A method and device for forming electroformed nickel parts

A technology of electroforming nickel and parts, which is applied in the field of surface treatment of parts, can solve problems such as nodules and burrs on the nickel layer, thick coating, and the influence of parts cutting and forming, so as to reduce burrs and nodules, reduce production cycle, and ensure product quality quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

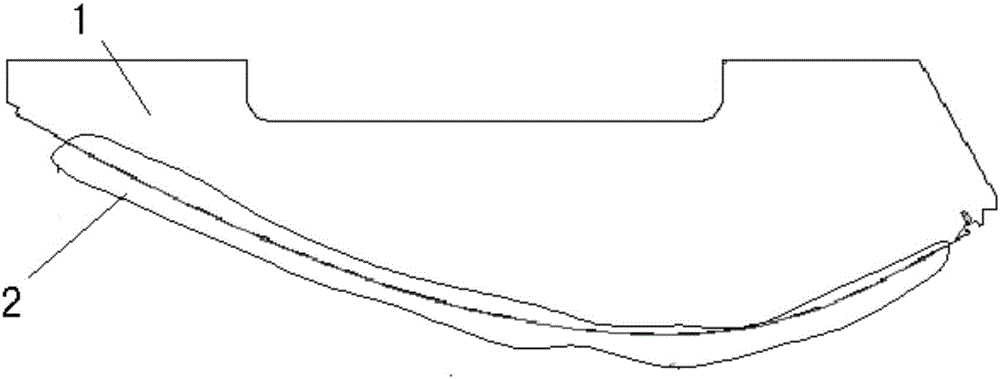

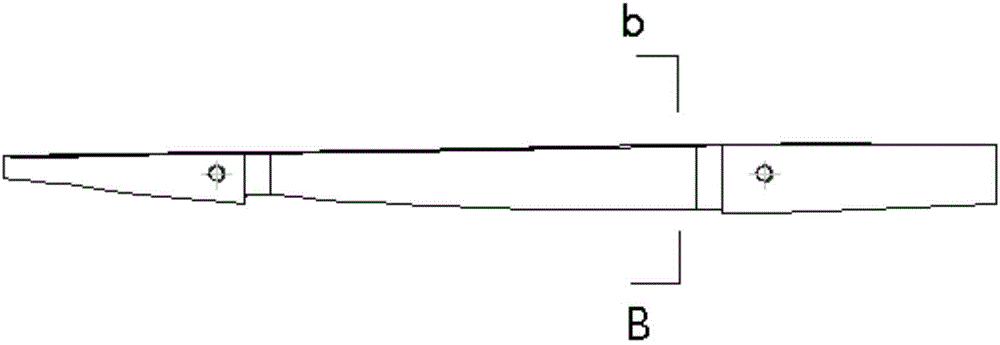

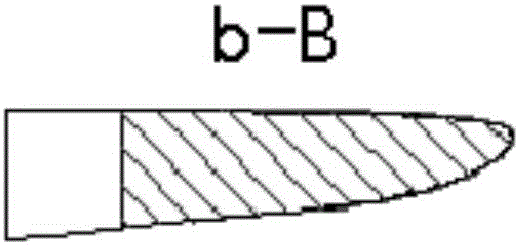

[0025] The front of the part is horn-shaped, but without sharp corners, the side is U-shaped, and the opening direction is the inner arc side; the auxiliary cathode is formed by bending two copper wires parallel to the part boundary, and connected to a copper wire parallel to the outer arc surface On the whole, it is a frame structure.

[0026] refer to Figure 4 , the pictographic auxiliary cathode includes a central frame 1 and wing frames 2 on the left and right sides, the central frame 1 is consistent with the tip contour of the mandrel, and the wing frame 2 is consistent with the contour of the boundary line of the part.

[0027] 2.1 Add pictographic auxiliary cathode on the mandrel

[0028] According to the distribution characteristics of the current on the mandrel, a pictographic auxiliary cathode is made in the area where the power lines are concentrated. The pictographic auxiliary cathode is a frame structure made of metal conductors. The pictographic auxiliary catho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com