Large-section aluminum-containing hot-rolled H-shaped steel and manufacturing method thereof

An H-beam, large-section technology, applied in the field of metallurgy, can solve the problems of the large difference in the service life of the nozzle, the addition of many alloying elements, and the unstable boron recovery rate, achieving high qualification rate, fewer production processes, and reducing nozzle nodules. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

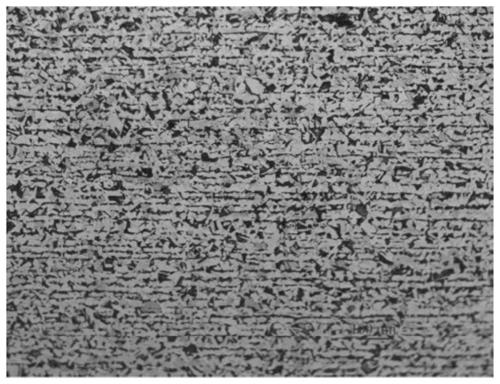

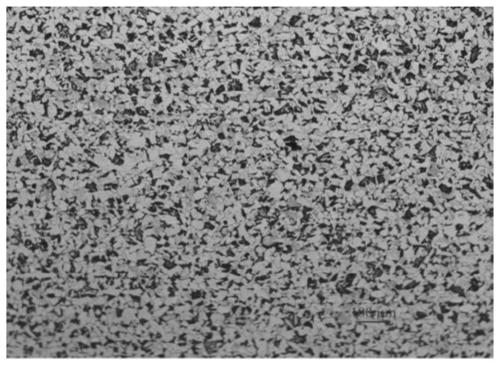

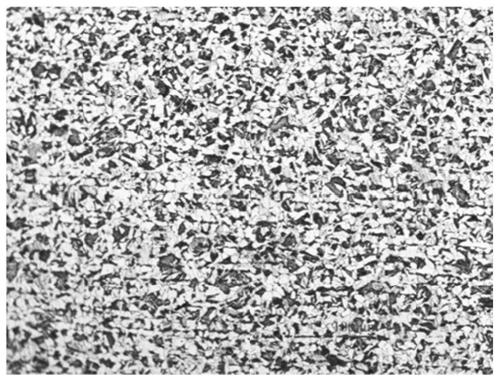

Image

Examples

Embodiment 1-5

[0040] The process route is: pre-desulfurization of molten iron→converter smelting→LF refining→single-point unbalanced full-protection continuous casting of near-net-shaped shaped billets→rolling→inspection and storage.

[0041] The main technological measures of the preparation method:

[0042] (1) Pre-desulfurization of molten iron: the arsenic content of molten iron entering the furnace is less than 80ppm; the sulfur content of molten iron after desulfurization is ≤0.008wt%.

[0043] (2) Converter smelting: Smelting in a converter with top-bottom combined blowing, the ladle is a red net ladle with good bottom blowing, and the baking temperature is 800°C to 1200°C; it is alloyed with silicomanganese, medium manganese, and ferrovanadium, and the addition amount is respectively 11.0-13.0kg / t steel, 7.5-8.0kg / t steel, 1.0-1.5kg / t steel; Al-Mn-Ferro deoxidation is used, the addition amount is 2.0-2.5kg / t steel, and Al-Mn is adjusted according to the peroxidation situation The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com