Emptying device and emptying method for bullet explosives

A technology of emptying device and projectile, applied in blasting and other directions, can solve problems such as poor applicability, unsatisfactory, polluting environment, and efficiency of pouring medicine, and achieve the effects of improving safety, saving resources, and enhancing controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

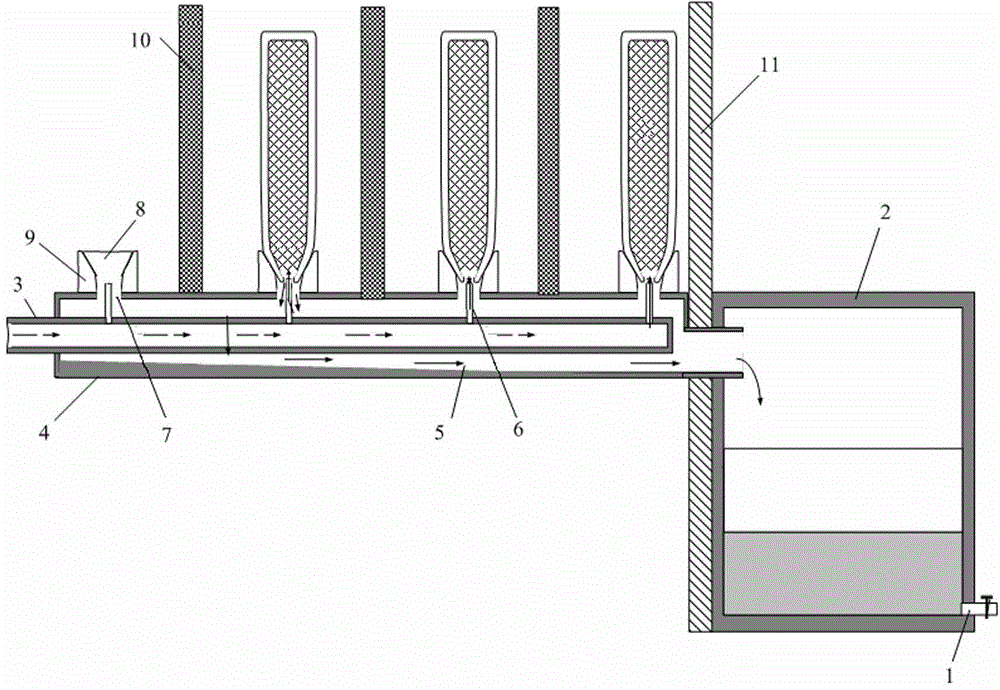

[0021] Such as figure 1 As shown, the projectile explosive emptying device includes a horizontally arranged pouring sleeve, a recovery tank 2 and a flameproof device, and the pouring sleeve includes an inner tube 3 and an outer tube 4, and the inner tube 3 is sleeved on the outer tube 4, there is a medicine collecting cavity 5 between the inner tube 3 and the outer tube 4, and the nozzles 6 are evenly spaced on the top surface of the inner tube 3, and the top surface of the outer tube 4 corresponds to the nozzle 6. The position is provided with a pouring hole 7, the nozzle 6 is facing the center of the pouring hole 7, and the outer edge of the pouring hole 7 is provided with a projectile support 9 with a through hole 8, and the center of the through hole 8 is facing the nozzle 6. There are 9 adjacent projectile supports on the outer pipe, and explosion-proof devices are provided between the pouring sleeve and the recovery tank 2; one end of the inner pipe 3 is a fluid input en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com