Patents

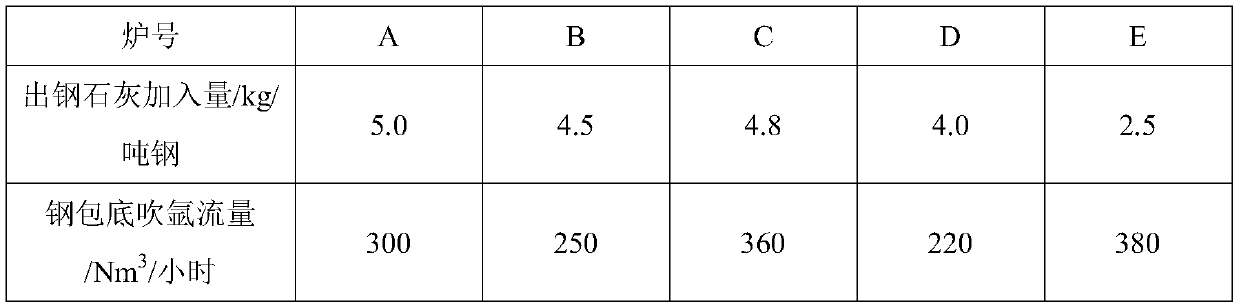

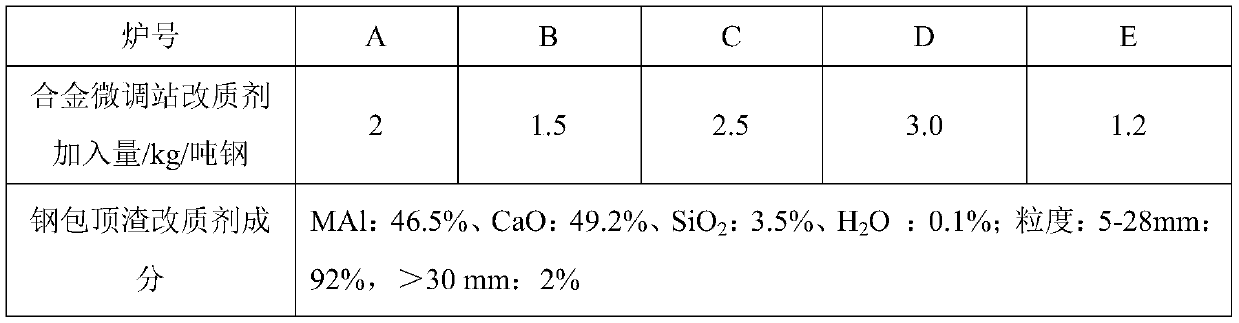

Literature

74results about How to "Increase the number of continuous pouring furnaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium-containing solder wire steel production method capable of alleviating continuous casting nozzle clogging

InactiveCN104259414AReduce nodulationIncrease the number of continuous pouring furnacesManufacturing convertersProcess efficiency improvementSteelmakingTitanium

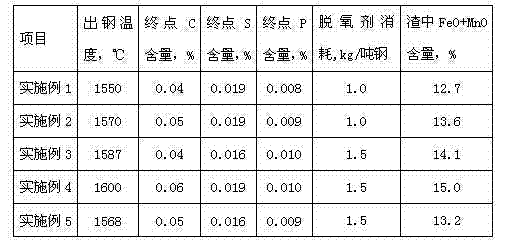

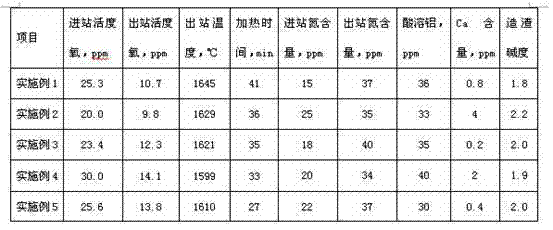

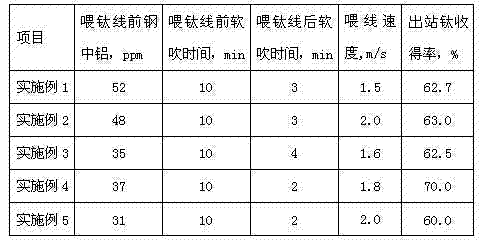

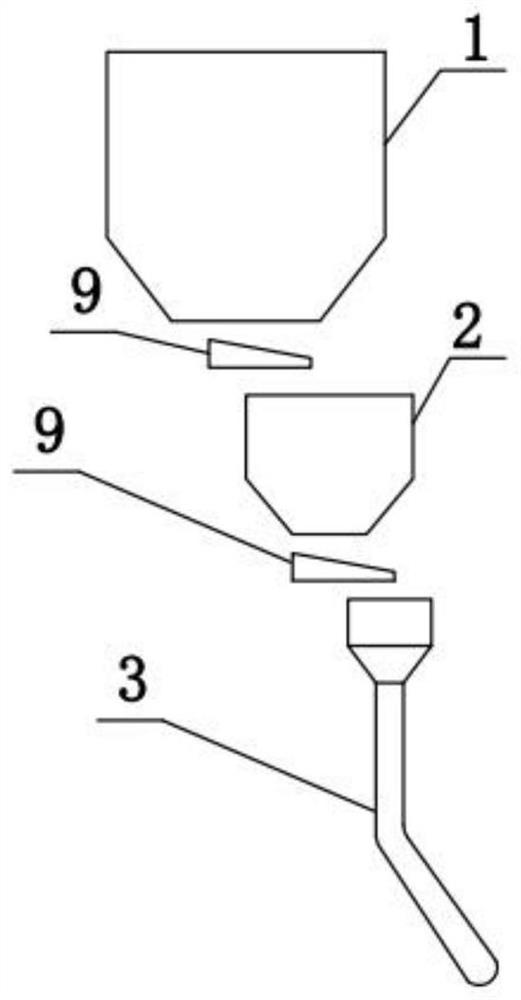

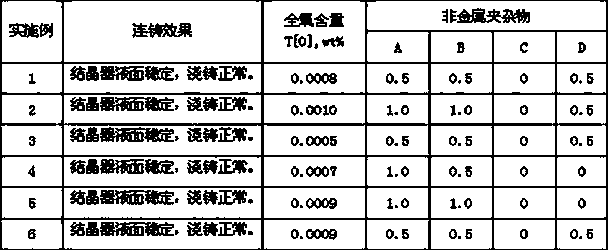

The invention discloses a titanium-containing solder wire steel production method capable of alleviating continuous casting nozzle clogging and belongs to the technical field of steel making. The titanium-containing solder wire steel production method capable of alleviating the continuous casting nozzle clogging includes processing steps that (1) smelting in a top-bottom combined blowing converter, to be specific, using low-sulfur molten iron and high-quality waste steel to blow; (2) refining in an LF furnace; (3) performing titanium alloying in an LF furnace, to be specific, softly blowing molten steel for 10 minutes, and feeding low-aluminum low-nitrogen 70Ti iron-packaged core to the molten steel to perform the titanium alloying after finishing soft blowing; (4) protecting casting in the whole process. The titanium-containing solder wire steel production method capable of alleviating the continuous casting nozzle clogging is aimed to solve the continuous casting water feed nozzle and submerged nozzle clogging problem for the titanium-containing solder wire steel production; the titanium-containing solder wire steel production method capable of alleviating the continuous casting nozzle clogging alleviates the nozzle clogging degree through optimizing the steel making, refining and continuous casting techniques, improves the continuous casting furnace number and cast blank yield and effectively lowers the production cost.

Owner:HEBEI IRON AND STEEL

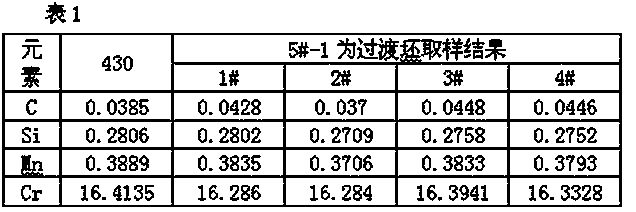

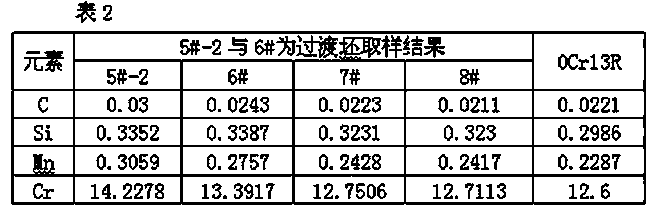

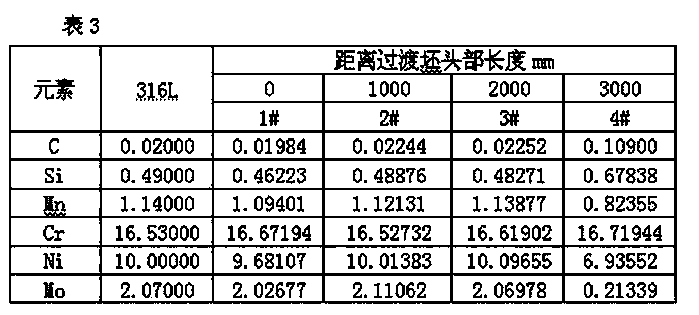

Continuous casting method of dissimilar stainless steel

The invention relates to a continuous casting method of dissimilar stainless steel. The continuous casting method comprises the following sequential steps of I, slowing down to 0.80 to 1.20 meters per minute for the first time when the previous furnace of molten steel is pulled to the end of large package casting and medium package molten steel remains 8.0 to 12 tons; II, slowing down for the second time when the medium package molten steel remains 4.0 to 8.0 tons and slowing down casting blank pulling to 0.35 to 0.45 meter per minute; III, slowing down the pulling to 0.10 meter per minute when the weight of the medium package molten steel decreases to 1.5 to 2.5 tons, placing a large package into a furnace and starting to cast and enabling the opening degree of a large package sliding plate to be the largest; IV, keeping the 0.10 meter per minute pulling speed within 10 to 60 seconds, speeding up to 0.4 to 0.6 meter per minute and maintaining the pulling speed within 60 to 110 seconds; V, speeding up to 0.6 to 0.8 meter per minute, maintaining the speed within 30 to 90 seconds, speeding up to the target speed and speeding up the casting blank pulling to 0.8 to 1.3 meters per minute. The continuous casting method of the dissimilar stainless steel reduces the production cost and improves the operation rate of casting machine equipment.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

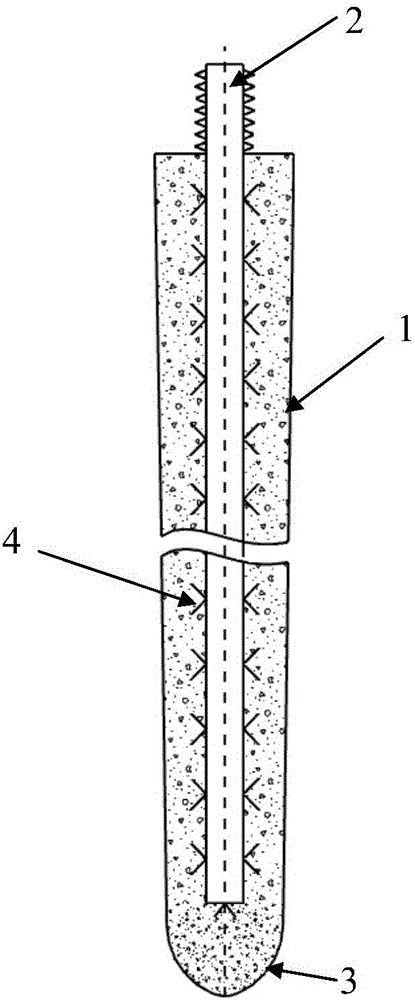

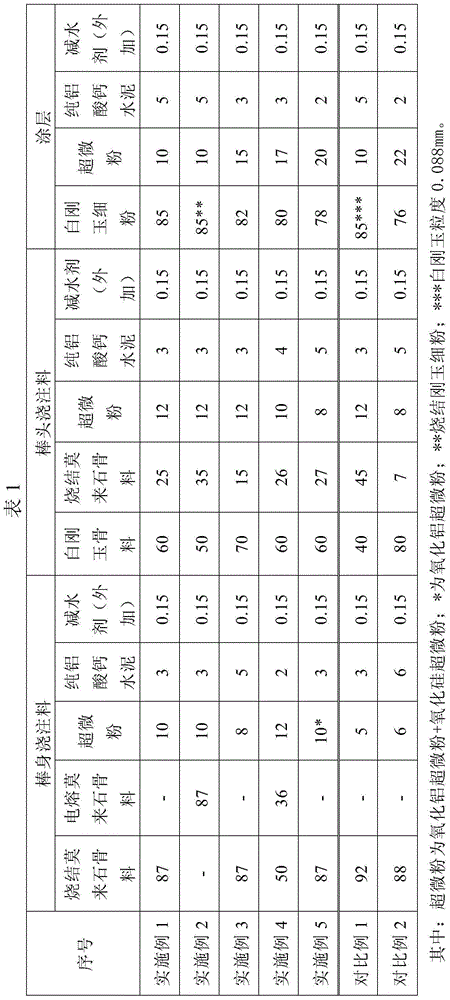

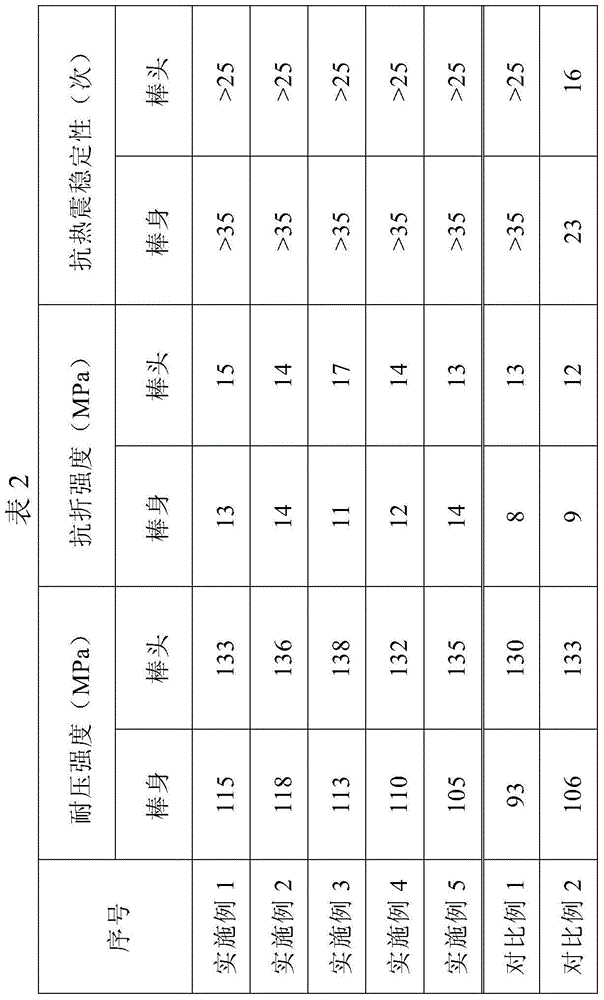

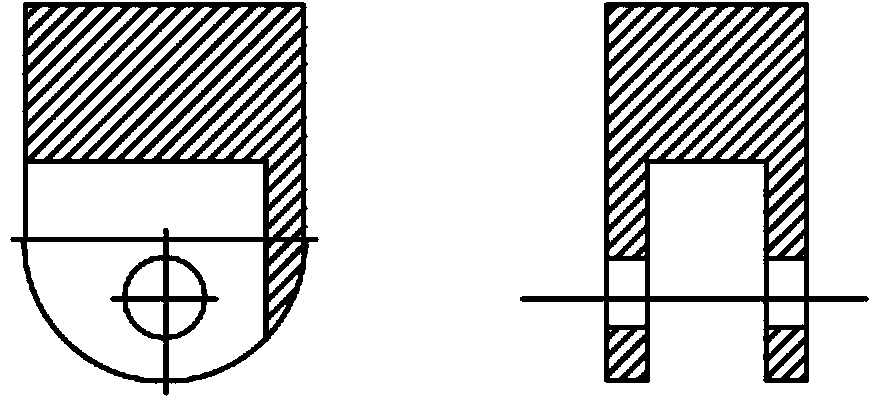

Continuous casting monolithic stopper and method of manufacture thereof

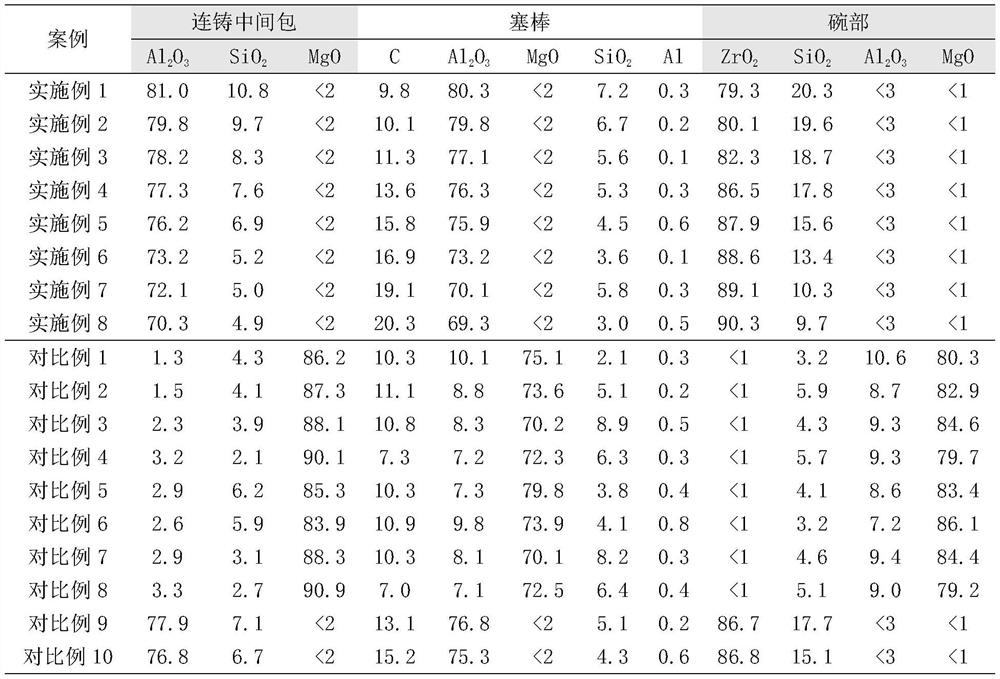

ActiveCN105753489AImprove thermal shock resistanceImprove erosion resistanceMelt-holding vesselsBrickMullite

The invention discloses a continuous casting monolithic stopper and a method of manufacture thereof.The monolithic stopper comprises a stopper body, a steel core inserted into the stopper body and a head connected to the lower end of the stopper body, the surface of the steel core is provided with an anchor, the surface of the monolithic stopper is coated with Al2O3 coating; the stopper body is made by casting castables comprising mullite, the head is made by casting castables comprising corundum and sintered mullite, and the monolithic stopper is manufactured by monolithic casting.The stopper obtained herein is good in monolithicity, is free of brick joint and head shedding problems of sleeve brick stoppers, has good thermal shock resistance, high strength and good resistance to molten steel scour erosion, is simple to manufacture and low in cost, and is suitable for stopping a tundish nozzle under low continuous casting, high-oxygen steel continuous casting and skid flow control.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for increasing continuous casting heats of aluminum-deoxidized bearing steel

InactiveCN102851443AImprove cleanlinessIncrease usageManufacturing convertersProcess efficiency improvementOxygen contentImpurity

A method for increasing continuous casting heats of aluminum-deoxidized bearing steel includes the steps of desulphurizing molten iron; smelting with a converter; allowing the converter to tap and alloying; performing argon stirring in an argon station; refining; vacuum-treating; feeding silicon calcium wire; performing protective casting and continuously casting to obtain blanks. The method has the advantages that original two continuous casting heats of the bearing steel is increased to more than five heats, and production efficiency is greatly improved; the number of using a ladle is increased, consumables consumption is reduced, and labor intensity of workers is reduced; low level of oxygen content and nonmetal impurities can be stably controlled, and steel cleanness is high.

Owner:武汉钢铁有限公司

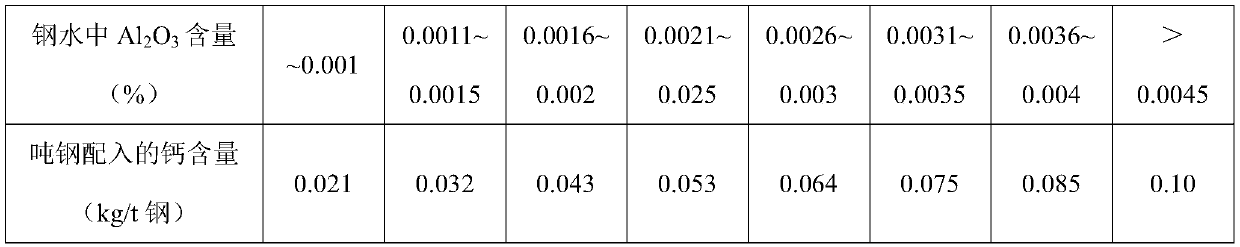

Calcium treatment process of rod wire alloy steel

The invention belongs to the technical field of metallurgy of iron and steel, and particularly relates to a calcium treatment process of rod wire alloy steel. The invention adopts a converter smelting-LF (ladle furnace) refining-RH refining-square billet continuous casting production technique. The calcium treatment process is implemented in a way that: after the LF refining finishes, feeding an iron calcium wire, silico-calcium wire or solid calcium wire into molten steel at the linear speed of 50-250m / min to control the mass percent of calcium aluminum in the molten steel at 0.08-0.16%; after the soft blow, carrying out RH treatment; after the RH treatment finishes, carrying out calcium carbonate treatment, and feeding the iron calcium wire, silico-calcium wire or solid calcium wire into molten steel at the linear speed of 50-250m / min to control the mass percent of calcium aluminum in the molten steel at 0.04-0.08%; and carrying out soft blow, and casting. When the treatment process is used for producing high-quality steel, the inclusion level can not deteriorate, the castability of the molten steel is good, the number of continuous casting furnaces is increased, the calcium content of the molten steel is low but does not influence the casting performance, and the treatment process plastifies the inclusions and improves the mechanical properties of steel.

Owner:NORTHEASTERN UNIV +1

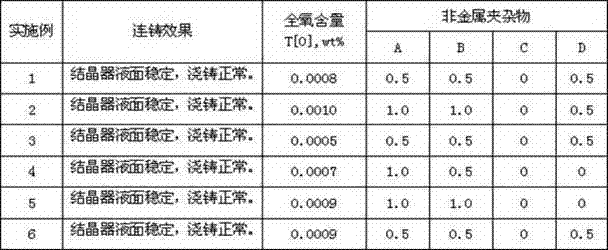

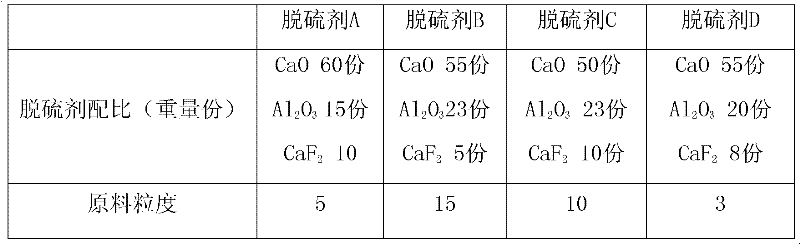

RH vacuum treatment desulfurizing agent used for non-oriented electrical steel, preparation method thereof, and desulfurizing method using same

InactiveCN102199687AGuaranteed electromagnetic performanceReduce iron lossElectrical steelRefractory

The invention relates to an RH vacuum treatment desulfurizing agent used for non-oriented electrical steel, a preparation method thereof, and a desulfurizing method using the same, belonging to the field of secondary refining of molten steel, so as to solve the problems that the RH vacuum treatment desulfurizing processes used for electrical steel in the prior art have serious erosion on refractory materials, high cost, slow melting speed and carburization risk to molten steel. The RH vacuum treatment desulfurizing agent used for non-oriented electrical steel is mainly composed of the following components: 50-60 weight parts of CaO, 10-25 weight parts of Al2O3 and 5-10 weight parts of CaF2. The invention also provides the preparation method of the RH vacuum treatment desulfurizing agent used for the non-oriented electrical steel, and the desulfurizing method using the RH vacuum treatment desulfurizing agent used for the non-oriented electrical steel. The RH vacuum treatment desulfurizing agent provided by the invention is mainly used for the RH vacuum treatment desulfurizing treatment of the non-oriented electrical steel.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

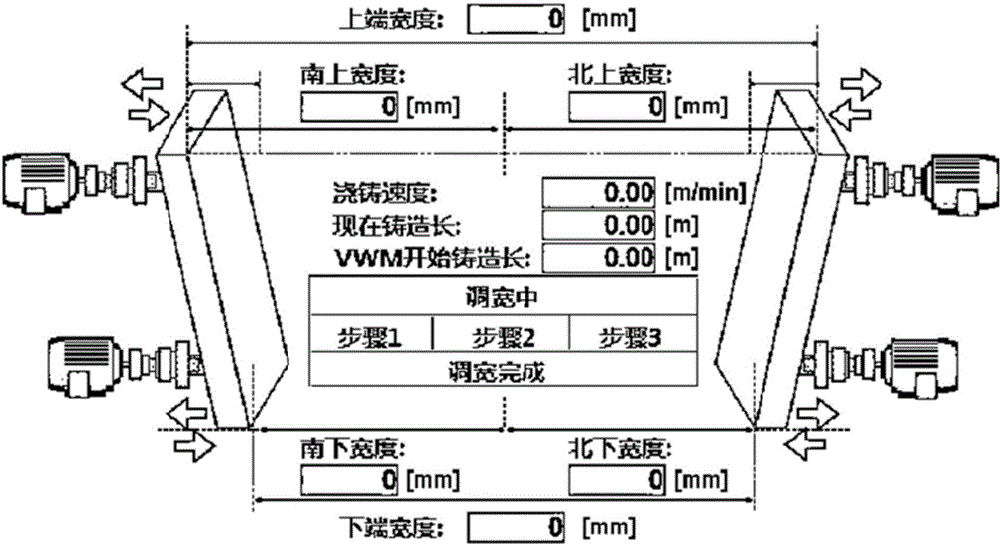

Online continuous casting billet preset width setting and tracking method

ActiveCN104942250AGuaranteed hot charging and hot delivery rateQuality improvementMetallurgyImage quality

The invention provides an online continuous casting billet preset width setting and tracking method. According to the method, casting plans, furnace orders, plate blank orders and other information are collected through an MES system, casting speeds, plate blank cutting performance, furnace cutting performance and other information are collected through a basic automated system, the width adjusting information and tendency in a whole CAST are worked out, and then the position and information of width adjusting plate blanks are locked. Basic data are provided for optimization of cutting length models, and indications are provided for operating personnel, so that the online width adjusting quality is better controlled, the plate quality is greatly corrected, the hot charging hot delivery rate of the plate blanks under high quality is guaranteed, and a better guarantee is provided for subsequent steel rolling products.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

Large-section aluminum-containing hot-rolled H-shaped steel and manufacturing method thereof

PendingCN110438397AImprove mechanical propertiesImprove low temperature resistanceNear net shapeImpurity

The invention discloses large-section aluminum-containing hot-rolled H-shaped steel and a manufacturing method thereof. Chemical components of the hot-rolled H-shaped steel comprise, by weight percent, 0.11-0.14% of C, 0.18-0.25% of Si, 1.40-1.50% of Mn, smaller than or equal to 0.025% of P, smaller than or equal to 0.008% of S, 0.040-0.050% of V, 0.012-0.02% of Ti, 0.040-0.050% of Al and the balance iron and trace impurity. The manufacturing method of the steel comprises the steps of molten iron pre-desulfuration, converter smelting, LF refining, near-net-shape beam bank continuous casting and rolling. According to the steel and the method, by means of vanadium-titanium composite microalloying, meanwhile, an aluminum element is used in cooperation, the refined crystalline strengthening and dispersion strengthening effect is achieved, and the comprehensive mechanical performance of the large-section H-shaped steel is improved. In the production process, the beam blank single-point flange non-equilibrium full-protection continuous casting technology is adopted, the cleanness degree of the molten steel is controlled strictly, scaffolding of a water opening is reduced, the inclusion content is low, the low-temperature impact performance of rolled materials is stable, and the yield is high.

Owner:SHANDONG IRON & STEEL CO LTD

Method for controlling continuous casting tundish submersed nozzle

The invention discloses a method for controlling a continuous casting tundish submersed nozzle. The method is characterized in that when a tundish pours molten steel to a crystallizer through the submersed nozzle, the tundish submersed nozzle is intermittently inserted into the molten steel of the crystallizer with a preset distance, and therefore the inserting depth of the submersed nozzle in the molten steel in the crystallizer can be intermittently increased. According to the method for controlling the continuous casting tundish submersed nozzle, the service life of the tundish submersed nozzle can be obviously prolonged.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

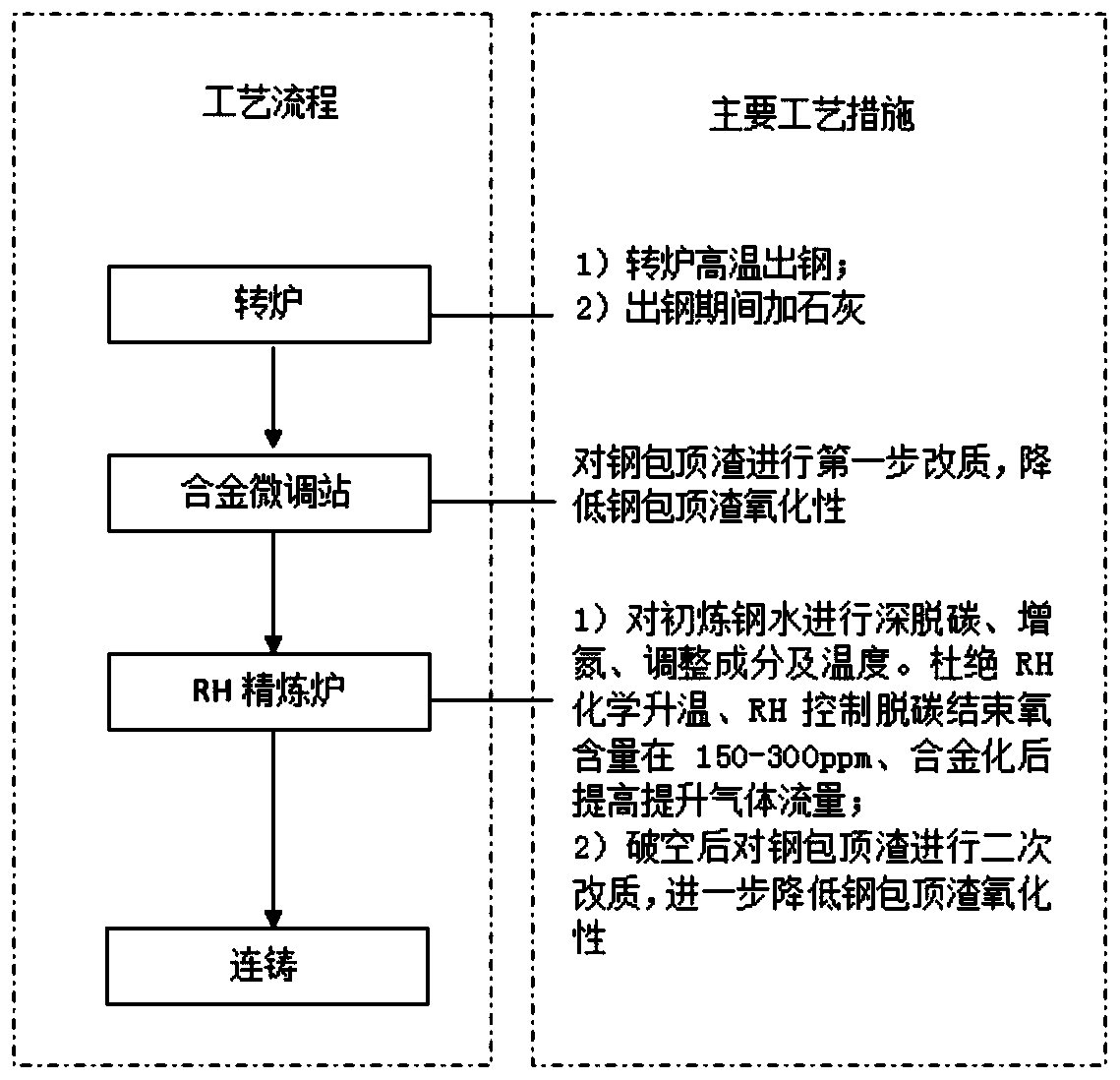

External refining method capable of increasing continuous casting heats of ultra-deep drawing cold-rolled enamel steel

The invention discloses an external refining method capable of increasing continuous casting heats of ultra-deep drawing cold-rolled enamel steel. The external refining method comprises the following steps: smelting molten iron and waste steel into primarily molten steel; performing first-step modifying on steel ladle slag in an alloy fine-tuning station process; performing decarburization and nitrogen pickup after RH molten steel is circulated, starting to measure oxygen before decarburization starts, adding aluminum particles to perform deoxidizing and alloying after decarburization is ended, and adding a steel ladle slag modifying agent to perform secondary modifying after performing RH vacuum-breaking. The external refining method disclosed by the invention increases continuous casting heats of ultra-deep drawing cold-rolled enamel steel to five-heat casting from three-heat casting with an increase rate of 66.7%, realizes batch, efficient and stable production of ultra-deep drawing cold-rolled enamel steel, and has remarkable economic benefits.

Owner:MAANSHAN IRON & STEEL CO LTD

SWRH82B high-carbon steel wire rod and preparation method thereof

ActiveCN113061688AImprove puritySatisfy the purityProcess efficiency improvementWire rodSmelting process

The invention relates to an SWRH82B high-carbon steel wire rod and a preparation method thereof, and belongs to the technical field of steel wire rods. In order to solve the problems that in an existing SWRH82B high-carbon steel wire rod production process, the number of aluminum oxide inclusions is high, the purity of molten steel is low, and the component uniformity is poor, the invention provides the SWRH82B high-carbon steel wire rod and the preparation method thereof. The preparation method comprises a primary smelting process, an LF refining process, a continuous casting process, a heating rolling process and a controlled cooling process. According to the preparation method, through production control of a primary smelting furnace, control of a refining position slag system and reasonable continuous casting process parameters, the qualified SWRH82B wire rod is finally rolled. According to the preparation method, aluminum-free deoxidation is carried out in the whole process, so that the purity of the molten steel is higher, and the obtained molten steel and a casting blank meet the requirements of the purity and the component uniformity. The preparation method has the advantages that the efficiency is high, the cost is low, the low-power segregation index of the obtained casting blank is within 1.05, the wire rod net carbon is within the second level, the martensite is less than or equal to 1.5 level, and the drawing use can be met.

Owner:建龙北满特殊钢有限责任公司

Composite modification material for reducing oxidizability of molten low-carbon-aluminum killed steel

The invention aims to provide a steel ladle modification material for solving the oxidizability problem of molten low-carbon-aluminum killed steel. For fulfilling the aim of the invention, the invention adopts a technical scheme that a ladle slag modifier and a ladle slag modification promoter are used at the same time. The modifier comprises 7 to 15 weight percent of CaF2, 11 to 20 weight percent of Al2O3, 42 to 55 weight percent CaO, 3 to 8 weight percent of MgO and 5 to 20 weight percent of passive calcium carbide (CaC2). The modification promoter comprises 20 to 27 weight percent of Al, 5 to 10 weight percent of CaF2, 25 to 32 weight percent of Al2O3, 22 to 30 weight percent of CaO and 10 to 14 weight percent of MgO, and the grain size of the modification promoter ranges from 5 to 30 millimeters. In the modification material, the ladle slag modifier is used an a main material, the amount of the promoter which serves as a regulation additive is small, and the weight ratio of the amount of the ladle slag modifier to that of the ladle slag modification prompter is (9-20):1.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Production method for improving pouring performance of high-aluminum bearing steel

InactiveCN113073252AFully reactive denaturationReduce binary alkalinityManufacturing convertersIron powderSlag

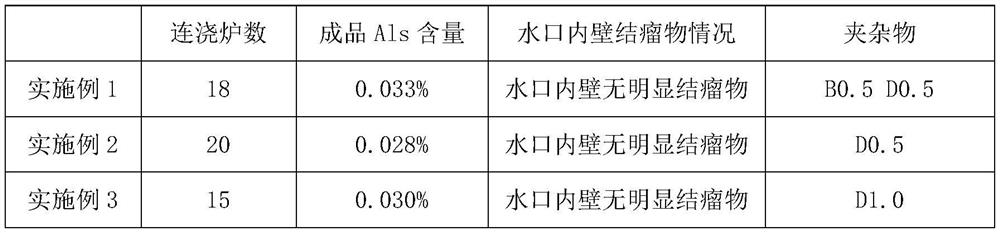

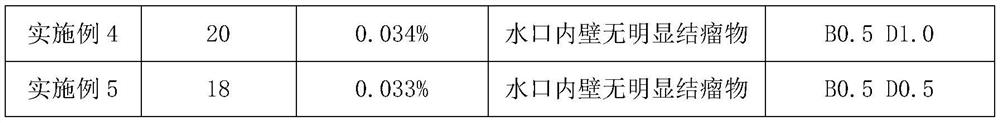

The invention belongs to the technical field of steel and iron smelting production, and discloses a production method for improving the pouring performance of high-aluminum bearing steel in order to control the risk that impurities in molten steel exceed the standards and improve the pouring performance of the bearing steel. steel ladle slag in a converter tapping process and at an initial stage of LF furnace refining is controlled to be binary high-basicity slag for Al2O3 denaturation reaction. In the middle stage of LF furnace refining, ferrosilicon and ferrosilicon powder are added, a ternary refining slag system with CaO-Al2O3-SiO2 as the core is subjected to large-range component adjustment, residual high-melting-point Al2O3 and xCaO.yAl2O3 are denatured into ternary low-melting-point inclusions, so that the problem of nozzle nodulation in the square billet pouring process is avoided; and under the condition that a calcium treatment process is not used, the continuous casting of the molten high-aluminum bearing steel for 15-20 furnaces is realized; and meanwhile, B-class and D-class non-metallic inclusions in the inclusions are less than or equal to 1.0 grade, and Ds-class non-metallic inclusions are less than or equal to 0.5 grade.

Owner:吕梁建龙实业有限公司

Deoxidization of calcium-silicon barium for smelting 82B steel

InactiveCN1778974AParticipate fully in the deoxygenation reactionImprove dynamic conditionsSlagAlloy

A deoxidizating technique by Si-Ba-Ca alloy in 82B steel-making which includes adding deoxidizing agent such as Al in tapping process. Its characters are as followsú‘adding Si-Ba-Ca alloy as deoxidizing agent to molten steel when tapping from converterú¿weight percentage of each component is Si 52-65ú¼ Ca í¦14ú¼Baí¦14ú¼Alíœ2ú¼Síœ0.15ú¼Píœ0.05 ú”granularity 10-50mmú”specific density 3.2g / cm3ú®. The deoxidizing agent is suggested to add into ladle with other alloy when the tapping percentage is in between 1 / 4 and 1 / 3. There are no Ba inclusion in finished steel and content of large-grained inclusion in finished steel decreased evidently because Baí»s great atomic radius made itself easier oxidated so that almost all the Ba were turned into slag. This technique could control the content of AlT íœ 0.002úÑin finished steel so as to prevent reoxidation of molten steel in continuous pouring process effectively and improve cleanliness of molten steel and increase numbers of pouring convertors. Ití»s highly suitable for pouring light section continuous casting billet and 82B steel for steel strand that requires superheat degree of molten steel more strictly.

Owner:SHOUGANG CORPORATION

Method for preventing flocculation flow of small square billet medium-carbon high-silicon low-manganese steel

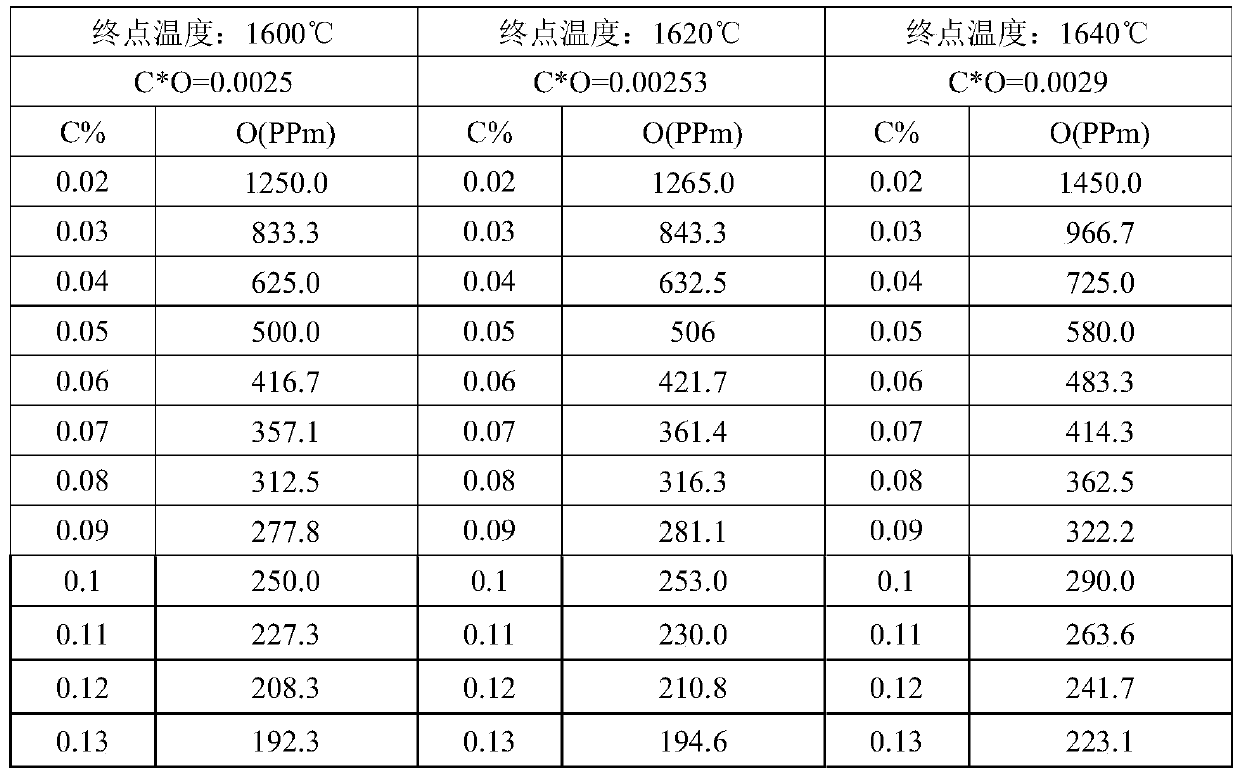

ActiveCN111041367AReduce flocculationIncrease the number of continuous pouring furnacesManufacturing convertersFlocculationSlag

The invention provides a method for preventing the flocculation flow of small square billet medium-carbon high-silicon low-manganese steel. Compared with the prior art, the method has the advantages that in order to improve the castability of the medium-carbon high-silicon steel, an end-point oxygen content and early-stage rapid slagging are controlled by optimizing end-point carbon and slag charge ratio of converter tapping, in a LF furnace process, large slag amount and high alkalinity are adopted to facilitate the deoxidation and desulfurization process, then a ladle argon blowing process is reasonably controlled, the argon blowing strength is properly set, the argon blowing time is properly prolonged, the floating and removal of oxide, sulfide and other inclusions in steel can be promoted, and the continuous casting nodulation can be obviously reduced through measures such as continuous casting process protection casting. Meanwhile, the molten steel casting temperature is properlyincreased, and the flocculation flow blockage phenomenon of a continuous casting intrusive water nozzle can be effectively avoided. By means of the method, the flocculation flow phenomenon of a smallsquare billet in the medium-carbon high-silicon steel PSB830 pouring process is reduced, and the multi-furnace stable continuous pouring and batch production are achieved.

Owner:WUHU XINXING DUCTILE IRON PIPES

Production method for reducing air hole defects of casting blank of ultra low carbon enamel steel with C being less than or equal to 0.0030%

PendingCN111187874AHigh removal rateIncrease the number of continuous pouring furnacesManufacturing convertersSteel platesArgon flow

The invention discloses a production method for reducing air hole defects of a casting blank of ultra low carbon enamel steel with C being less than or equal to 0.0030%. A smelting process adopts a low-oxygen smelting mode to reduce generation of inclusions, the RH alloying process is optimized, and the inclusion removing rate is increased; and a low stopper blowing argon flow is adopted, and thecontinuous casting heats are increased on the basis of decreasing the casting blank defect incidence rate. Low-oxygen smelting of the ultra low carbon enamel steel is achieved, molten steel pourability is improved, generation of the air hole defects of the casting blank is reduced, and the surface defect rate of an ultra low carbon enamel steel plate is decreased to be 3% or below.

Owner:MAANSHAN IRON & STEEL CO LTD

AOD smelting technique for stainless steel

The invention discloses an AOD smelting technique for stainless steel. The AOD smelting technique comprises the technological steps that material balance and heat balance are calculated according to steel element requirements and chemical heating parameters of all elements, and the adding quantities of raw materials are determined; and target requirements are calculated, specifically, the basicity of slag formed after a main blowing decarburization stage is ended is 3.0-4.0, and the main blowing ending temperature is controlled to 1680-1700 DEG C. According to the AOD smelting technique for the stainless steel, the smelting cost can be reduced, and the production order can be stabilized; the smelting cycle can be obviously shortened, material consumption is reduced, and the number of continuous casting is increased; and a steelmaking plant is assisted in reasonably selecting equipment investment through calculation of the material balance and heat balance according to the raw material condition, and equipment type selection mistakes are avoided.

Owner:XINGTAI IRON & STEEL

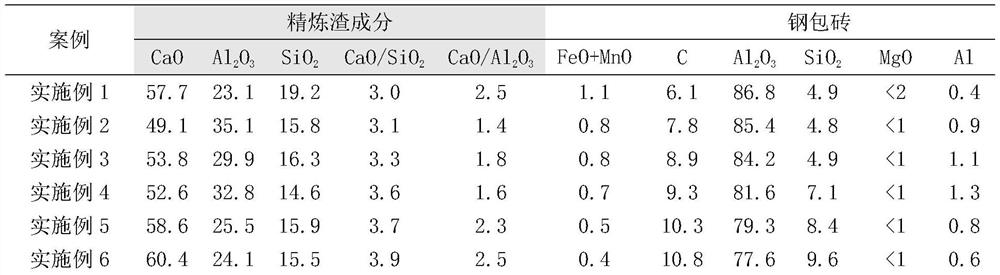

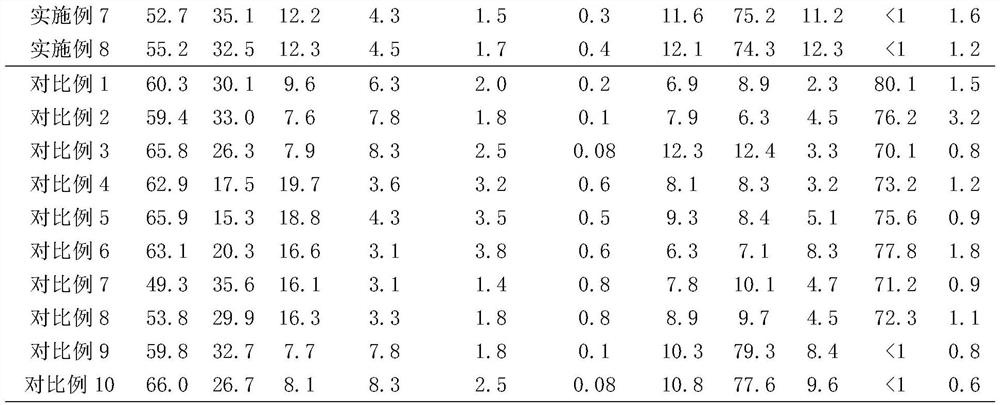

Production process for increasing continuous casting heats of aluminum deoxidized high-carbon chromium bearing steel

ActiveCN113444857AReduce MgReduce oxygen contentProcess efficiency improvementRefining (metallurgy)Slag

The invention belongs to the field of ferrous metallurgy, and relates to a production process for increasing the continuous casting heats of aluminum deoxidized bearing steel. LF refining slag adopts a CaO-Al2O3-SiO2 slag system, the final slag alkalinity CaO / SiO2 control range is 3.0-4.5, the final slag CaO / Al2O3 control range is 1.3-2.5, the refining slag addition amount is 8-10 kg / t, and meanwhile the final slag FeO + MnO is required to be smaller than 0.8%; and a steel ladle molten pool and a ladle bottom are made of aluminum carbon, a middle ladle is made of an alumina dry material, and a stopper rod is made of an integral aluminum carbon material. According to the process, the reaction between molten steel and refractory can be reduced while the slag steel reaction is inhibited, the generation of spinel inclusions is reduced, and the continuous casting heats and the water immersion flaw detection qualification rate are obviously improved.

Owner:ZENITH STEEL GROUP CORP +1

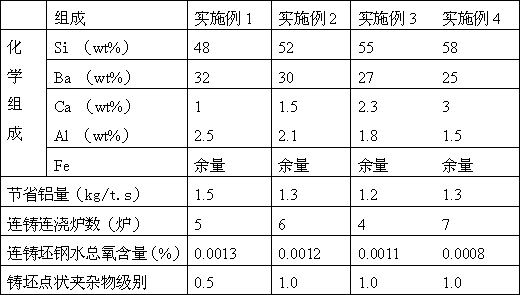

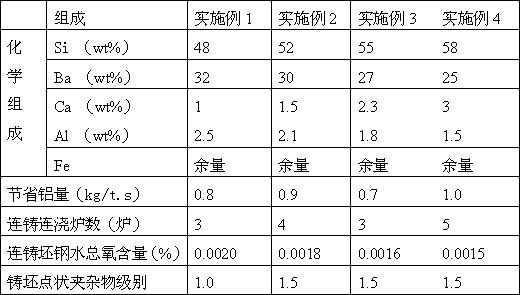

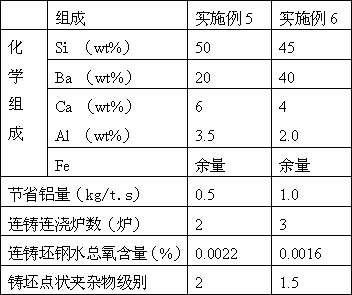

Molten steel composite deoxidation method good for improving pouring

The invention belongs to the category of metallurgy and steelmaking processes, and particularly relates to a molten steel composite deoxidation method good for improving pouring, which is applicable to smelting of gear steel, non-quenched and tempered steel and constructional steel as well as high-titanium solder wire series steel, wherein a silicon barium alloy is fed into the deep part of molten steel through a core-spun yarn to complete the composite deoxidation of the molten steel, a core wire in the core-spun yarn comprises the components of 48%-58% of silicon, 25%-32% of barium and the balance of iron according to weight percentage. The method has the advantages that the deoxidation effect of the molten steel is enhanced and the consumption of an aluminum alloy in the deoxidation of the molten steel is reduced through the regulation of alloy elements; meanwhile, the purity of molten steel and the quality of the molten steel are remarkably improved, an occluded foreign substance in the molten steel is effectively promoted to be gathered and float upwards to the slag, the smoothness of multi-furnace sequence casting production is guaranteed, the cleanliness of the molten steel is increased, the smoothness of the continuous casting is guaranteed, the number of furnaces for sequence casting in continuous casting is improved, a continuous casting water gap is prevented from being blocked, and the consumption of deoxidation aluminum is reduced.

Owner:SHANGHAI BAOHUI METALLURGICAL FLUX CO LTD

Device and method for different steel grade continuous casting automatic iron plate insertion

ActiveCN103862009AFully automatedIncrease the number of continuous pouring furnacesMelt-holding vesselsRefractoryAutomation

The invention discloses a device for different steel grade continuous casting automatic iron plate insertion, and belongs to the technical field of metallurgy continuous casting. The device comprises a T-shaped base of a tundish, a nozzle quick-changing oil cylinder swing part, a movable swing part and an iron plate insertion body part. The invention also discloses a method for different steel grade continuous casting automatic iron plate insertion, which comprises the steps of during different steel grade continuous casting, inserting the movable swing part on the T-shaped base of the tundish so as to enable the movable swing part to be located at the middle of the bottom of the tundish, meanwhile putting down a swing rod of the nozzle quick-changing oil cylinder swing part, respectively connecting two long rods of the iron plate insertion body part into hollow swing rods at the lower parts of the nozzle quick-changing oil cylinder swing part and the movable swing part from the inner arc side of a crystallizer, and connecting firmly by using iron wires. By adopting the device and the method, the different steel grade same-tundish continuous casting iron plate insertion automation is realized, the continuous casting furnace number of a casting machine is increased, the cost of tundish refractories is reduced, the operability of the casting machine is indirectly improved, the production preparation time is saved, and the molten steel yield is also improved.

Owner:BEIJING SHOUGANG CO LTD

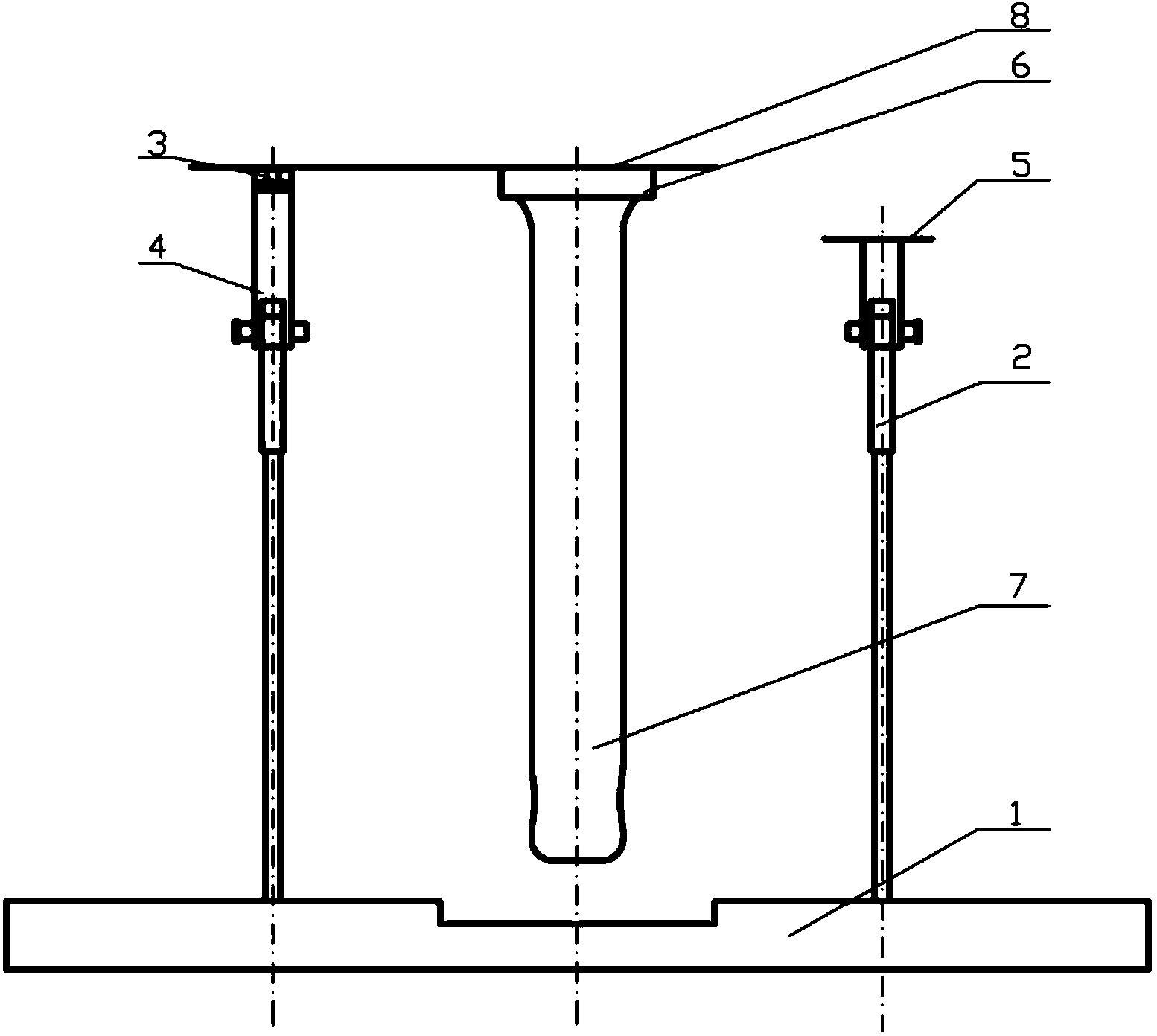

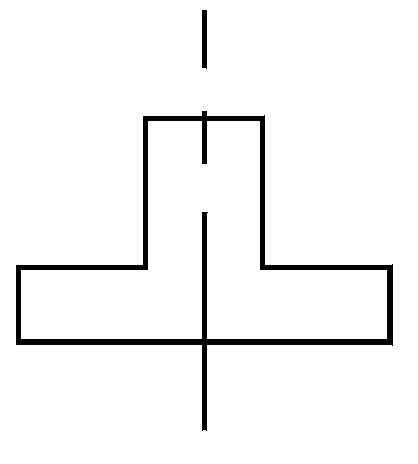

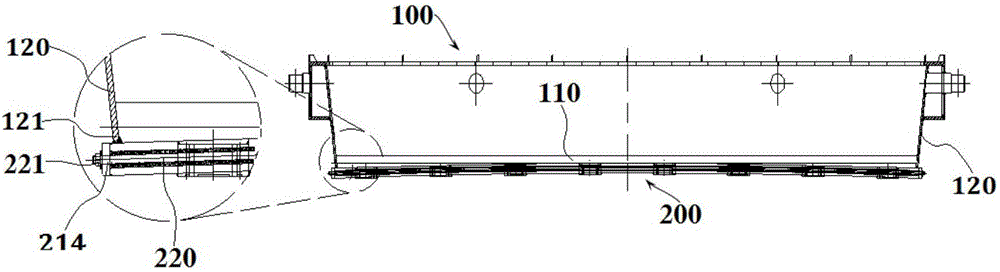

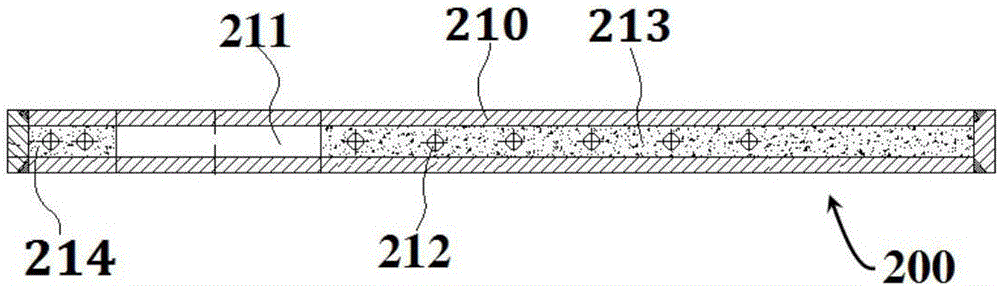

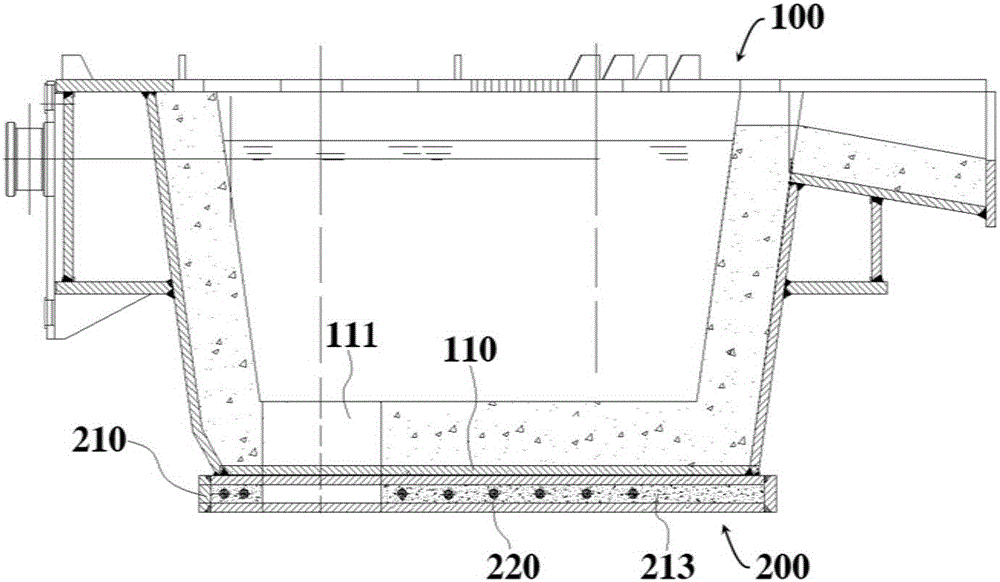

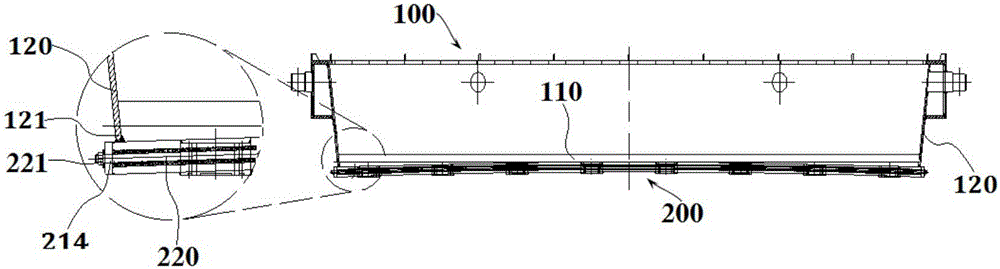

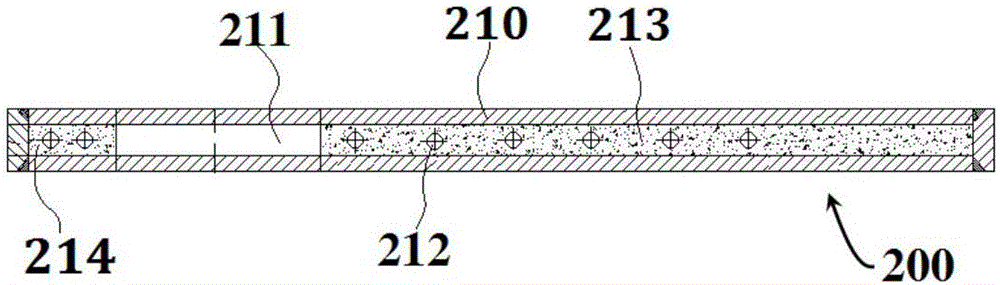

Method for assembling tundish prestressing force applying mechanism and preparation technology of downwarping-preventing tundish

ActiveCN106735146AExtended service lifeIncrease the number of continuous pouring furnacesMelt-holding vesselsPre stressSlurry

The invention discloses a method for assembling a tundish prestressing force applying mechanism and a preparation technology of a downwarping-preventing tundish, and belongs to the technical field of steel metallurgy continuous casting. The method includes the steps that (1) concrete is prepared, and concrete components are mixed and stirred to obtain heat-resistant concrete slurry; (2) the prestressing force applying mechanism is poured, the heat-resistant concrete slurry is poured into a shaping tank, then prestressed steel bars are mounted into corresponding steel bar sleeves, and the prestressing force applying mechanism is curved to generate deflection; and (3) installation is performed to apply prestressing force in a matched mode, the prestressing force applying mechanism is installed on the lower portion of a tundish main body, the arc-shaped top of the prestressing force applying mechanism makes contact with a tundish base plate so that installation can be completed, and the downwarping-preventing tundish can be obtained by means of preparation after the tundish prestressing force applying mechanism is assembled. According to the prestressing force applying mechanism, the prestressing force applied to the tundish base plate offsets the gravity of molten steel, down deflection of the tundish is controlled, the service life of the tundish is prolonged, and continuous casting heat is increased.

Owner:河南济源钢铁(集团)有限公司

Composite type ladle top slag modifier and production method thereof

InactiveCN101463413AIncrease the number of continuous pouring furnacesImprove surface qualityProcess efficiency improvementAlkalinitySlag

The invention discloses a composite ladle top slag modifier and a preparing method thereof. Deoxidation materials of Cao, Al, Si, Ca, SiO2, CaF2 and Al2O3 are ground and mixed evenly according to the proportion of 45-50 to 20-30 to 2-5 to 2-8 to 5-10 to 5-10 to 5-15 and packaged to obtain the composite ladle top slag modifier. The percentage of FeO in the ladle top slag is effectively lowered, which means the oxidizability of the slag is lowered, the top slag alkalinity is improved, the secondary oxidation of a slag-steel interface is lowered obviously, impurities in steel are reduced, the nozzle nodulation probability during the casting process is lowered and the number of furnace of sequence casting is increased. Covering flux is used for replacing the ladle top. Therefore, the smelting cost is saved effectively.

Owner:SHENYANG WANSHUI IND & TRADE

SPHC low-carbon type steel production technology

ActiveCN109880972APromote full buoyancyReduce temperature dropMelt-holding vesselsManufacturing convertersSlagMolten steel

The invention discloses an SPHC low-carbon type steel production technology. A following control method is adopted and comprises the steps that converter end point content low-level control is guaranteed on the premise that it is guaranteed that the converter end point temperature meets the requirements; the CAS refining effect is improved, slag inclusion adsorption is conducted, and meanwhile theRH station inlet oxygen content is decreased to ensure the pouring property of molten steel; a CAS argon blowing model is optimized, argon gas stirring pressure models in the different stages are made, therefore, full floating of inclusions is effectively promoted, and meanwhile the process temperature drop is reduced; RH low oxygen level control is achieved, the RH station inlet oxygen content is decreased, the RH residual oxygen content is precisely controlled, the aluminum consumption is reduced, and the production yield is indirectly decreased; and the continuous casting machine protective pouring argon gas flow is optimized, and the condition that the pouring property is influenced due to water port inclusion concentration is avoided. According to the SPHC low-carbon type steel production technology, the purposes that on the basis that a water port is not displaced in the pouring process, the continuous pouring number is increased, and meanwhile the production cost of the processes is reduced are achieved.

Owner:SD STEEL RIZHAO CO LTD

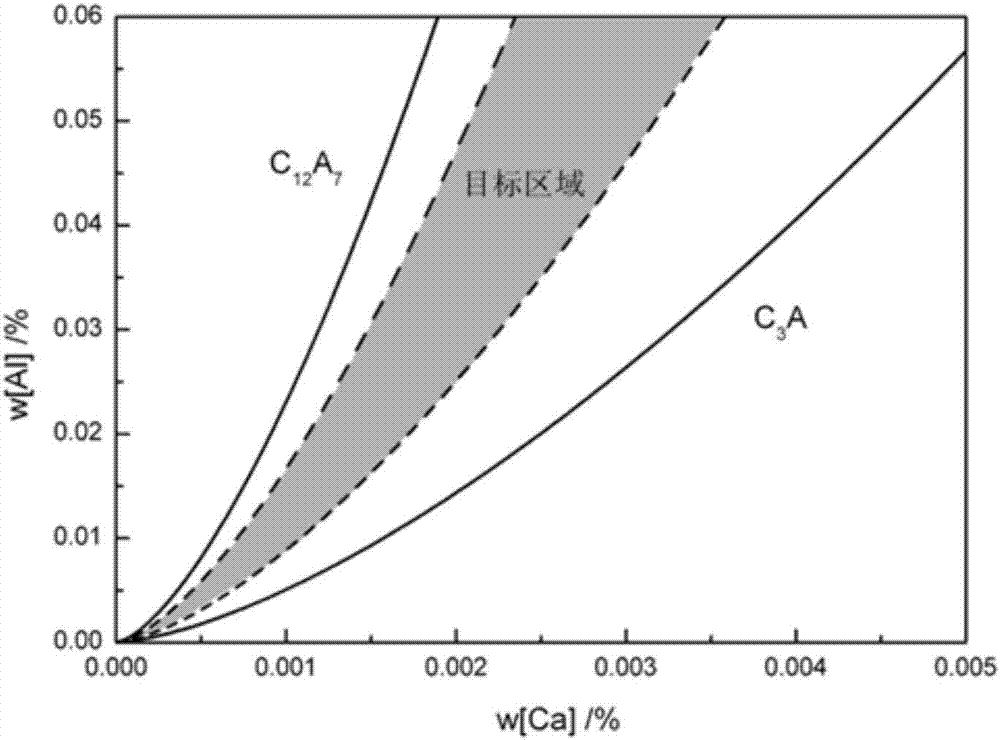

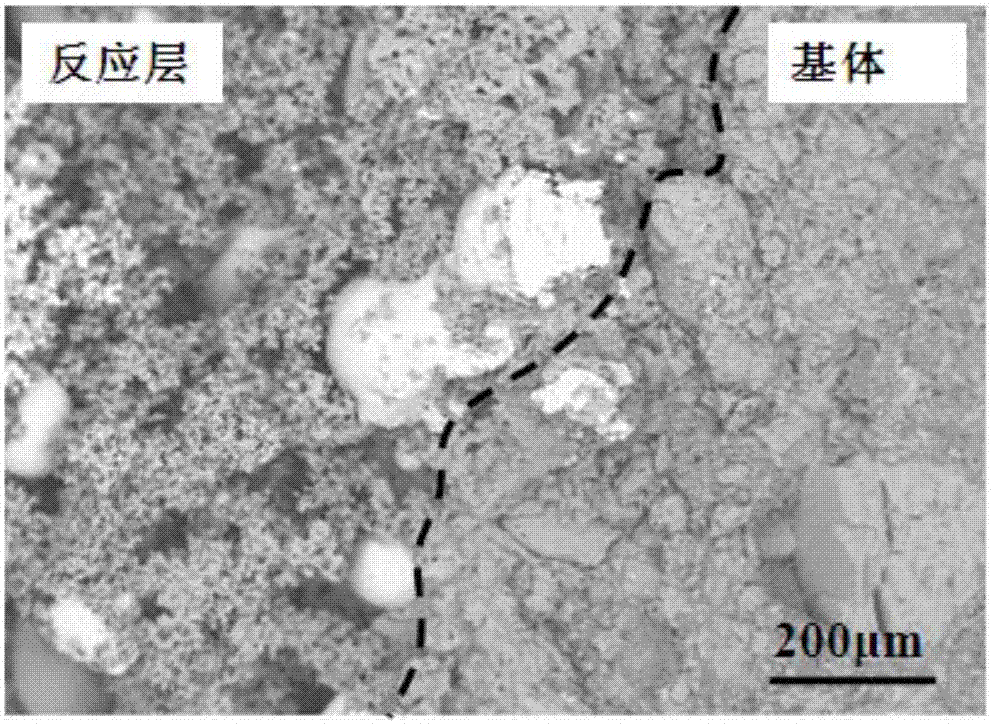

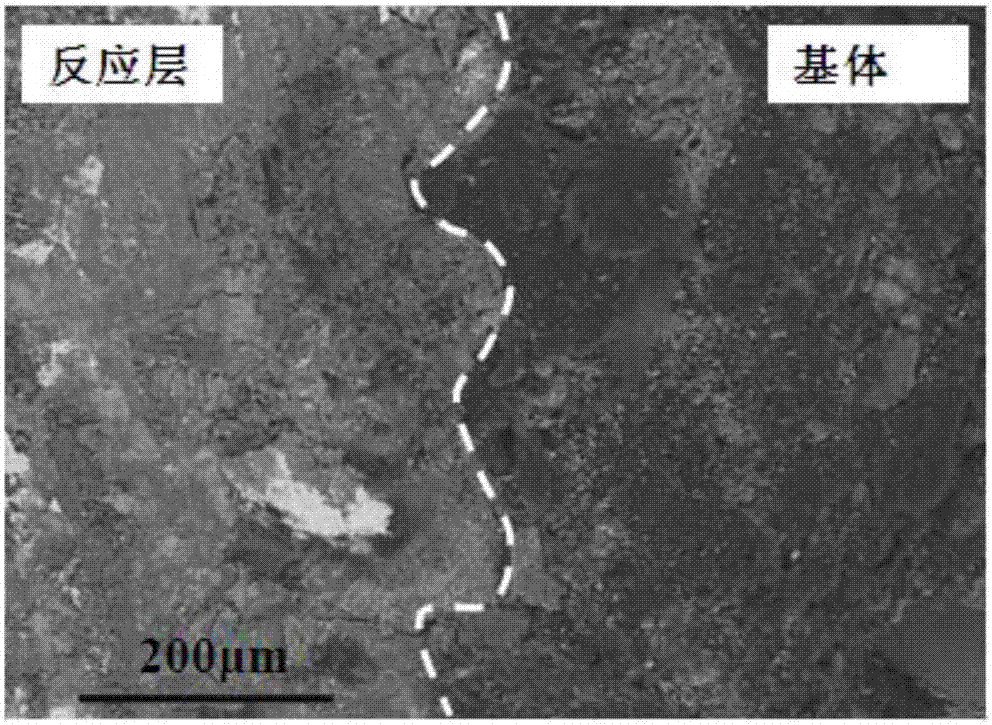

Method for reducing erosion of Al2O3-C stopper during pouring of aluminum killed cold heading steel

InactiveCN107475484AThoroughly modifiedStopper erosion avoidanceMelt-holding vesselsLadle furnaceErosion

The invention discloses a method for reducing the erosion of an Al2O3-C stopper during pouring of aluminum killed cold heading steel. The whole Al2O3-C stopper is adopted to control the flow rate of molten steel in a pouring process; the pouring of the aluminum killed cold heading steel comprises LF (Ladle Furnace) refining and tundish pouring; during steel tapping in the LF refining, [Al] in the molten steel is controlled at 0.030 to 0.055 percent, w[Ca]<3>% / w[Al]<2>% is (3.6 to 12.8)x10<-6>, and accords with conditions that in the whole Al2O3-C stopper, the mass percentage of Al2O3 is not less than 50 percent, the mass percentage of SiO2 is not more than 15 percent, and the mass percentage of ZrO2 is not less than 5 percent. By selection of proper measures of the ranges of [Al] and [Ca] in the molten steel, optimization of the LF refining and tundish pouring processes and the like, on one hand, inclusions such as aluminum oxide in the molten steel is fully modified, and on the other hand, severe stopper erosion is avoided. Compared with existing certain processes, the technological method has the advantages that the cleanness and the pourability of the molten steel are improved, the problem of fluctuation of a liquid level in the pouring process is effectively controlled, and the number of continuous pouring furnaces and the quality of a cast billet are also obviously improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

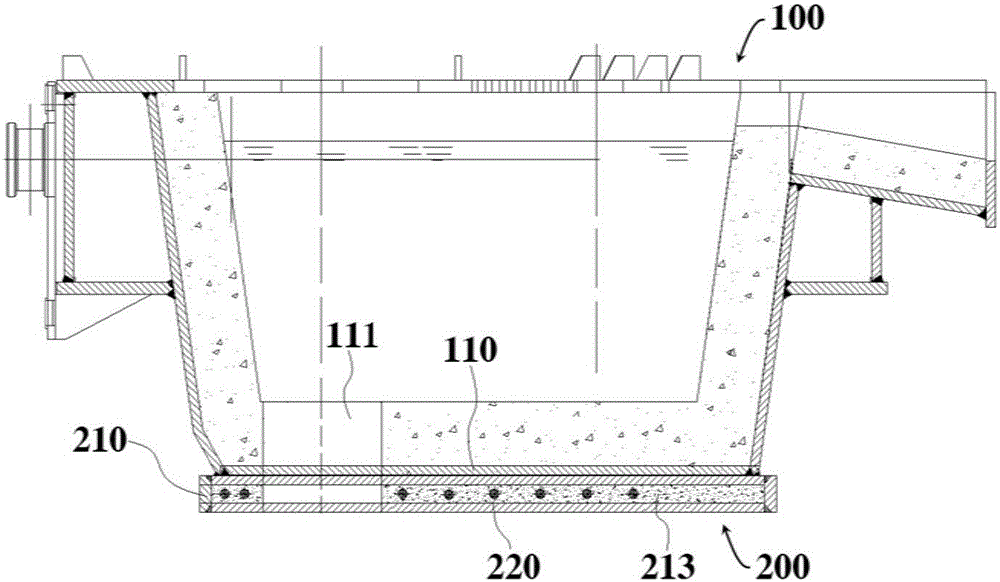

Continuous casting machine for molten steel continuous casting

ActiveCN106583675AIncrease the number of continuous pouring furnacesIncrease productivityMolten steelSteelmaking continuous casting

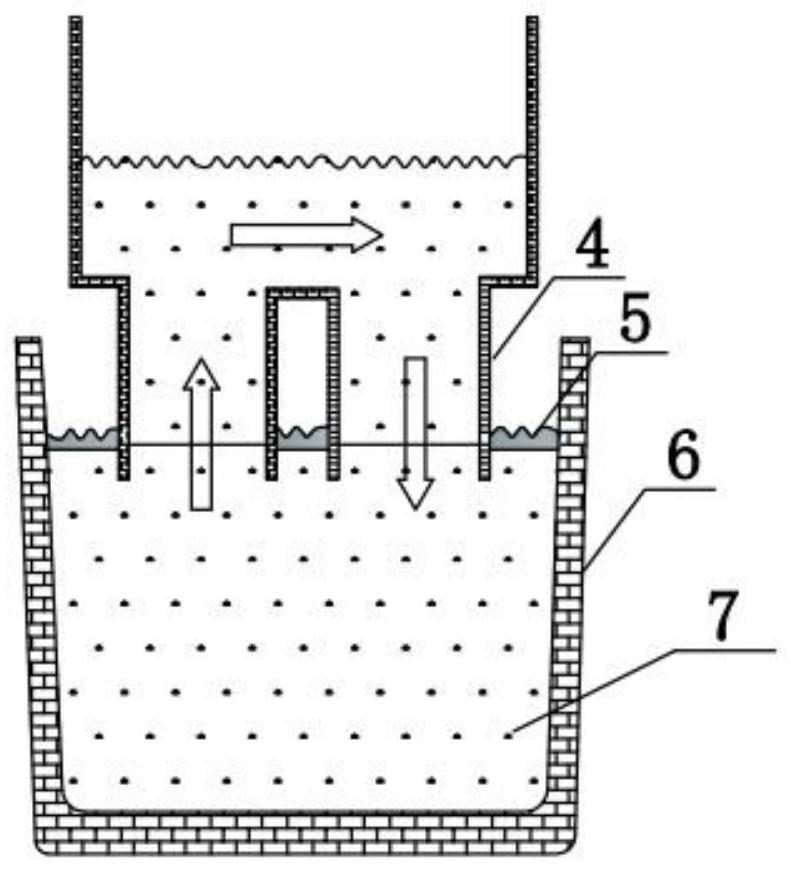

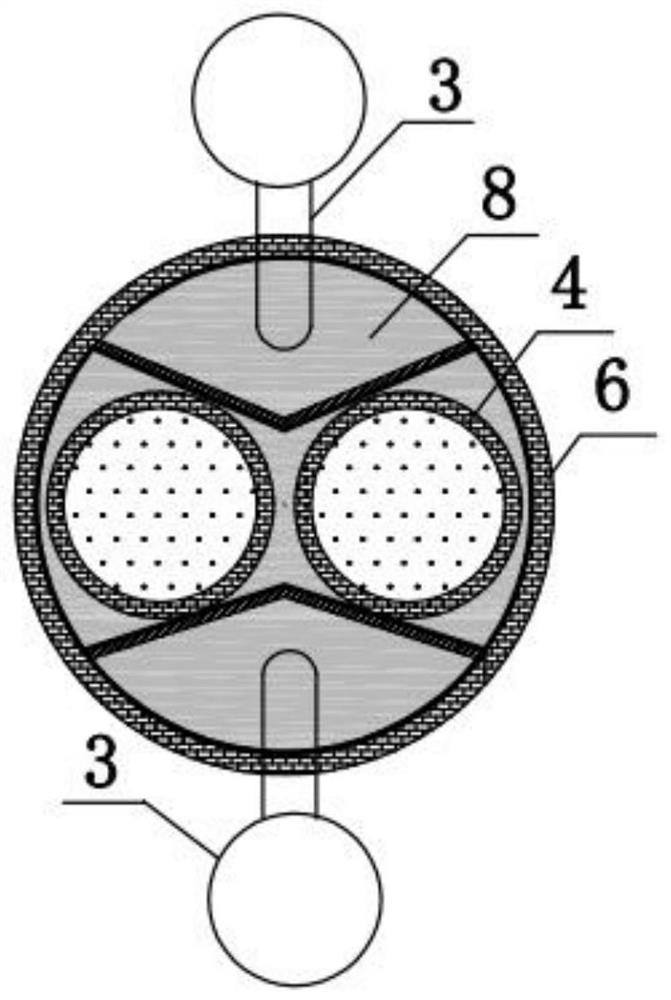

The invention discloses a continuous casting machine for molten steel continuous casting, and belongs to the technical field of steelmaking continuous casting in the metallurgical industry. A set of crystallizers are arranged on the lower portion of a steel ladle side by side. A billet-drawing forming section is arranged on the lower portion of each crystallizer. A tundish is arranged between the crystallizers and the steel ladle, the steel ladle is connected with the tundish through a sliding gate, molten steel flows from the steel ladle to the tundish through the sliding gate, and the sliding gate is located in the middle of the tundish. The tundish comprises a tundish body and a prestress application mechanism, and a tundish bottom plate is arranged horizontally. The middle of the prestress application mechanism is bent upwards in an arc shape and makes contact with the tundish bottom plate, and the prestress application mechanism applies prestress to the tundish bottom plate. The prestress applied by the prestress application mechanism to the tundish bottom plate is counteracted with the gravity of molten steel, down-warping deformation of the tundish is controlled, the replacement frequency of the tundish is reduced, and the number of continuous casting heat times of the continuous casting machine is increased.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method of sulfur-containing aluminum-containing steel

ActiveCN113969375AImprove responseGood for aggregation and absorptionMaterials scienceContinuous casting

The invention discloses a preparation method of sulfur-containing aluminum-containing steel, and belongs to the technical field of sulfur-containing aluminum-containing steel production. The technical problem to be solved by the method is flow condensing in the preparation process of the sulfur-containing aluminum-containing steel. The technological process comprises the steps of electric furnace / converter smelting, LF refining, vacuum VD and continuous casting. The sulfur-containing aluminum-containing steel is prepared from 0.43-0.47 wt% of C, 0.23-0.27 wt% of Si, 0.63-0.67 wt% of Mn, 0.31-0.35 wt% of Cr, 0.020-0.030 wt% of Al, 0.020-0.030 wt% of S, smaller than or equal to 0.015 wt% of P and the balance Fe. After the process is improved, the number of continuous casting furnaces of the sulfur-containing and aluminum-containing steel is increased from 5 to 10, the average oxygen content is 6.5 ppm, and inclusions pass inspection according to ISO-4967 standard inspection.

Owner:建龙北满特殊钢有限责任公司

RH vacuum furnace slag surface feeding device and furnace slag modification method

The invention discloses an RH vacuum furnace slag surface feeding device and a furnace slag modification method, and belongs to the technical field of steelmaking. The RH vacuum furnace slag surface feeding device comprises a high-position material bin, a material weighing bin and a telescopic and rotatable feeding guide pipe. The feeding device is mounted at a treatment station of an RH vacuum furnace, so that in the treatment stage of the RH vacuum furnace, a deoxidizing agent, synthetic slag and the like are added to the slag surface at any time to adjust the components of steel ladle slag. The operation defect that the furnace slag components cannot be directly adjusted in a traditional RH vacuum furnace treatment process is overcome, particularly for steel types such as automobile sheets, tinplates and SPHD which are subjected to converter boiling tapping and are directly conveyed to RH deep decarburization treatment, after RH decarburization treatment, the deoxidizing agent or a modifying agent can be added to the slag surface of a steel ladle through the vacuum feeding device, in combination with improvement of an RH treatment process, the oxidability of the furnace slag is reduced, and the cleanliness and pouring performance of molten steel are improved. The technology has great significance for improving the cleanliness and the pouring performance of RH single-link process cold-rolled substrate steel types.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +3

Method for increasing continuous casting heats of aluminum-deoxidized bearing steel

InactiveCN102851443BImprove cleanlinessIncrease usageManufacturing convertersProcess efficiency improvementContinuous castingLadle

A method for increasing continuous casting heats of aluminum-deoxidized bearing steel includes the steps of desulphurizing molten iron; smelting with a converter; allowing the converter to tap and alloying; performing argon stirring in an argon station; refining; vacuum-treating; feeding silicon calcium wire; performing protective casting and continuously casting to obtain blanks. The method has the advantages that original two continuous casting heats of the bearing steel is increased to more than five heats, and production efficiency is greatly improved; the number of using a ladle is increased, consumables consumption is reduced, and labor intensity of workers is reduced; low level of oxygen content and nonmetal impurities can be stably controlled, and steel cleanness is high.

Owner:武汉钢铁有限公司

Continuous casting method for high-titanium steel slab

The invention belongs to the technical field of metallurgy, and particularly relates to a continuous casting method for a high-titanium steel slab. In order to solve the problem that an existing continuous casting method for high-titanium steel cannot avoid nozzle clogging, the continuous casting method for the high-titanium steel slab is provided. The method includes the following steps that a, agas curtain barricade is adopted in a tundish, argon protection is adopted for a liquid surface, protected casting with protective sleeves is adopted in the whole process from a steel ladle to the tundish and from the tundish to a crystallizer, and before a first furnace starts casting and ladle changing is performed, a steel tube is connected to a long nozzle; b, when the N content in steel is less than or equal to 30 ppm, a high-superheat casting process is adopted, wherein the pulling rate is less than or equal to 1.1 m / min; and c, a technology of dynamic soft reduction at the final stageof solidification is adopted, and a secondary cooling system of strong cooling in the terminal area of solidification is adopted for secondary cooling. The method can reduce secondary inclusions by 30-50% and avoid the massive generation of TiN in the tundish, so that the problem of nozzle clogging is avoided, and the number of continuous casting heats is increased to be greater than 2. The methodachieves continuous casting of the high-titanium steel on the premise of ensuring the quality of the cast slab and has great significance.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

Al-Ca-Fe alloy contg. trace carbon, low slilicon, low phosphorus, low sulphur used for steelmaking

The invention relates to a micro low carbon, low silicon, low phosphor, and low sulfur Al-Ca-Fe alloy used in steel-making. It uses as deoxidizer and contains 20-85wt% Al, 1-20wt% Ca, C less than 0.02wt%, Si less than 1.0wt%, P less than 0.02wt%, S less than 0.02wt%, the rest is Fe. It is smelted from line frequency furnace. The invention has the advantage of easy to use, stable, and could improve the recovery factor of the metal element. The molten steel treated by the deoxidizer has good fluidity, high work rates, high benefits, etc. The deoxidizer could discharge the impurity, and it has good mechanical behavior, good quality, long useful life and good social benefit.

Owner:本溪冶炼集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com