Antibacterial glass cleaning agent as well as preparation method and application thereof

An antibacterial glass and cleaning agent technology, applied in cleaning methods, preparation of detergent mixture compositions, detergent compositions, etc., can solve problems such as low production efficiency, endangering workers' health, and strong odor, and achieve excellent performance and improved Decontamination ability, effect of increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

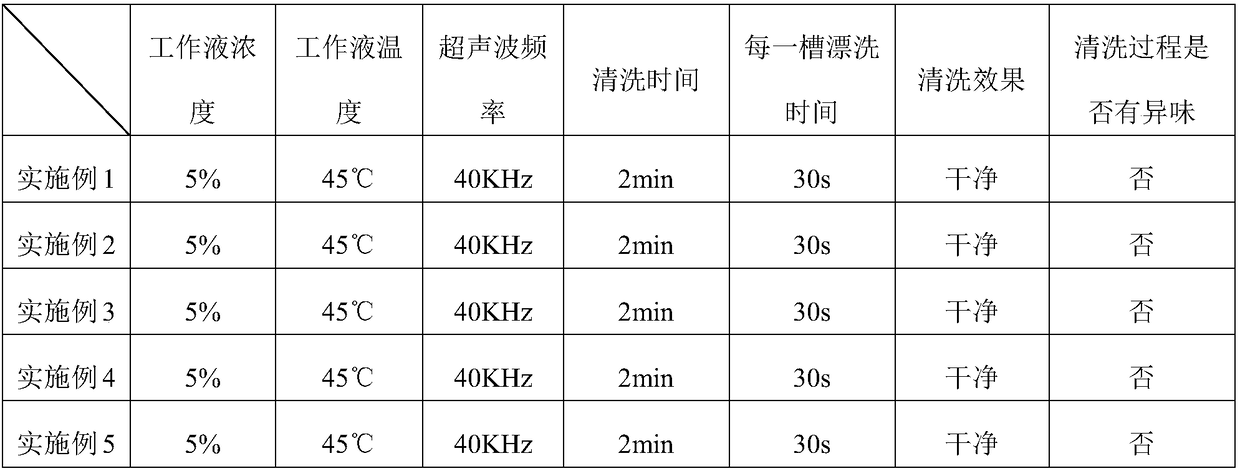

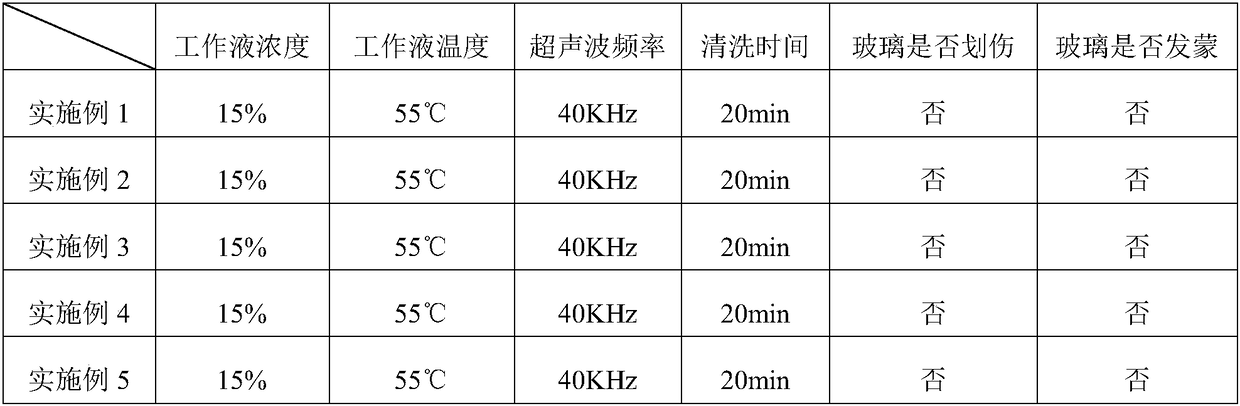

Examples

Embodiment 1

[0026] A kind of antibacterial glass cleaning agent, by weight percentage, comprises following component:

[0027] 3 parts sodium citrate, 4 parts sodium gluconate, 2 parts triethanolamine, 3 parts sodium molybdate, 3 parts sodium phosphate, 4 parts isopropanol, 4 parts ethylene glycol monomethyl ether, 3 parts dodecylbenzene Sodium sulfonate, 2 parts of n-nonyl alcohol polyoxyethylene (6) ether, 1 part of coconut oil fatty acid diethanolamide, 0.5 part of polydimethylsiloxane and 70.5 parts of deionized water.

[0028] The cleaning agent in the present embodiment is made by the following method: first 70.5 parts of water are added to the container, then 3 parts of sodium citrate are added successively, 4 parts of sodium gluconate, 2 parts of triethanolamine, 3 parts of sodium molybdate, 3 parts sodium phosphate, 4 parts isopropyl alcohol, 4 parts ethylene glycol monomethyl ether, 3 parts sodium dodecylbenzene sulfonate, 2 parts n-nonyl alcohol polyoxyethylene (6) ether, 1 par...

Embodiment 2

[0030] A kind of antibacterial glass cleaning agent, by weight percentage, comprises following component:

[0031] 2 parts of disodium edetate, 3 parts of potassium sodium tartrate, 2 parts of monoethanolamine, 3 parts of sodium molybdate, 2 parts of sodium tripolyphosphate, 5 parts of isopropanol, 5 parts of diethylene glycol monoethyl ether, 4 parts Part 2-octyl alcohol ethoxylate, 2 parts ten-polyethylene glycol dilaurate, 1 part fatty alcohol polyoxyethylene ether sodium sulfate, 0.5 part polydimethylsiloxane, 0.2 part ethylene glycol siloxane alkane and 70.3 parts of deionized water.

[0032] The cleaning agent in this embodiment is prepared by the following method: first, 70.3 parts of water are added to the container, and then 2 parts of disodium edetate, 3 parts of potassium sodium tartrate, 2 parts of monoethanolamine, 3 parts of Sodium molybdate, 2 parts of sodium tripolyphosphate, 5 parts of isopropanol, 5 parts of diethylene glycol monoethyl ether, 4 parts of 2-oc...

Embodiment 3

[0034] A kind of antibacterial glass cleaning agent, by weight percentage, comprises following component:

[0035] 4 parts of potassium sodium tartrate, 4 parts of sodium citrate, 2 parts of monoethanolamine, 2 parts of sodium metasilicate pentahydrate, 1 part of sodium phosphate, 5 parts of heptanediol, 7 parts of diethylene glycol monoethyl ether, 4 parts of octyl Alcohol polyoxyethylene ether, 4 parts of coconut oil fatty acid diethanolamide, 2 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 1 part of ethylene glycol siloxane and 64 parts of deionized water.

[0036] The cleaning agent in this embodiment is prepared by the following method: first, 64 parts of water are added to the container, and then 4 parts of potassium sodium tartrate, 4 parts of sodium citrate, 2 parts of monoethanolamine, and 2 parts of silicon metasilicate pentahydrate are added successively sodium phosphate, 1 part of sodium phosphate, 5 parts of heptanediol, 7 parts of diethylene glycol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com