Powder metallurgy prescription and technique

A technology of powder metallurgy and formula, applied in the field of powder metallurgy formula and process, can solve the problems of poor adaptability and achieve the effect of reliable finished product performance, low cost and optimized process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

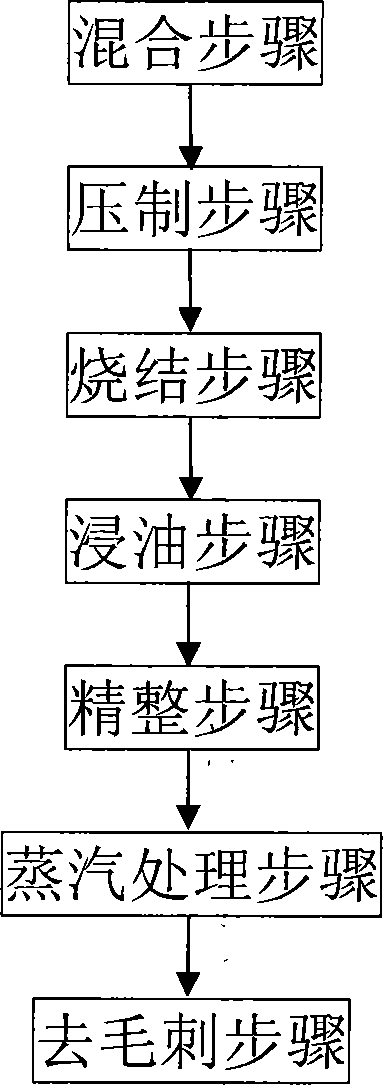

[0019] figure 1 Shown is a schematic representation of the process flow of the embodiment of the present invention, including:

[0020] Mixing step: mix raw and auxiliary materials according to parts by weight, graphite powder is 0.05% to 5%, zinc stearate is 0.08% to 7%, copper powder is 0.1% to 10%, and the rest is iron powder Than mix evenly.

[0021] Pressing step: Send the mixed iron powder into the upper part of the press, and put it into the cavity of the mold through the powder filling box for automatic pressing. The pressing speed is 8 pieces per minute, and then send it to the turntable with a manipulator.

[0022] Sintering steps: sintering in the mesh belt sintering furnace, conveying from the inlet with a stainless steel mesh belt, and discharging from the outlet takes 4 hours, the preheating temperature is 730°C with electric heating, and the sintering temperature is 1100°C. with H 2 and N 2 As a protective atmosphere, its purpose is H 2 Reduction of oxygen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com