Double-suction multi-flow-channel impeller and design method thereof

A design method and multi-channel technology, applied to mechanical equipment, radial flow pumps, components of pumping devices for elastic fluids, etc., can solve problems such as poor fluidity, poor fluidity, and poor diversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

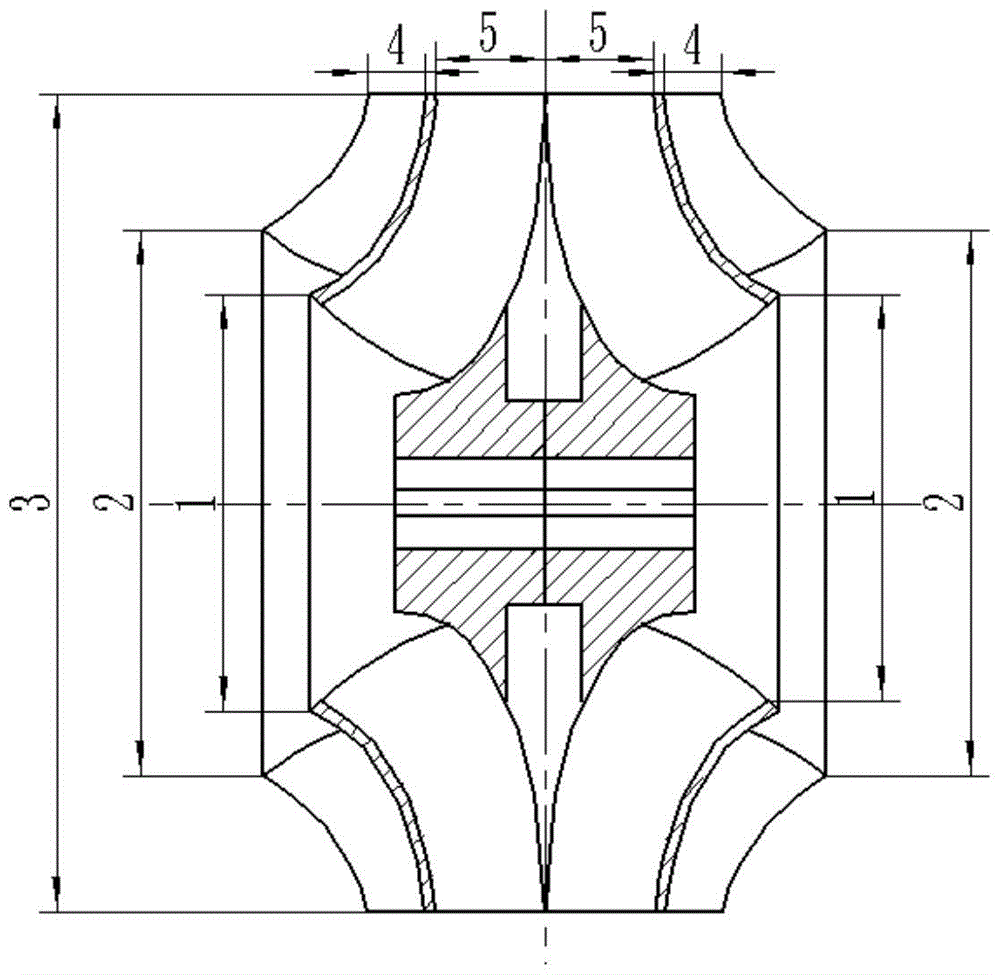

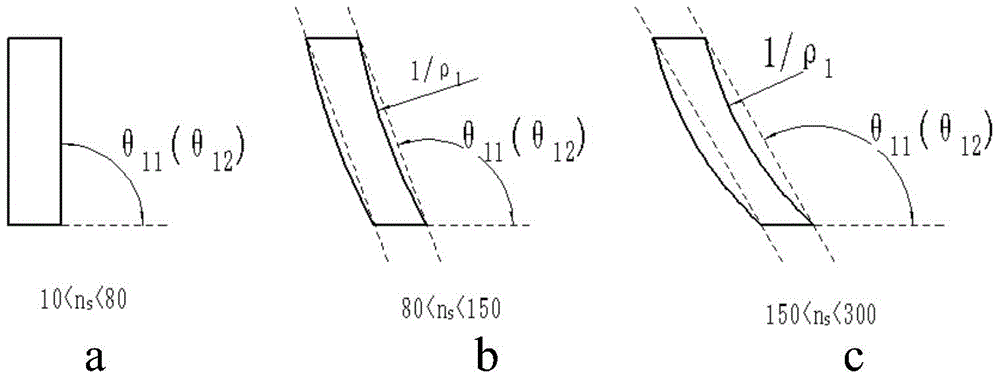

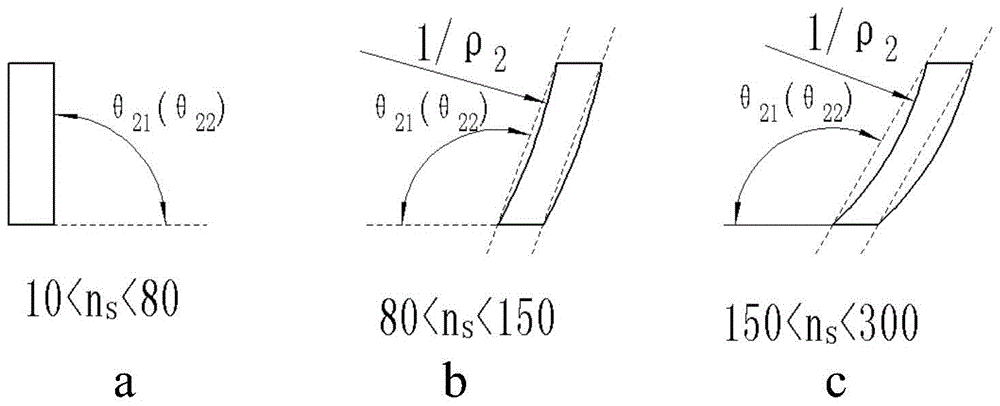

[0143] figure 1 The geometry and size of the double-suction multi-channel impeller of this embodiment are determined. In the present invention, the diameter D of the impeller inlet in the double-suction multi-channel is determined by the following relations j1 , Outer impeller inlet diameter D j2 , Inner impeller blade length L 1 , Outer impeller blade length L 2 , Inner impeller inlet blade deflection angle θ 11 , Outer impeller inlet blade deflection angle θ 21 , Inner impeller outlet blade deflection angle θ 12 , Outer impeller outlet blade deflection angle θ 22 , impeller inlet edge curvature ρ 1 , The curvature ρ of the impeller outlet 2 Important design parameters of the impeller.

[0144] D j 1 = K 1 2 ( - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com