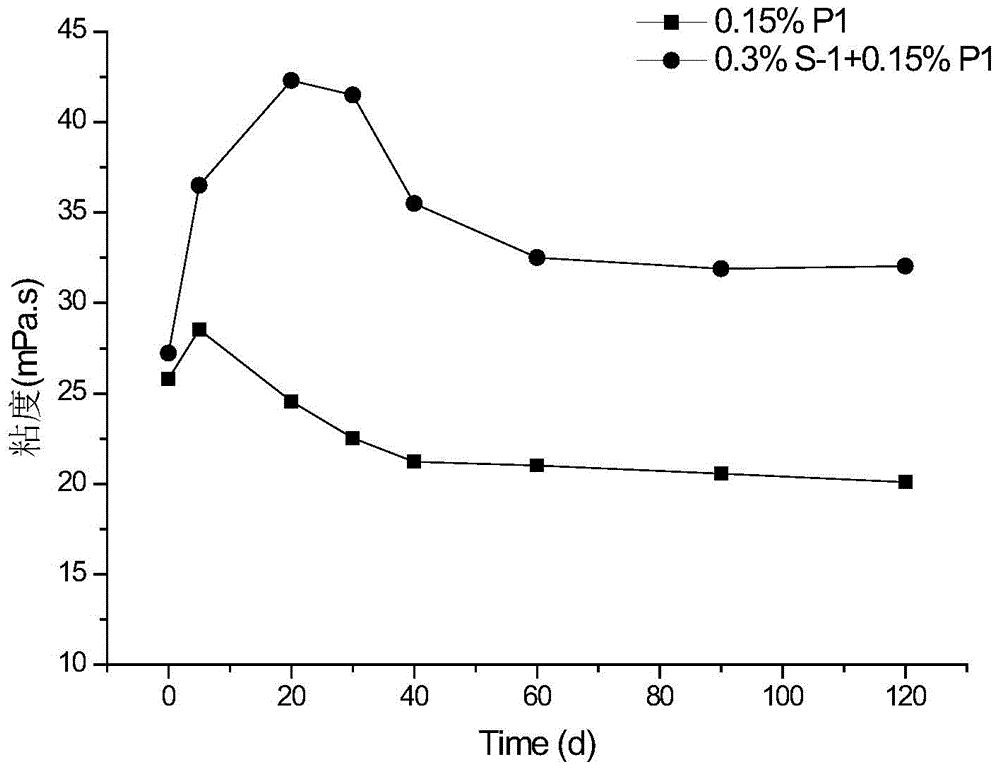

ActiveCN109705246BHigh cloud pointIncrease subcoolingDrilling compositionKinetic InhibitorCombinatorial chemistry

The invention provides a hydrate kinetic inhibitor. The hydrate kinetics inhibitor is formulated from vinylimidazole copolymer and auxiliary agent; the hydrate kinetics inhibitor is poly N-vinyl caprolactam modified by terminal hydroxyl, and its structure is shown in formula I , wherein n=10~1000. The hydrate kinetic inhibitor is a hydroxyl-modified amide type hydrate kinetic inhibitor, and is a new type of high-efficiency hydrate inhibitor with low dosage, high cloud point and ability to withstand a large degree of supercooling.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

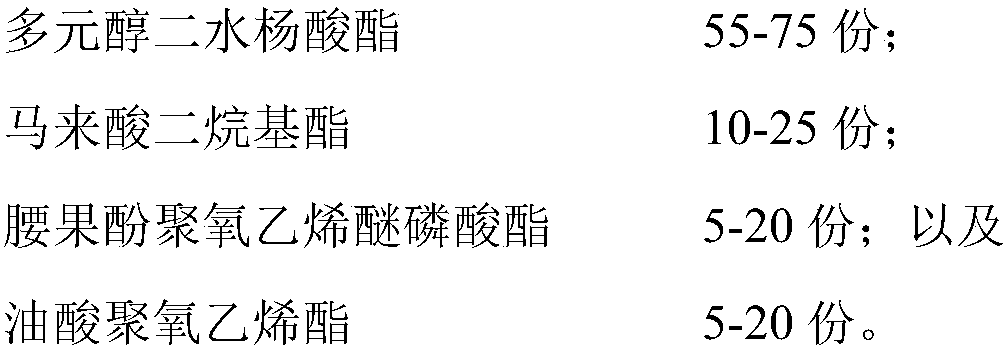

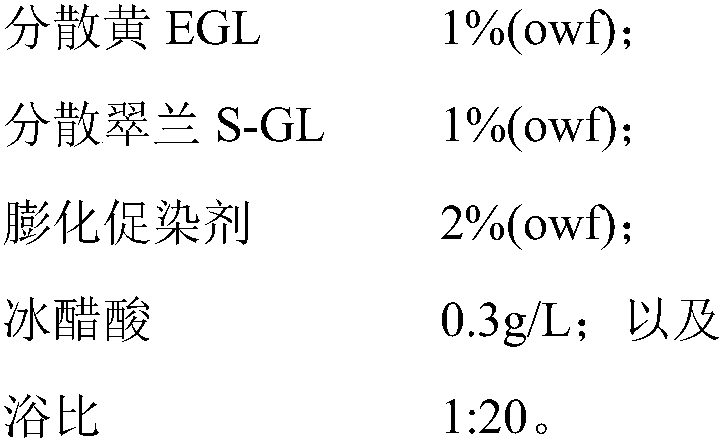

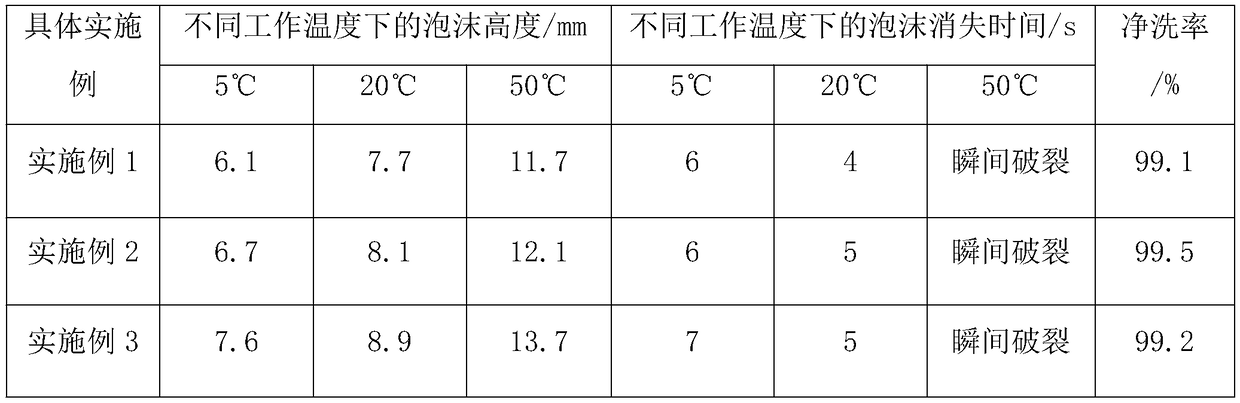

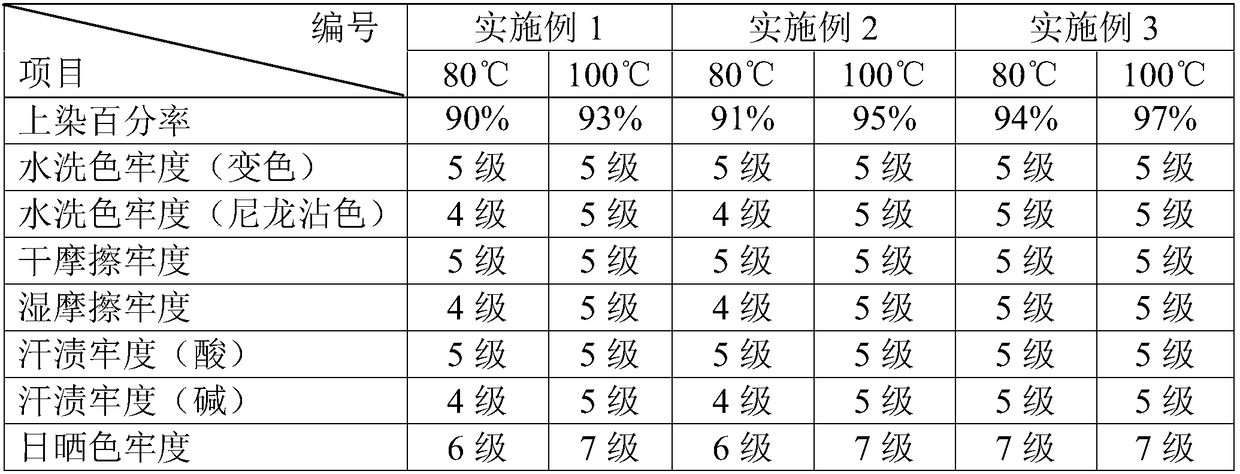

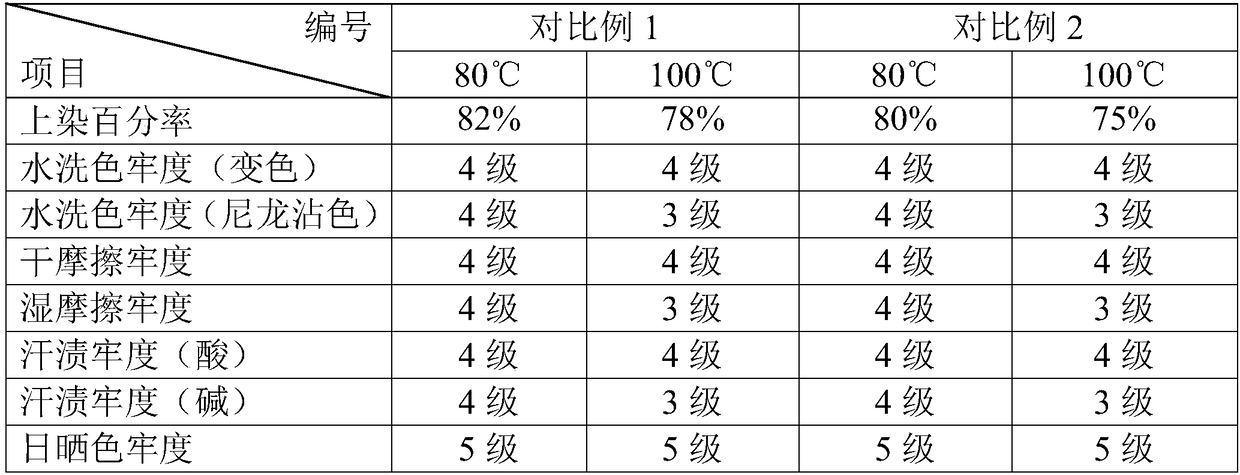

Expanding dyeing accelerant and preparation method thereof

The invention provides an expanding dyeing accelerant and a preparation method thereof. The expanding dyeing accelerant contains the following raw materials in parts by mass: 55-75 parts of polyol disalicylate, 10-25 parts of dialkyl maleate, 5-20 parts of cardanol polyoxyethylene ether and 5-20 parts of polyoxyethylene oleate. The expanding dyeing accelerant provided by the invention is green andfriendly to environment; the expanding dyeing accelerant is suitable for disperse dyeing of polyester fiber and blended fabrics thereof, yarn and velvet under low temperature conditions; the expanding dyeing accelerant can promote plasticization and expansion of the polyester fiber in a dyeing liquid and has the ability of solubilizing, dispersing and transferring disperse dyes to ensure that thedyes are easier to diffuse and migrate from the dye liquid to the interior of the fiber and the generation of colored spots can be avoided at the same time; and therefore, the low-temperature dyeingcan be realized in a real sense.

Owner:苏州联胜化学有限公司

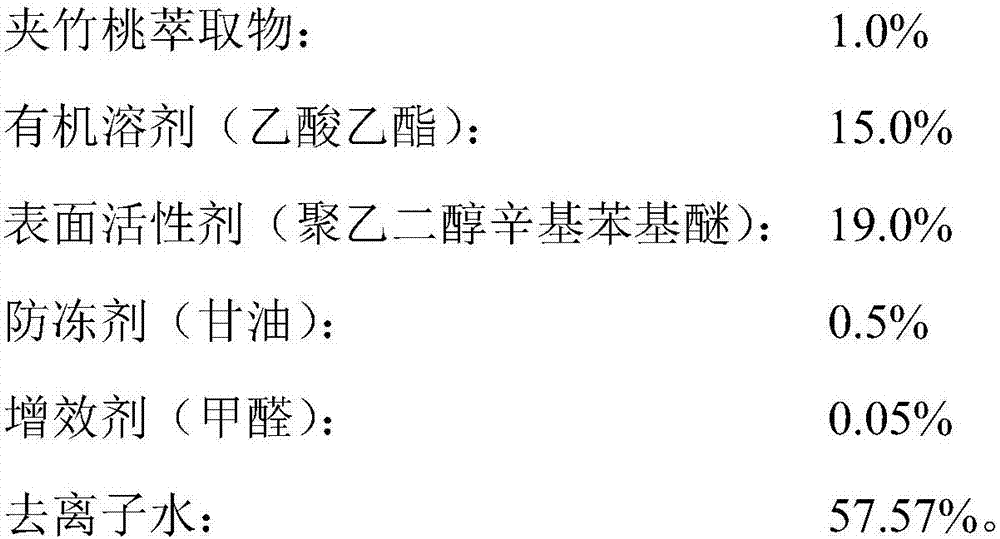

Biological orchard cleaning agent for apple orchards as well as preparation method and application method of biological orchard cleaning agent

InactiveCN107047547ANo pollution in the processLower resistanceBiocideDead animal preservationNerium Oleander ExtractInsect pest

The invention discloses a biological orchard cleaning agent for apple orchards as well as a preparation method and an application of the biological orchard cleaning agent and belongs to the technical field of biopesticide production. The orchard cleaning agent used for the apple orchards in winter is prepared from a melia azedarach extract and a nerium oleander extract as main raw materials with a compounding and blending technology, and in combination with physical orchard cleaning in winter, the purposes of controlling injurious insects and killing pathogenic bacteria are achieved. Most injurious insects and pathogenic bacteria lurk in deadwood and fallen leaves of apple trees in forms of worm eggs and spores in winter, vital movement is quite weak, a toosendanin and nerium oleander mixed pesticide is sprayed while the deadwood and the fallen leaves are removed through shearing, so that plant diseases and insect pests of the apple orchards can be eliminated / reduced, and the biological orchard cleaning agent has quite remarkable control effects on apple rot, ring rot, anthracnose, early-falling disease and core rot and has positive significance in reduction of apple damage caused by tetranychidae, peach fruit moth, oriental fruit moth and adoxophyes orana.

Owner:SHAANXI UNIV OF SCI & TECH

Monocrystalline silicon texturing additive with strong dirt-removing power and application thereof

PendingCN113584597AHigh cloud pointImprove cleanlinessPolycrystalline material growthAfter-treatment detailsCritical micelle concentrationActive agent

The invention discloses a monocrystalline silicon texturing additive with strong decontamination capability and an application thereof. The texturing additive comprises the following components in percentage by mass: 1%-6% of a first surfactant, 2%-5% of a second surfactant, 3%-5% of an ether defoaming agent, 0.5%-3% of a nucleating agent, 1%-2% of a cosolvent, 0-0.1% of a chelating agent and the balance being deionized water. The invention discloses the novel monocrystalline silicon texturing additive with strong decontamination capability, and an unconventional surfactant has a wrapping effect only when reaching a certain concentration and is not limited by the critical micelle concentration, so that the decontamination effect of the texturing additive is greatly improved, and the cleanliness of the surface of a textured silicon wafer is improved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Preparation method for cleaning agent high in defoaming speed

ActiveCN109504971AIncrease electrophilicityIncrease the rate of the rate-controlling reactionDefoamerCarboxylate

The invention provides a preparation method for a cleaning agent high in defoaming speed. According to the formula of the cleaning agent, the cleaning agent comprises 0.8-2.0% of anhydrous sodium metasilicate, 2-4% of an antirust agent, 2-5% of amine carboxylate, 0.5-1.0% of methylbenzotriazole, 3-5% of DissolvineH-40, 4-6% of Gemini quaternary ammonium salt C12022811, 2-5% of a foam inhibitor, 5-8% of a polyether modified organosilicone defoaming agent and the balance water, wherein a preparation method of the polyether modified organosilicone defoaming agent comprises the steps that hydrogencontaining silicone oil is prepared; mixed liquid A is prepared; synthetic reaction is conducted; and viscous solid B, that is the polyether modified organosilicone defoaming agent, is obtained. According to the preparation method, the cleaning agent is low in foam height and good in cleaning effect.

Owner:WUHAN SPACEFLIGHT SCI & TECH PETROCHEM CO LTD

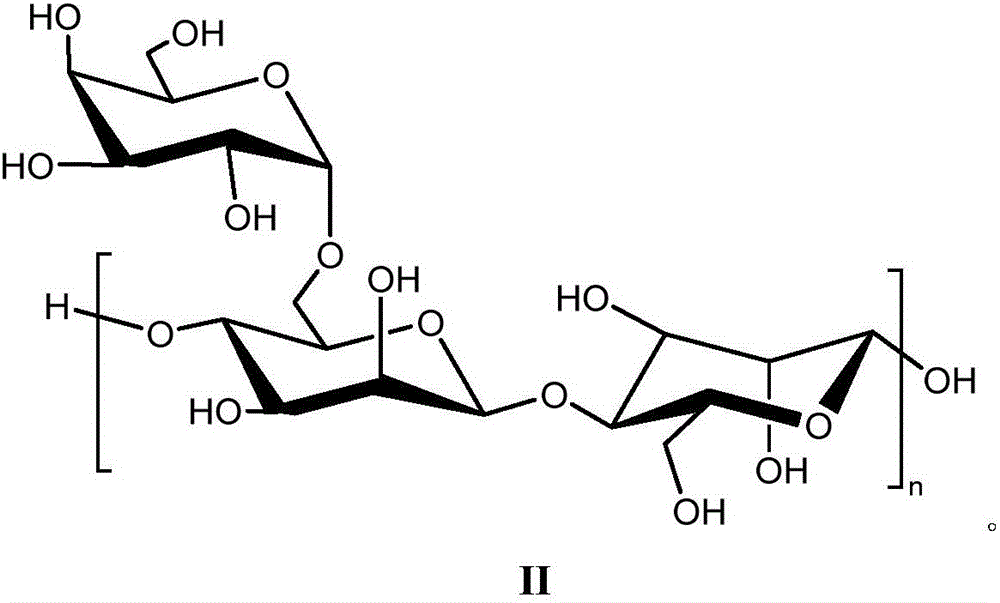

Polysaccharide hydrate dynamics inhibitor and application thereof

InactiveCN107522792AEnhanced inhibitory effectImprove performanceDrilling compositionEnvironmental resistanceHydrogen

The invention discloses a polysaccharide hydrate dynamics inhibitor and application thereof. The polysaccharide hydrate dynamics inhibitor is characterized in that the hydrogen of a mannose molecule on a galactomannan main chain is substituted by hydroxypropyl trimethylammonium chloride; the mass by using hydrate to generate raw water is used as the basis, and the concentration of the inhibitor is 0.2wt% to 3.5wt%. The polysaccharide hydrate dynamics inhibitor has the characteristics that the green and environment-friendly effects are realized, the usage amount is small, and the acid-resistant, salt-resistant, and heat-resistant properties are strong; the requirement of inhibiting the hydrate under multiple extreme conditions can be met, the preventing and control cost of the hydrate is greatly reduced, and the adverse effect to environment is decreased.

Owner:SOUTH CHINA UNIV OF TECH

Dyeing auxiliary and application thereof to dyeing assistance of disperse dyes

The invention discloses a dyeing auxiliary and an application thereof to dyeing assistance of disperse dyes. The dyeing auxiliary comprises following components in percentage by mass: 40%-68% of polyoxyethylene aliphatic alcohol ether, 2%-4% of polyoxyethylene stearate, 5%-8% of triethylene glycol monobutyl ether, 5%-12% of N-alkyl betaine, 6%-10% of polyamide-polyamine-epichlorohydrin and 3%-5% of chitosan. According to the dyeing auxiliary, polyoxyethylene aliphatic alcohol ether is taken as a main component, polyoxyethylene stearate is added to realize compounding synergistic interaction with polyoxyethylene aliphatic alcohol ether, and therefore, the solubilizing dyeing effect of the dyeing auxiliary is improved; the dyes are promoted to be more powerfully combined with fibers with addition of triethylene glycol monobutyl ether, cloud point of polyoxyethylene aliphatic alcohol ether is increased with addition of N-alkyl betaine, contact probability of the dyes and the fibers is increased with addition of polyamide-polyamine-epichlorohydrin, diffusion rate of the dyes in the fibers is increased with addition of chitosan, and dye uptake of the dyes is increased.

Owner:卢梅雅

Cleaning composition

InactiveCN104334702AHigh cloud pointEnhance cleaning effectNon-ionic surface-active compoundsOrganic detergent compounding agentsGlycosideFatty alcohol

A cleaning composition comprises A) a fatty alcohol-alkylene oxide copolymer, B) a glycoside, and C) a benzene sulfonate, wherein, the weight ratio of the component B and the component C is less than or equal to 5 : 1. The cleaning composition can be used as a detergent for cleaning medical appliances.

Owner:3M INNOVATIVE PROPERTIES CO

Oil-displacing composition, preparing method of oil-displacing composition and intensified oil production method

ActiveCN105368431AImprove temperature resistanceImprove interface performanceDrilling compositionArylMass ratio

The invention relates to an oil-displacing composition, a preparing method of the oil-displacing composition and an intensified oil production method to mainly solve the problem that the oil-displacing efficiency of an oil-displacing composition is poor in the prior art. The oil-displacing composition is prepared from, by mass, 1 part of surfactant, 0-50 parts of a polymer which accounts for larger than 0 part and 0-50 parts of alkaline matter which accounts for larger than 0 part, wherein the surfactant is a mixture formed by non-ionic surfactant shown in the formula (1) and anionic surfactant show in the formula (2) at the mass ratio of 1:(0.1-1), R1 and R2 are the same or different C4-C40 aliphatic groups, or the same or different aryl groups replaced by saturated or unsaturated alkyl with C4-C30 linear chains or branched chains, Z1 is -R01Y1, R01 is selected from C1-C5 alkylidene or alkylidene replaced by hydroxyl, and Y1 is selected from SO3M or COON. The problem is well solved through the technical scheme, and the oil-displacing composition can be used for an oil field and intensified oil production. The formula (1) and the formula (2) can be seen in the specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com