Wing sail and ship with same

A ship and sail surface technology, which is applied in ship propulsion, ship construction, ship parts, etc., can solve the problems that the energy saving effect of the wing sail cannot be further improved, the safety hazard of the wing sail, and the area of the wing sail are limited, so as to achieve good propulsion performance and easy operation. Convenience and the effect of increasing energy saving benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

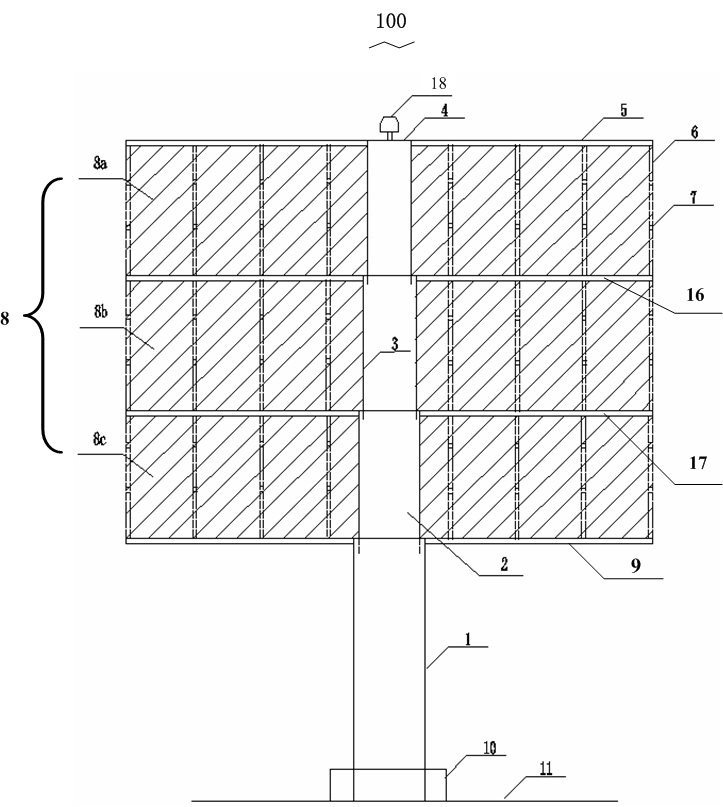

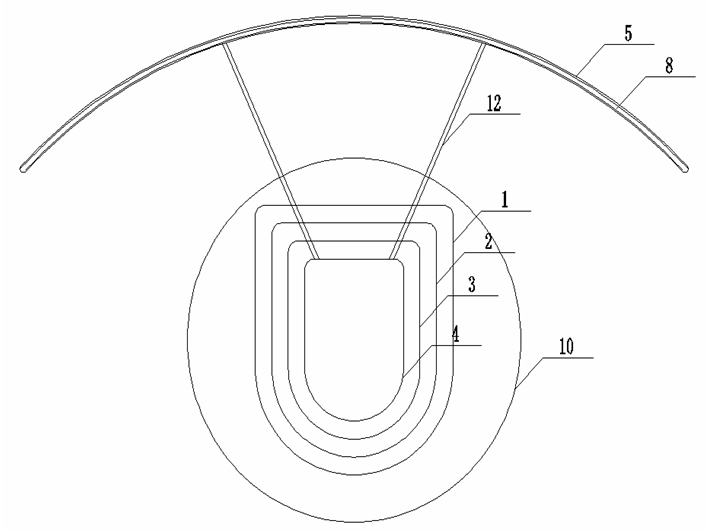

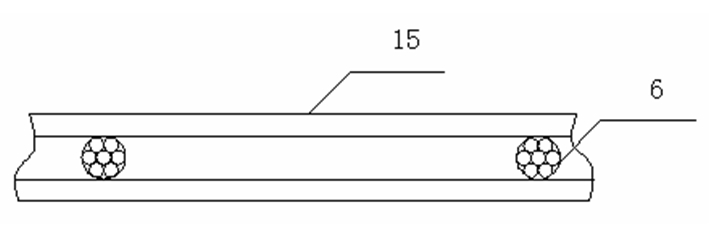

[0037] Please refer to Figure 1 to Figure 7 , Which is a wing sail 100 provided by the first embodiment of the present invention. The wing sail 100 includes a mast body 1, a first telescopic mast 2, a second telescopic mast 3, a third telescopic mast 4, a sail surface 8, and a hydraulic mechanism.

[0038] The hydraulic mechanism includes a base 10, three positioning devices 13, and a hydraulic cylinder 14. The base 10 is fixed on the deck 11. The mast body 1 is arranged on the base 10 and can rotate relative to the base 10. In this embodiment, the three telescopic masts 2, 3, 4 and the hydraulic cylinder 14 are housed in the mast body 1. In this embodiment, the mast body 1, the first telescopic mast 2, the second telescopic mast 3, and the third telescopic mast 4 are all hollow, which are arranged in order along the direction away from the base 10, and the width gradually decreases. In this embodiment, the central axes of the hydraulic cylinder 14, the mast body 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com