Method for increasing continuous casting heats of aluminum-deoxidized bearing steel

An aluminum deoxidation bearing and continuous casting technology, which is applied in the field of smelting, can solve the problems of limited inclusion effect, easy solidification, and inability to solve the production problems of bearing steel continuous casting, so as to reduce the labor intensity of workers, improve the cleanliness of steel, and reduce the number of times of use. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

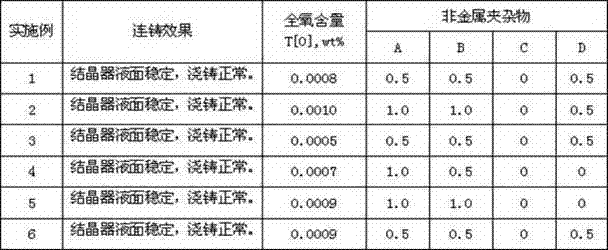

Examples

Embodiment 1

[0022] Embodiment 1 (the first furnace of continuous casting and pouring):

[0023] 1) Desulfurization of molten iron. The temperature of molten iron entering the molten iron tank of the blast furnace is 1320°C. After desulfurization of the molten iron, the weight percentages of the following components in the molten iron are controlled as follows: S: 0.005%, P: 0.15%, Si: 0.30%;

[0024] 2) Converter smelting, control the temperature of desulfurized molten iron entering the converter at 1250°C, control the basicity R of the oxide slag: 3.5, and control the content of C at the end of the converter to 0.08% by weight;

[0025] 3) The converter is tapped and alloyed, and the thickness of the amount of slag flowing into the ladle from the converter is controlled to be 80mm; when the steel is tapped to 1 / 4 of the total amount of molten steel, aluminum is added at a time at 0.50Kg / ton of steel;

[0026] 4) Argon blowing and stirring at the argon station, after 3 minutes of blowing ...

Embodiment 2

[0032] Embodiment 2 (the 2nd furnace of continuous casting and pouring):

[0033] 1) Desulfurization of molten iron, the temperature of molten iron entering the molten iron tank of the blast furnace is 1325°C, after desulfurization of the molten iron, the weight percentage content of the following components in the molten iron is controlled as follows: S: 0.008%, P: 0.10%, Si: 0.10%;

[0034] 2) Converter smelting, control the temperature of desulfurized molten iron entering the converter at 1260°C, control the basicity R of the oxide slag: 3.0, and control the content of C at the end of the converter to 0.15% by weight;

[0035] 3) The converter is tapped and alloyed, and the thickness of the amount of slag flowing into the ladle from the converter is controlled to be 50mm; when the steel is tapped to 1 / 4 of the total amount of molten steel, aluminum is added at a time according to 0.70Kg / ton of steel;

[0036] 4) Argon blowing and stirring at the argon station, after 3 minut...

Embodiment 3

[0042] Embodiment 3 (the 3rd furnace of continuous casting and pouring):

[0043] 1) Desulfurization of molten iron, the temperature of molten iron entering the molten iron tank of the blast furnace is 1330°C, after desulfurization of the molten iron, the weight percentage content of the following components in the molten iron is controlled as follows: S: 0.008%, P: 0.12%, Si: 1.0%;

[0044] 2) Converter smelting, control the temperature of desulfurized molten iron entering the converter at 1290°C, control the basicity R of the oxide slag: 3.8, and control the content of C at the end of the converter to 0.3% by weight;

[0045] 3) The converter is tapped and alloyed, and the thickness of the amount of slag flowing into the ladle from the converter is controlled to be 150mm; when the steel is tapped to 1 / 4 of the total amount of molten steel, aluminum is added at a time according to 0.80Kg / ton of steel;

[0046] 4) Argon blowing and stirring at the argon station, after 6 minutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com