Patents

Literature

30results about How to "Good particle size dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

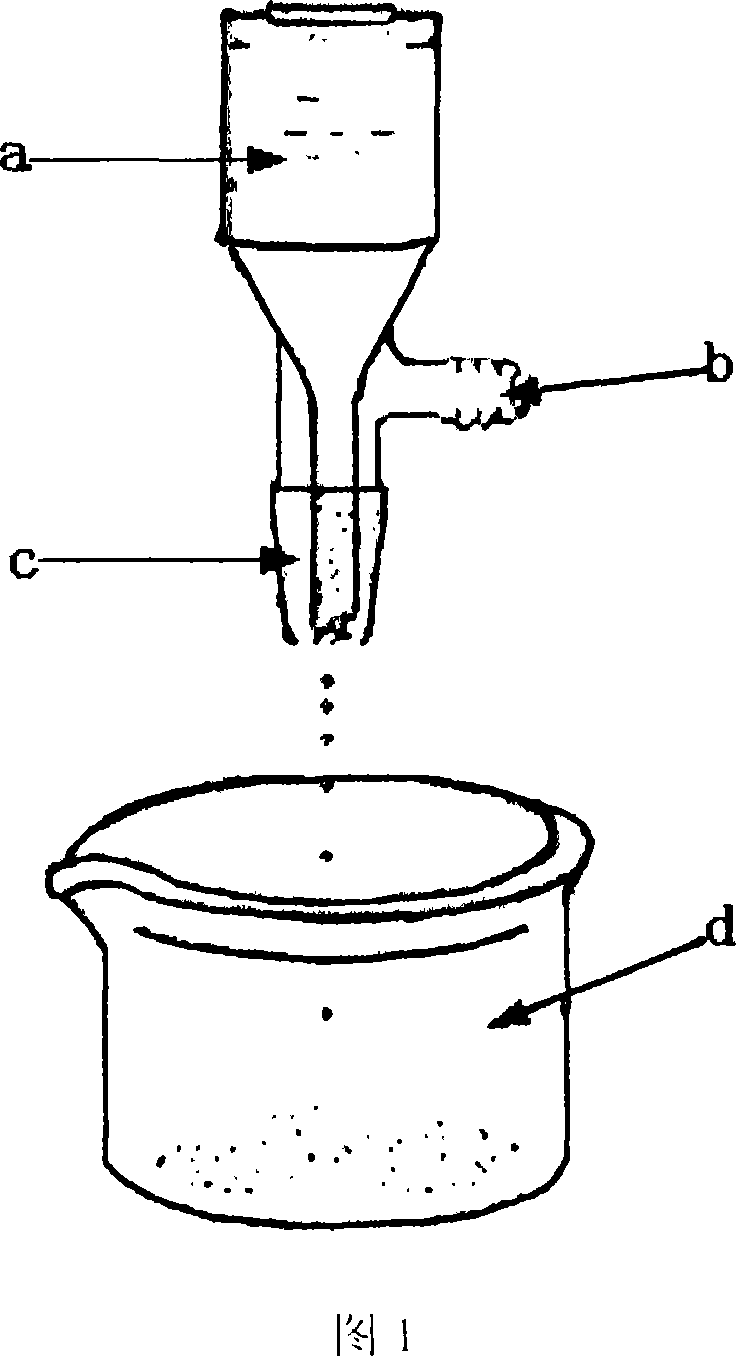

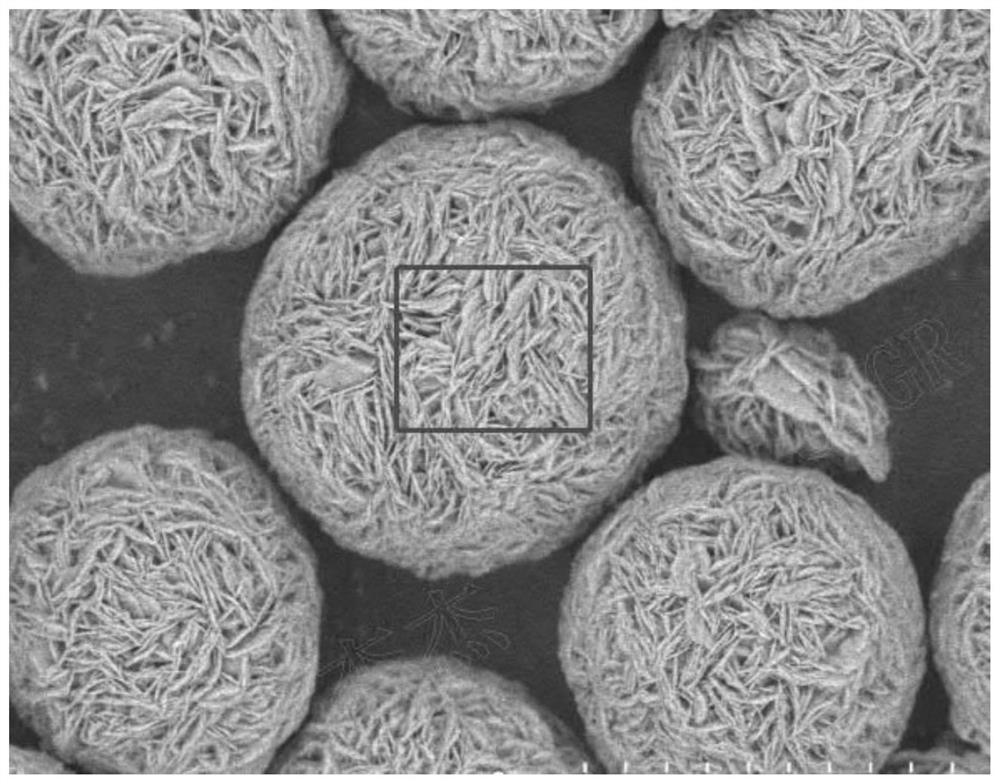

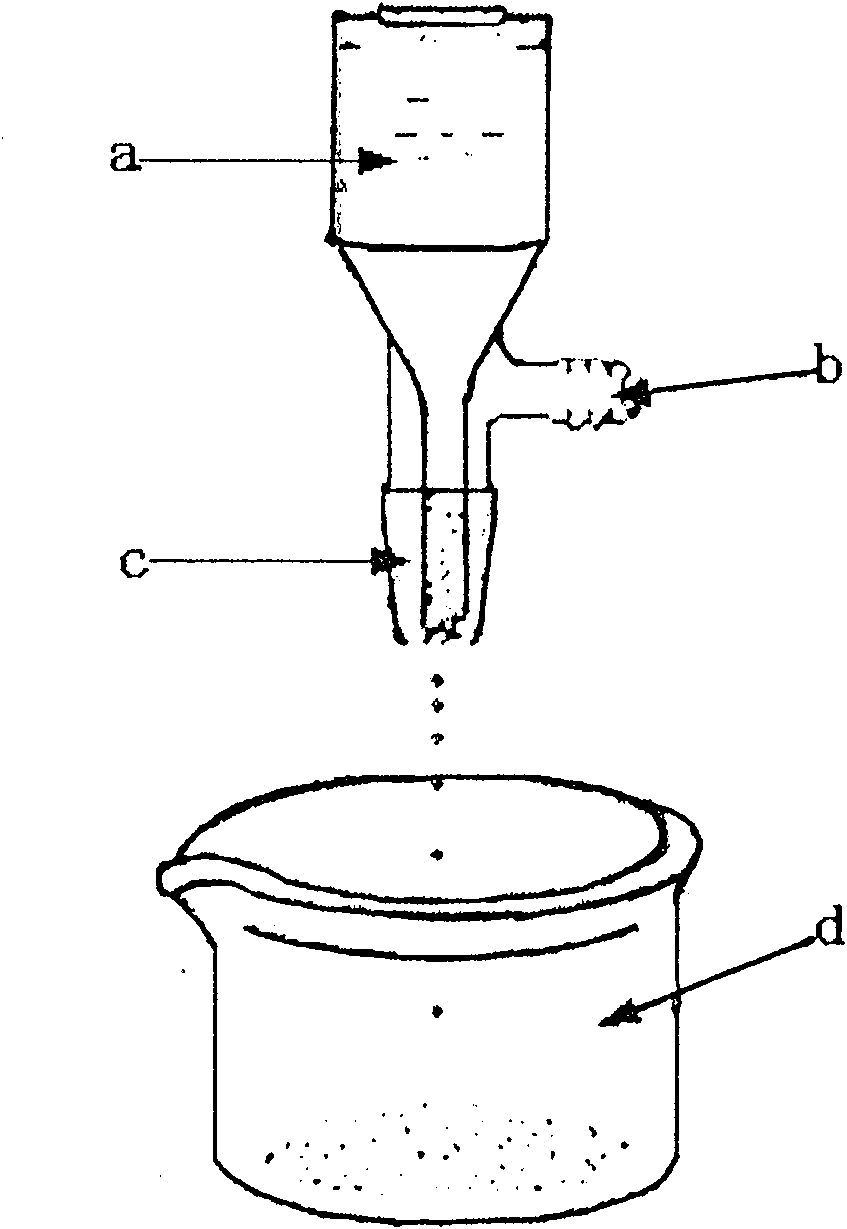

Freeze forming prepn process of ternary lithium ceramic microphere

The freeze forming preparation process of ternary lithium ceramic microsphere includes the following steps: mixing the material for ternary lithium ceramic microsphere, high molecular adhesive and solvent, mixing in a ball mill to form suspension slurry and defoaming; dropping the slurry into cooling medium to form microsphere in a microsphere forming unit, and low temperature vacuum drying in a freezing drier to form ceramic microsphere precursor; roasting, calcining and sintering; and programmed heat treatment to obtain ternary lithium ceramic microsphere. The ternary lithium ceramic microsphere has high sphericity, controllable size, high size dispersivity, high apparent density, high phase purity, high strength and other features.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Ternary-system chip negative temperature coefficient thermal resistor

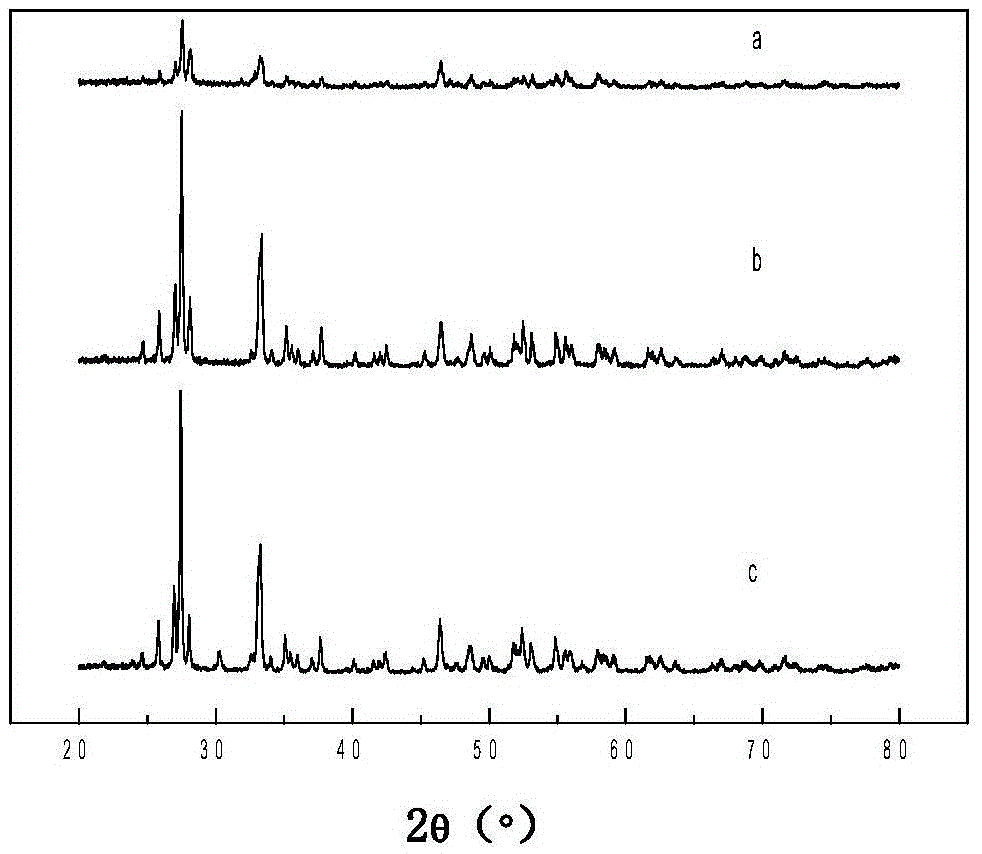

InactiveCN101719404ALow costImprove yieldNegative temperature coefficient thermistorsEpoxyReaction temperature

The invention relates to a ternary-system chip negative temperature coefficient thermal resistor, which uses manganese nitrate, nickel nitrate and cobalt nitrate as raw materials and ammonium bicarbonate as precipitator, is prepared by a liquid-phase co-precipitation method, and comprises the following steps: improving the agglomeration phenomenon of the precipitated particles by controlling the molar ratio of nitrate to precipitator ammonium bicarbonate, the reaction temperature and the pH value, washing out the impurities in the product by modes of water washing and alcohol washing to obtain superfine and uniform thermal resistor powder, drying, calcining to obtain evenly dispersed mixed oxide powder of Mn, Ni and Co, briquetting and moulding the powder, isopressing, sintering under high temperature, slicing by a semiconductor to obtain a thermal resistor chip, and encapsulating with epoxy resin to obtain the ternary-system chip negative temperature coefficient thermal resistor with high performance which has the characteristics of good uniformity, high stability, capability of repeatability and interconversion, and is suitable for temperature measurement, control and line compensation in the household appliance field such as refrigerators, air conditioners and the like.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

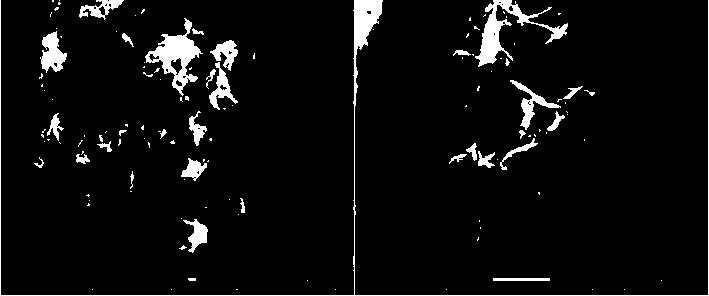

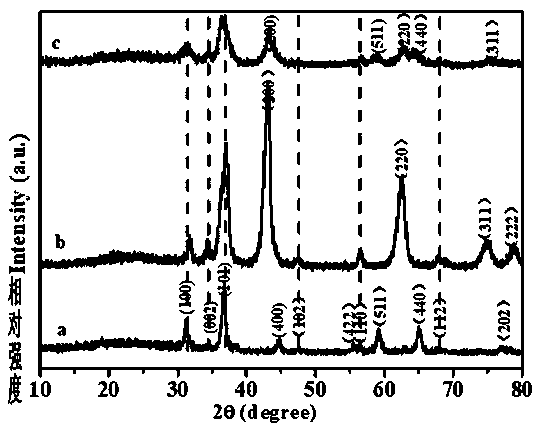

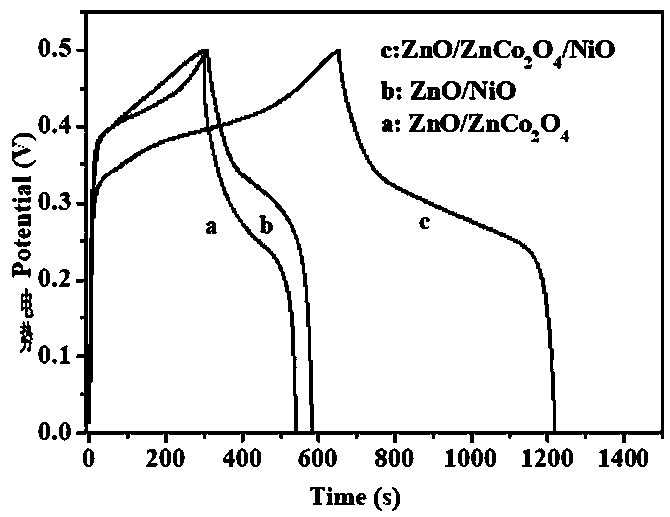

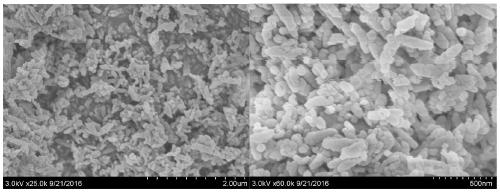

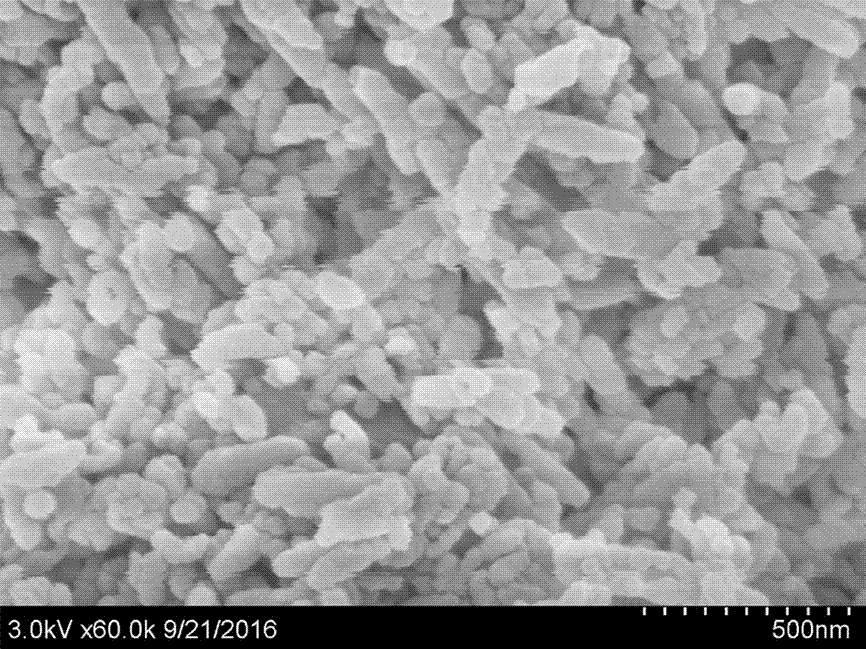

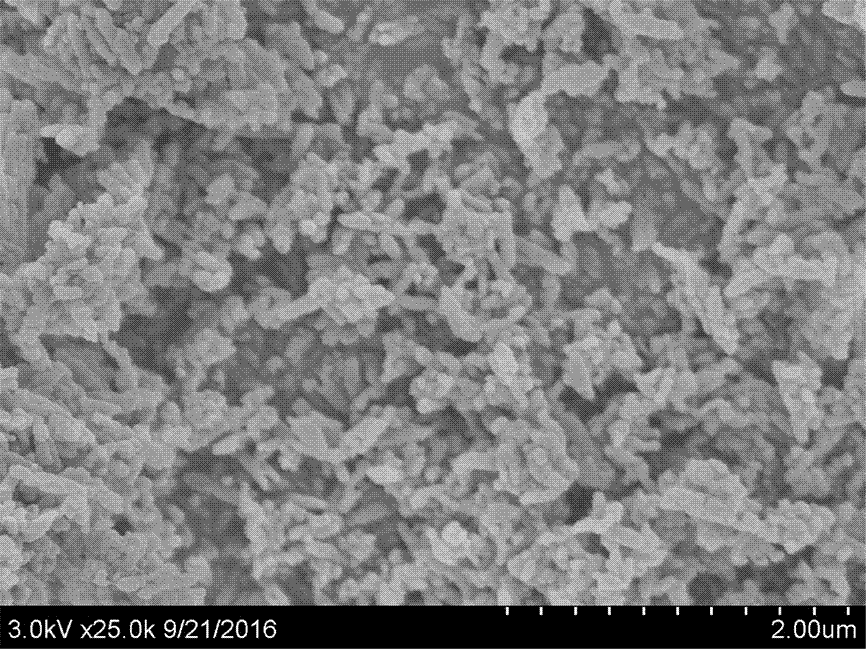

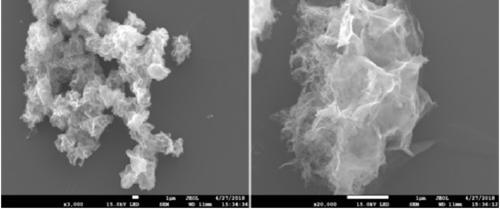

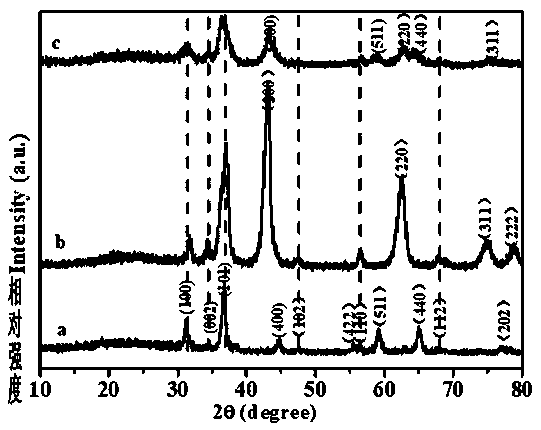

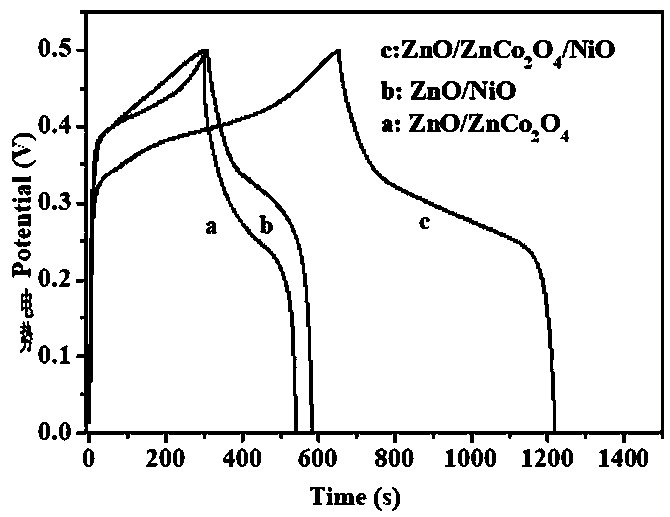

Method for synthesizing ZIF-8-based ternary composite ZnO/ZnCo2O4/NiO by solvothermal process and application of method

ActiveCN108806998AUniform particle distributionGood particle size dispersionHybrid capacitor electrodesSolventChemistry

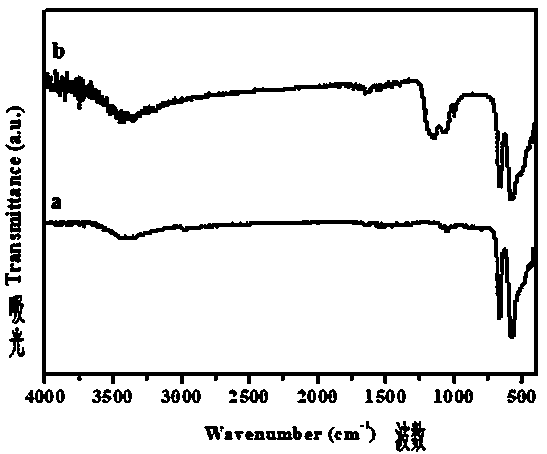

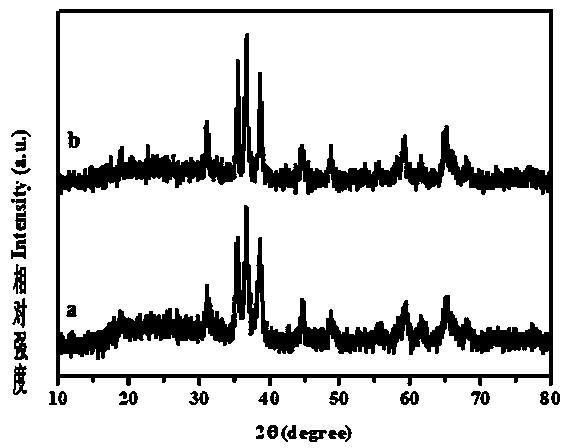

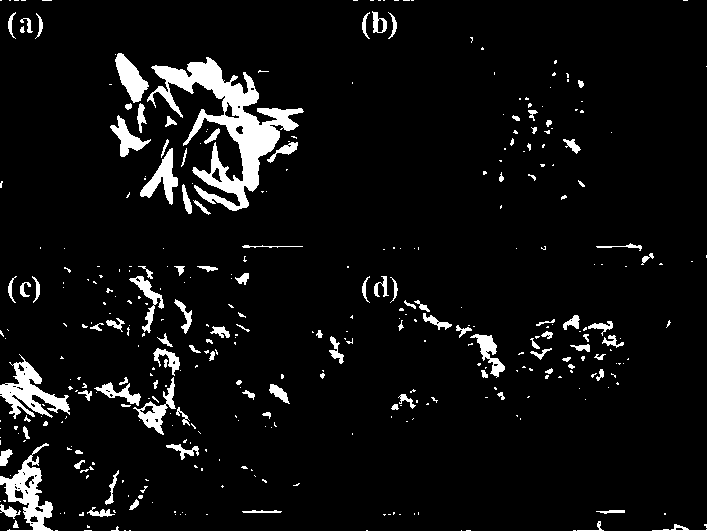

The invention belongs to the technical field of metal organic framework materials, and relates to a method for preparing a ternary composite material by using zeolitic imidazolate frameworks as a template, in particular to a method for synthesizing a ZIF-8-based ternary composite ZnO / ZnCo2O4 / NiO by a solvothermal process and application of the method. The method disclosed by the invention comprises: dispersing per 290 mg of ZIF-8 polyhedron in 30-90 mL of ethanol containing 0.6-1.4 mmol of nickel nitrate, 0.6-1.4 mmol of cobalt nitrate and 421 mg of hexamethylenetetramine, stirring and mixinguniformly, transferring to a reaction kettle, heating at 100 DEG C to 120 DEG C for 2-4 h, cooling to room temperature, collecting by centrifugation and drying at 60 DEG C to 80 DEG C for 12-24 h to obtain a precursor, and annealing the precursor in the air at 300-350 DEG C by rate of 2 DEG C.min<-1> for 2-3 h, so the ternary composite ZnO / ZnCo2O4 / NiO is obtained. The prepared ZIF-8-based ternarycomposite ZnO / ZnCo2O4 / NiO has uniform particle distribution and good particle size dispersion, and has excellent electrochemical performance and good cycling stability when being used as an electrodematerial of a supercapacitor. The method has the advantages of simple process, low preparation cost and less pollution, and is suitable for industrial production.

Owner:JIANGSU UNIV

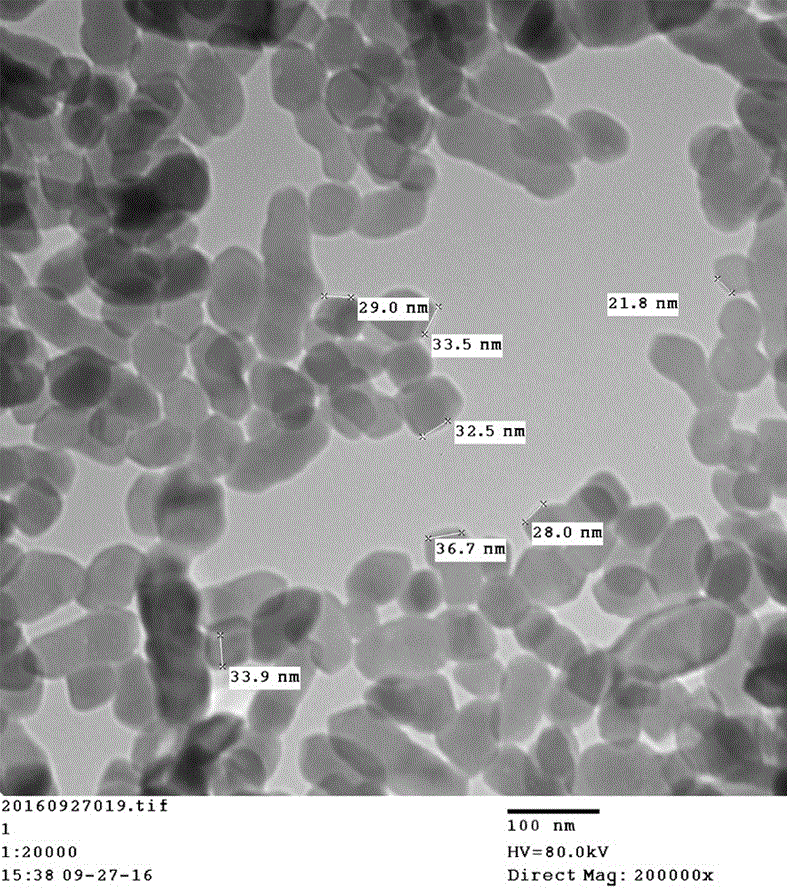

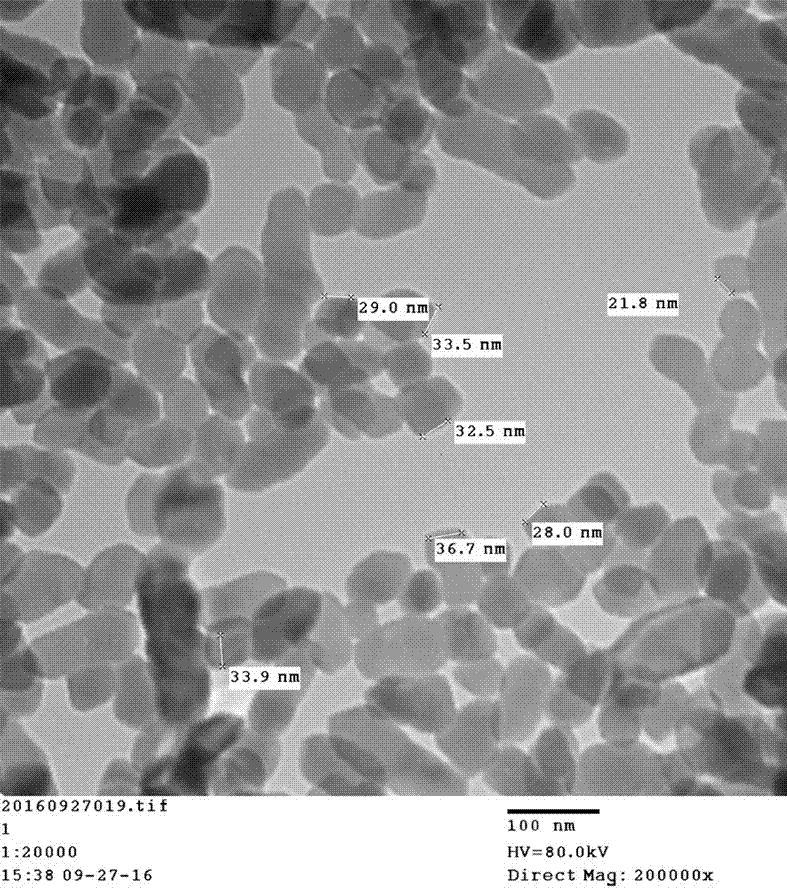

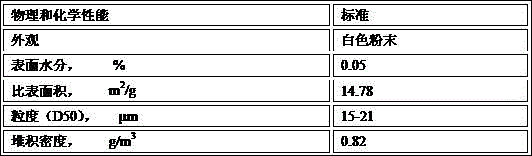

Preparation process of nano calcium carbonate

ActiveCN106542557AHigh purityGood particle size dispersionCalcium/strontium/barium carbonatesNanotechnologyThree stageCarbonization

The invention discloses a preparation process of nano calcium carbonate. High-activity quicklime and high purity carbon dioxide are adopted as the raw materials, and a three-stage carbonization tower is taken as the reaction equipment to carry out reaction for preparation of nano calcium carbonate. The high-activity quicklime has an activity degree of 360-380; the purity of the high purity carbon dioxide is greater than or equal to 99%; and the three-stage carbonization tower is formed by series connection of a first stage carbonization tower, a second stage carbonization tower and a third stage carbonization tower of different capacities in order, the effective reaction volume ratio of the first stage carbonization tower, the second stage carbonization tower and the third stage carbonization tower is 1:4:16, and the introduction amount per hour of the high purity carbon dioxide in each carbonization tower and the effective reaction volume of the carbonization tower are in a ratio of 2-3:0.08. The nano calcium carbonate prepared by the method provided by the invention has the advantages of good particle size dispersion and uniform size distribution in the range of 20-30nm, regular morphology and high purity, etc. Also, the preparation process provided by the invention greatly shortens the carbonization reaction time, has high production efficiency, also improves the utilization of the reaction equipment, and is suitable for popularization and application in industrial production.

Owner:李岳

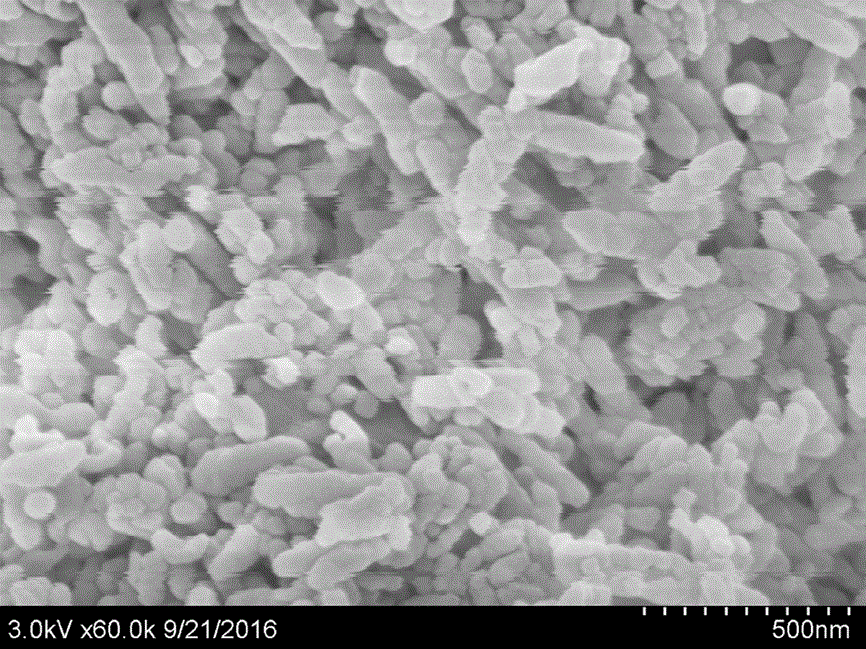

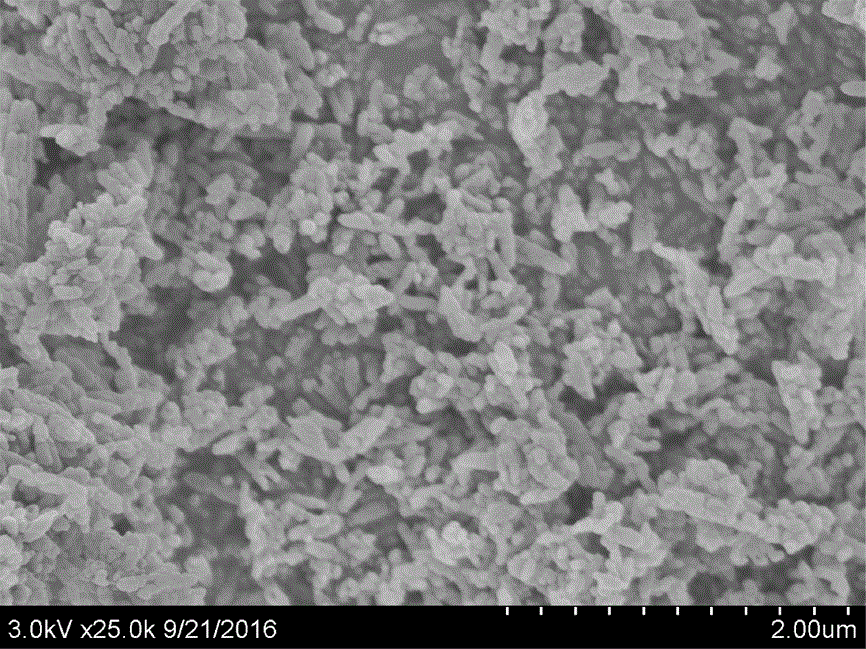

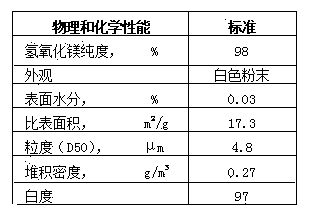

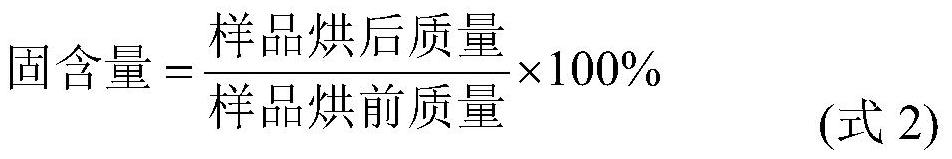

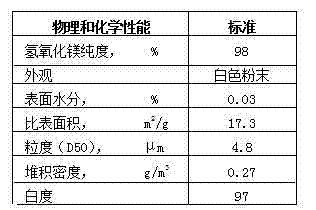

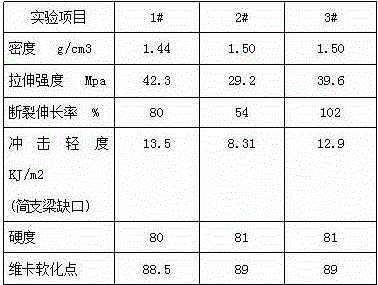

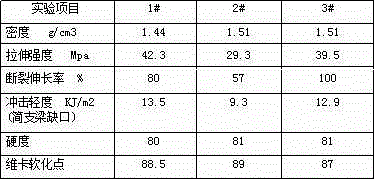

Method for preparing modified magnesium hydroxide flame retardant

ActiveCN103965656AGood compatibilitySimple processPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsEmulsionActive agent

The invention discloses a method for preparing a modified magnesium hydroxide flame retardant. The method comprises the following steps: preparing a compound emulsifier; dissolving sodium lauryl sulfate and triethanolamine in water to prepare a transparent solution, adding the compound emulsifier and an auxiliary emulsifier in oxidized polyethlene wax, adding the transparent solution after the oxidized polyethlene wax is melted, and agitating to obtain an emulsion; adding an ammonia water solution into the emulsion to obtain an organic modified emulsion; adding an anionic surfactant water solution into magnesium hydroxide, and agitating to obtain powder; drying to obtain magnesium hydroxide powder; adding the organic modified emulsion into the magnesium hydroxide powder, adding a dispersant, cooling to a room temperature, and obtaining magnesium hydroxide modified by the organic emulsion. The modified magnesium hydroxide flame retardant has great dispersibility and great compatibility with organic substances, can be uniformly dispersed in a base material, and cannot cause agglomeration. After the modified magnesium hydroxide flame retardant is added to an organic material, the mechanical property losses of the material can be effectively reduced. The method has the advantages of simple preparing technology, easiness in operation, strong controllability and simple equipment. As no pollution is caused in the whole technical process, energy-saving and environment-friendly requirements are met.

Owner:山东大耀特种材料有限公司

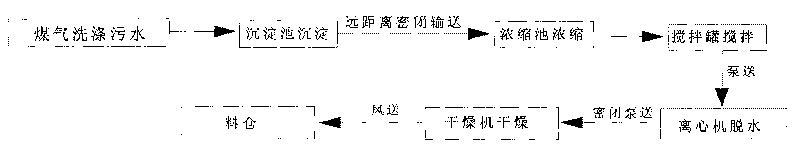

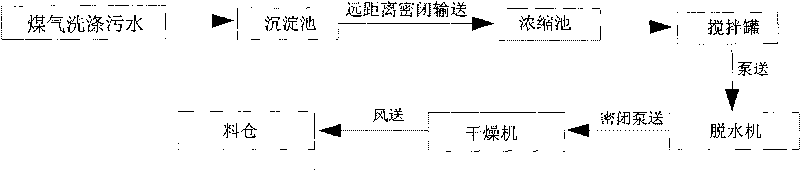

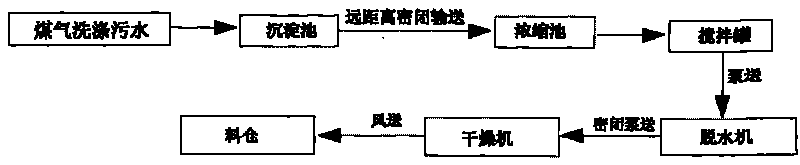

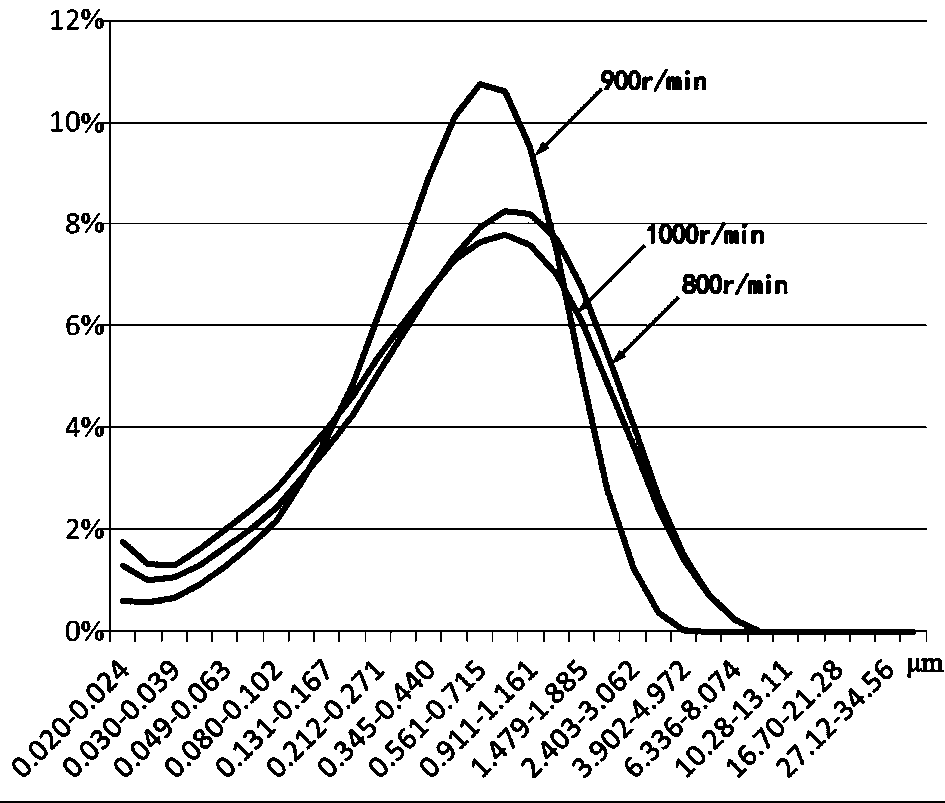

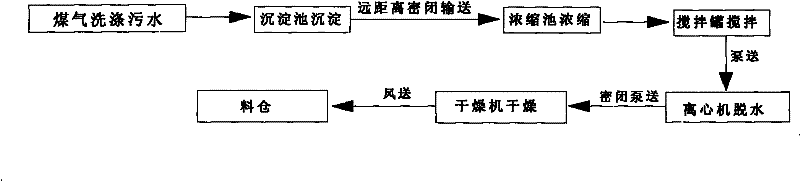

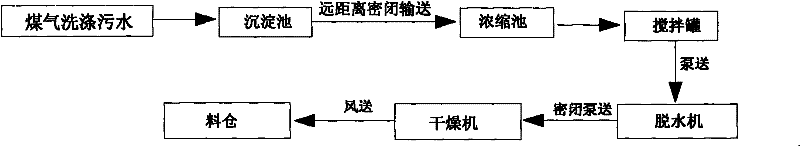

Dehydration and drying method and device of metallurgical slurry with no pollution

ActiveCN101700955AAvoid secondary pollutionGood particle size dispersionSludge treatment by de-watering/drying/thickeningMetallurgySludge

The invention provides a dehydration and drying method of metallurgical slurry with no pollution, which is characterized by comprising the following steps: conveying the metallurgical slurry into a sedimentation tank until the solid content is 5%-15%; then conveying to a concentration tank through the pipeline in an airtight manner and concentrating until the solid concentration is 20%-40%; pumping into a stirring pot for stirring and pumping into a dehydrator for dehydrating into sludge paste with the solid concentration being 75%-80%; pumping into a dryer and drying into sludge powder with the water content being less than or equal to 6%; and pneumatically conveying to a feed bin. The invention also provides a device for realizing the dehydration and drying method of metallurgical slurry with no pollution, and in the device, the sedimentation tank, the concentration tank, the stirring pot, the dehydrator, the dryer and the feed bin are connected by the pipeline in sequence; the slurry is conveyed to the concentration tank, the stirring pot, the dehydrator and the dryer in sequence from the sedimentation tank by taking a slurry pump as motive power, and the dried sludge powder is pneumatically conveyed to the feed bin. The invention can avoid the secondary pollution of the solid wastes, the dried sludge powder does not agglomerate and the granularity has good dispersity.

Owner:MAANSHAN IRON & STEEL CO LTD

Preparation process of spindle-shaped nano calcium carbonate

ActiveCN107792872AHigh purityGood particle size dispersionCalcium/strontium/barium carbonatesProductsDispersityCarbonization

The invention discloses a preparation process of spindle-shaped nano calcium carbonate. High-activity quicklime and carbon dioxide are used as raw materials, and a two-stage carbonization tower is used as reaction equipment for reaction preparation; and the two-stage carbonization tower is formed by serially connecting a primary carbonization tower with a secondary carbonization tower, the effective reaction volume ratio of the primary carbonization tower to the secondary carbonization tower is 1: 4, and the effective reaction volume ratio of the feeding amount of carbon dioxide in every carbonization tower per hour to the carbonization tower is 3-5 L / min: 0.8 L. The spindle-shaped nano calcium carbonate prepared by the method has the advantages of good particle dispersity, uniform size, draw ratio being 200: 40 nm, regular shape, high purity, good dispersion effect and the like. Moreover, the carbonization reaction time of the provided preparation process is greatly shortened, the production efficiency is high, meanwhile, the utilization rate of the reaction equipment is increased, and thus, the preparation process is suitable for being popularized and used in industrial production.

Owner:李岳

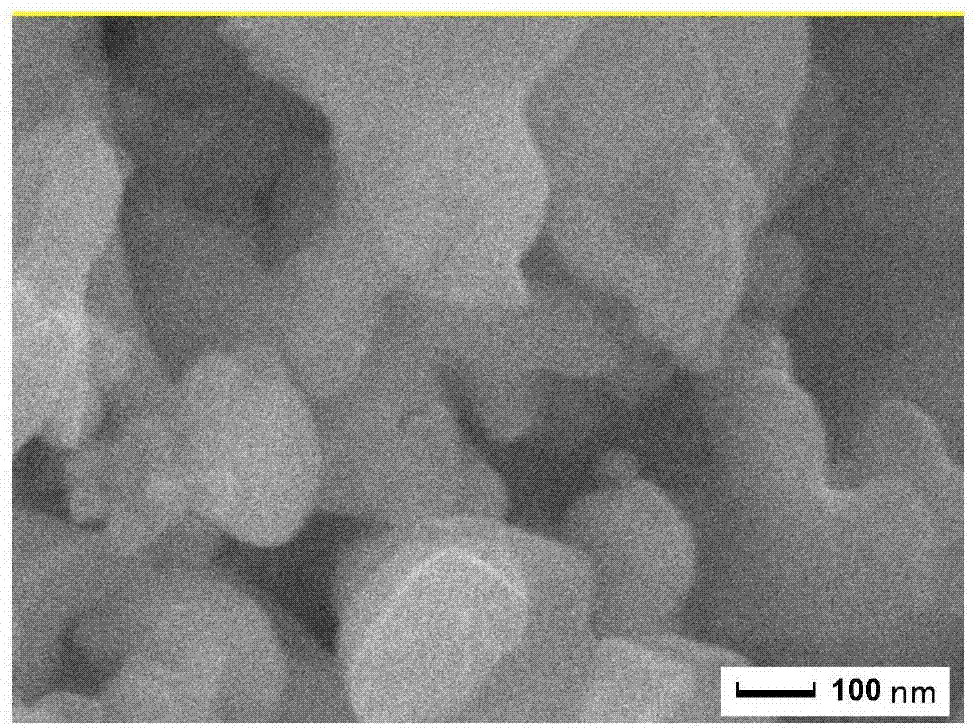

Preparation of copper cobalt oxide composite electrode material by solvothermal method and application thereof

InactiveCN109103027AHigh purityGood crystal formHybrid capacitor electrodesHybrid/EDL manufactureSolventMaterials science

The invention belongs to the technical field of nanometer material preparation, and relates to a preparation of copper cobalt oxide composite electrode material by a solvothermal method and application thereof. The method comprises the steps of: using urea as precipitant, and copper salt, cobalt salt, sodium lignosulfonate as raw material, wherein the above copper salt, cobalt salt, sodium lignosulfonate and deionized water or absolute ethanol have a volume ratio of 1-4 mmol: 2-9 mmol: 2-12 mmol: 0-0.4 g: 50-85 mL; performing thermoprecipitation via a solvent; adjusting the content of a precipitator and the copper salt, cobalt salt, sodium lignosulfonate and other variable; performing calcinating, drying and calcinating to obtiain the copper cobalt oxide composite electrode material. The method of the invention has the advantages of low cost, simple operation, uniform particle distribution of the prepared product, high particle performance, relatively stable dispersion system, good particle size dispersion and good morphology. The prepared copper cobalt oxide nanocomposite electrode material is fixed on the nickel foam substrate by binder and applied to the supercapacitor, which has excellent electrochemical performance and is suitable for industrial production.

Owner:JIANGSU UNIV

A kind of preparation technology of spindle-shaped nano-calcium carbonate

ActiveCN107792872BHigh purityGood particle size dispersionCalcium/strontium/barium carbonatesProductsDispersityCarbonization

The invention discloses a preparation process of spindle-shaped nano calcium carbonate. High-activity quicklime and carbon dioxide are used as raw materials, and a two-stage carbonization tower is used as reaction equipment for reaction preparation; and the two-stage carbonization tower is formed by serially connecting a primary carbonization tower with a secondary carbonization tower, the effective reaction volume ratio of the primary carbonization tower to the secondary carbonization tower is 1: 4, and the effective reaction volume ratio of the feeding amount of carbon dioxide in every carbonization tower per hour to the carbonization tower is 3-5 L / min: 0.8 L. The spindle-shaped nano calcium carbonate prepared by the method has the advantages of good particle dispersity, uniform size, draw ratio being 200: 40 nm, regular shape, high purity, good dispersion effect and the like. Moreover, the carbonization reaction time of the provided preparation process is greatly shortened, the production efficiency is high, meanwhile, the utilization rate of the reaction equipment is increased, and thus, the preparation process is suitable for being popularized and used in industrial production.

Owner:李岳

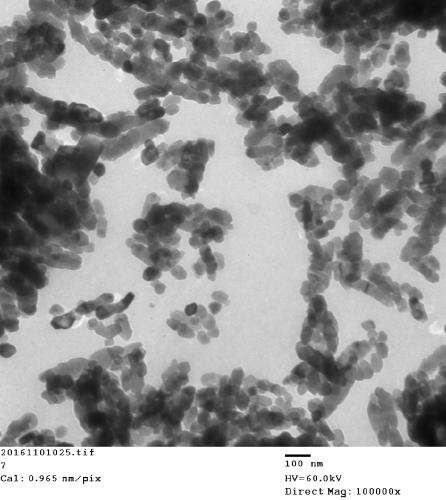

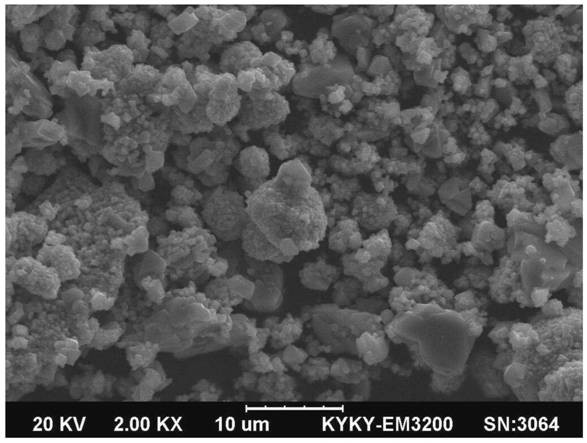

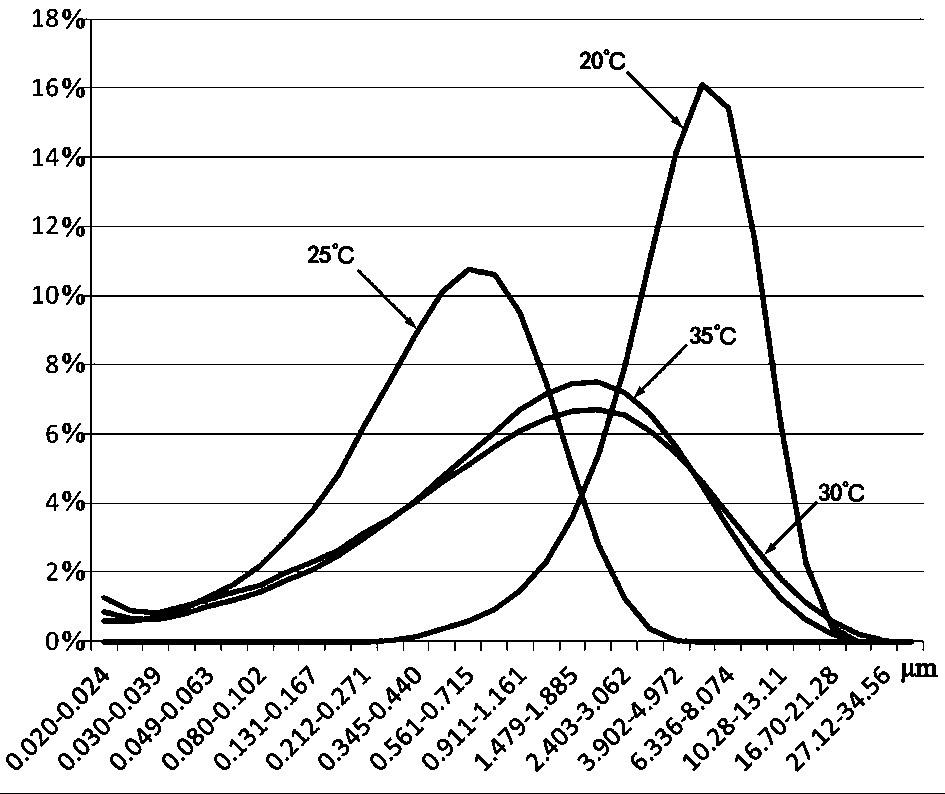

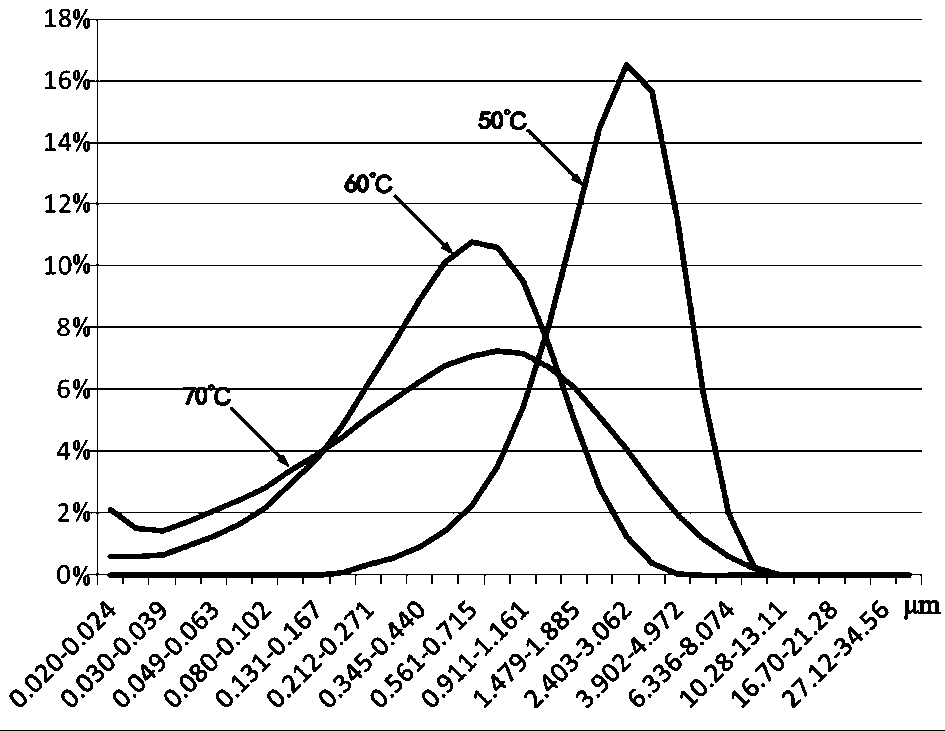

Method for preparing nano bismuth oxide by using liquid phase precipitation method

ActiveCN104743610AEvenly distributedGood particle size dispersionMaterial nanotechnologyBismuth compoundsDispersitySodium hydroxide

The invention belongs to the field of nano materials, and discloses a method for preparing nano bismuth oxide by using a liquid phase precipitation method in the presence of lignosulfonate serving as a surfactant. According to the technical scheme of the method, lignosulfonate is used as a surfactant and bismuth nitrate and sodium hydroxide are used as raw materials; the concentration of sodium lignosulfonate is adjusted to 2.5-7.5 g / L, and then nano bismuth oxide is prepared by using a liquid phase precipitation method. In the process of precipitation, the addition of different amounts of surfactants can achieve a steric hindrance effect, so that the direct contact between particles is reduced, the surface tension is lowered, and the surface energy is reduced, thereby lowering the aggregation degree of a dispersion system, caused by the action of a hydrogen bond or VDW (Van der Waals' force), keeping the dispersion system stable realtively, and effectively controlling the size and morphology of nanoparticles. The method for preparing nano bismuth oxide by using a liquid phase precipitation method disclosed by the invention is low in cost and simple to operate, and prepared products are uniform in particle distribution, high in particle properties, good in particle size dispersity and good in morphology; therefore the method can be easily industrialized.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

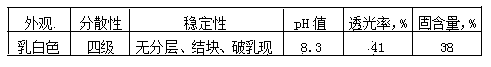

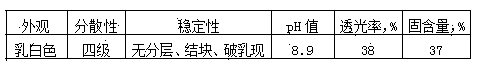

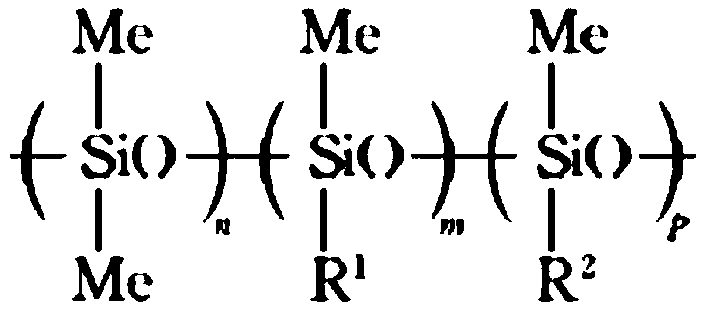

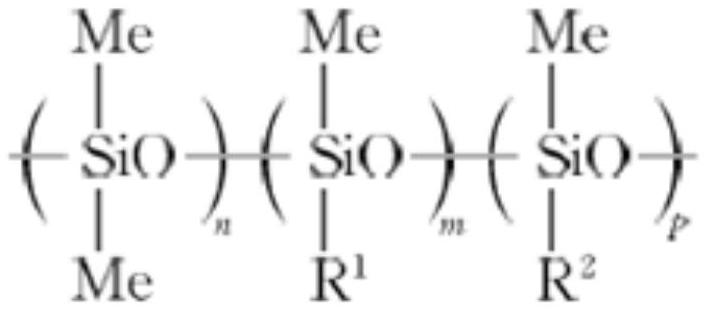

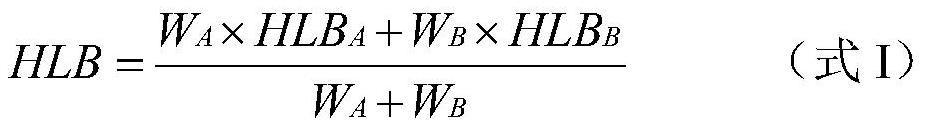

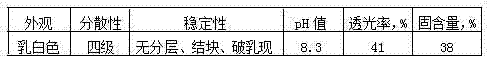

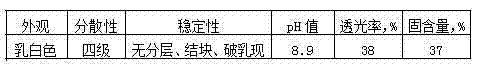

Preparation method of high-viscosity silicon raw rubber emulsion and application

The invention provides a preparation method of high-viscosity silicon raw rubber emulsion. The preparation method comprises the following steps: slowly adding high-viscosity silicon raw rubber into low-viscosity silicone oil under a stirring condition for uniform mixing, adding an emulsifier, an emulsification aid and emulsification water in batches, and slowly adding water to finally obtain a silicon raw rubber emulsion finished product, wherein the emulsification aid is polyether modified silicone oil. According to the preparation method of the emulsion, which is disclosed by the invention,20,000,000 cp of ultrahigh-viscosity silicon raw rubber can be effectively dispersed, and the obtained emulsion is uniformly dispersed, small in particle size and excellent in stability; under conditions such as long-time placement or high temperature, centrifugation and the like, extremely high stability can be still maintained, and no demulsification and no layering occur. The silicon raw rubberemulsion prepared by the preparation method is a smoothing agent or a softening agent; after a fabric is treated with the emulsion, the handfeel of the fabric is greatly enhanced; furthermore, no toxic organic solvent or other substances possibly injuring the skin are used, so that the potential safety hazard is avoided; and the high-viscosity silicon raw rubber emulsion is an environmentally-friendly, healthy and nontoxic fabric smoothing agent.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

A kind of preparation technology of nano calcium carbonate

ActiveCN106542557BHigh purityGood particle size dispersionCalcium/strontium/barium carbonatesNanotechnologyThree stageCarbonization

The invention discloses a preparation process of nano calcium carbonate. High-activity quicklime and high purity carbon dioxide are adopted as the raw materials, and a three-stage carbonization tower is taken as the reaction equipment to carry out reaction for preparation of nano calcium carbonate. The high-activity quicklime has an activity degree of 360-380; the purity of the high purity carbon dioxide is greater than or equal to 99%; and the three-stage carbonization tower is formed by series connection of a first stage carbonization tower, a second stage carbonization tower and a third stage carbonization tower of different capacities in order, the effective reaction volume ratio of the first stage carbonization tower, the second stage carbonization tower and the third stage carbonization tower is 1:4:16, and the introduction amount per hour of the high purity carbon dioxide in each carbonization tower and the effective reaction volume of the carbonization tower are in a ratio of 2-3:0.08. The nano calcium carbonate prepared by the method provided by the invention has the advantages of good particle size dispersion and uniform size distribution in the range of 20-30nm, regular morphology and high purity, etc. Also, the preparation process provided by the invention greatly shortens the carbonization reaction time, has high production efficiency, also improves the utilization of the reaction equipment, and is suitable for popularization and application in industrial production.

Owner:李岳

Method for directly preparing M-phase vanadium dioxide nano-powder through ultrasonic spray pyrolysis

ActiveCN112174207AGood particle size dispersionEasy shape controlNanotechnologyVanadium oxidesBarium sulfateUltrasonic atomizer

The invention relates to the field of preparation of vanadium dioxide powder, in particular to a method for directly preparing M-phase vanadium dioxide nano-powder through ultrasonic spray pyrolysis,which is simple in synthesis process, short in flow and capable of directly preparing monodisperse and high-purity nano vanadium dioxide powder with high yield. The method comprises the following steps: a, dissolving vanadyl sulfate in deionized water, preparing a vanadyl sulfate solution of a vanadium source, carrying out ultrasonic dispersion, adding equimolar barium chloride into the vanadyl sulfate solution, fully reacting, and filtering out the generated barium sulfate precipitate to obtain a vanadyl dichloride precursor solution, and b, putting the precursor solution prepared in the stepa into an ultrasonic atomizer, atomizing to generate fog drops, carrying the small liquid drops through carrier gas to pass through a vertical tube furnace, collecting through a high-voltage electrostatic collector, then putting the collected powder into deionized water, and performing ultrasonic treatment, filtration and vacuum drying to obtain the M-phase vanadium dioxide nano-powder. The method is particularly suitable for preparing the M-phase vanadium dioxide nano-powder.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

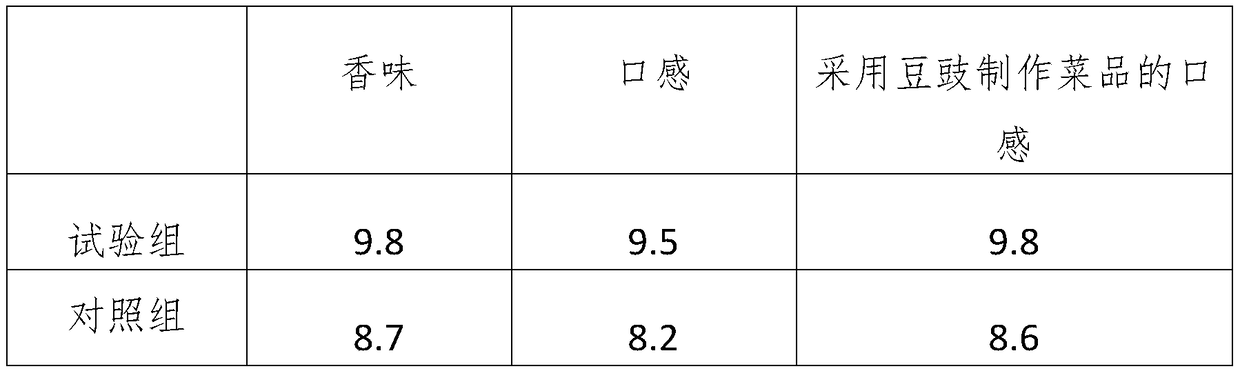

Probiotic fermented soya beans and making method thereof

InactiveCN108719807AHigh nutritional valuePromote reproductive growthFungiBacteriaBiological activationSoya bean

The invention relates to the technical field of fermented foods, in particular to probiotic fermented soya beans and a making method thereof. The fermented soya beans comprise strain activation substances, a fermenting substance and seasonings. The fermented soya beans are compounded through scientific compounding ratio and fine processing, and are free from additives, rich in mouth feel, fresh and tender in cooking liquor, simple to operate, convenient to use and rich in nutrients.

Owner:贵州省铜仁市永进食品有限公司

Method for preparing M-phase vanadium dioxide nano-powder by salt-assisted ultrasonic pyrolysis method

ActiveCN112209442AGood particle size dispersionReduce crystallinityNanotechnologyVanadium oxidesVanadium dioxidePhysical chemistry

The invention relates to the field of preparation methods of inorganic functional materials, in particular to a method for preparing M-phase vanadium dioxide nano-powder by a salt-assisted ultrasonicpyrolysis method, and the preparing method is simple in synthesis process and short in flow and can be used for efficiently preparing monodisperse and high-purity nano-vanadium dioxide powder. The preparation method comprises the following steps: a, preparing a precursor solution: dissolving auxiliary salt and tetravalent vanadate in deionized water to prepare a precursor solution of a vanadium source, and carrying out ultrasonic dispersion treatment; and b, preparing M-phase vanadium dioxide nano-powder: putting the precursor solution prepared in the step a into an ultrasonic atomizer, conducting atomizing to generate fog drops, collecting the fog drops carried by carrier gas through a vertical tube furnace and a high-voltage electrostatic collector, then putting the collected powder intodeionized water, and performing ultrasonic treatment and filtration, and conducting drying in vacuum to obtain the M-phase vanadium dioxide nano-powder. The preparation method is particularly suitable for the preparation process of the M-phase vanadium dioxide nano-powder.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Environment-friendly iron oxide red for permanent magnetic ferrite and preparation method

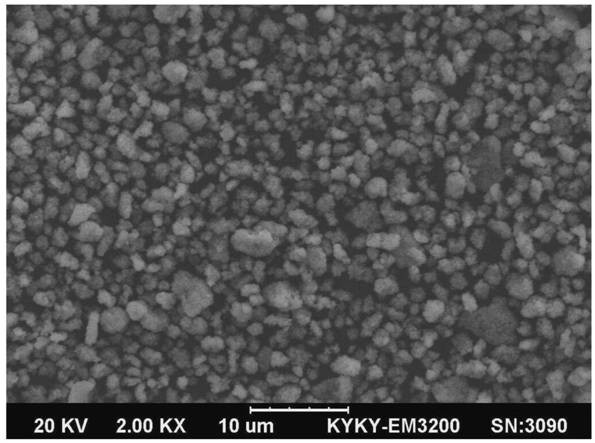

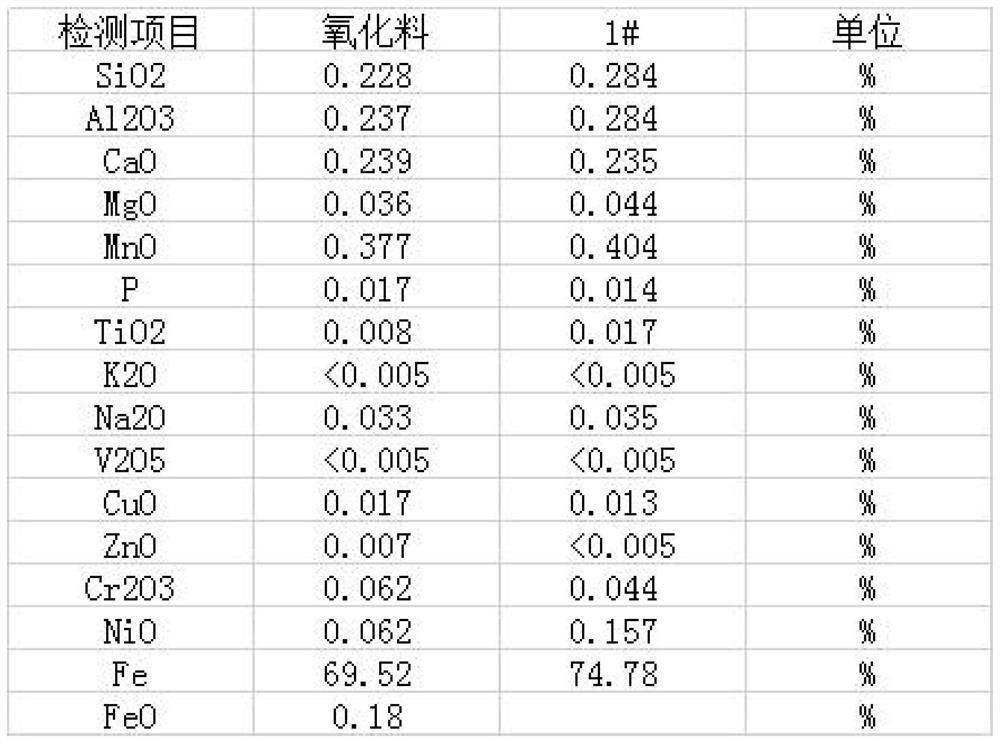

PendingCN112125343AGive full play to the effect of coagulation and sedimentationGive full play to the electricityInorganic material magnetismFerric oxidesIron sulfatePhysical chemistry

The invention discloses environment-friendly iron oxide red for permanent magnetic ferrite and a preparation method. The method comprises the steps of A, screening, B, grinding and silicon removal, C,pre-oxidation, D, re-oxidation, E, annealing, F, powder preparation and G, testing, wherein chemical component analysis is conducted on the iron powder in the step of testing. According to the method, firstly, iron scales are dissolved, then various inorganic and organic high-molecular polymers are added, on the basis of a polyferric sulfate and cationic guar gum composite silicon removal agent,high-molecular polymer sodium alginate is added, the high-molecular polymer sodium alginate can be used as a carrier to adsorb colloidal silicon particles in a solution, meanwhile, the sodium alginatecan enable the polyferric sulfate and the cationic guar gum to stably exist in a weakly acidic system, and the coagulating sedimentation effect, the electric neutralization capability and the bridgeadsorption effect of a silicon removal agent are fully exerted, so that the purpose of deep silicon removal is achieved.

Owner:SINOSTEEL TIANYUAN MAANSHAN TONGLI MAGNETIC MATERIAL

A kind of preparation method and application of high-viscosity silicone raw rubber emulsion

ActiveCN109912814BGood particle size dispersionSmall particle sizeVegetal fibresPolymer scienceOrganic solvent

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Method for preparing modified magnesium hydroxide flame retardant

ActiveCN103965656BGood compatibilitySimple processPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsEmulsionActive agent

The invention discloses a method for preparing a modified magnesium hydroxide flame retardant. The method comprises the following steps: preparing a compound emulsifier; dissolving sodium lauryl sulfate and triethanolamine in water to prepare a transparent solution, adding the compound emulsifier and an auxiliary emulsifier in oxidized polyethlene wax, adding the transparent solution after the oxidized polyethlene wax is melted, and agitating to obtain an emulsion; adding an ammonia water solution into the emulsion to obtain an organic modified emulsion; adding an anionic surfactant water solution into magnesium hydroxide, and agitating to obtain powder; drying to obtain magnesium hydroxide powder; adding the organic modified emulsion into the magnesium hydroxide powder, adding a dispersant, cooling to a room temperature, and obtaining magnesium hydroxide modified by the organic emulsion. The modified magnesium hydroxide flame retardant has great dispersibility and great compatibility with organic substances, can be uniformly dispersed in a base material, and cannot cause agglomeration. After the modified magnesium hydroxide flame retardant is added to an organic material, the mechanical property losses of the material can be effectively reduced. The method has the advantages of simple preparing technology, easiness in operation, strong controllability and simple equipment. As no pollution is caused in the whole technical process, energy-saving and environment-friendly requirements are met.

Owner:山东大耀特种材料有限公司

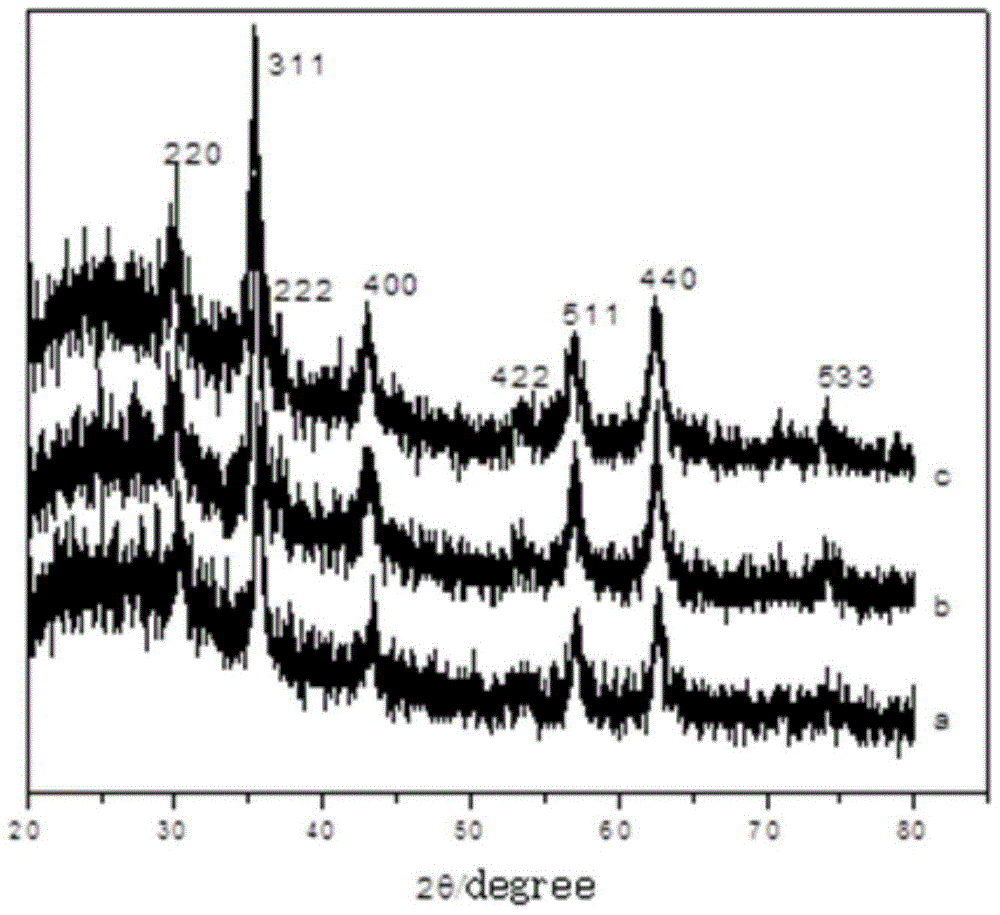

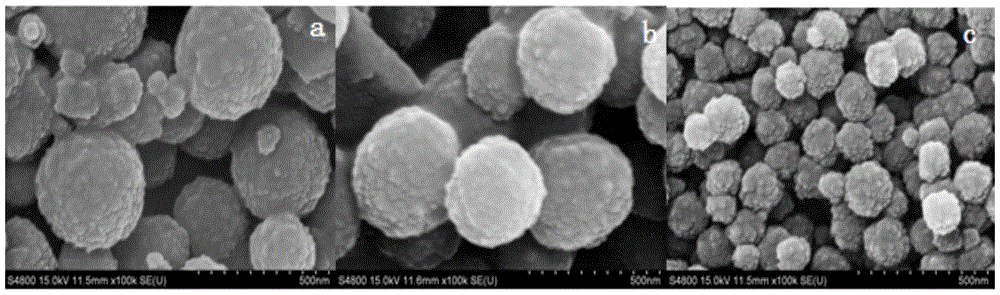

Solvothermal synthesis of zif-8-based ternary complex zno/znco 2 o 4 The method of /nio and its application

ActiveCN108806998BEasy to getUniform particle distributionHybrid capacitor electrodesHexamethylenetetramineMaterials science

The invention belongs to the technical field of metal organic framework materials, and relates to a method for preparing a ternary composite material by using zeolitic imidazolate frameworks as a template, in particular to a method for synthesizing a ZIF-8-based ternary composite ZnO / ZnCo2O4 / NiO by a solvothermal process and application of the method. The method disclosed by the invention comprises: dispersing per 290 mg of ZIF-8 polyhedron in 30-90 mL of ethanol containing 0.6-1.4 mmol of nickel nitrate, 0.6-1.4 mmol of cobalt nitrate and 421 mg of hexamethylenetetramine, stirring and mixinguniformly, transferring to a reaction kettle, heating at 100 DEG C to 120 DEG C for 2-4 h, cooling to room temperature, collecting by centrifugation and drying at 60 DEG C to 80 DEG C for 12-24 h to obtain a precursor, and annealing the precursor in the air at 300-350 DEG C by rate of 2 DEG C.min<-1> for 2-3 h, so the ternary composite ZnO / ZnCo2O4 / NiO is obtained. The prepared ZIF-8-based ternarycomposite ZnO / ZnCo2O4 / NiO has uniform particle distribution and good particle size dispersion, and has excellent electrochemical performance and good cycling stability when being used as an electrodematerial of a supercapacitor. The method has the advantages of simple process, low preparation cost and less pollution, and is suitable for industrial production.

Owner:JIANGSU UNIV

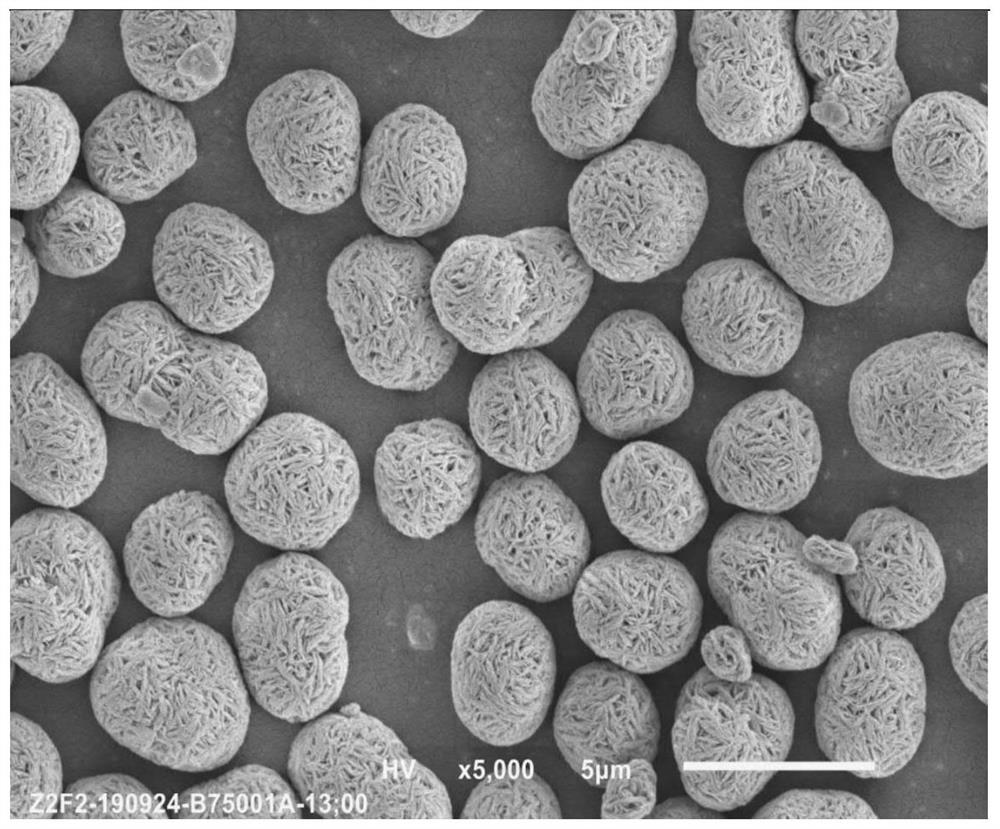

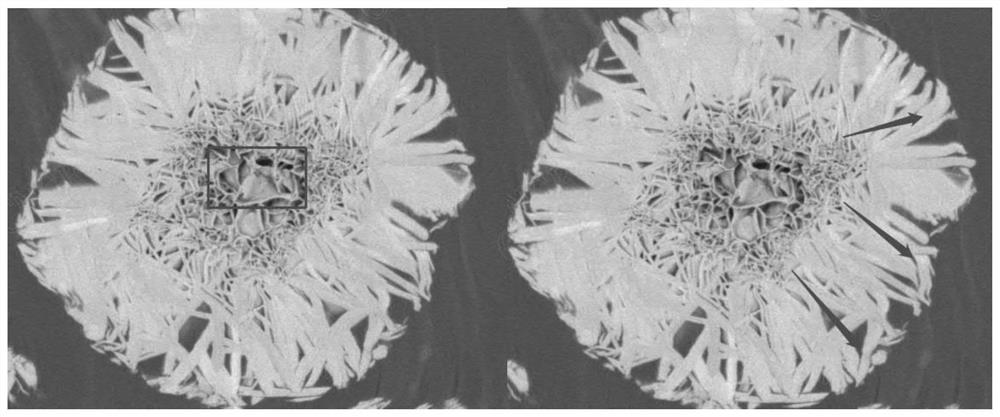

Binary precursor and preparation method thereof, lithium ion battery positive electrode material, lithium ion battery and electric equipment

PendingCN114195202ALow costIncrease capacityCell electrodesSecondary cellsElectrical batteryManganese

The invention provides a binary precursor and a preparation method thereof, a lithium ion battery positive electrode material, a lithium ion battery and electric equipment. The binary precursor comprises an inner layer area and an outer layer area arranged on the surface of the inner layer area; the inner layer area comprises primary particles arranged in a honeycomb shape, and the outer layer area comprises primary particles arranged in a radial shape. The preparation method comprises the following steps: mixing materials including a complexing agent, hydroxide and water to obtain a base solution, then simultaneously and continuously adding the complexing agent, the hydroxide and a nickel-manganese binary mixed salt solution into the base solution, and carrying out a co-precipitation reaction under a stirring condition to obtain a binary precursor; raw materials of the lithium ion battery positive electrode material comprise a binary precursor. The raw material of the lithium ion battery comprises the lithium ion battery positive electrode material. And the electric equipment comprises a lithium ion battery. The positive electrode material prepared from the precursor provided by the invention is large in capacity, high in cycle retention rate and high in charging and discharging speed.

Owner:CNGR ADVANCED MATERIAL CO LTD

Technological method for organically wrapping inorganic powder material

InactiveCN106243779AGood compatibilityClear processPigment treatment with macromolecular organic compoundsWaxPerchlorate salt

The invention discloses a technological method for organically wrapping an inorganic powder material. The technological method comprises the following steps: adding small-molecule-weight and high-density polyethylene powder, a solid oxidant (KMnO4, KClO4, Na2O2 and K2O2), a metalloscene catalyst and the like into an oil heating rotary reaction kettle together, then performing constant-speed heating to enable the temperature to rise to certain temperature, preserving the temperature for a period of time to enable the materials to be subjected to oxidization reaction slowly, so as to prepare oxidized polyethlene wax, adding an emulsifier, a co-emulsifier, deionized water, a polymerization inhibitor and the like into the prepared oxidized polyethlene wax to prepare emulsion, atomizing the prepared oxidized polyethlene wax emulsion, and performing spraying stirring on the inorganic powder material to realize organic wrapping of inorganic powder.

Owner:潍坊大耀新材料有限公司

Method for preparing m-phase vanadium dioxide nano-powder by salt-assisted ultrasonic pyrolysis

ActiveCN112209442BGood particle size dispersionReduce crystallinityNanotechnologyVanadium oxidesVanadium dioxideTube furnace

The invention relates to the field of preparation methods for inorganic functional materials, in particular to a salt-assisted ultrasonic pyrolysis method for preparing M-phase dioxide with a simple synthesis process and a short process, which can efficiently prepare monodisperse, high-purity nanometer vanadium dioxide powders The method for vanadium nano-powder includes the following steps: a. Preparing a precursor solution: dissolving auxiliary salt and tetravalent vanadium salt in deionized water, configuring into a precursor solution of vanadium source, and ultrasonically dispersing; b. preparing M Phase vanadium dioxide nano-powder: put the precursor solution prepared in step a in an ultrasonic atomizer and atomize to generate droplets, which are carried by the carrier gas through a vertical tube furnace and through a high-voltage electrostatic collector Collect, then put the collected powder in deionized water, carry out ultrasonic treatment and filtration, and obtain M-phase vanadium dioxide nano-powder after vacuum drying. The invention is especially suitable for the preparation process for preparing M-phase vanadium dioxide nano-powder.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Freeze forming preparation process of ternary lithium ceramic microphere

The invention provides a method for preparing ternary lithium ceramic microspheres by freeze molding, which is characterized in that: mixing the reactant raw materials of ternary lithium ceramic microspheres or ceramic powder with a polymer binder and a solvent, and mixing them in a ball mill Mix evenly to form a suspension slurry, and perform defoaming treatment. The slurry after defoaming treatment is transferred to the microsphere forming device, and the slurry is dropped into the low-temperature cooling medium through the microsphere forming device. During the movement of the droplets, microspheres are formed due to the surface tension, and the microspheres enter the low-temperature cooling medium. The spherical shape can be maintained by rapid cooling, and the ceramic microsphere precursor is formed by low-temperature vacuum drying in a freeze dryer. The microsphere green body undergoes multi-step program-controlled temperature-controlled heat treatment of calcination, calcination and sintering, and finally forms ternary lithium ceramic microspheres. Ceramic microspheres have good sphericity, controllable particle size, good particle size dispersion, high apparent density, high phase purity, and high breaking strength. The preparation method of the invention has the characteristics of simple process and low cost, and is easy to expand to large-scale production.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Preparing technology of organic coating of high purity industrial product zinc sulfide powder

InactiveCN106336690AGood compatibilitySimple processPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsWaxHigh density

The invention discloses a preparing technology of organic coating of high purity industrial product zinc sulfide powder. Firstly, polyethylene powdery material with small molecular weight and high density as well as catalyst are heat in the reaction kettle to increase temperature, afterwards oxidizing agent (hot air, O2 or H2O2) is introduced to prepare oxidized polyethlene wax, the prepared oxidized polyethlene wax is added into emulsifier, polymerization inhibitor, co-emulsifier and the like, emulsification is conducted under status of heating and stirring to obtain oxidized polyethlene wax emulsion, then the oxidized polyethlene wax emulsion is atomized to conduct spraying of the high purity industrial product zinc sulfide powder, so that organic coating of the high purity industrial product zinc sulfide powder is achieved.

Owner:潍坊大耀新材料有限公司

A kind of preparation technology of spherical nano-calcium carbonate

ActiveCN107827136BHigh purityGood particle size dispersionCalcium/strontium/barium carbonatesNanotechnologyCarbonizationProduct gas

Owner:李岳

Dehydration and drying method and device of metallurgical slurry with no pollution

ActiveCN101700955BAvoid secondary pollutionGood particle size dispersionSludge treatment by de-watering/drying/thickeningDispersityGranularity

The invention provides a dehydration and drying method of metallurgical slurry with no pollution, which is characterized by comprising the following steps: conveying the metallurgical slurry into a sedimentation tank until the solid content is 5%-15%; then conveying to a concentration tank through the pipeline in an airtight manner and concentrating until the solid concentration is 20%-40%; pumping into a stirring pot for stirring and pumping into a dehydrator for dehydrating into sludge paste with the solid concentration being 75%-80%; pumping into a dryer and drying into sludge powder with the water content being less than or equal to 6%; and pneumatically conveying to a feed bin. The invention also provides a device for realizing the dehydration and drying method of metallurgical slurry with no pollution, and in the device, the sedimentation tank, the concentration tank, the stirring pot, the dehydrator, the dryer and the feed bin are connected by the pipeline in sequence; the slurry is conveyed to the concentration tank, the stirring pot, the dehydrator and the dryer in sequence from the sedimentation tank by taking a slurry pump as motive power, and the dried sludge powder ispneumatically conveyed to the feed bin. The invention can avoid the secondary pollution of the solid wastes, the dried sludge powder does not agglomerate and the granularity has good dispersity.

Owner:MAANSHAN IRON & STEEL CO LTD

A kind of method for preparing nano-bismuth oxide by liquid phase precipitation method

ActiveCN104743610BEvenly distributedGood particle size dispersionMaterial nanotechnologyBismuth compoundsDispersityPrecipitation

The invention belongs to the field of nano materials, and discloses a method for preparing nano bismuth oxide by using a liquid phase precipitation method in the presence of lignosulfonate serving as a surfactant. According to the technical scheme of the method, lignosulfonate is used as a surfactant and bismuth nitrate and sodium hydroxide are used as raw materials; the concentration of sodium lignosulfonate is adjusted to 2.5-7.5 g / L, and then nano bismuth oxide is prepared by using a liquid phase precipitation method. In the process of precipitation, the addition of different amounts of surfactants can achieve a steric hindrance effect, so that the direct contact between particles is reduced, the surface tension is lowered, and the surface energy is reduced, thereby lowering the aggregation degree of a dispersion system, caused by the action of a hydrogen bond or VDW (Van der Waals' force), keeping the dispersion system stable realtively, and effectively controlling the size and morphology of nanoparticles. The method for preparing nano bismuth oxide by using a liquid phase precipitation method disclosed by the invention is low in cost and simple to operate, and prepared products are uniform in particle distribution, high in particle properties, good in particle size dispersity and good in morphology; therefore the method can be easily industrialized.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Method for Direct Preparation of m-phase Vanadium Dioxide Nanopowder by Ultrasonic Spray Pyrolysis

ActiveCN112174207BGood particle size dispersionEasy shape controlNanotechnologyVanadium oxidesVanadium dioxideBarium dichloride

The invention relates to the field of vanadium dioxide powder preparation, in particular to an ultrasonic spray pyrolysis method for directly preparing monodisperse and high-purity nano-vanadium dioxide powder with simple synthesis process and short flow process, which can directly prepare M phase. The method of vanadium dioxide nanopowder: a, dissolve vanadyl sulfate in deionized water, configure the vanadyl sulfate solution of vanadium source, and ultrasonically disperse, then add equimolar barium chloride to the vanadyl sulfate solution, After fully reacting, filter out the barium sulfate precipitation that generates, obtain the vanadyl dichloride precursor solution; b, the precursor solution prepared in step a is placed in the ultrasonic nebulizer and atomized to produce mist droplets, carried by the carrier gas The above-mentioned small droplets are collected by a vertical tube furnace and a high-voltage electrostatic collector, and then the collected powder is placed in deionized water, and subjected to ultrasonic treatment and filtration, and the M-phase vanadium dioxide nano-powder is obtained after vacuum drying body. The invention is especially suitable for preparing M-phase vanadium dioxide nanometer powder.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

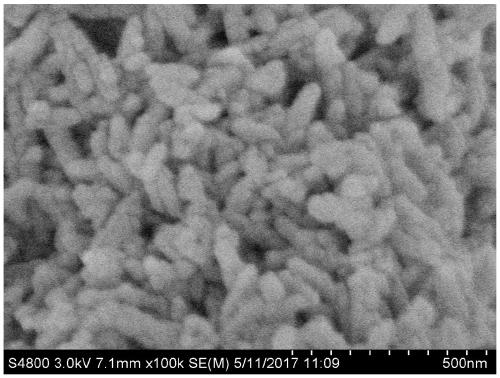

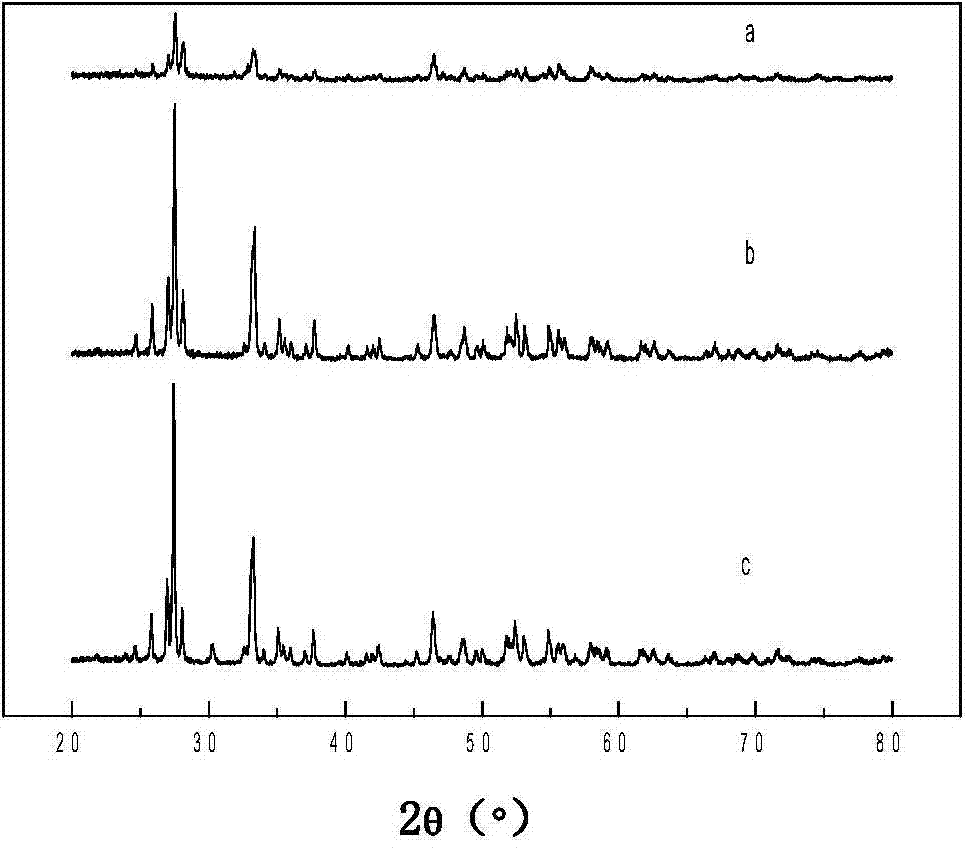

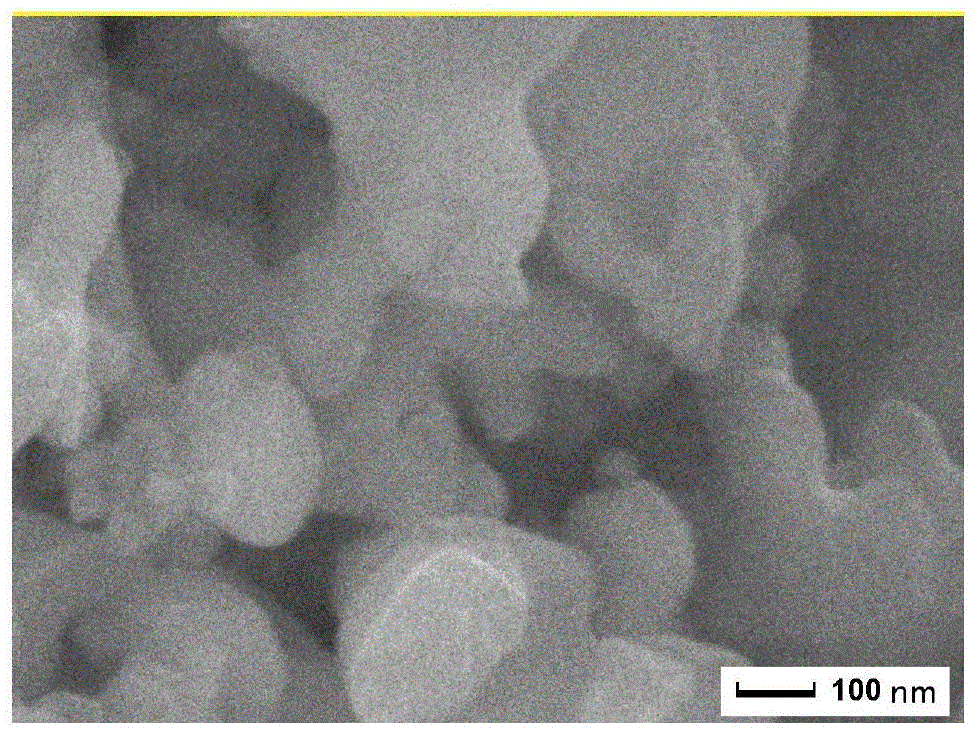

A kind of method that solvothermal method prepares nano ferric oxide

InactiveCN104925870BAchieve reuseParticle size controllableMaterial nanotechnologyFerroso-ferric oxidesLignosulfonatesSolvent

The invention provides a solvothermal method for preparing nano-grade ferroferric oxide. According to the invention, lignosulfonate is adopted as a surfactant, and nano-grade ferroferric oxide is prepared with the solvothermal method. The ferroferric oxide has controllable particle size. The applied lignosulfonate is a waste produced from a paper-making process, such that cost is saved, and the environment is protected.

Owner:JIANGSU UNIV

A kind of surface modification method of zns powder

ActiveCN103965657BSimple methodLow equipment requirementsPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPolymer sciencePollution

The invention discloses a surface modification method of ZnS powder. The surface modification method comprises the following steps: stirring oxidized polyethylene powder, deionized water, an emulsifier and other reagents at the normal temperature, heating the mixture and sealing, pressurizing and stirring, keeping pressurization, naturally cooling, adjusting the air pressure to be 0.1-0.5 MPa, stirring the solution until the temperature of the solution is the room temperature, adjusting the pressure to be standard atmospheric pressure, filtering the emulsion, adding ammonia water in the obtained emulsion, adjusting the pH value to be 8.0-9.0, adding the organic modified emulsion in the ZnS powder, stirring the solution, and standing; drying the modified ZnS powder, and naturally cooling the ZnS powder to obtain the surface modified ZnS powder. The modified ZnS powder can be dispersed in a base material well, is high in compatibility, has good antimicrobial, mildew-proof and algae-removing effects in the internal and external wall coating, can be used as a white pigment in the coating and plastics to enhance whiteness, and is high in cohesiveness to bind other inorganic materials; the process is simple, the operation is easy, the preparation process is free of pollution, and the energy-saving and environment-friendly requirements can be met.

Owner:潍坊大耀新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com