Disperse dye dyeing defect preventing agent and preparation method thereof

A technology of disperse dyes and preventive agents, which is applied in the field of polyester high-temperature and high-pressure disperse dyeing and color flower preventers. It can solve the problems of greater influence of shade in polyester dyeing and insufficient dyeing performance, and achieve uniform dyeing and improve solubility. and the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

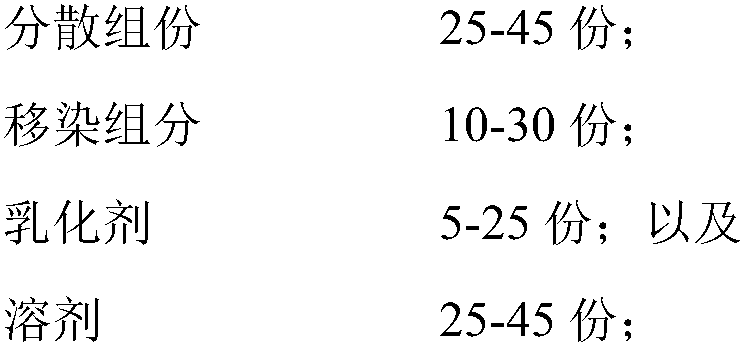

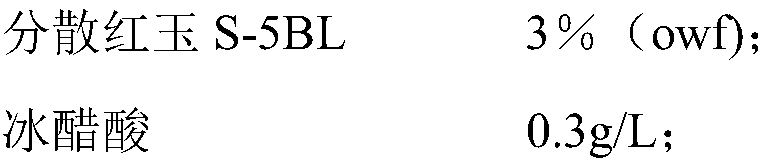

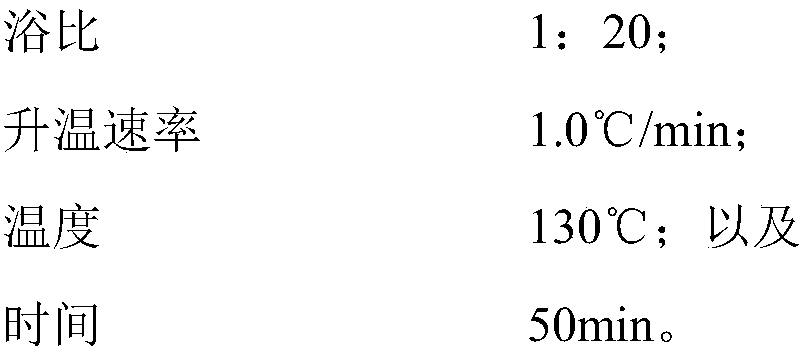

Method used

Image

Examples

Embodiment 1

[0030] The disperse dye color flower preventer involved in this embodiment is specifically prepared from the following raw materials in parts by mass: 30 parts by mass of polyoxyethylene oleate, 25 parts by mass of benzyl cinnamate, 5 parts by mass of Isomerized lauryl alcohol polyoxyethylene ether and 40 parts by mass of ethanol.

[0031] The preparation method of the described disperse dye color flower preventing agent involved in the present embodiment is carried out in the following steps:

[0032] A) fully mix the described polyoxyethylene oleate of 30 mass parts and the described benzyl cinnamate of 25 mass parts, stir;

[0033] B) Add 5 parts by mass of the isomeric lauryl alcohol polyoxyethylene ether and 40 parts by mass of ethanol in sequence to the above mixed solution to obtain the disperse dye color flower preventive agent involved in this embodiment .

Embodiment 2

[0035] The described disperse dye color flower preventing agent involved in the present embodiment is specifically prepared from the following raw materials by mass: 33 mass parts of coconut oil polyoxyethylene ester, 20 mass parts of benzyl salicylate, 10 mass parts Tween-80 and 37 parts by mass of isopropanol.

[0036] The preparation method of the described disperse dye color flower preventing agent involved in the present embodiment is carried out in the following steps:

[0037] A) fully mix the described coconut oil polyoxyethylene ester of 33 mass parts and the described benzyl salicylate of 20 mass parts, stir;

[0038] B) Adding 10 parts by mass of the Tween-80 and 37 parts by mass of the isopropanol in sequence to the above mixed solution to obtain the disperse dye color flower preventive agent involved in this embodiment.

Embodiment 3

[0040] The disperse dye color flower preventer involved in this embodiment is specifically prepared from the following raw materials in parts by mass: 36 parts by mass of castor oil polyoxyethylene ether, 15 parts by mass of benzyl diethylene glycol disalicylate ester, 15 parts by mass of sulfonated agricultural milk 600# and 34 parts by mass of diethylene glycol.

[0041] The preparation method of the described disperse dye color flower preventing agent involved in the present embodiment is carried out in the following steps:

[0042] A) the described castor oil polyoxyethylene ether of 36 mass parts and the described benzyl diethylene glycol disalicylate of 15 mass parts are fully mixed, stir;

[0043] B) Adding 15 parts by mass of the sulfonated agricultural milk 600# and 34 parts by mass of the diethylene glycol in sequence to the above mixed solution, the disperse dye color flower preventive agent involved in this embodiment can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com