Method for preparing modified magnesium hydroxide flame retardant

A technology of magnesium hydroxide and flame retardant, which is applied in the treatment of dyed low-molecular organic compounds, dyed high-molecular organic compounds, and fibrous fillers. It can solve the problems of poor dispersion and compatibility, large particle size distribution, and product The problem of uneven quality can achieve the effect of good compatibility, low equipment requirements and good particle size dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, a kind of preparation method of modified magnesium hydroxide flame retardant, this preparation method comprises the following steps:

[0038] (1) Use alkanolamide polyoxyethylene ether and sodium didodecylphenyl ether disulfonate as the main emulsifiers to prepare a composite emulsifier with an HLB value of 15;

[0039] (2) Dissolve 5g sodium lauryl sulfate and 8g triethanolamine in 61kg water to make a transparent solution;

[0040] (3) Add 86kg of oxidized polyethylene wax to the reactor, then add 32kg of compound emulsifier with an HLB value of 15, add 6kg of emulsifying aid, and then heat the reactor to 105°C to emulsify the oxidized polyethylene wax;

[0041] (4) After the oxidized polyethylene wax in (3) is melted, slowly add 61kg of a mixed aqueous solution of sodium lauryl sulfate and triethanolamine heated to 85°C, then seal it, and first stir at a speed of 75 rpm for 23 minutes , then stirred for 47 minutes at a speed of 186 rpm;

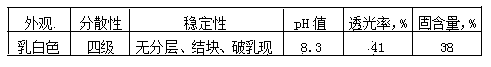

[0042] (5) S...

Embodiment 2

[0051] Example 2 , a preparation method of a modified magnesium hydroxide flame retardant, the preparation method comprising the following steps:

[0052] (1) Use fatty alcohol polyoxyethylene ether and sodium lauryl sulfate as the main emulsifiers to prepare a composite emulsifier with an HLB value of 11;

[0053] (2) Dissolve 15g sodium lauryl sulfate and 18g triethanolamine in 185kg water to make a transparent solution;

[0054] (3) Add 212kg of oxidized polyethylene wax to the reactor, then add 59kg of compound emulsifier with an HLB value of 11, add 13kg of emulsifying aid, and then heat the reactor to 123°C to emulsify the oxidized polyethylene wax;

[0055] (4) After the oxidized polyethylene wax in (3) is melted, slowly add 185 kg of a mixed aqueous solution of sodium lauryl sulfate and triethanolamine heated to 84 ° C, then seal it, and first stir at a speed of 79 rpm for 26 minutes , then stirred for 39 minutes at a speed of 265 rpm;

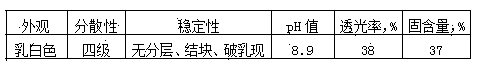

[0056] (5) Stop heating, nat...

Embodiment 3

[0065] Example 3 , a preparation method of a modified magnesium hydroxide flame retardant, the preparation method comprising the following steps:

[0066] (1) Use alkylphenol polyoxyethylene ether and sodium p-methoxy fatty amidobenzenesulfonate as the main emulsifiers to prepare a composite emulsifier with an HLB value of 16;

[0067] (2) Dissolve 15g sodium lauryl sulfate and 20g triethanolamine in 200kg water to make a transparent solution;

[0068] (3) Add 300kg of oxidized polyethylene wax to the reactor, then add 60kg of compound emulsifier with an HLB value of 16, add 20kg of emulsifying aid, and then heat the reactor to 119°C to emulsify the oxidized polyethylene wax;

[0069] (4) After the oxidized polyethylene wax in (3) is melted, slowly add 200kg of a mixed aqueous solution of sodium lauryl sulfate and triethanolamine heated to 86°C, then seal it, and first stir at a speed of 81 rpm for 26 minutes , then stirred for 44 minutes at a speed of 265 rpm;

[0070] (5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com