Freeze forming prepn process of ternary lithium ceramic microphere

A technology of ceramic microspheres and freeze molding, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of insufficient internal pore structure, difficulty in high density of lithium ceramic microspheres, and poor sphericity of ceramic microspheres. Controllable particle size of microspheres, good internal pore structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

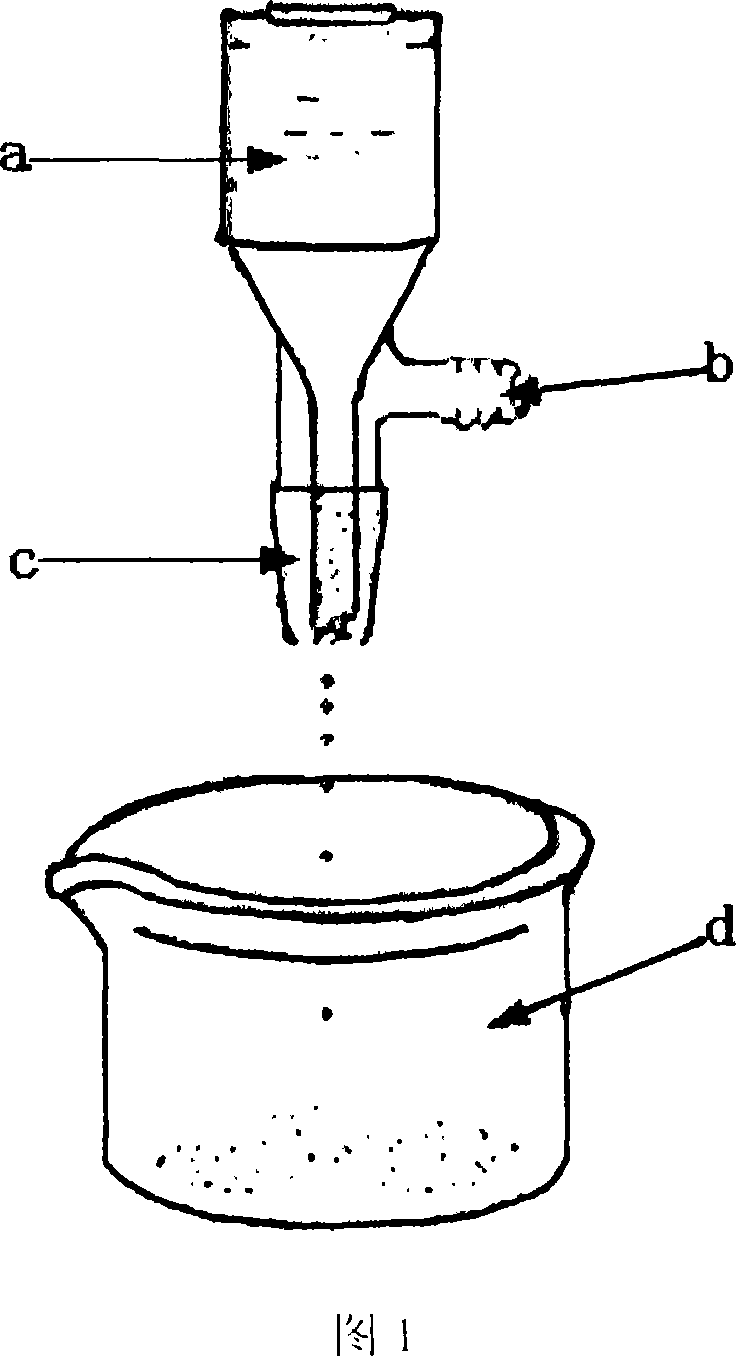

Embodiment 1

[0032] (1) Dissolve 4g of polyvinyl alcohol in 96g of distilled water completely, and let it stand for use; (2) Weigh 150g of lithium carbonate and silicon dioxide mixture according to the metering ratio, and add it into the prepared polyvinyl alcohol solution of (1) , Grind on a planetary grinder for 3 hours to form a stable suspension slurry; (3) transfer the suspension slurry to a container with a nozzle, open the pressure control system, the pressure is controlled at 40kPa, and the slurry flows from the nozzle Squirt out and drop into a container with liquid nitrogen at the bottom to form a ceramic microsphere precursor; (4) transfer the ceramic microsphere precursor to an enamel plate, put it into a freeze dryer and freeze-dry it for 12 hours at a temperature of -30°C; (5) Put the dried microspheres obtained from (4) into a high-temperature sintering furnace, and perform programmed heating treatment, 120°C for 24 hours, then 500°C for 36 hours, and then heat up to 1000°C f...

Embodiment 2

[0034] (1) Dissolve 2g of polyvinyl alcohol in 98g of distilled water until transparent and ready to use; (2) Weigh 150g of lithium nitrate and silicon dioxide mixture according to the metering ratio, add it to (1), and grind it on a planetary grinder for 4 (3) the suspension is poured into a container with a nozzle, the pressure control system is opened, the pressure is controlled at 40kPa, the droplets are ejected from the nozzle, and drop to the bottom of the container equipped with liquid nitrogen. In the container, the formed ceramic microsphere precursor; (4) transfer the ceramic microsphere precursor to an enamel plate, put it into a freeze dryer and freeze-dry it for 8 hours at a temperature of -30°C; The dried microspheres obtained from the treatment were placed in a high-temperature sintering furnace, and subjected to programmed heating treatment, treated at 120°C for 24 hours, then at 400°C for 48 hours, then raised to 1050°C for 24 hours, and continued to heat up to...

Embodiment 3

[0036] (1) Dissolving 5g polyvinyl alcohol in 95g ethanol, leave standstill for use; (2) Weigh 150g lithium carbonate and titanium dioxide mixture according to the metering ratio, join in (1), grind 2 hours on planetary grinder, Obtain a stable suspension slurry; (3) transfer the suspension slurry to a container with a nozzle, open the pressure control system, the pressure is controlled at 70kPa, the droplets are ejected from the nozzle mouth, and become spherical due to surface tension , dripped into the ethylene glycol liquid nitrogen mixture at the bottom to form a ceramic microsphere precursor; (4) transfer the microsphere precursor to an enamel plate, put it into a freeze dryer and freeze-dry it for 10 hours, and the freezing temperature is - 20°C; (5) Put the dried microspheres obtained through (4) into a high-temperature sintering furnace, and perform programmed heating treatment, 150°C for 24 hours, 700°C for 18 hours, and then heat up to 1100°C for 12 hours, and contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com