Guide vane for improving self-priming performance of jet-type centrifugal pump

A centrifugal pump, jet technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

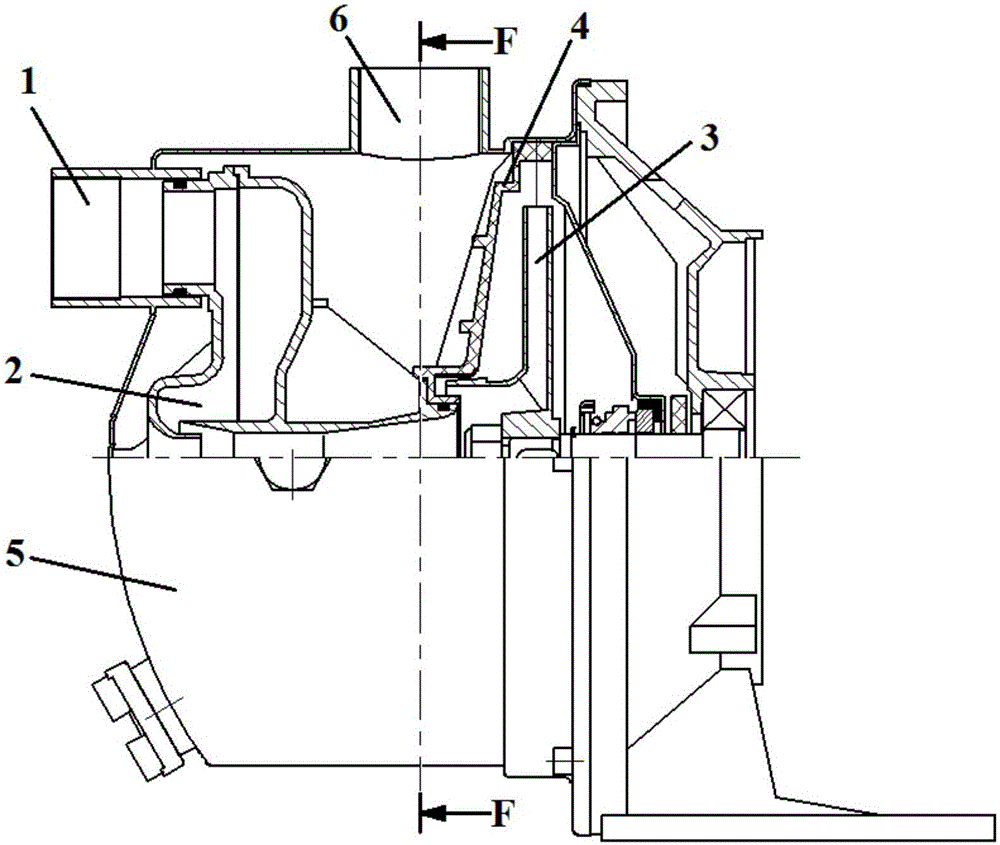

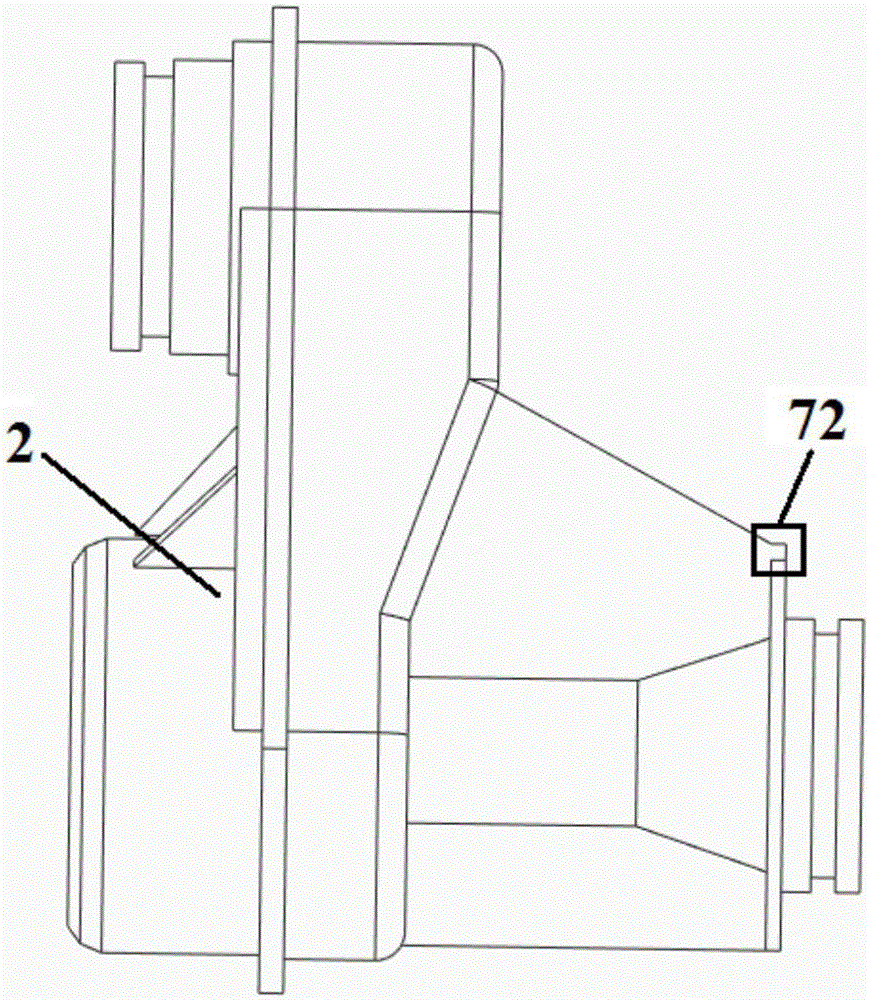

[0021] Such as figure 1 As shown, a jet-type centrifugal pump with self-priming performance includes an inlet pipeline 1 , an ejector 2 , a centrifugal impeller 3 , guide vanes 4 , a pump chamber 5 and an outlet pipeline 6 .

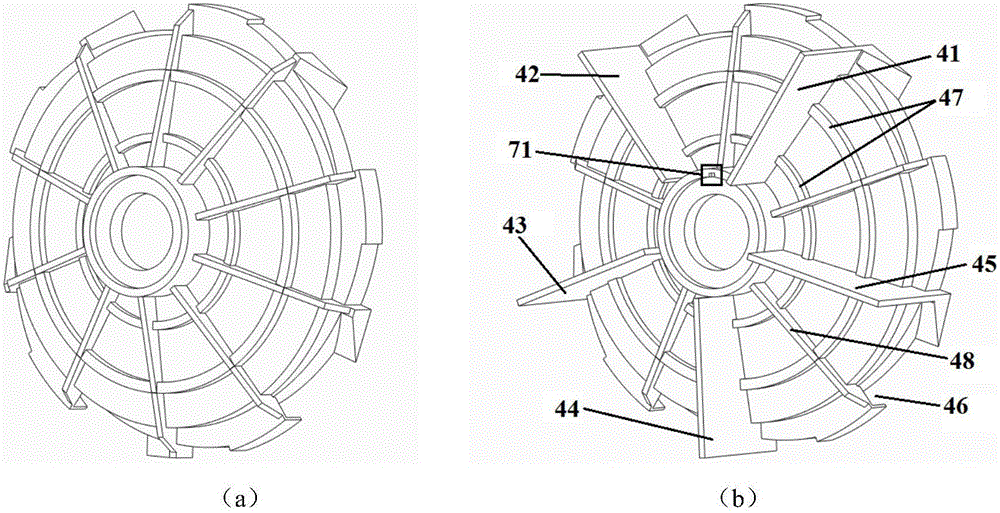

[0022] figure 2 (a) shows the prototype guide vane of jet centrifugal pump, figure 2 (b) shows the modified guide vane, that is, a guide vane that can improve the self-priming performance of the jet centrifugal pump. To block the outflow from the circumferential direction of each guide vane outlet, including back baffles I41, back baffles II42, back baffles III43, back baffles IV44, back baffles V45, guide vane outlets 46, circumferential ribs 47, Radial ribs 48, positioning grooves 71, the axial size of the baffle should be greater than or equal to the distance from the back of the guide vane outlet to the farthest position of the pump chamber outlet, and the radial size of the baffle should be flush with the upper edge of the guide vane outlet , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com