Biological flocculant for processing fluorine and calcium in wastewater and preparation and application methods thereof

A biological flocculant and wastewater treatment technology, which is applied in the field of environmental engineering, can solve the problems of nitrite ion easily exceeding the standard and causing cancer, difficulty in meeting discharge standards, high operation and maintenance costs, etc., to achieve improved treatment effect, fast sedimentation speed, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Set the initial pH value to 2.0, the initial Fe 2+ Inoculate the 9K culture medium with the bacterial solution with a concentration of 9g / L, adjust the pH value to 1.5 with 30% concentrated sulfuric acid during the cultivation process, transfer when the cultured bacterial solution turns red, repeat the inoculation and culture for 3 to 5 times, and cultivate the bacterial solution T1 , inoculate the bacterial solution T1 into the 9K medium, and gradually add FeSO 4 ·7H 2 O, making Fe 2+ After the concentration reaches 45g / L, transfer the cultured bacteria solution when it turns red, and then repeat the inoculation and culture for 3 to 5 times to obtain the bacterial solution T2, inoculate the bacterial solution T2 to (NH 4 ) 2 SO 4 The concentration is 0.5g / L and no Ca(NO 3 ) 2 9K culture medium, transfer when the culture liquid turns red, repeat inoculation and culture for 3 to 5 times, and obtain Thiobacillus ferrooxidans bacterial liquid T3;

[0029] The compos...

Embodiment 2

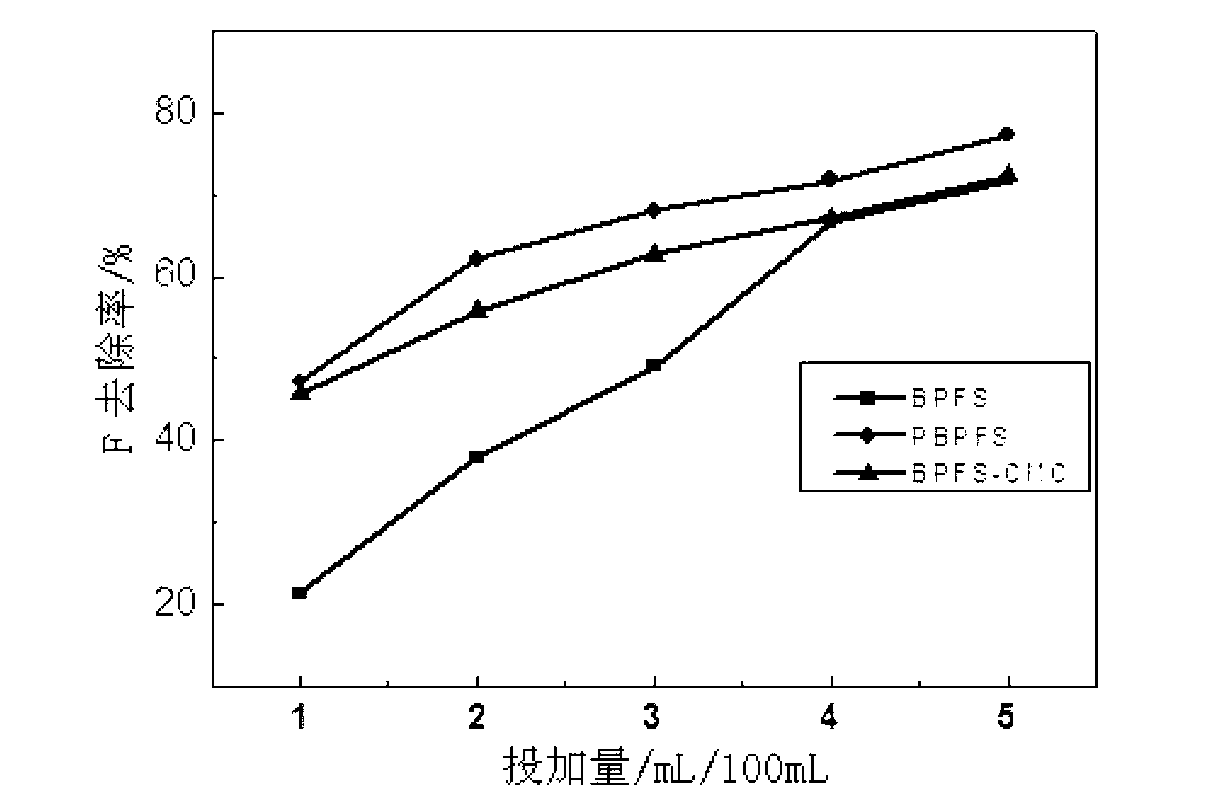

[0034] Take 200mL F - The concentration is 20mg·L -1 Under stirring conditions, 4 mL of the biological flocculant of Example 1 was added, reacted for 30 min, allowed to settle for 30 min, and the supernatant was taken to determine the residual fluoride ion concentration to be 4.96 mg / L.

Embodiment 3

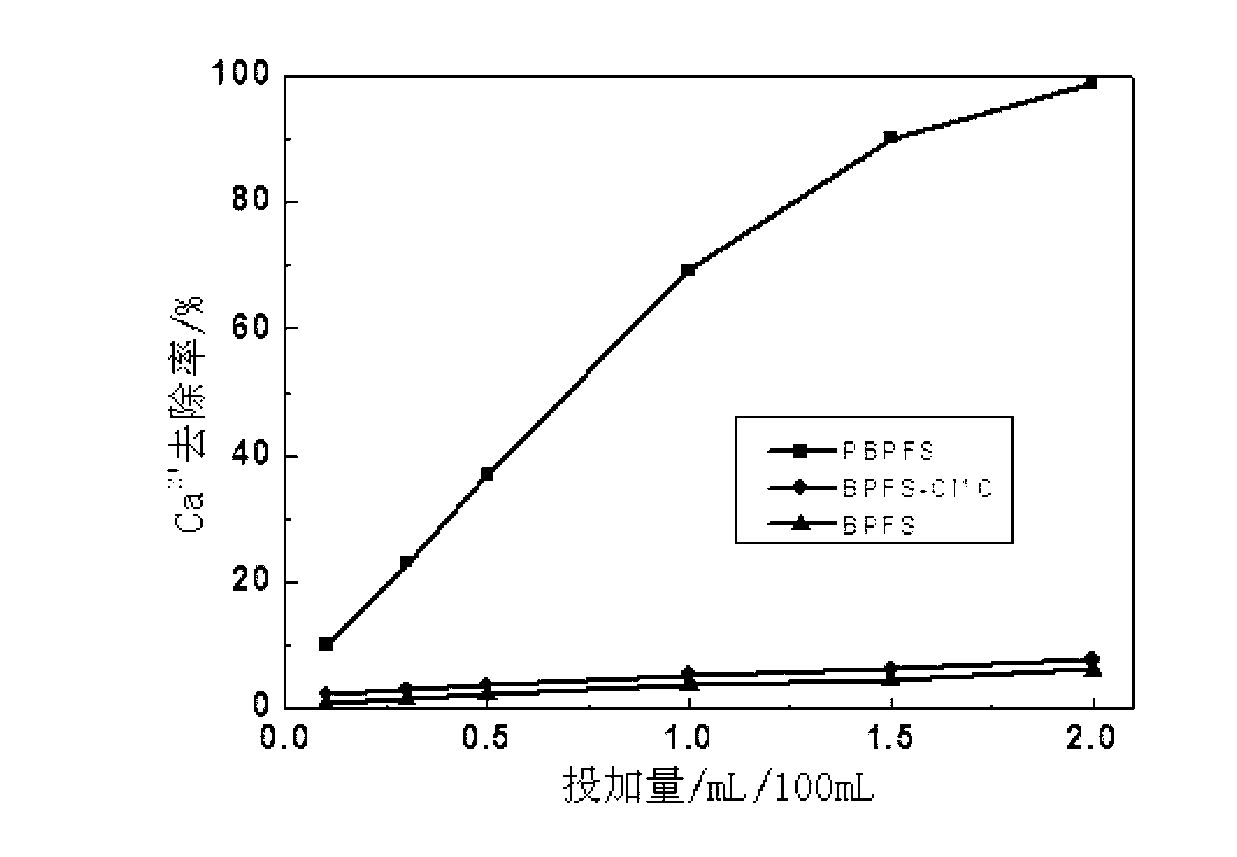

[0036] Take 200mLCa 2+ For wastewater with a concentration of 520 mg / L, 4 mL of the biological flocculant of Example 1 was added under stirring conditions, reacted for 20 min, allowed to settle for 30 min, and the supernatant was taken to determine the residual Ca ion concentration to be 5.6 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com