Device and method for different steel grade continuous casting automatic iron plate insertion

A technology for inserting iron plates and different steel grades, which is used in casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing contract production, increasing the number of mixed-casting billets, and particularly serious composition effects. The effect of increasing the number of continuous pouring furnaces, improving the operation rate and reducing the cutting loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

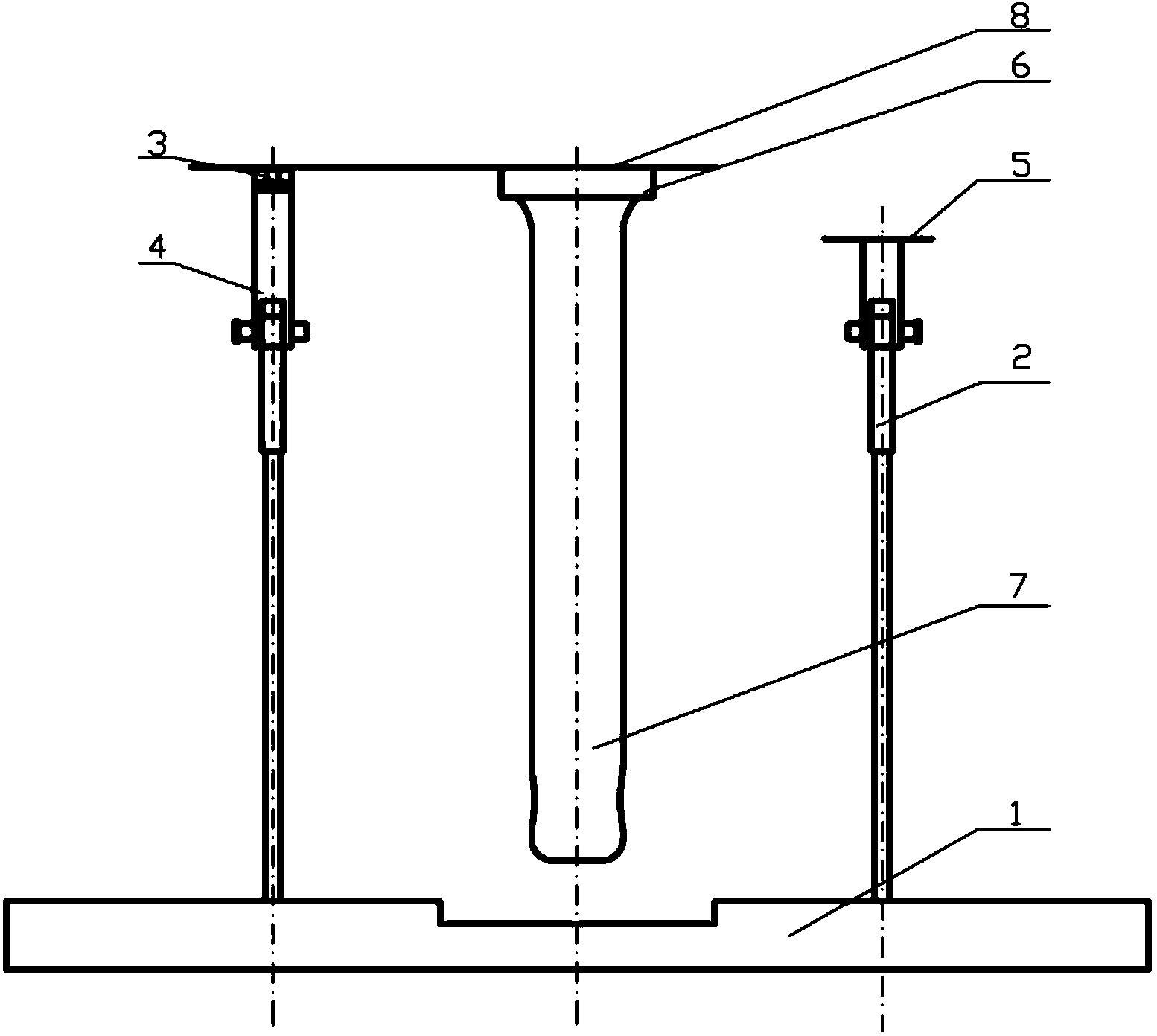

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] The embodiment of the present invention provides a device for continuous casting and automatic insertion of iron plates for different steel types, which realizes the automation of continuous casting and insertion of iron plates for different steel types in the same tundish, and at the same time provides an operation method for automatic insertion of iron plates, reducing Solved the problem of increasing the number of continuous pouring of different steel types. The implementation of this device and method increases the number of continuous casting furnaces of the casting machine, reduces the cost of refractory materials for the tundish, indirectly improves the operation rate of the casting machine, saves production preparation time, and also reduces the prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com