Synergic action device of preventing breath heavily and expanding stability of airbleed inside stator of multistage axial flow air compresdsor

A technology for axial flow compressors and stators, applied to components, mechanical equipment, machines/engines, etc. of pumping devices for elastic fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

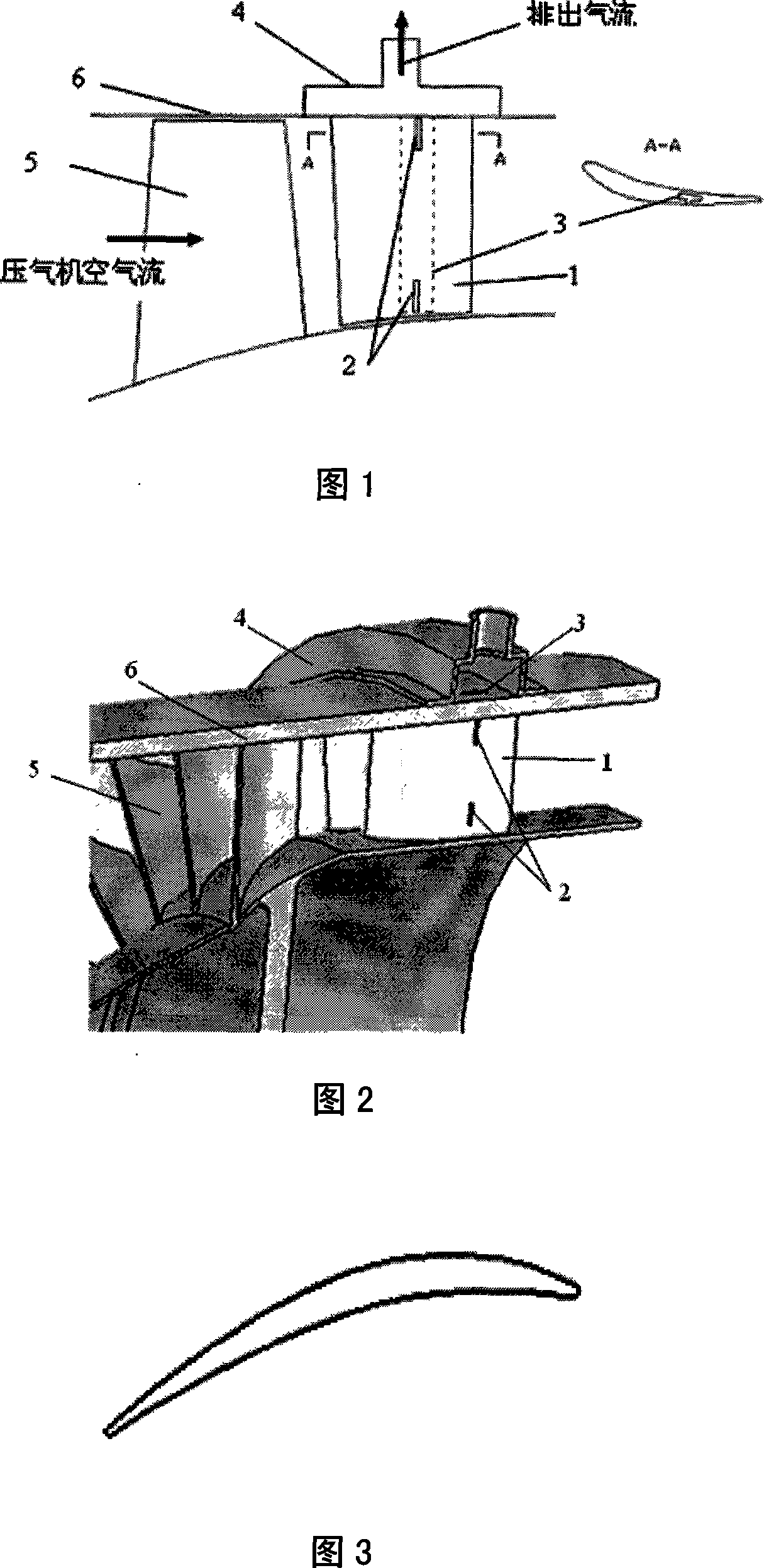

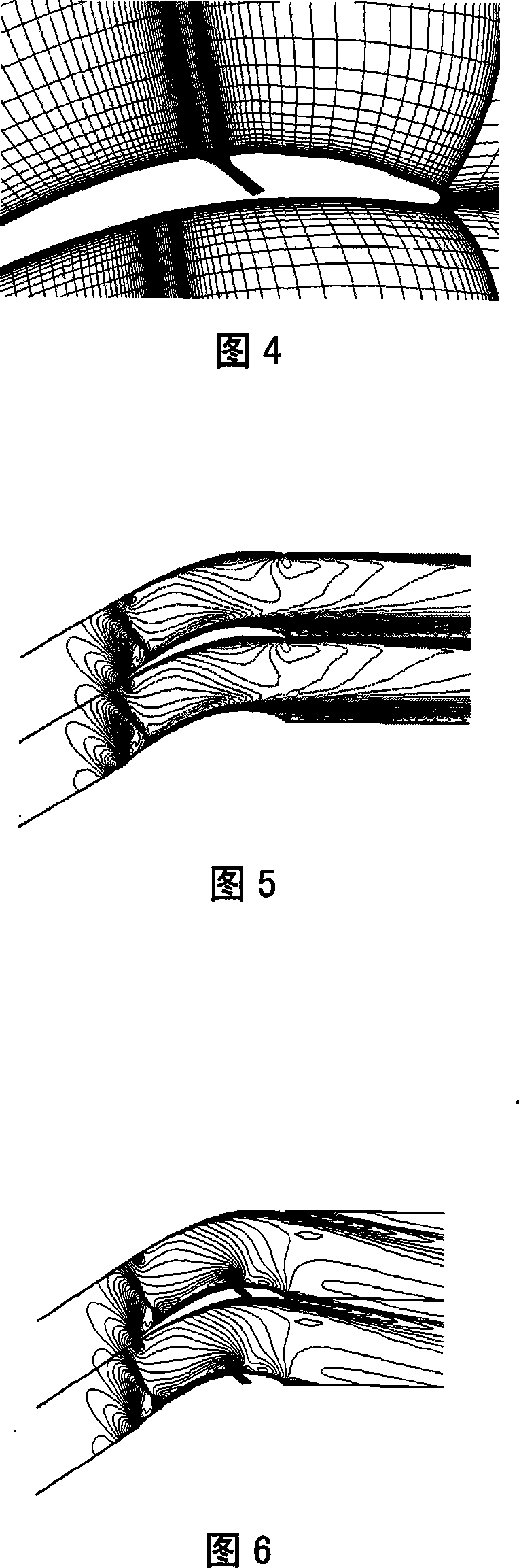

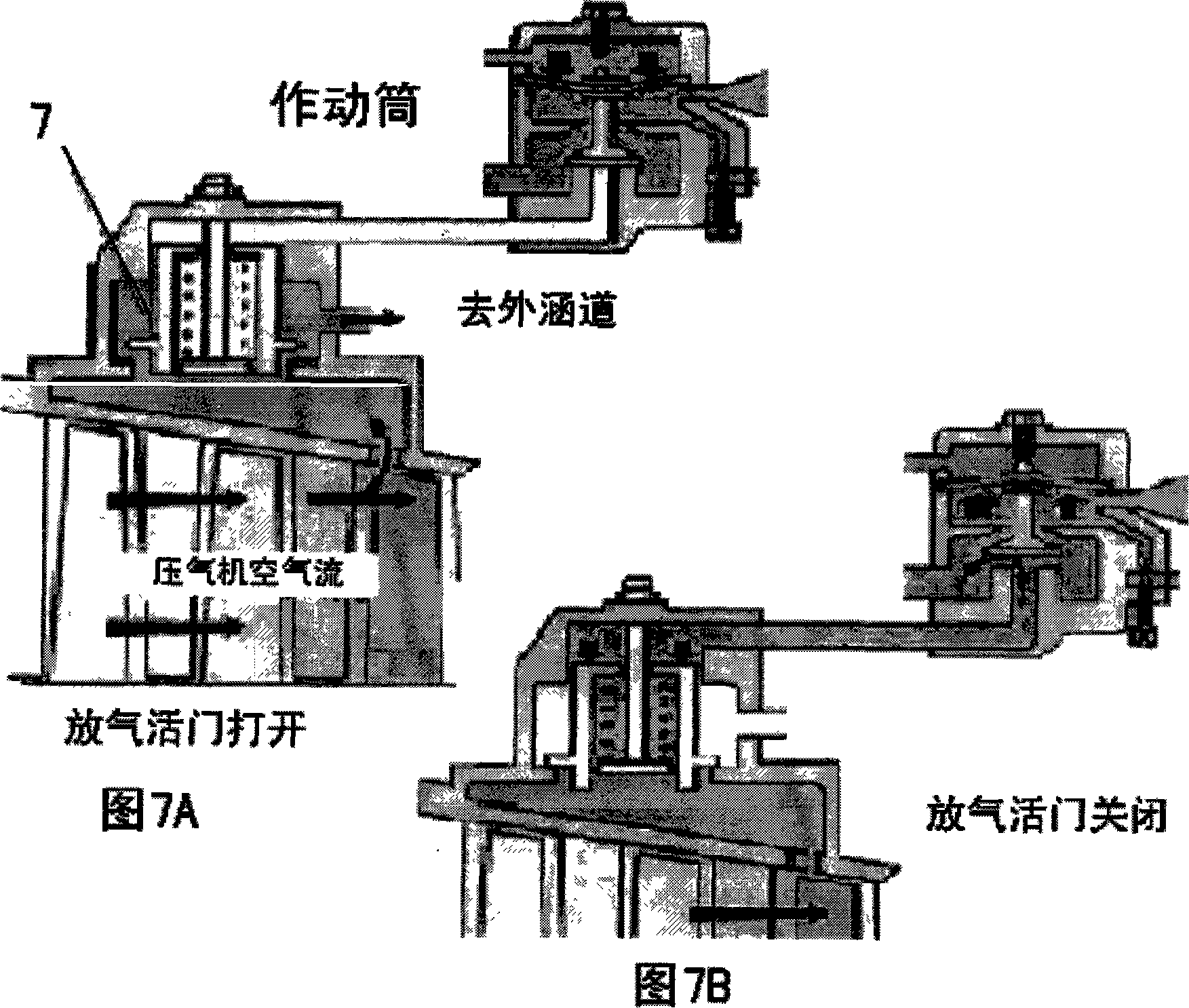

[0023] The present invention is a multi-stage axial flow compressor stator vane internal air-induction synergistic anti-surge expansion and stability device, as shown in Figure 1, is composed of a stator 1, air suction groove (or air suction hole) 2, air induction pipe 3, collecting Air chamber 4 is formed. Stator 1 is a certain stator blade in a multi-stage axial flow compressor; the suction slot (or suction hole) 2 is located on the surface of the suction surface of the stator 1, and there is a similar area of flow separation, which can be one or more; the air induction pipe 3 Located inside the blade of the stator 1, it is a ventilation pipe connecting each suction pipe; the air collection chamber 4 is located outside the flow channel casing 6, after the suction groove (or suction hole) 2 on the surface of the stator 1 sucks a small low-energy airflow The chamber where the air flows through the bleed tube 3. The suction groove (or suction hole) 2 sucks the low-energy flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com