Roasting shaft furnace

A shaft furnace and roasting technology, applied in the field of mineral roasting equipment, can solve the problems of low furnace operation rate, loss of cooling beam wall effect, short maintenance cycle, etc., to reduce investment and maintenance costs, reduce oil resource consumption, and increase operations. The effect of rate and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

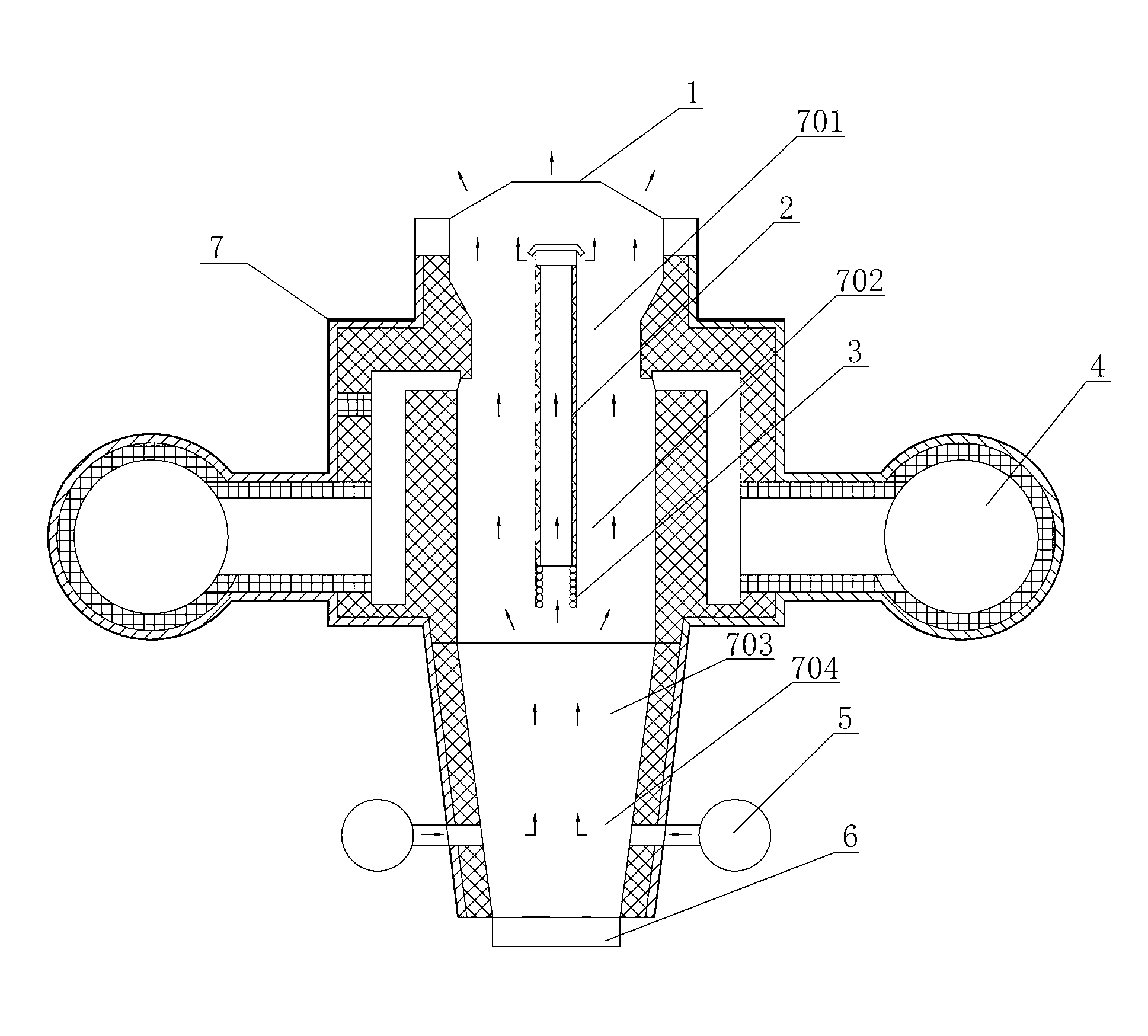

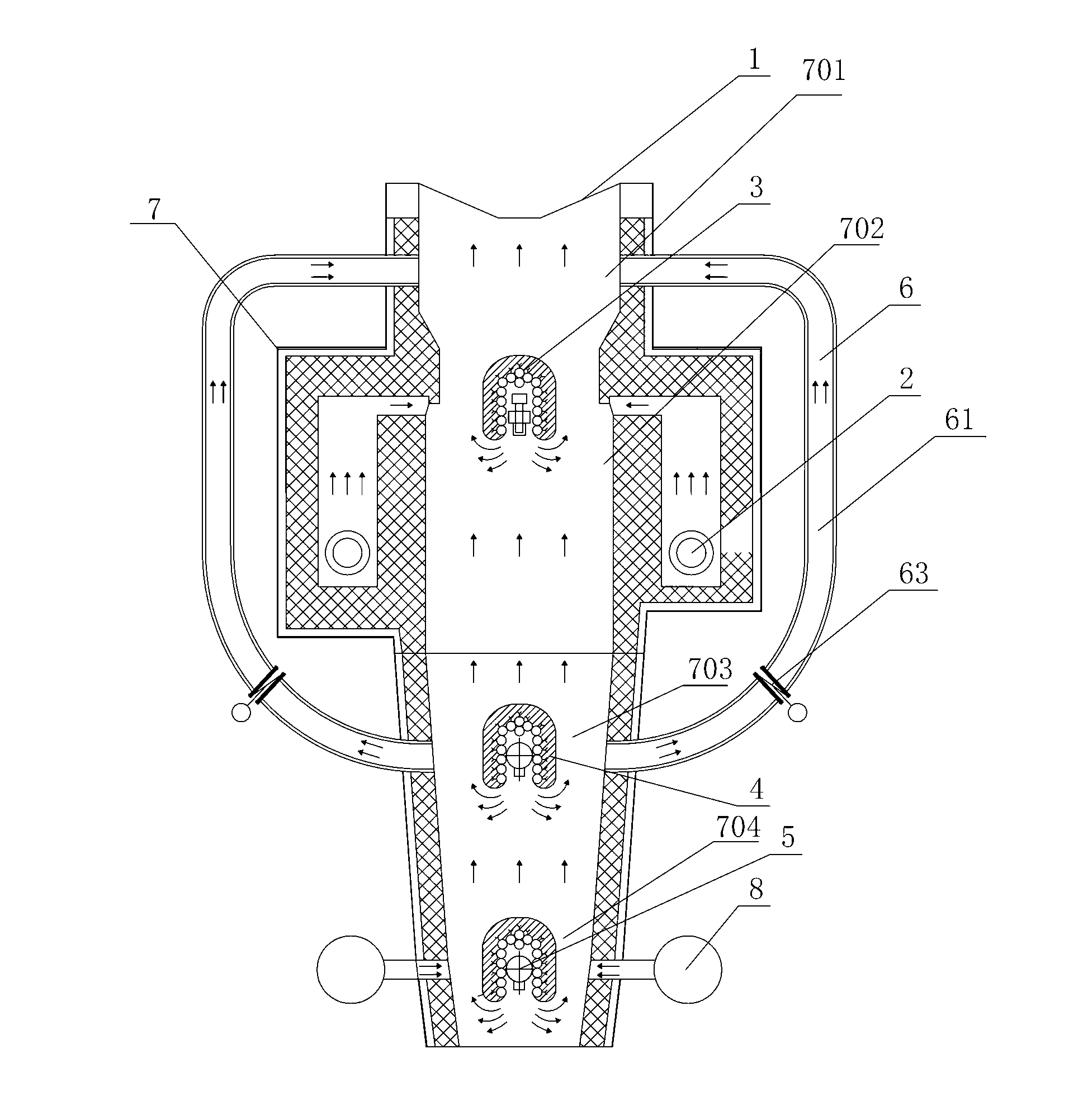

[0038] Such as figure 2 As shown, the roasting shaft furnace of the present invention includes a furnace body 7, more than two combustion chambers 4 and a drying bed 1 positioned at the top of the furnace body 7, and the inner chamber of the furnace body 7 is divided into drying sections 701 from top to bottom. , roasting section 702, soaking section 703 and cooling section 704 (various airflows in the furnace run in the direction of the arrow in the figure), the combustion chamber 4 is located at the position corresponding to the side of the furnace body 7 and the roasting section 702 and communicates with the furnace cavity. The furnace body 7 is provided with a return hot air assembly 6, the air inlet end of the return hot air assembly 6 communicates with the furnace inner cavity located at the bottom of the combustion chamber 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com