Titanium-containing solder wire steel production method capable of alleviating continuous casting nozzle clogging

A continuous casting nozzle and production method technology, applied in the field of steelmaking, can solve the problems that the spatter of the finished welding wire is difficult to control, cannot be significantly reduced, the titanium alloying process and the actual production control technology are unknown, and other problems, so as to reduce the nozzle nodule The effect of increasing the number of continuous pouring furnaces and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The method for producing titanium-containing welding wire steel for reducing nodule at a continuous casting nozzle comprises the following steps:

[0029] (1) Top-bottom double blowing converter smelting: low-sulfur molten iron and high-quality scrap steel are selected for blowing, and the sulfur content is S ≤ 0.030wt%. The control target of the converter end point is shown in Table 1. tail;

[0030] The tapping is made of low carbon and low phosphorus raw materials for alloying, and the deoxidizers are silicon aluminum barium and aluminum manganese titanium magnesium, which are added to the ladle along with the steel flow. The amount of deoxidizer added is shown in Table 1; Oxide and nitride inclusions are fully floated and excluded.

[0031] The top slag was pre-deoxidized with an aluminum-free deoxidizer, and the FeO+MnO content in the slag is shown in Table 1.

[0032] (2) LF furnace refining: the process control parameters are shown in Table 2, the LF refining s...

Embodiment 2-4

[0039] In Example 2-4, the steps are the same as in Example 1, and the process parameters are controlled as shown in Table 1-8.

[0040]

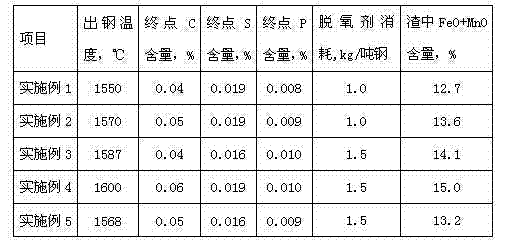

[0041] Table 1 End point of converter and deamination alloying control parameters (weight percentage, the same below)

[0042]

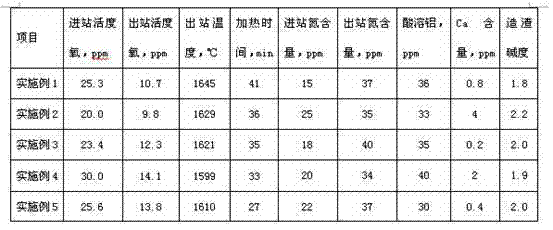

[0043] Table 2 LF refining process control parameters

[0044]

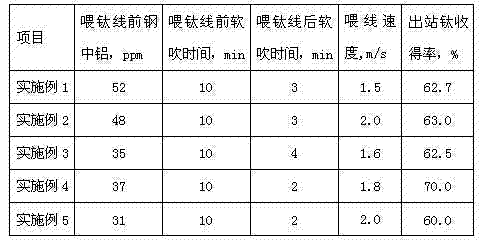

[0045] Table 3 LF furnace titanium alloying route

[0046]

[0047] Table 4 Technical parameters of low-aluminum and low-nitrogen 70Ti iron-clad wire

[0048]

[0049] Table 5 Control of refining slag composition

[0050]

[0051] Table 6 Continuous casting process control parameters and slab yield

[0052]

[0053] Note: The liquidus temperature is about 1512°C.

[0054] Covering agent chemical composition in Table 7, %

[0055]

[0056] Table 8 Composition of finished welding wire steel, %

[0057]

[0058] In Examples 1-5, there is basically no nodule formation on the nozzle of the tundish, and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com