Molten steel composite deoxidation method good for improving pouring

A composite deoxidation and molten steel technology, which is applied in the field of metallurgical steelmaking process, can solve problems such as high content, poor continuous pouring, smooth production and impact on molten steel quality, so as to improve the purity of molten steel, increase the number of continuous casting furnaces, The effect of improving the cleanliness of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Adopting the electric furnace-LF-VD-continuous casting process to produce gear steel, non-quenched and tempered steel, structural steel and high-titanium welding wire series steel has high requirements on the pouring performance of molten steel, and requires high cleanliness of molten steel. The shape of inclusions, Composition, size distribution, etc. meet the requirements, and it is necessary to carry out deep deoxidation of molten steel and carry out inclusion control.

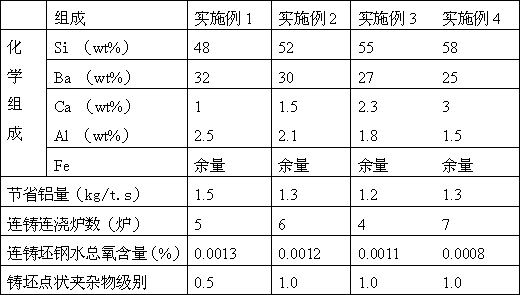

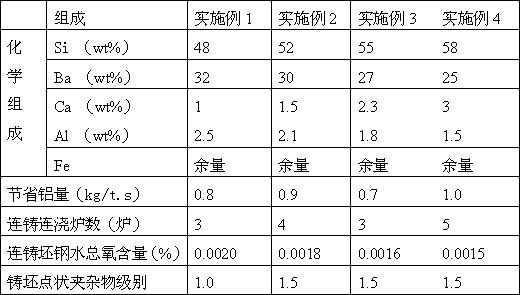

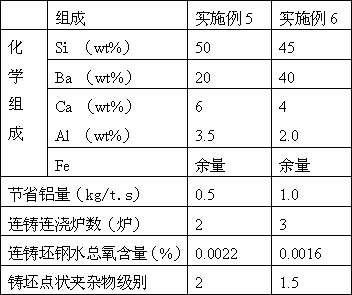

[0012] The following examples provide a multi-component composite cored wire such as silicon-barium and other multi-component cored wires that are deeply deoxidized for gear steel, non-quenched and tempered steel, structural steel, and high-titanium welding wire series steels, wherein the weight percentages of each component of the core wire They are: silicon 48%-58%, barium 25%-32%, calcium 1%-3%, aluminum 1.5-2.5%, and the balance is iron.

[0013] The following four specific examples use co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com