A kind of method that solvothermal method prepares nano ferric oxide

A technology of ferroferric oxide and solvothermal method, which is applied in the field of nanomaterials, can solve the problems of expensive surfactants and increased production costs, and achieve good particle size dispersion, waste recycling, and uniform particle distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 0.008mol of Fe(NO 3 ) 3 9H 2 O and 0.04mol of NaAc·3H 2 O, respectively dissolved in 35mL of ethylene glycol, after mixing, add 0.2g sodium lignosulfonate, stir to dissolve, then magnetically stir for 20 minutes to make it evenly dispersed; React for 16 hours, cool to room temperature; centrifuge the resulting precipitated mixture, wash the precipitate with deionized water 3 times, then wash 3 times with absolute ethanol, and centrifuge; put the separated solid in a constant temperature drying oven and dry it for 12 hours. The temperature of the above-mentioned constant temperature drying oven is 60° C.; the particle diameter of the obtained nano ferric oxide is about 470 nm.

Embodiment 2

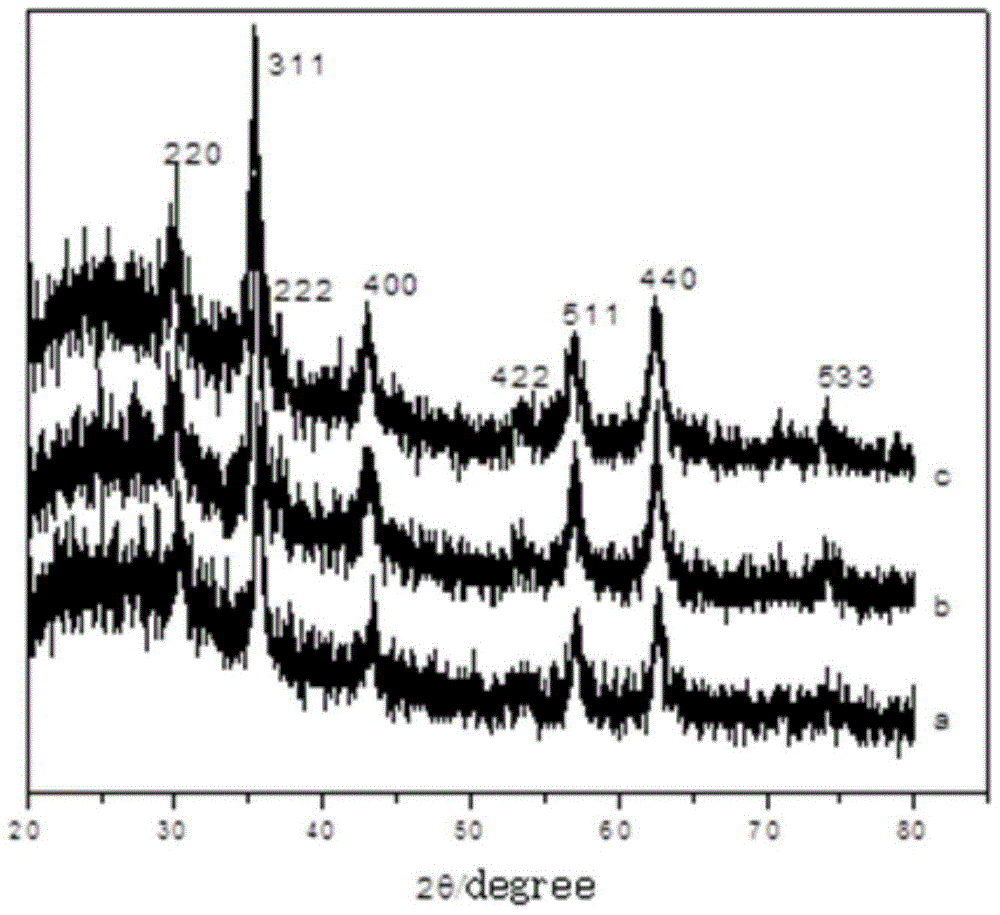

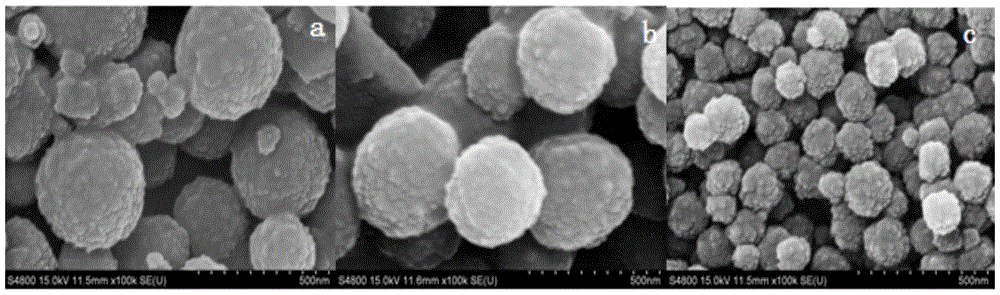

[0027] Take 0.008mol of Fe(NO 3 ) 3 9H 2 O and 0.04mol of NaAc·3H 2 O, respectively dissolved in 35mL of ethylene glycol, after mixing, add 0.4g sodium lignosulfonate, stir to dissolve, and then stir magnetically for 20 minutes to make it evenly dispersed; move the above solution into an autoclave, at 180°C React for 12 hours, cool to room temperature; centrifuge the resulting precipitated mixture, wash the precipitate with deionized water 3 times, then wash 3 times with absolute ethanol, and centrifuge; put the separated solid in a constant temperature drying oven and dry for 12 hours. The temperature of the constant temperature drying oven is 60°C. The XRD pattern of the sample is as follows figure 1 In a, it shows that nano-Fe3O4 particles have been successfully prepared; the scanning electron microscope image is as follows figure 2 a, the particle size of the obtained nano ferric oxide is about 430nm.

Embodiment 3

[0029] Take 0.008mol of Fe(NO 3 ) 3 9H 2 O and 0.04mol of NaAc·3H 2 O, respectively dissolved in 35mL of ethylene glycol, after mixing, add 0.6g sodium lignosulfonate, stir to dissolve, and then magnetically stir for 20 minutes to make it evenly dispersed; move the above solution into an autoclave, and heat it at 180°C React for 16 hours, cool to room temperature; centrifuge the resulting precipitated mixture, wash the precipitate with deionized water 3 times, then wash 3 times with absolute ethanol, and centrifuge; put the separated solid in a constant temperature drying oven and dry it for 12 hours. The temperature of the constant temperature drying oven is 60°C. The XRD pattern of the sample is as follows figure 1 In b, it shows that the nano-Fe3O4 particles were successfully prepared; the scanning electron microscope image is as follows figure 2 b, the particle size of the obtained nano ferric oxide is about 380nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com