Environment-friendly iron oxide red for permanent magnetic ferrite and preparation method

A technology of iron oxide red and permanent magnetic ferrite, which is applied in the manufacture of iron oxide, iron oxide/iron hydroxide, inductors/transformers/magnets, etc., which can solve the problem of deep removal of silicon dioxide and unsatisfactory ferrite grades. Improvement and other issues, to achieve the effect of less other impurities, enhanced activity, and high content of ferric oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

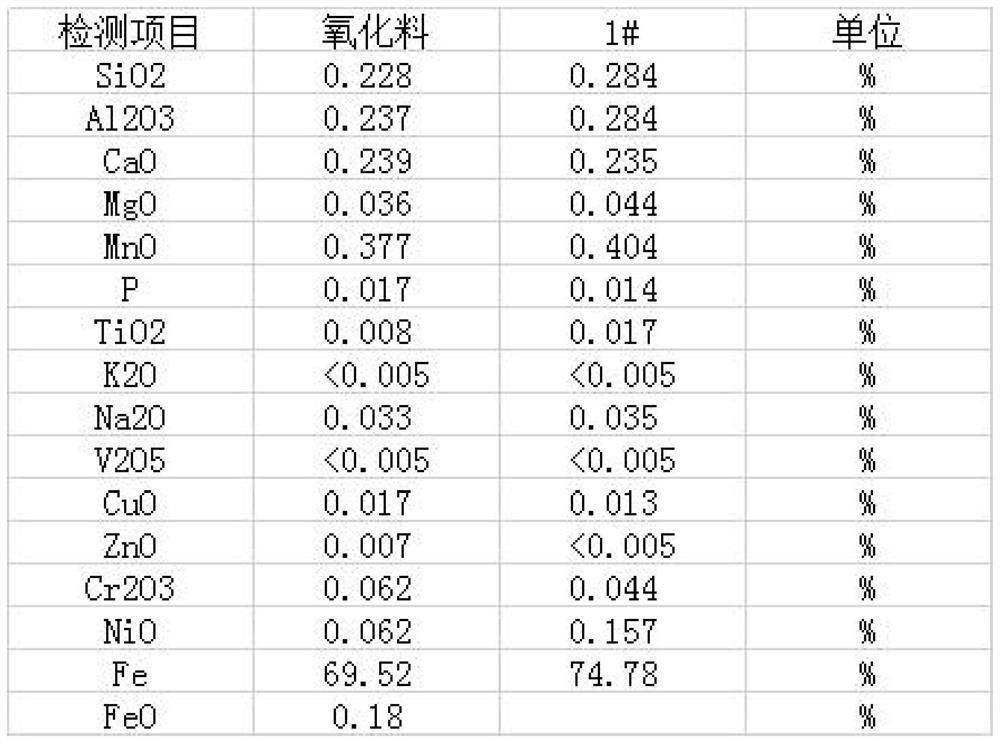

[0037] A, sieving; the iron scale rolled by a certain iron and steel plant is sieved with a grading vibrating sieve to remove more than 5 mm in diameter;

[0038] B. Grinding and desiliconization: Grinding with a disc jet mill to obtain 5 micron iron powder; leaching the iron powder with sulfuric acid for 12 hours, then adding a mixed solution of polyferric sulfate, cationic guar gum, and sodium alginate, wherein The mass percent content of polymerized ferric sulfate, cationic guar gum, and sodium alginate in water is 500ppm, 100ppm, and 100ppm, respectively, and the temperature of the system is controlled within the range of 30°C. Add ammonia water to keep the pH value of the system at 5.0, and stir for 15 minutes. , let stand for 6 hours, and filter to obtain the mixed solution after deep silicon removal;

[0039] C. Pre-oxidation: Ammonium bicarbonate is used as a precipitant to convert ferrous carbonate into ferrous carbonate; after that, it is calcined and decomposed to o...

Embodiment 2

[0056] A, sieving; the iron scale rolled by a certain iron and steel plant is sieved with a grading vibrating sieve to remove more than 5 mm in diameter;

[0057] B. Grinding and desiliconization: Grinding with a disc jet mill to obtain 7 micron iron powder; leaching the iron powder with sulfuric acid for 18 hours, then adding a mixed solution of polyferric sulfate, cationic guar gum, and sodium alginate, wherein The mass percent content of polymeric ferric sulfate, cationic guar gum and sodium alginate in water is 10000ppm, 1000ppm and 1000ppm respectively, the temperature of the system is controlled within the range of 60°C, ammonia water is added to keep the pH value of the system at 5.5, and stirred for 20 minutes , let stand for 6 hours, and filter to obtain the mixed solution after deep silicon removal;

[0058] C. Pre-oxidation: Ammonium bicarbonate is used as a precipitant to convert ferrous carbonate into ferrous carbonate; after that, it is calcined and decomposed to...

Embodiment 3

[0065] A, sieving; the iron scale rolled by a certain iron and steel plant is sieved with a grading vibrating sieve to remove more than 5 mm in diameter;

[0066] B. Grinding and desiliconization: Grinding with a disc jet mill to obtain iron powder of 9 microns; leaching the iron powder for 24 hours with sulfuric acid, then adding a mixed solution of polyferric sulfate, cationic guar gum, and sodium alginate, wherein The mass percent content of polymerized ferric sulfate, cationic guar gum, and sodium alginate in water is 5000ppm, 2000ppm, and 500ppm respectively, and the temperature of the system is controlled within the range of 45°C. Add ammonia water to keep the pH value of the system at 5.0, and stir for 30 minutes , stand still for 12 hours, filter to obtain the mixed solution after deep silicon removal;

[0067] C. Pre-oxidation: Ammonium bicarbonate is used as a precipitant to convert ferrous carbonate into ferrous carbonate; after that, it is calcined and decomposed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com