Synthetic method of polyaluminum ferric chloride

A technology of polyaluminum ferric chloride and synthesis method, which is applied in chemical instruments and methods, inorganic chemistry, iron compounds, etc., can solve the problems of unguaranteed basicity of products, many equipment requirements, high cost, etc., and achieve production cost Low, reduce pollution, shorten the production cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

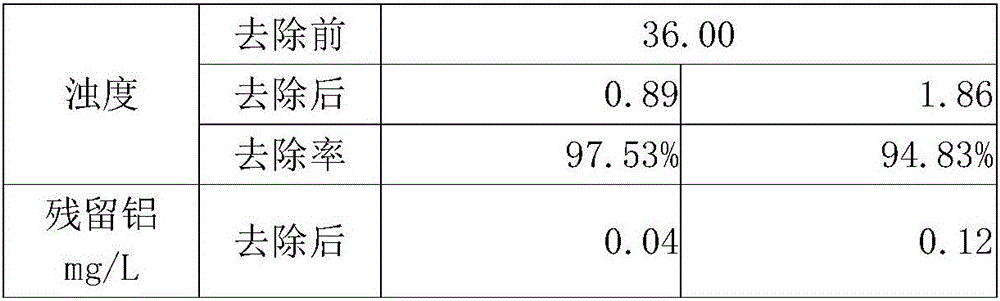

Examples

Embodiment

[0024] A synthetic method for polyaluminum ferric chloride, comprising the following steps:

[0025] 1), add 2530t of waste iron-containing hydrochloric acid, 181kg of hydrochloric acid, and 10kg of water into the closed stirred tank to obtain compound waste iron-containing hydrochloric acid, then put the compound waste iron-containing hydrochloric acid into the circulating oxidation reactor, and turn on the circulation pump to start circulation;

[0026] 2), sodium nitrite is configured into a sodium nitrite solution with a mass fraction of 25 wt %;

[0027] 3), slowly add sodium nitrite solution into the circulating oxidation reaction kettle, and feed oxygen at the same time, the total sodium nitrite dosing time is 1.0h, the total sodium nitrite dosing amount is 45kg; the total oxygen feeding amount is 33kg;

[0028] 4), when the reaction temperature reaches 50±5°C, and there is no significant change in the material temperature and the pressure in the circulating oxidation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com