Production method for improving pouring performance of high-aluminum bearing steel

A casting performance, high-aluminum bearing technology, applied in the manufacture of converters, etc., can solve the problems of nozzle flocculation, poor fluidity, alumina inclusion flocculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

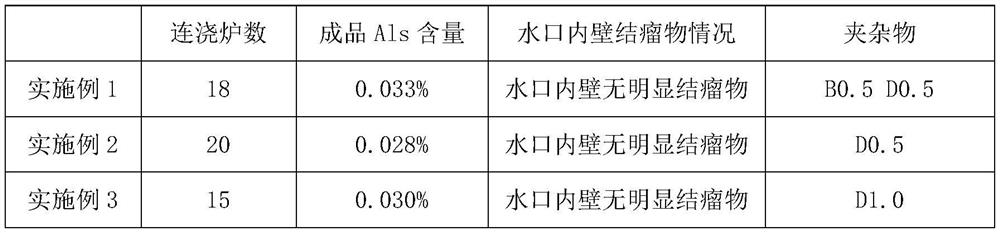

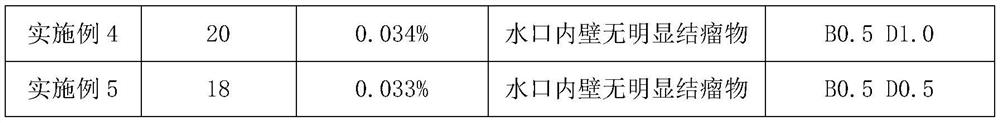

Examples

Embodiment 1

[0031] The production method for improving the pouring performance of high-aluminum bearing steel in this embodiment is suitable for the production of bearing steel steel grades and their weight percentages: C: 0.90% to 1.10%, Si: 0.20% to 0.30%, Mn: 0.20 % to 0.40%, Cr: 1.00% to 1.50%, Al: 0.025% to 0.035%.

[0032] Include the following steps:

[0033] (1) Converter smelting: Top-bottom double-blown converter is used. The dissolved oxygen content of molten steel tapped from the converter is 285ppm. Aluminum blocks, recarburizers, ferrosilicon, ferromanganese and other alloys are added during the tapping process for deoxidation alloying. The silicon content is 0.042%, and the silicon content is 0.09%. When the tapping rate is 70%, 3.5kg / ton of lime and high-basic pre-melted slag are added each, and the binary basicity of ladle slag is 8.2.

[0034] (2) LF refining: LF refining treatment time is 38 minutes, LF furnace starts heat treatment for 3 minutes, adds lime 3.5kg / ton o...

Embodiment 2

[0038] (1) Converter smelting: Top-bottom double-blown converter is used. The dissolved oxygen content of molten steel tapped from the converter is 367ppm. During the tapping process, aluminum blocks, recarburizers, ferrosilicon, ferromanganese and other alloys are added for deoxidation and alloying. The silicon content is 0.046%, and the silicon content is 0.10%. When the tapping rate is 70%, 3.5kg / ton of lime and high-basicity pre-melted slag are added each, and the binary basicity of ladle slag is 8.0.

[0039] (2) LF refining: LF refining treatment time is 40 minutes, LF furnace starts heating treatment for 3 minutes and adds lime 3.8kg / ton of steel, does not feed aluminum wire, finished molten steel has aluminum 0.028%; starts to add ferrosilicon powder 0.8kg / ton of steel after treatment for 15 minutes , quartz sand 0.6kg / ton steel, ferrosilicon alloy 1.0kg / ton steel; molten steel finished silicon content 0.25%, LF furnace final slag composition CaO: 47.2%, SiO2: 18.1%, Al...

Embodiment 3

[0043] (1) Converter smelting: Top-bottom double-blown converter is used. The dissolved oxygen content of molten steel tapped from the converter is 248ppm. Aluminum blocks, recarburizers, ferrosilicon, ferromanganese and other alloys are added during the tapping process for deoxidation alloying. The silicon content is 0.040%, and the silicon content is 0.08%. When the tapping rate is 70%, 3.5kg / ton of lime and high-basic pre-melted slag are added each, and the binary basicity of ladle slag is 8.5.

[0044] (2) LF refining: LF refining treatment time is 40 minutes, LF furnace starts heat treatment for 3 minutes, adds lime 3.8kg / ton steel, heats for 10 minutes, feeds aluminum wire 30m, controls the aluminum content of molten steel to 0.048%, and the finished product aluminum of molten steel is 0.030%; processing for 15 minutes Start to add ferrosilicon powder 1.2kg / ton of steel, quartz sand 0.5kg / ton of steel, ferrosilicon alloy 1.2kg / ton of steel; the finished silicon content of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com