A nozzle swirl generating device and a nozzle swirl continuous casting method

A generating device and swirl generator technology, which is applied to casting equipment, casting molten material containers, metal processing equipment, etc., can solve the problem of affecting the service life of the submerged nozzle, the guide groove is easily blocked or eroded, and the swirl strength is weakened, etc. problems, achieve the effect of reducing nozzle nodulation, preventing nozzle clogging, and improving flow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

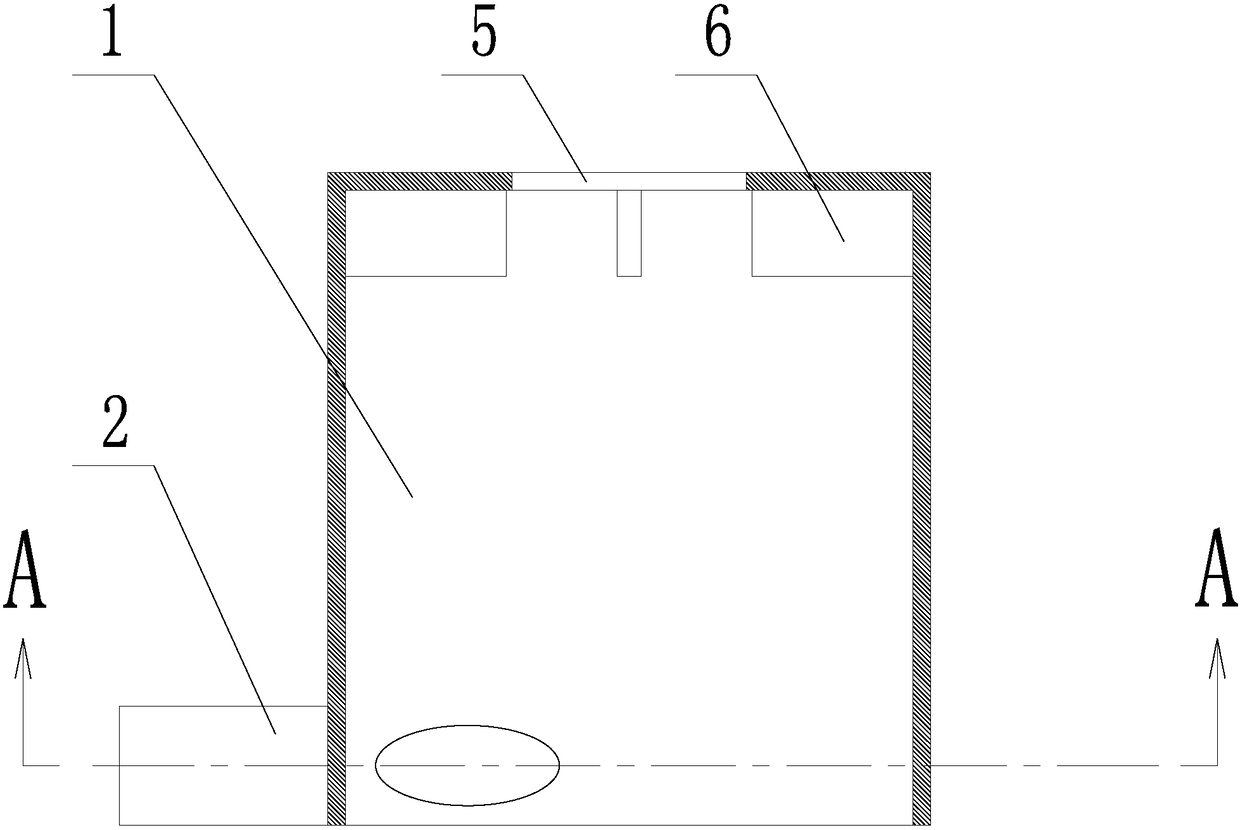

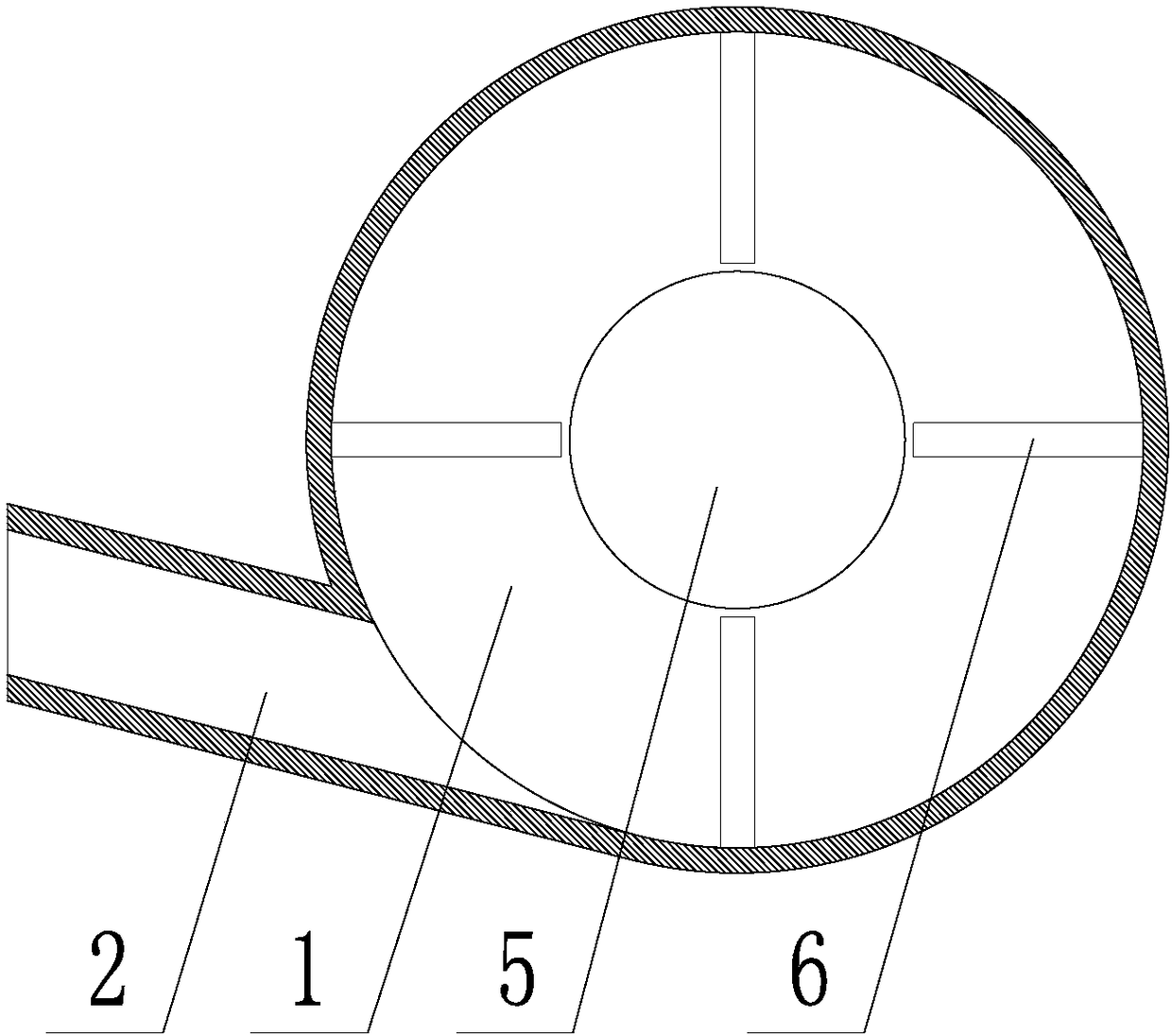

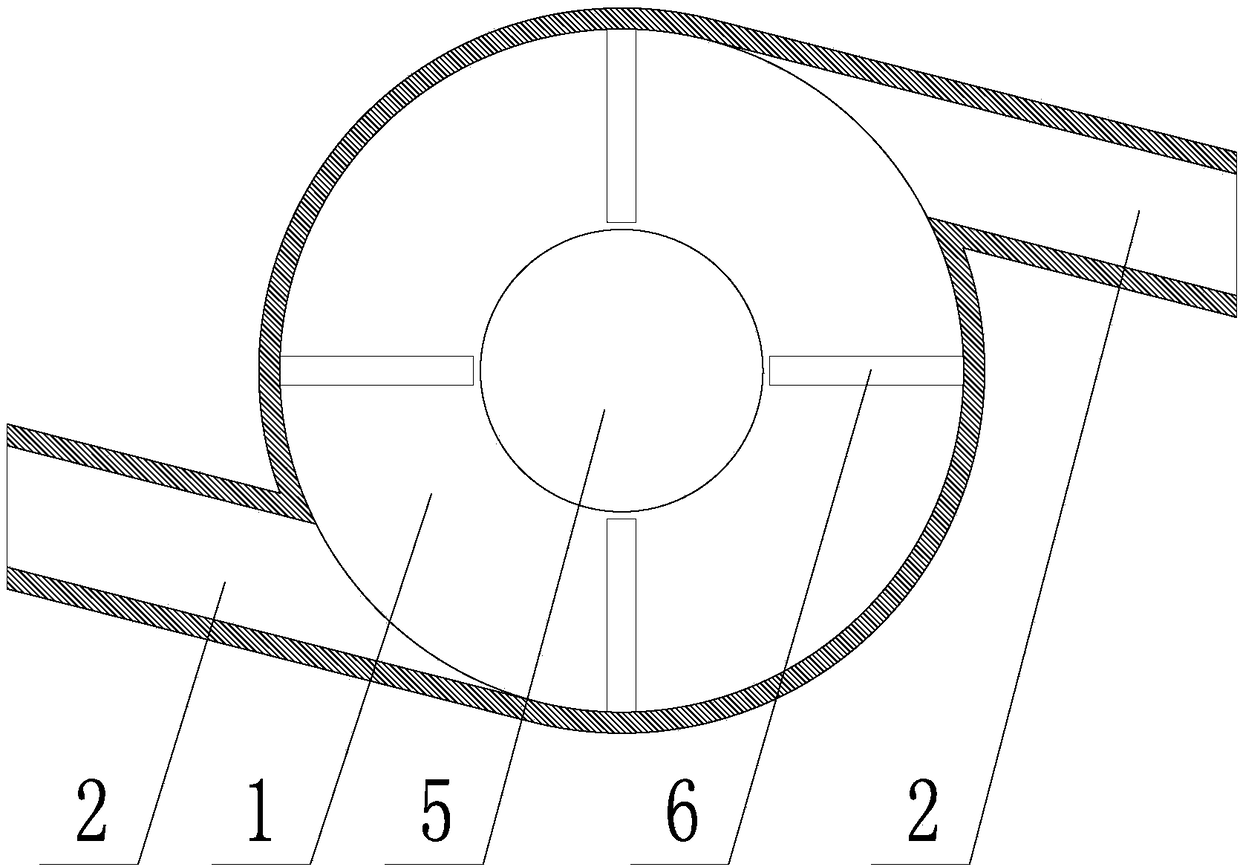

[0052] In the continuous casting production process, the size of the cylindrical swirl generator and the cylindrical swirl tundish can be set according to the actual production capacity requirements. The specific dimensions are as follows:

[0053] Cylindrical swirl generator: the generator cylinder 1 can be of equal diameter structure or variable diameter structure. When the equal diameter structure is preferred, the inner diameter of the generator cylinder 1 is 100mm-500mm, and the generator molten steel inlet 2 can be a circular pipe , rectangular tube or other shape tubes, preferably circular tubes, the inner diameter of the generator molten steel inlet 2 is 10 mm to 100 mm, the number of generator molten steel inlets 2 is preferably 1 to 2, and the number of slag retaining weirs 6 is preferably 4 and can be cuboid The length, width and height of the slag retaining weir 6 are 20mm-100mm, 20mm-50mm and 20mm-200mm respectively.

[0054] Cylindrical swirling tundish: the tund...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com