Method for preventing flocculation flow of small square billet medium-carbon high-silicon low-manganese steel

A low-manganese steel and billet technology, which is applied in the field of steel smelting, can solve the problems that hinder the high-efficiency continuous casting of medium-carbon, high-silicon and low-manganese steel, poor castability, and improper production technology, so as to avoid continuous casting flocculation shutdown and The effect of returning molten steel accidents, reducing flocculation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preventing flocculation of medium-carbon high-silicon and low-manganese steel in a billet. The medium-carbon high-silicon and low-manganese steel is PSB830 steel, which is smelted for 3,200 tons. The tundish is planned to be 26 heats, and the casting furnace number is B1020- B1045 was smelted according to this production method, and there was no intrusive nozzle blockage in the whole casting process, and the production plan was completed. Now take the first pot of molten steel B1020 heat as an example to illustrate specific examples. The PSB830 steel B1020 heat includes the following components C0.40%, Si 1.55%, Mn 0.91%, V 0.136%, P0.015%, S 0.007%, and the balance of Fe and unavoidable impurities.

[0042] The method for preventing flocculation comprises the following operations:

[0043] 1. Converter process

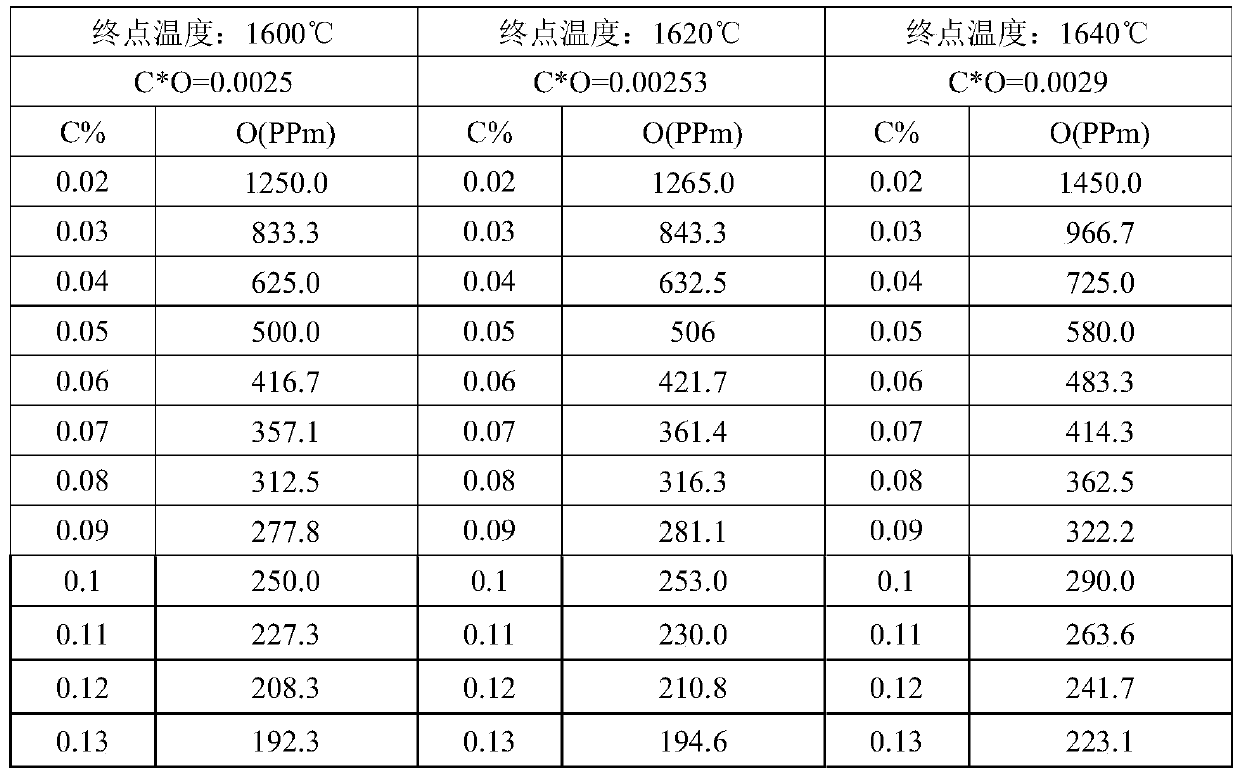

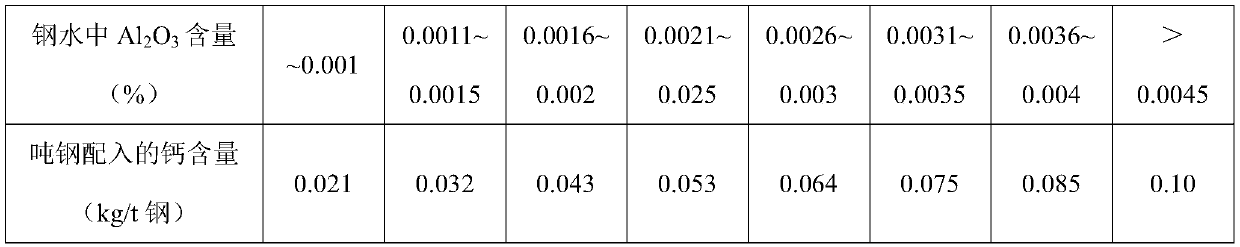

[0044] 1) When the converter adopts the high-drawing point blowing method, the high-drawing carbon is poured into the steel, the tapping tempera...

Embodiment 2

[0057] A method for preventing flocculation of medium-carbon high-silicon and low-manganese steel in a billet. The medium-carbon high-silicon and low-manganese steel is PSB830 steel with a smelting output of 3,400 tons. The tundish is planned to be 28 heats, and the casting furnace number is A1241 -A1268, smelted according to this production method, there is no intrusive nozzle blockage in the whole casting process, and the production plan is completed. Now take the tail tank molten steel furnace number as A1268 as an example to illustrate the specific embodiment. The A1268 heat of the PSB830 steel is the 28th furnace of the continuous casting tank, including the following components C 0.42%, Si1.58%, Mn 0.89%, V 0.138%, P 0.018%, S 0.008%, and the balance of Fe and unavoidable impurities.

[0058] The method for preventing flocculation comprises the following operations:

[0059] 1. Converter process

[0060] 1) When the converter adopts the high-drawing point blowing metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com