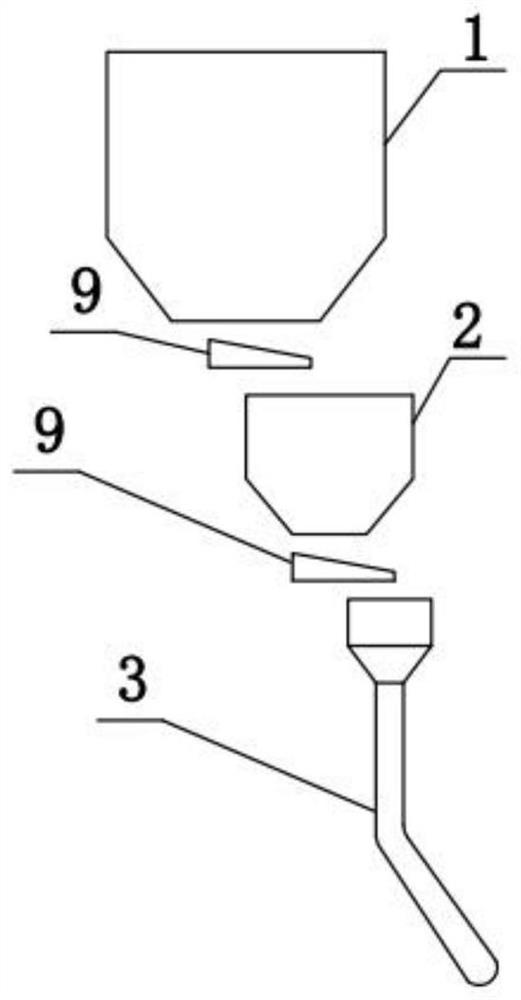

RH vacuum furnace slag surface feeding device and furnace slag modification method

A feeding device and vacuum furnace technology, applied in the field of steelmaking, can solve the problems of reducing the oxidation of slag, inability to fully react with slag, and increasing the gas content of molten steel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The 180t converter is used for smelting, and the smelting steel is IF steel.

[0031] (1) During the tapping process of the converter, the slag retaining cone is used to retain the slag, and the synthetic slag is added.

[0032] Table 1 Amount of slag in converter tapping and components of synthetic slag

[0033] furnace number Slag amount, kg / t CaO, % Al 2 o 3 ,%

CaF 2 ,%

Metal Aluminum Powder MgO, % (a) 1.0 50 25 3 15 2 (b) 1.5 45 20 5 20 4 (c) 2.0 40 15 8 25 6

[0034] (2) After the converter is tapped, the molten steel is transported to the RH station for decarburization. After the decarburization is completed, various alloys are added from the vacuum alloy chamber for deoxidation alloying.

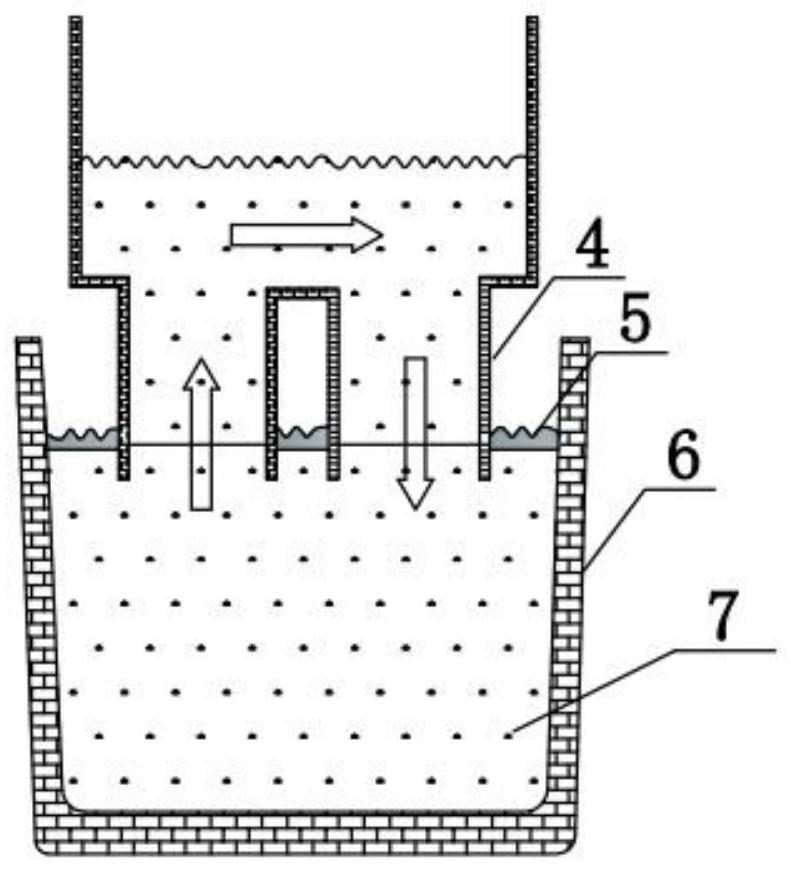

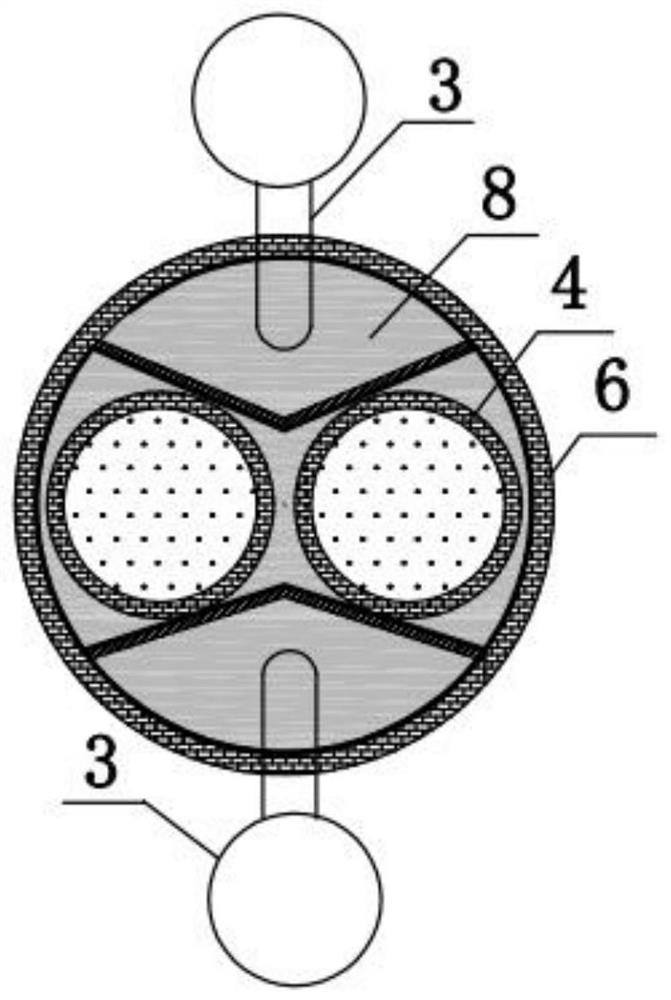

[0035] (3) During the RH deoxidation alloying process, the slag surface is added to the triangular area 8 and its symmetrical triangular area surrounded by the RH double dipping pipe 4 and the ladle wall 6 thro...

Embodiment 2

[0048] The 180t converter is used for smelting, and the smelting steel is ST5 steel.

[0049] (1) During the tapping process of the converter, the sliding plate is used to stop the slag, and the synthetic slag is added. The amount of slag dropped and the composition of the synthetic slag are shown in Table 6.

[0050] Table 6 Amount of slag in converter tapping and components of synthetic slag

[0051] furnace number Slag amount, kg / t CaO, % al 2 o 3 ,%

CaF 2 ,%

Metal Aluminum Powder MgO, % (a) 1.0 50 25 3 15 2 (b) 1.5 45 20 5 20 4 (c) 2.0 40 15 8 25 6

[0052] (2) After the converter is tapped, the molten steel is transported to the RH station for decarburization. After the decarburization is completed, various alloys are added from the vacuum alloy chamber for deoxidation alloying.

[0053] (3) During the RH deoxidation alloying process, the slag surface is added to the triangular area 8 and its symmetrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com