Expanding dyeing accelerant and preparation method thereof

A dyeing accelerator and puffing technology, which is applied in the dyeing process, textiles and papermaking, etc., can solve the problems of heavy smell of puffing agent, difficulty in cleaning completely, and peculiar smell of dyed fabrics, and achieve the effect of promoting dissolution and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

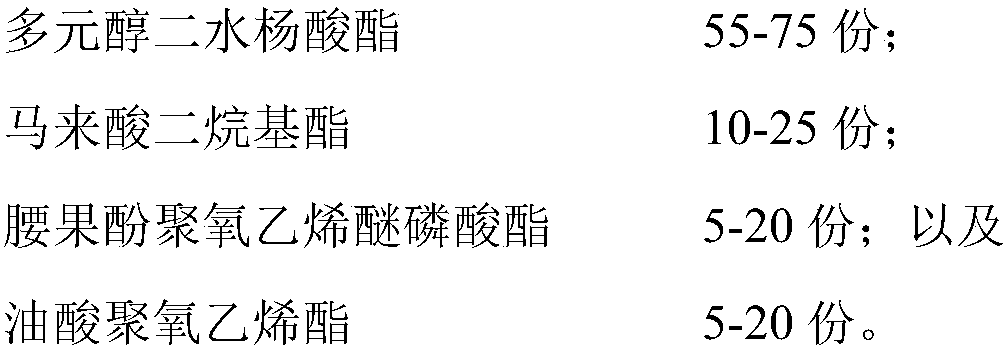

[0032] The swelling accelerator involved in this embodiment is specifically prepared from the following raw materials in parts by mass: 60 parts by mass of diethylene glycol disalicylate, 20 parts by mass of diisooctyl maleate, 5 parts by mass parts of cardanol polyoxyethylene ether phosphate and 15 parts by mass of polyoxyethylene oleate.

[0033] The preparation method of the described expanded dyeing accelerator involved in the present embodiment is carried out in the following steps:

[0034] A) by: the described diethylene glycol disalicylate of 60 mass parts and the described diisooctyl maleate of 20 mass parts fully mix, stir;

[0035] B) sequentially adding 5 parts by mass of the cardanol polyoxyethylene ether phosphate and 15 parts by mass of the polyoxyethylene oleate into the above mixed solution to obtain the swelling accelerator.

Embodiment 2

[0037] The swelling accelerator involved in this embodiment is specifically prepared from the following raw materials by mass: 65 parts by mass of triethylene glycol disalicylate, 15 parts by mass of dioctyl maleate, 10 parts by mass of cardanol polyoxyethylene ether phosphate and 10 parts by mass of polyoxyethylene oleate.

[0038] The preparation method of the described expanded dyeing accelerator involved in the present embodiment is carried out in the following steps:

[0039] A) fully mix the described triethylene glycol disalicylate of 65 mass parts with the described dioctyl maleate of 15 mass parts, stir;

[0040] B) Adding 10 parts by mass of the cardanol polyoxyethylene ether phosphate and 10 parts by mass of the polyoxyethylene oleate in sequence to the above mixed solution to obtain the swelling accelerator.

Embodiment 3

[0042] The puffing dyeing accelerator involved in this embodiment is specifically prepared from the following raw materials in parts by mass: 70 parts by mass of dipropylene glycol disalicylate, 10 parts by mass of diethyl maleate, 15 parts by mass of cashew nuts Phenol polyoxyethylene ether phosphate and 5 parts by mass of polyoxyethylene oleate.

[0043] The preparation method of the described expanded dyeing accelerator involved in the present embodiment is realized in the following steps:

[0044] A) the described dipropylene glycol disalicylate of 70 mass parts is fully mixed with the described diethyl maleate ester of 10 mass parts, stir;

[0045] B) sequentially adding 15 parts by mass of the cardanol polyoxyethylene ether phosphate and 5 parts by mass of the polyoxyethylene oleate to the above mixed solution to obtain the swelling accelerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com