SWRH82B high-carbon steel wire rod and preparation method thereof

A high-carbon steel and wire technology, applied in the field of SWRH82B high-carbon steel wire and its preparation, can solve the problems of low purity of molten steel, poor composition uniformity, high amount of aluminum oxide inclusions, etc., to ensure that the drawing does not break, High purity, the effect of increasing the number of continuous pouring furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

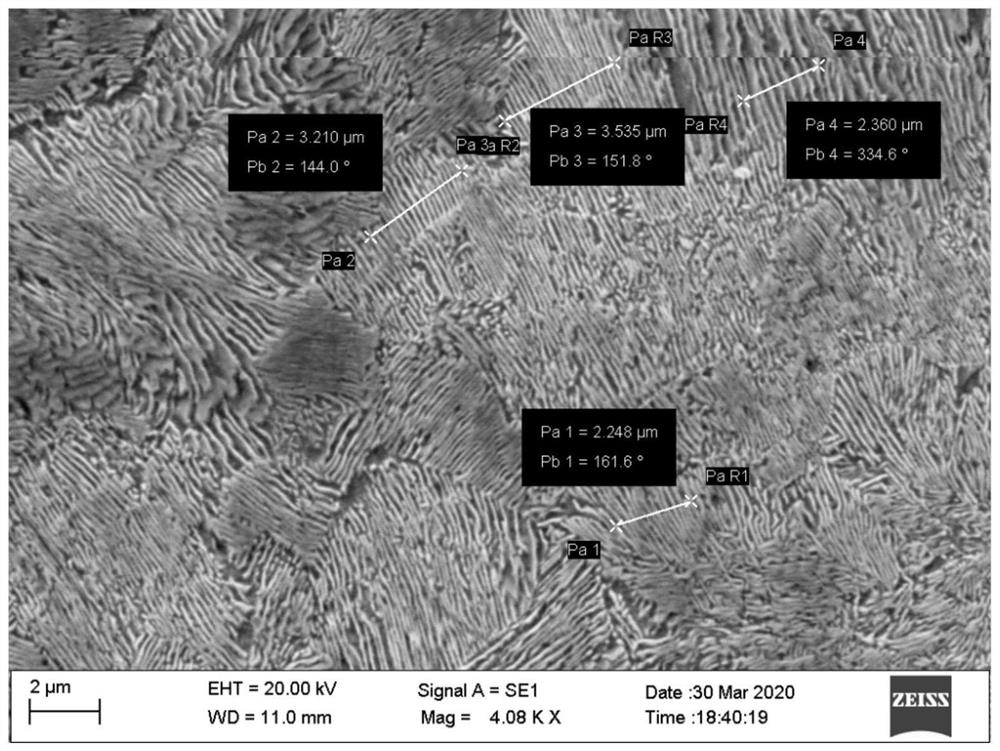

Image

Examples

Embodiment 1

[0030] This embodiment provides a preparation method of SWRH82B high-carbon steel wire rod, including primary refining process→LF refining process→continuous casting process→heating and rolling process→controlled cooling process, wherein during the primary refining process:

[0031] Converter or electric furnace is used for smelting, the C content of tapping is not less than 0.15wt%, the tapping temperature is 1620-1640°C, fusible slag is added before tapping, silicon-calcium-barium, carbon powder, and lime are added during tapping. The chemical composition of the steel type is added to the alloy to ensure that the composition in place is controlled within ±0.2%;

[0032] During LF refining:

[0033] The refining position uses carbon powder and silicon carbide powder for deoxidation in the whole process. The refining position is powered once, and lime, fluorite, diffusion deoxidizer silicon carbide, and carbon powder are added; the second power transmission is added with diffu...

Embodiment 2

[0041] The difference between this embodiment and embodiment 1 is that in the initial refining process of this embodiment:

[0042] The materials for smelting iron and steel are molten iron and steel scrap, wherein the molten iron accounts for 85wt% and the scrap steel accounts for 15wt%. Converter or electric furnace is used for production, and the temperature of molten iron is controlled above 1200°C.

[0043]In order to realize the high-efficiency production of qualified slabs by matching the furnace and machine, the primary smelting furnace must reasonably control the smelting time, prevent the molten steel from overoxidation, and control the oxygen content in the steel. Using a 4-hole Lava oxygen lance, the oxygen blowing time is controlled within 15 minutes, and the smelting time is controlled within 30-35 minutes. Effectively controlling the blowing time can ensure the normal casting of continuous casting.

[0044] The C content of the molten steel reaches more than 0....

Embodiment 3

[0048] The difference between this embodiment and embodiment 1 or 2 is that in the LF refining process of this embodiment:

[0049] In order to ensure that the refining station can quickly smelt qualified molten steel for continuous casting and pouring, the refining process is all produced using turnover ladles, and the production process is summed up for rapid temperature rise and slag formation, and the superheat is reasonably controlled at 20-28 °C.

[0050] After temperature measurement and sampling of the molten steel in place, the components in place are judged, power is sent to the refining station once, lime 1-3Kg / t, fluorite 0-1Kg / t, diffusion deoxidizer silicon carbide 0.7-0.8Kg / t, carbon powder 0.3-0.5 Kg / t; secondary power transmission plus diffusion deoxidizer silicon carbide 0.4~0.5Kg / t, carbon powder 0.2~0.3Kg / t.

[0051] Carbon powder and silicon carbide powder are used for deoxidation throughout the refining process to create an acidic slag system, and the bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com