Double-suction double-layer double-channel impeller and design method thereof

A design method and double-channel technology, applied to mechanical equipment, components of pumping devices for elastic fluids, non-variable pumps, etc., can solve problems such as large axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

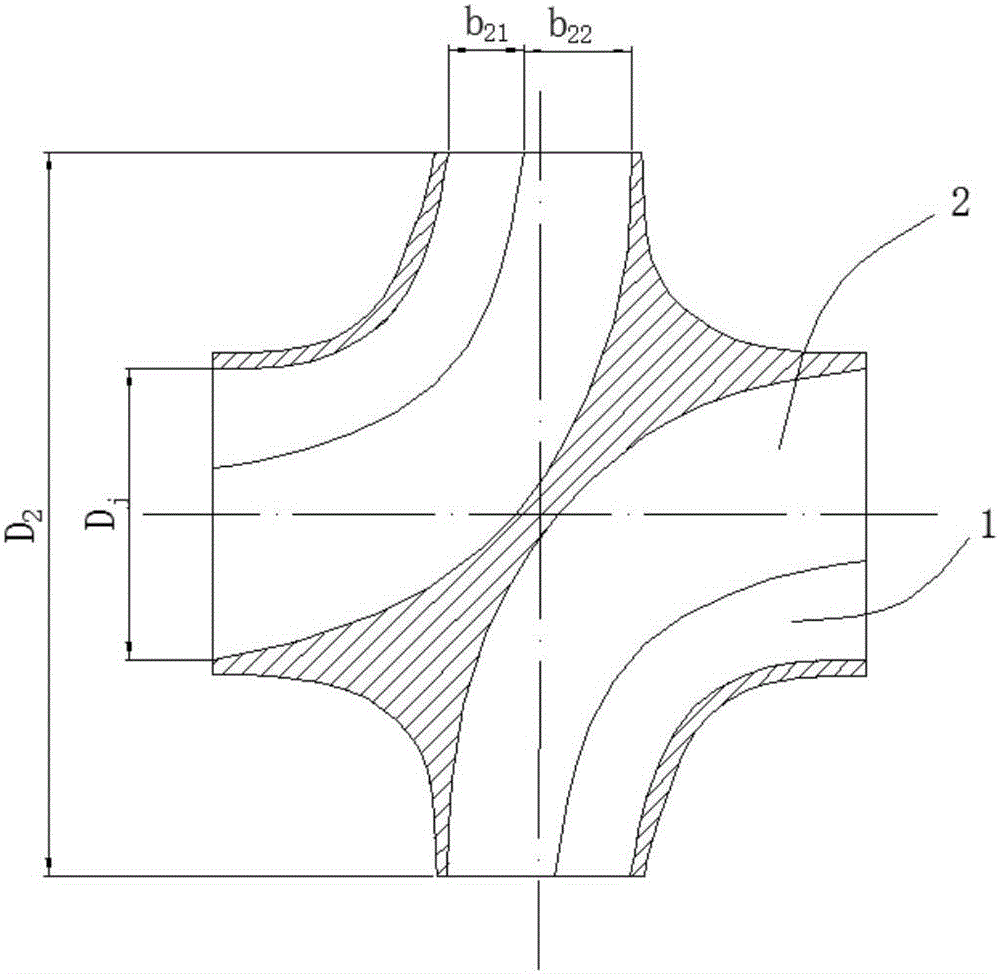

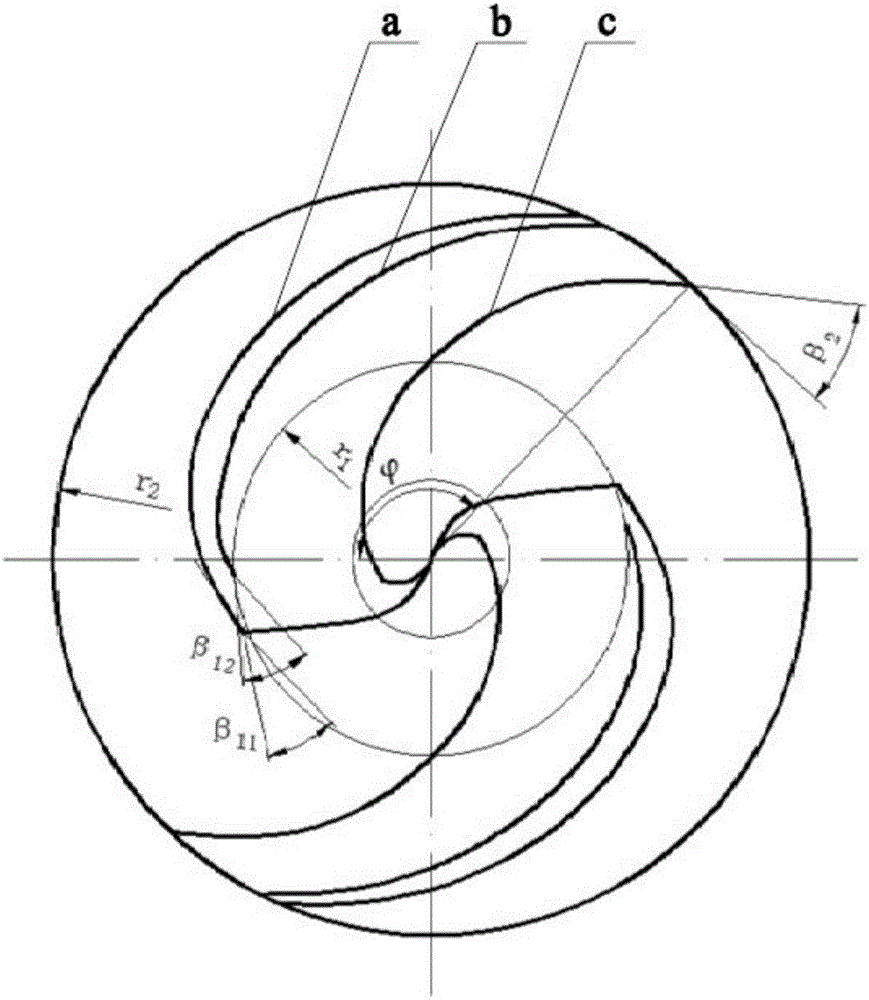

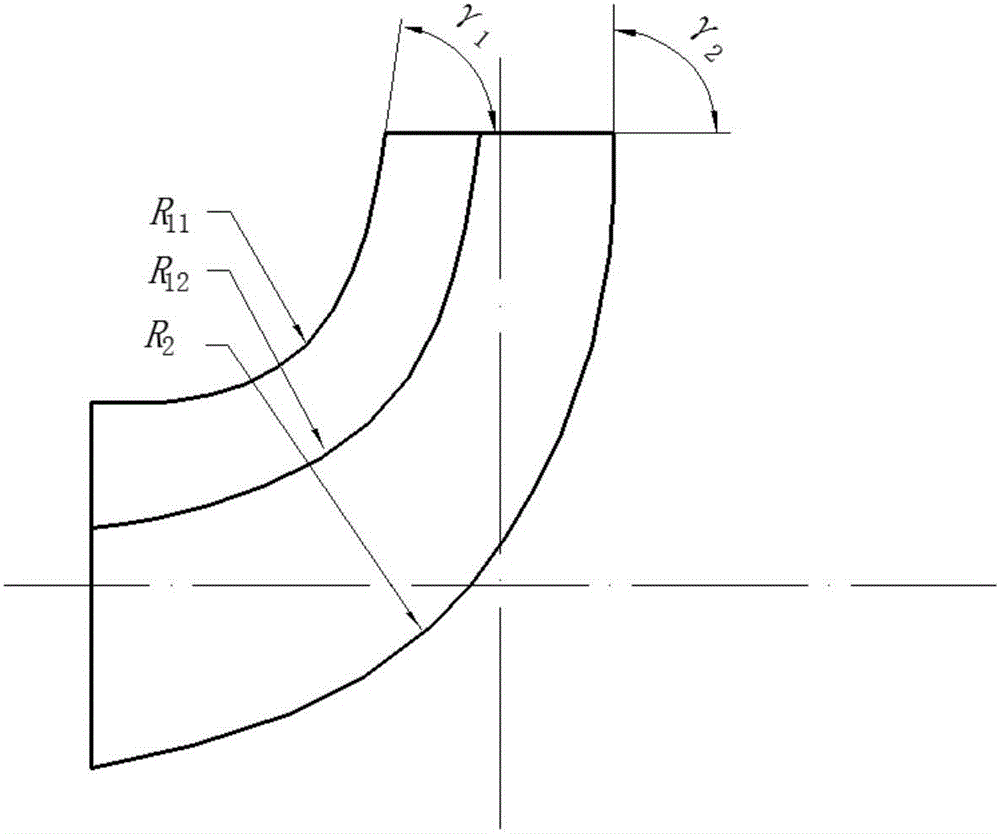

[0101] figure 1 and Figure 4 As shown, a double-suction double-layer double-channel impeller is characterized in that the double-channel impeller is an asymmetrical double-suction structure, the left and right flow channels are 180° mirror image distribution, and each flow channel is a double-layer impeller; the double-flow channel Each channel of the impeller corresponds to a suction port, and the suction port is symmetrically arranged on both sides of the double-suction, double-channel, and double-channel impeller; It is the first layer of flow channel 1, and the second layer of flow channel 2 is far away from the inlet cover plate of the flow channel. The axial width of the first layer of flow channel 1 and the second layer of flow channel 2 is different, and the Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com