Preparation method of cationic high-molecular polymer

A high molecular polymer and cationic technology, applied in the field of chitosan, can solve the problems of being poor and only soluble in acidic solutions, and achieve the effects of low flocculation effect, excellent flocculation performance, and avoiding gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

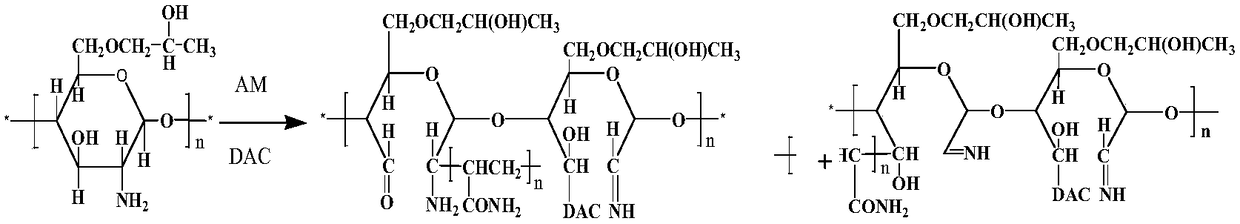

[0030] The present invention also provides a preparation method of a cationic high molecular polymer, comprising free radical copolymerization of hydroxypropyl chitosan, acryloyloxyethyltrimethylammonium chloride (DAC) and acrylamide (AM), to obtain a cationic high molecular weight polymer. Molecular polymers, that is, cationic polymers, the specific process is:

[0031] see figure 1 , step 1, acrylamide is divided into two parts, and each part is added to water to obtain the first part of acrylamide aqueous solution and the second part of acrylamide aqueous solution; hydroxypropyl chitosan is added to three ports containing 25mL distilled water In the flask, stir to dissolve evenly;

[0032] Step 2, pass nitrogen gas for 30 minutes to remove oxygen, and raise the temperature to 50-80°C;

[0033] Step 3, add a certain amount of cerium ammonium nitrate aqueous solution, trigger 20min;

[0034] Step 4, slowly dropwise adding a mixture of a certain amount of acryloyloxyethyltr...

Embodiment 1

[0045] A method for preparing a cationic high molecular polymer, comprising free radical copolymerization of hydroxypropyl chitosan and acrylamide, acryloyloxyethyltrimethylammonium chloride to obtain a cationic high molecular polymer, the specific process is:

[0046] Step 1, divide the acrylamide into two parts, and add each part into water to obtain the first part of acrylamide aqueous solution and the second part of acrylamide aqueous solution; add 1g of hydroxypropyl chitosan into three ports containing 25mL of distilled water In the flask, stir at 250r / min to make it dissolve evenly;

[0047] Step 2, pass nitrogen gas for 30 minutes to remove oxygen, and raise the temperature to 55°C;

[0048] Step 3, adding cerium ammonium nitrate aqueous solution with a mass concentration of 0.22%, and initiating for 20 minutes; the mass of ceric ammonium nitrate is 1.1% of the mass of hydroxypropyl chitosan.

[0049] Step 4, slowly dropwise adding a mixture of an aqueous solution of ...

Embodiment 2

[0055] A method for preparing a cationic high molecular polymer, comprising free radical copolymerization of hydroxypropyl chitosan and acrylamide, acryloyloxyethyltrimethylammonium chloride to obtain a cationic high molecular polymer, the specific process is:

[0056] Step 1, divide the acrylamide into two parts, and add each part into water to obtain the first part of acrylamide aqueous solution and the second part of acrylamide aqueous solution; add 1g of hydroxypropyl chitosan into three ports containing 25mL of distilled water In the flask, stir at 250r / min to make it dissolve evenly;

[0057] Step 2, pass nitrogen gas for 30 minutes to remove oxygen, and raise the temperature to 65°C;

[0058] Step 3, adding cerium ammonium nitrate aqueous solution with a mass concentration of 0.42%, and triggering for 20 minutes; the mass of ceric ammonium nitrate is 2.1% of the mass of hydroxypropyl chitosan.

[0059] Step 4, slowly dropwise adding a mixture of acryloyloxyethyltrimeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com