Method for preparing iron oxide red by utilizing titanium dioxide byproduct ferrous sulfate, product and application of product

A technology of iron oxide red and ferrous sulfate, which is applied in the direction of iron sulfate, iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of limited application range of iron oxide red, improve the effect of coagulation and precipitation, and inhibit hydrolysis The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

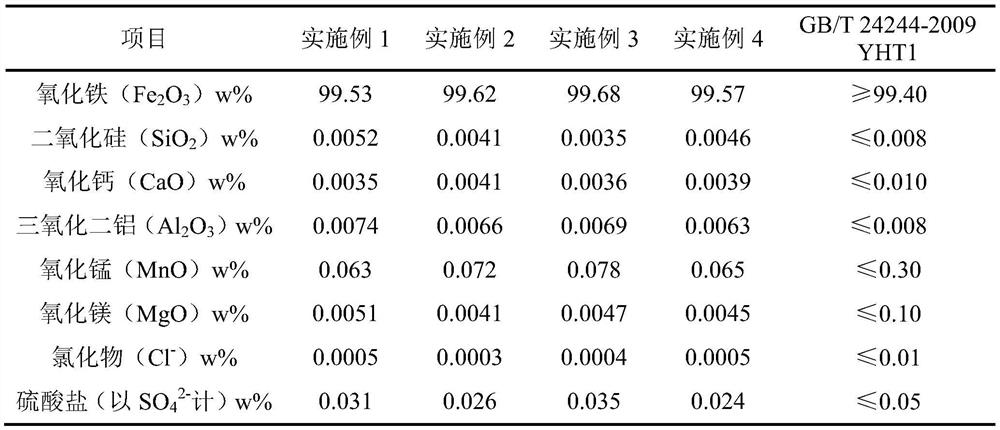

Examples

Embodiment 1

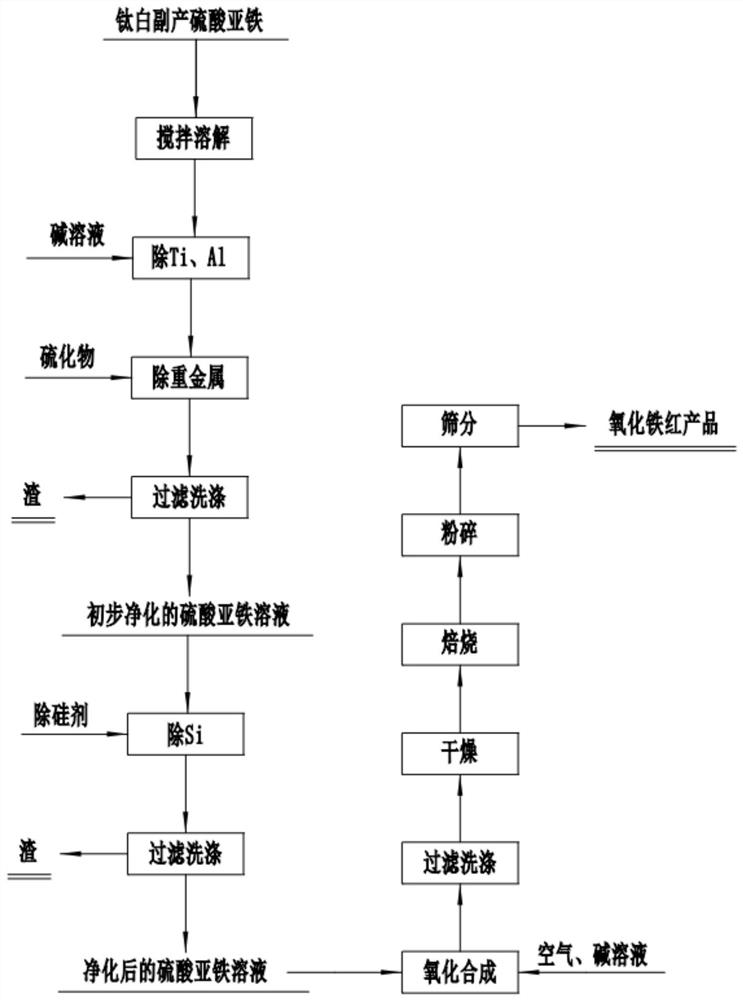

[0058] As shown in the flow chart, the method for preparing iron oxide red by utilizing titanium dioxide by-product ferrous sulfate in this implementation:

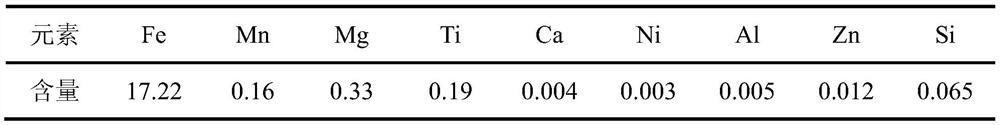

[0059] (1) Purification and removal of impurities: Dissolve ferrous sulfate, a by-product of titanium dioxide, in water under stirring, control the reaction temperature at 50°C, add 5mol / L ammonia water to make the pH of the system 4.5; then add 0.2mol / L sulfuric acid Ammonium, stirred for 15 minutes; filtered and washed to obtain a preliminary purified ferrous sulfate solution; adding silicon remover to the preliminary purified ferrous sulfate solution, polymerized ferric sulfate, cationic guar gum, and sodium alginate in water were added to the silicon remover The mass percentage contents of the ions are 5000ppm, 500ppm and 120ppm respectively; control the temperature of the system at 50°C, add 5mol / L ammonia water to make the pH of the system 5.0, stir for 20 minutes, let stand for 6 hours, and filter to obtain Fe after...

Embodiment 2

[0063] The titanium dioxide by-product ferrous sulfate used in the present embodiment is the same as that in Embodiment 1.

[0064] The method for preparing iron oxide red by using titanium dioxide by-product ferrous sulfate in this implementation: (1) Purify and remove impurities: dissolve titanium dioxide by-product ferrous sulfate in water under stirring, control the reaction temperature at 30°C, add 5mol / The sodium hydroxide solution of 1 L makes the system pH value be 5.0; Then add the sodium sulfide of 0.2mol / L, stir 15 minutes; Filter, wash and obtain the ferrous sulfate solution of initial purification; The silicon agent, the mass percentage content of polyferric sulfate, cationic guar gum, and sodium alginate in water in the silicon-removing agent are 2000ppm, 500ppm, and 550ppm respectively; the temperature of the control system is 50°C, adding 5mol / L sodium hydroxide solution Make the pH value of the system 5.0, stir for 20 minutes, let stand for 10 hours, filter t...

Embodiment 3

[0068] The titanium dioxide by-product ferrous sulfate used in the present embodiment is the same as that in Embodiment 1.

[0069]The method for preparing iron oxide red by using titanium dioxide by-product ferrous sulfate in this implementation: (1) Purify and remove impurities: dissolve titanium dioxide by-product ferrous sulfate in water under stirring, control the reaction temperature at 50°C, add 2mol / The sodium hydroxide solution of 1 L makes the system pH value be 4.0; Then add the sodium sulfide of 0.4mol / L, stir 20 minutes; Filter, wash and obtain the ferrous sulfate solution of initial purification; The silicon agent, the mass percent content of polyferric sulfate, cationic guar gum, and sodium alginate in water in the silicon-removing agent are 8000ppm, 2000ppm, and 1000ppm respectively; the temperature of the control system is 60°C, adding 2mol / L sodium hydroxide solution and Make the pH value of the system 5.0, stir for 20 minutes, let stand for 12 hours, filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com