Backward centrifugal wind wheel

A centrifugal wind wheel and wind wheel technology, which is applied to the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve the problem of low technical performance, low noise quality and noise It can eliminate the phenomenon of gas separation, optimize the flow state, and reduce the aerodynamic noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

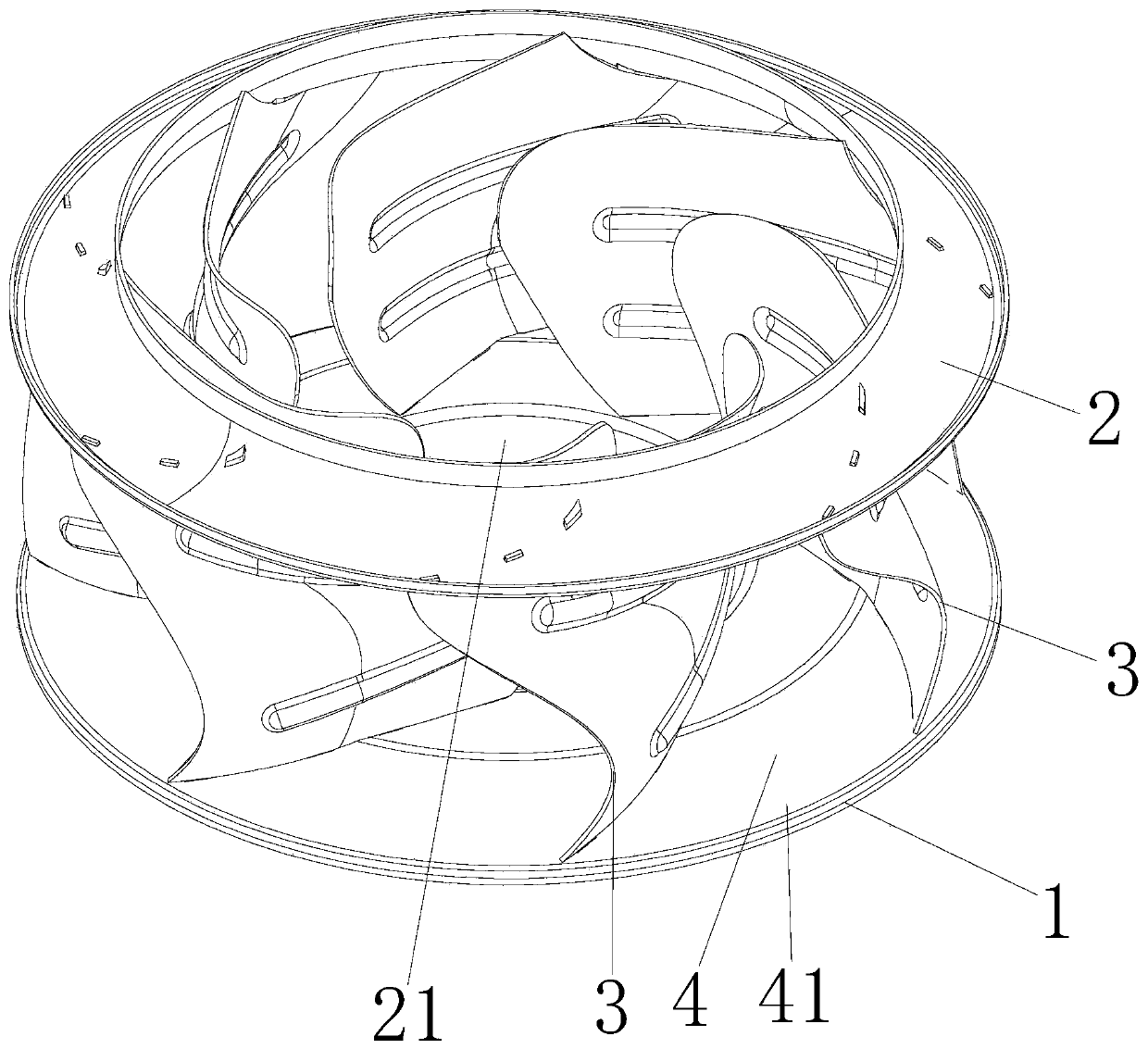

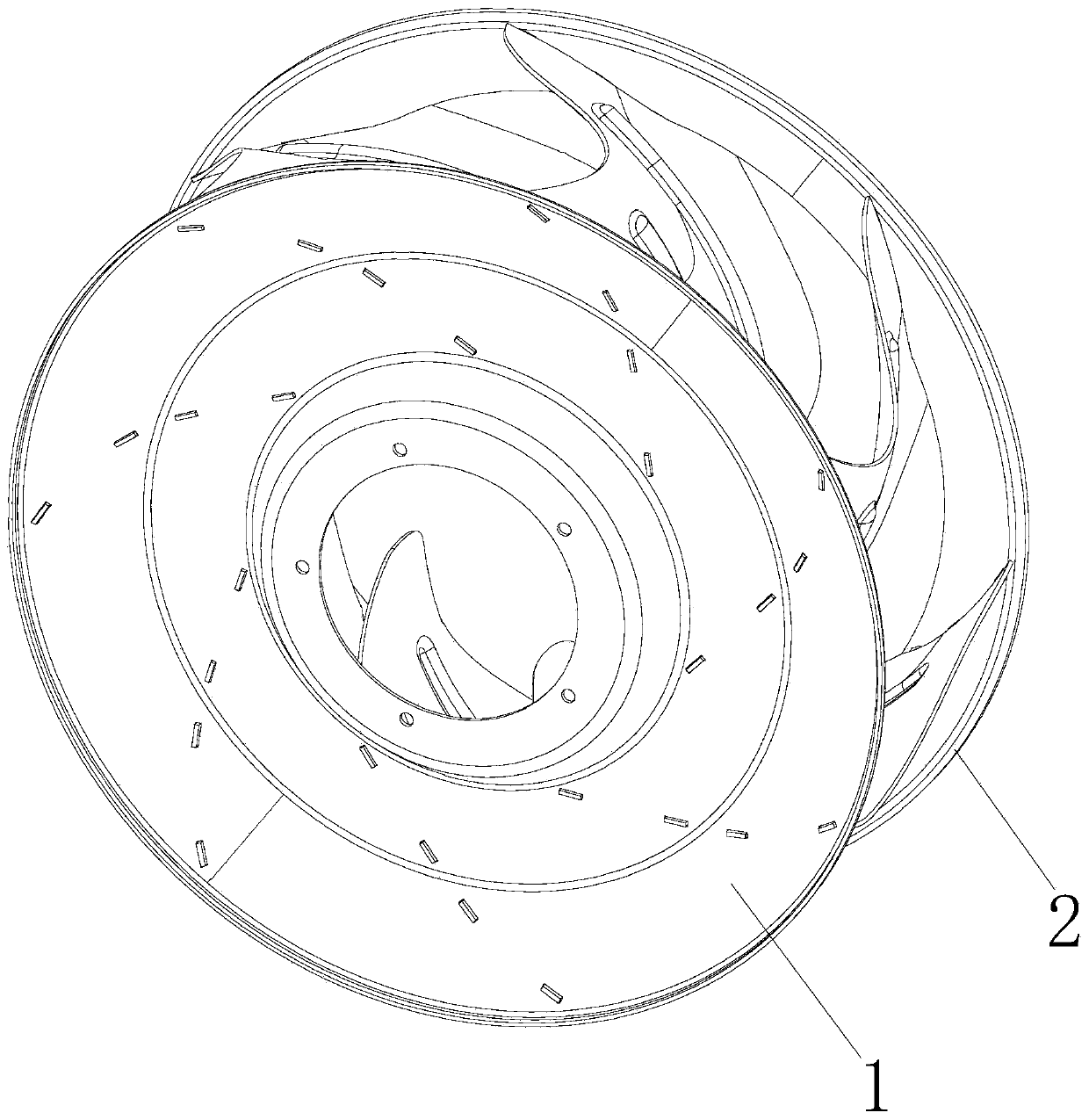

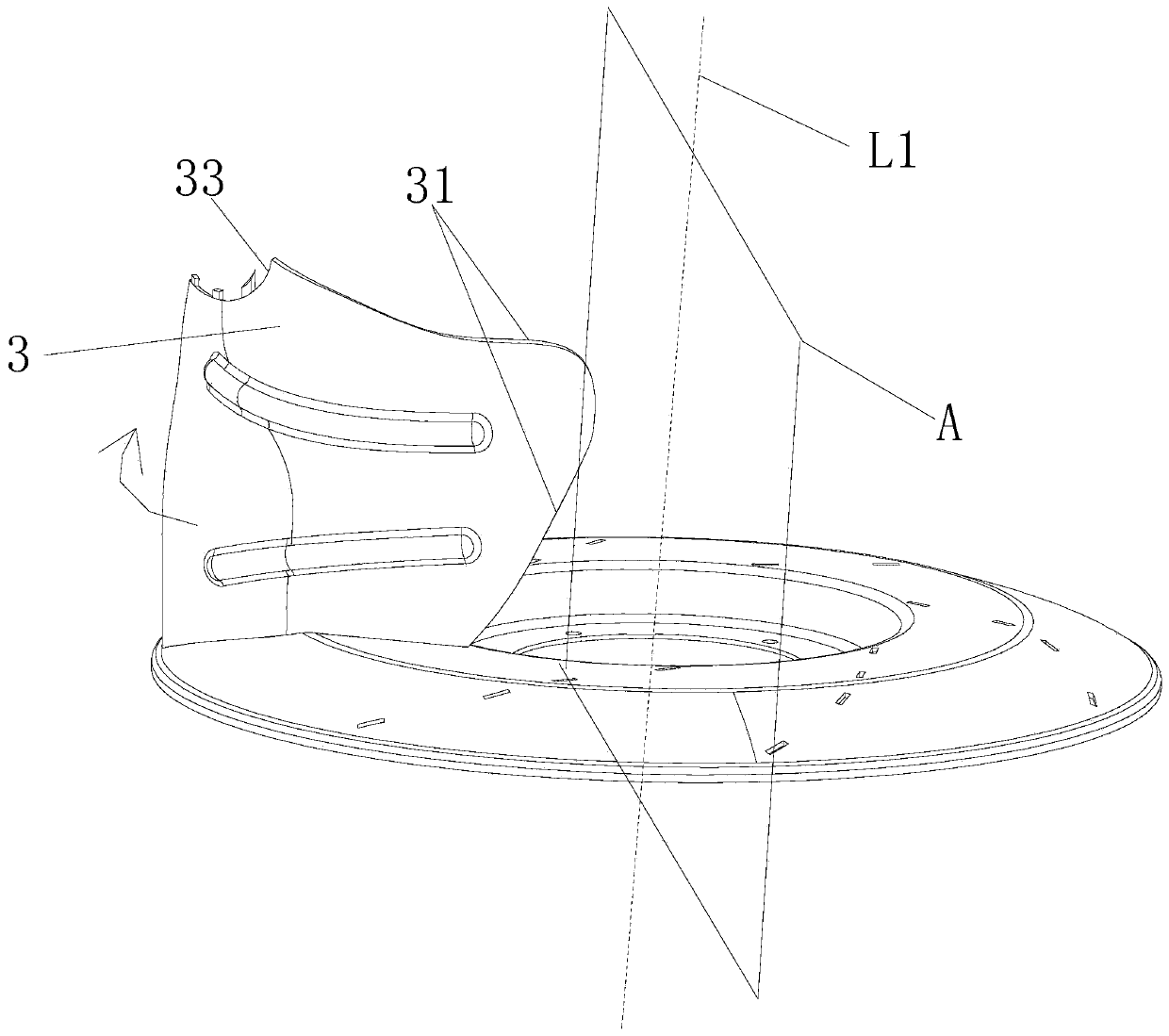

[0042] Such as Figure 1 to Figure 15 As shown, this embodiment provides a backward centrifugal wind wheel, which includes a wheel disc 1 at the bottom, a wheel cover 2 at the top, and several three-dimensional twisted blades 3. The center of the wheel cover 2 is provided with an air inlet 21, and the wheel 1 and the wheel cover 2 are installed with several three-dimensional twisted blades 3, and an air duct 4 is formed between two adjacent three-dimensional twisted blades 3, and an air outlet 41 is formed on the outer edge of the air duct 4. The three-dimensional twisted blades 3 includes a leading edge 31, a trailing edge 32, an upper edge 33, and a lower edge 34, and is characterized in that: a surface passing through the rotor axis L1 is set as a meridian plane A, and when the leading edge 31 rotates along the rotor axis L1, the leading edge 31 When each point on the meridian plane A intersects with a curve L2, the distance between each point on the curve L2 on the meridia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com