Double-outlet multipurpose external mixing type self-priming pump with quasi-spiral suction chamber

A spiral-shaped, suction chamber technology, applied in the field of double-outlet multi-purpose external mixing self-priming pumps, can solve problems such as liquid flow disorder, damage to bearings and sealing parts, and increased hydraulic loss of the volute, so as to improve the flow state, Easy installation and maintenance, and the effect of reducing hydraulic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

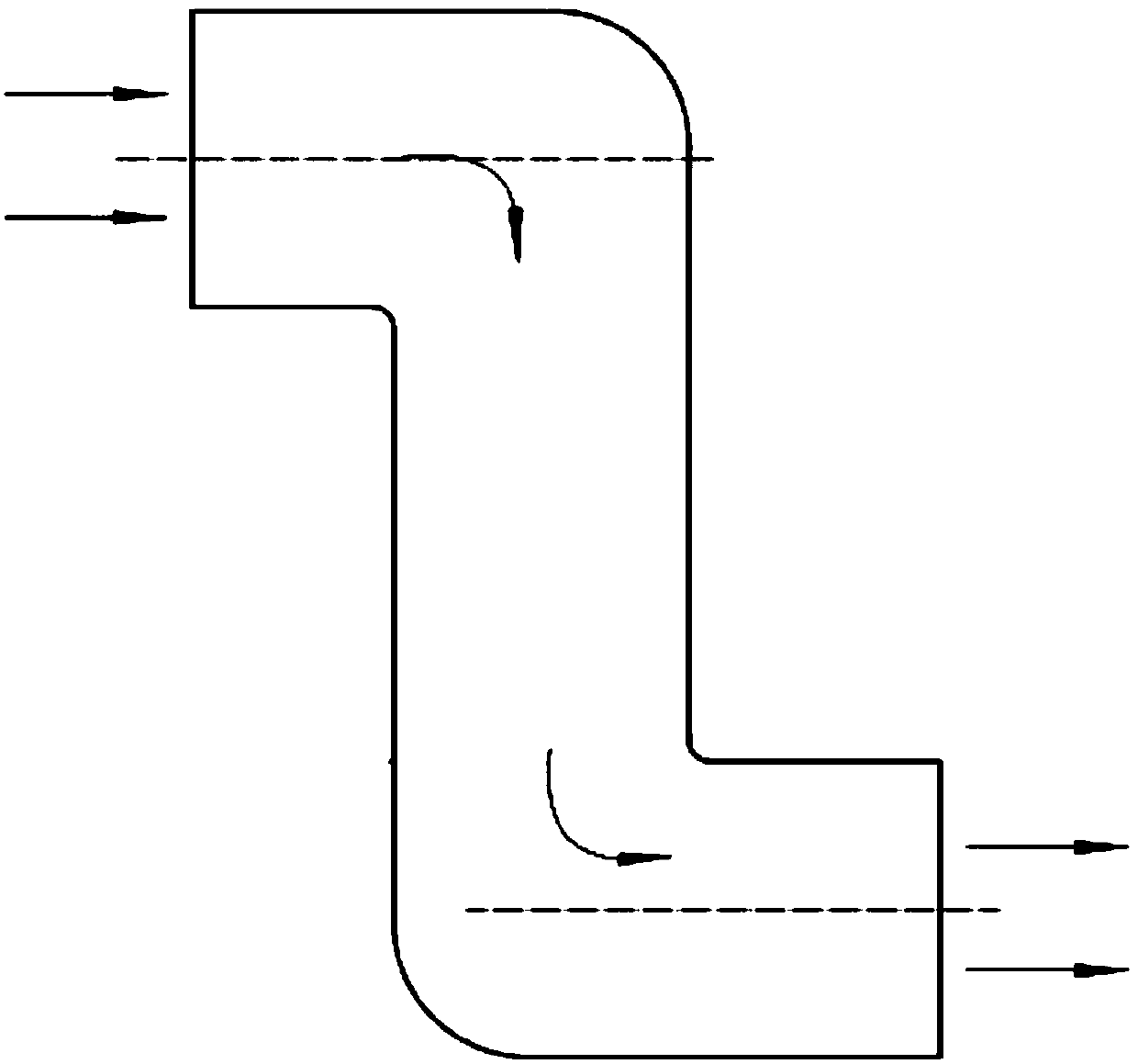

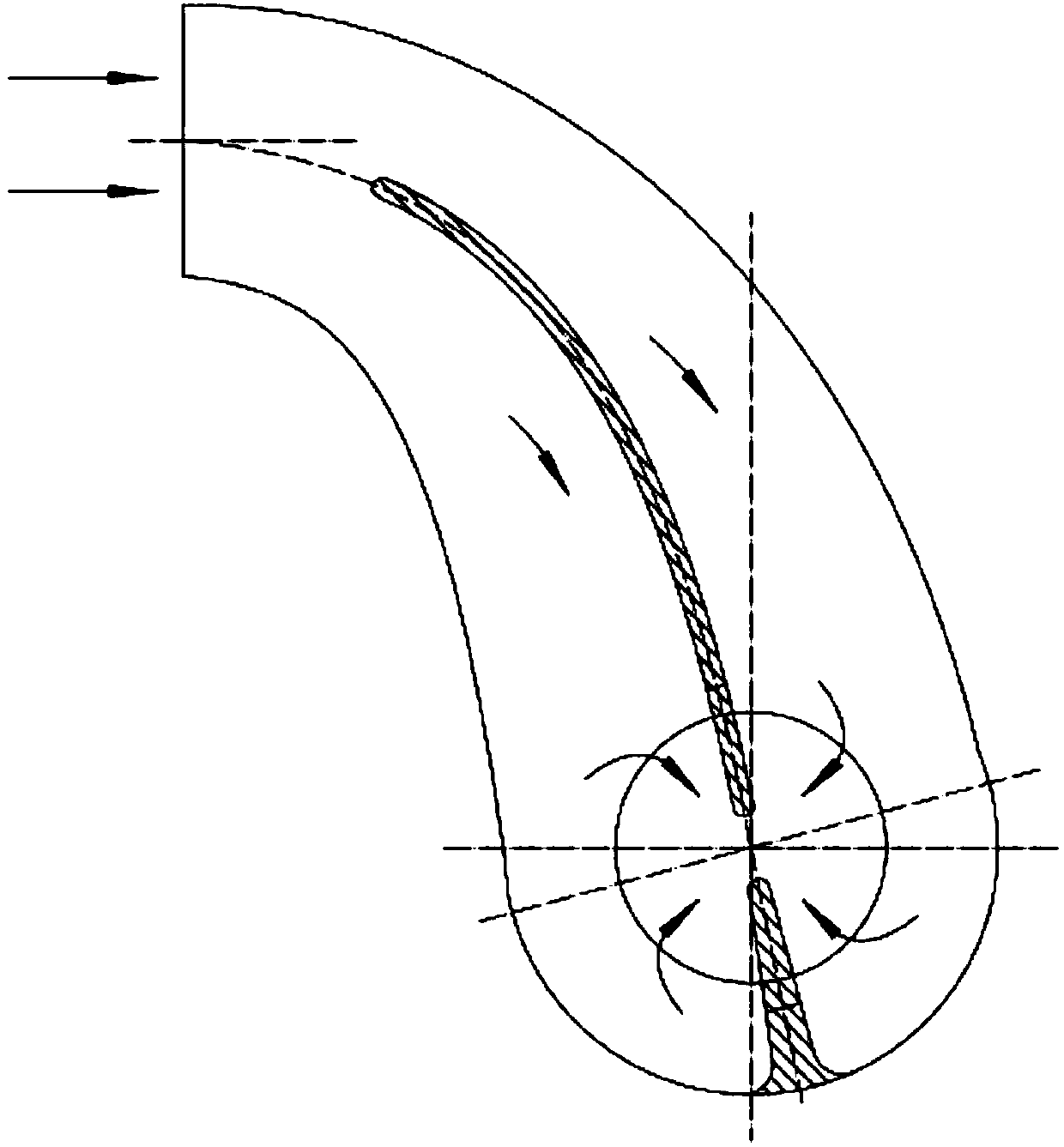

[0049] Attached figure 2 It is a plan view of a quasi-spiral suction chamber of an embodiment of a dual-outlet multi-purpose external mixing self-priming pump with a quasi-spiral suction chamber according to the present invention. The figure shows the liquid flow in the quasi-spiral suction chamber of the present invention. direction;

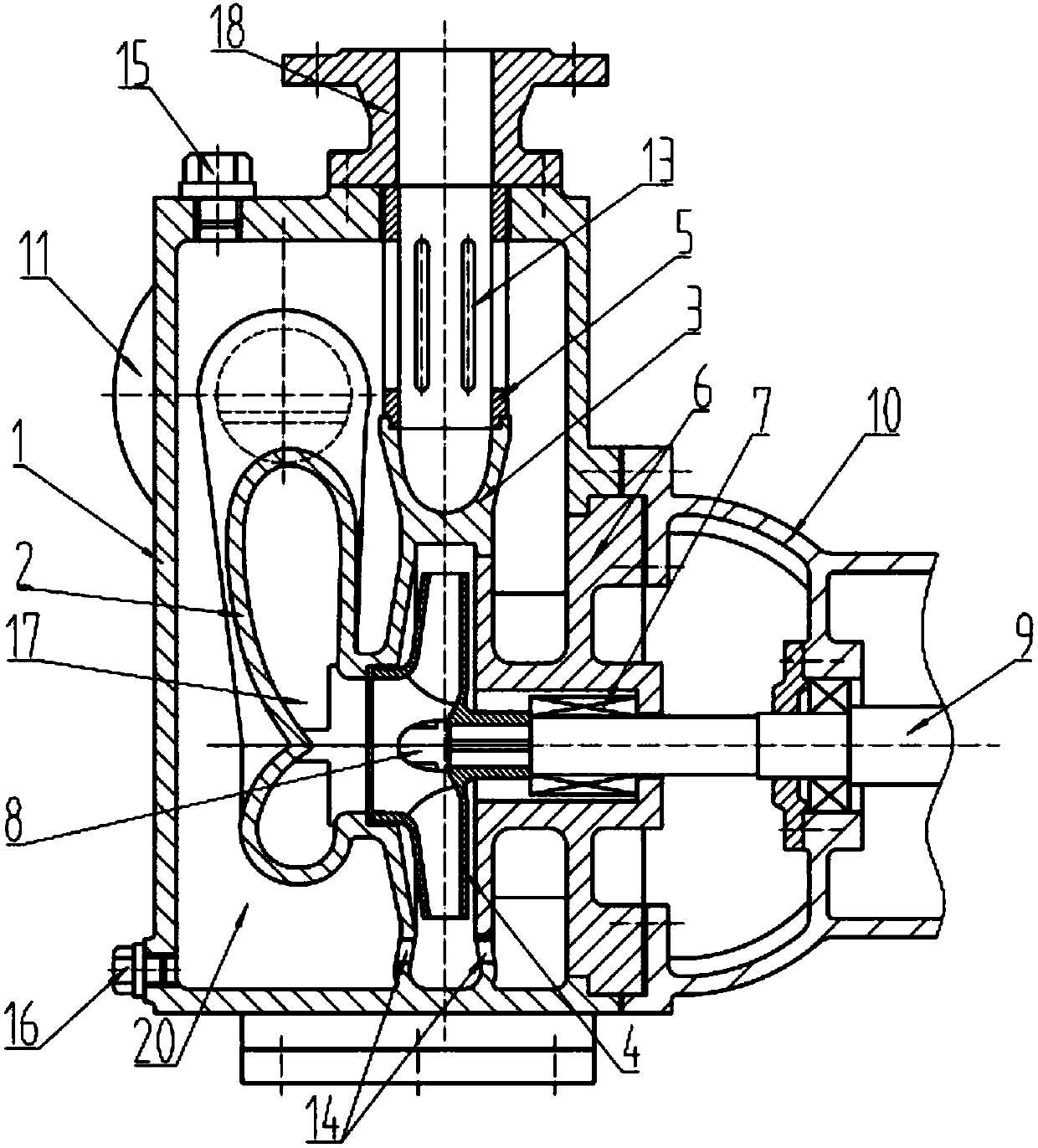

[0050] Attached image 3 , 4 is a cross-sectional view and left side view of an embodiment of a double-outlet multi-purpose external mixing self-priming pump with a quasi-spiral suction chamber according to the present invention;

[0051] A dual-outlet multi-purpose external-mixing self-priming pump with a quasi-spiral suction chamber. It mainly includes an inlet flange connection pipe 11, a pump body 1, an impeller 4, a gas-liquid separation pipe 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com