Method for separating valuable metals from copper slag

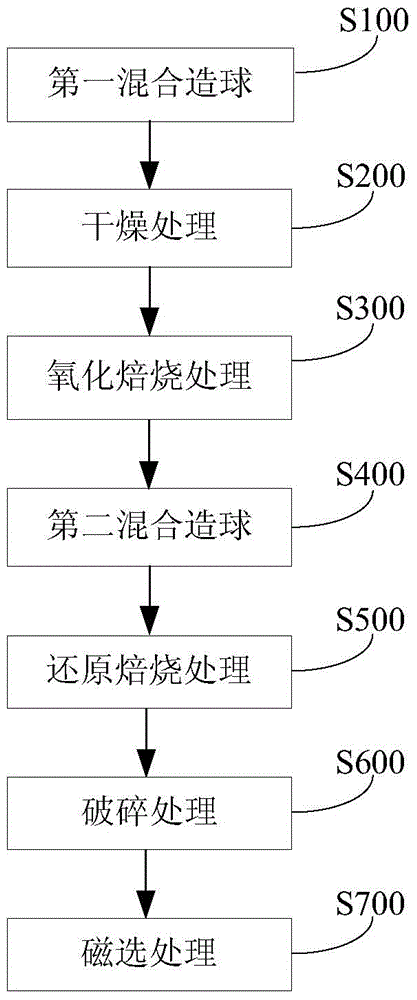

A valuable metal and copper slag technology, applied in the field of metallurgy, can solve the problems of low degree of automation, increased oxygen production, oxygen supply equipment, low production efficiency of roasting kilns, etc., to improve the metallization rate of pellets and the recovery of metal iron efficiency, reduction in treatment costs, reduction in time and consumption of reducing agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Copper slag composition: 39.12wt% TFe, 0.36wt% Cu, 1.53wt% Zn and 0.46wt% Pb;

[0054] Separation step: Use starch solution with 10% weight of copper slag as a binder to mix evenly with copper slag, and then pelletize to obtain copper slag pellets with a particle size of 5mm. Dry the copper slag pellets and send them to the rotary hearth furnace for internal oxidation In a neutral atmosphere, oxidation roasting treatment was carried out at 850 degrees Celsius for 25 minutes to obtain copper slag pellets through oxidation roasting treatment, wherein, the burner fuel of the rotary hearth furnace was natural gas, the air excess coefficient was 1.3, and the furnace was rich in oxygen. The copper slag pellets that have been oxidized and roasted are used as cue balls for pelletizing, and the outside is wrapped with a mixture of reduced coal, limestone and bentonite (the mass ratio of the ingredients of the mixture is reducing agent:limestone:bentonite=100:40:20), and the reduc...

Embodiment 2

[0056] Copper slag composition: with embodiment 1;

[0057]Separation step: Use starch solution with 10% weight of copper slag as a binder to mix evenly with copper slag, and then pelletize to obtain copper slag pellets with a particle size of 5mm. Dry the copper slag pellets and send them to the rotary hearth furnace for internal oxidation Under a neutral atmosphere, oxidize and roast at 700 degrees Celsius for 35 minutes to obtain copper slag pellets that have undergone oxidation and roast. The burner fuel of the rotary hearth furnace is natural gas, the air excess coefficient is 1.5, and the furnace is rich in oxygen. The copper slag pellets that have been oxidized and roasted are used as cue balls for pelletizing, and the outside is wrapped with a mixture of reduced coal, limestone and bentonite (the mass ratio of the ingredients of the mixture is reducing agent:limestone:bentonite=100:40:20), and the reduction The fixed carbon content of the agent is 63wt%, the CaO conten...

Embodiment 3

[0059] Copper slag composition: with embodiment 1;

[0060] Separation step: Use starch solution with 10% weight of copper slag as a binder to mix evenly with copper slag, and then pelletize to obtain copper slag pellets with a particle size of 5mm. Dry the copper slag pellets and send them to the rotary hearth furnace for internal oxidation Under a neutral atmosphere, oxidize and roast at 700 degrees Celsius for 35 minutes to obtain copper slag pellets that have undergone oxidation and roast. The burner fuel of the rotary hearth furnace is natural gas, the air excess coefficient is 2.0, and the furnace is rich in oxygen. The copper slag pellets that have been oxidized and roasted are used as cue balls for pelletizing, and the outside is wrapped with a mixture of reduced coal, limestone and bentonite (the mass ratio of the ingredients of the mixture is reducing agent:limestone:bentonite=100:40:20), and the reduction The fixed carbon content of the agent is 65wt%, the CaO conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com