Patents

Literature

104results about How to "Good granularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing MnO2 supported catalyst as well as method of using the same and apparatus for treating waste water

InactiveCN101406831AGood granularityEasy to recycleMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATESesquioxide

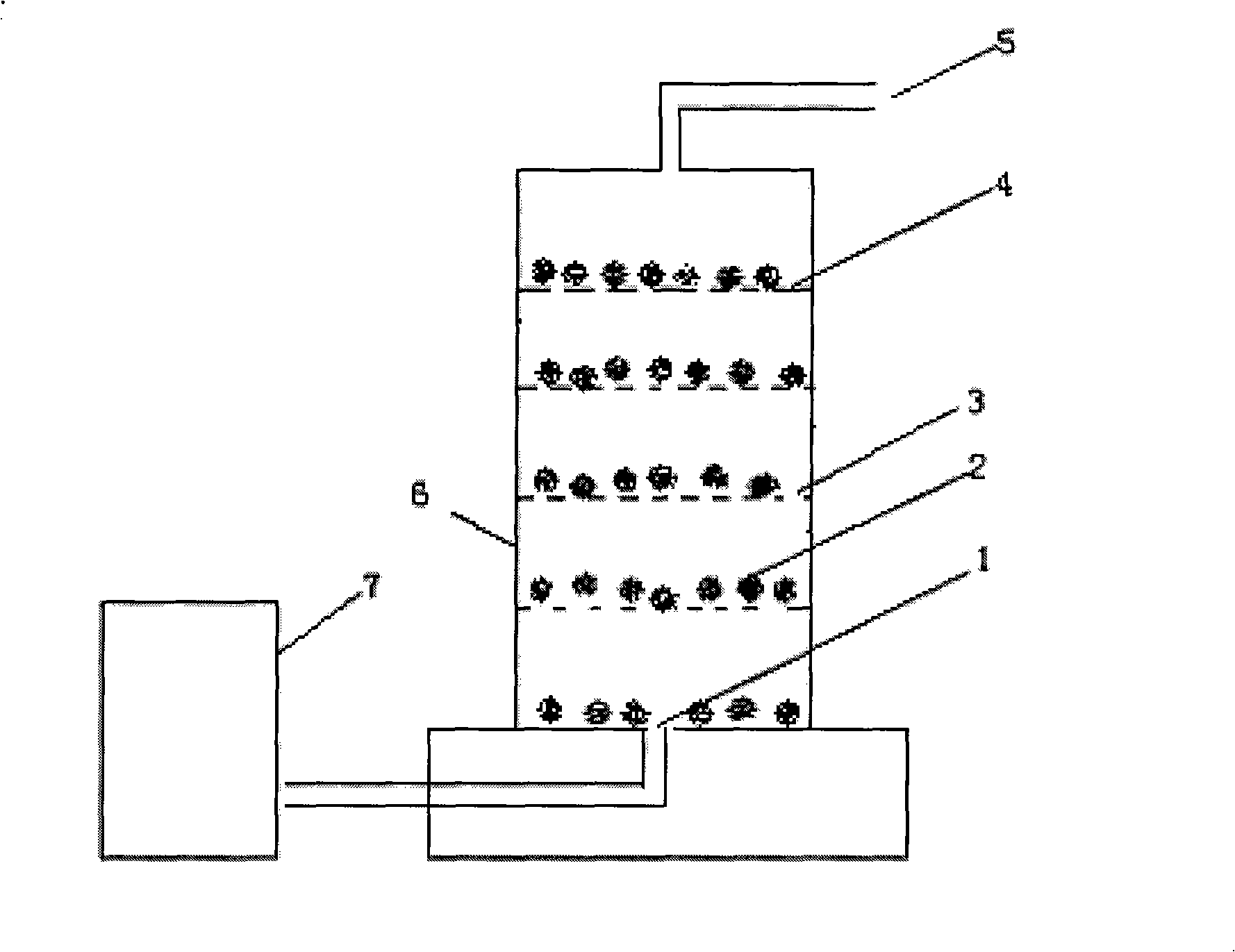

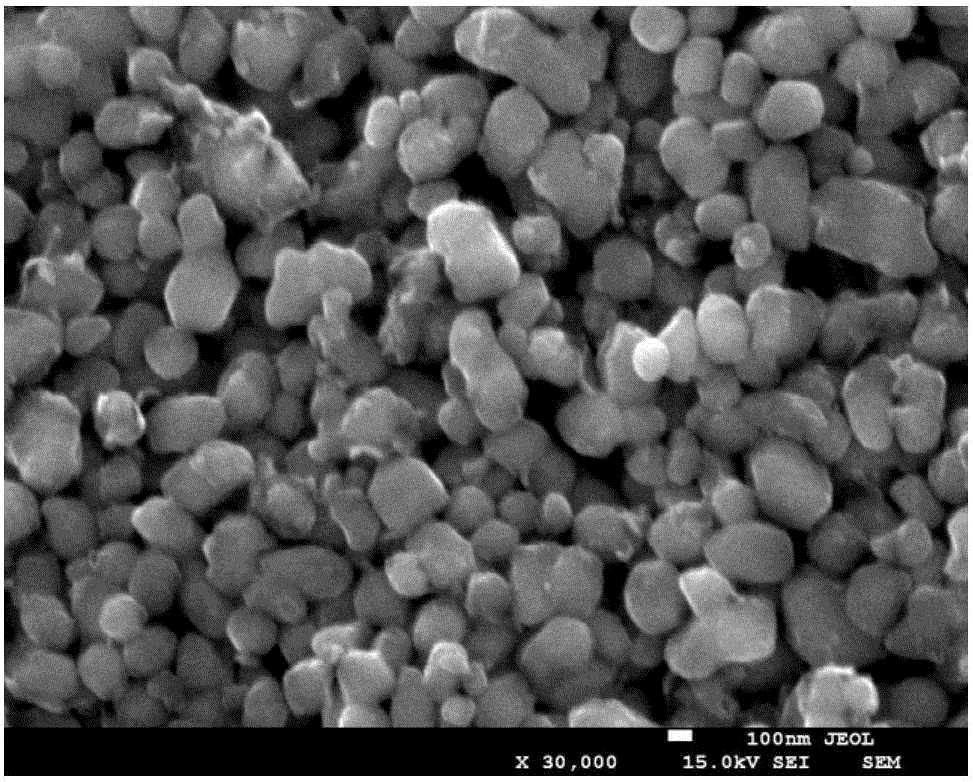

The invention discloses a method for preparing MnO2 supported catalysts, an application method thereof and a wastewater treatment device. The preparation method comprises the following steps: manganese acetate is prepared into a solution; one of activated carbon, active aluminium sesquioxide, white silica gel, a molecular sieve, zeolite or diatomite is taken as a carrier and dipped in the solution; and supported solid catalysts are prepared through dipping, evaporation, concentration, drying and roasting. A reactor of the wastewater treatment device is divided into a plurality of reaction spaces by baffles, and the catalysts exist as fluidized beds on every baffle. When the MnO2 supported catalysts prepared by the method are used in the reaction of degrading refractory organic matter through ozone catalytic oxidation, the contact time among the MnO2 supported catalysts, wastewater and ozone is between10 and 120 minutes, and the mass ratio of the adding amount of the catalysts to the wastewater in the reaction is between 1 to 200 and 1 to 20. The MnO2 supported catalysts prepared by the method have the characteristics of easy recovery, high repeat utilization property and high efficiency of catalyzing and degrading refractory organic matters.

Owner:GUANGDONG UNIV OF TECH

The method of accurate loading-and-filling ball of two sections of milling mine

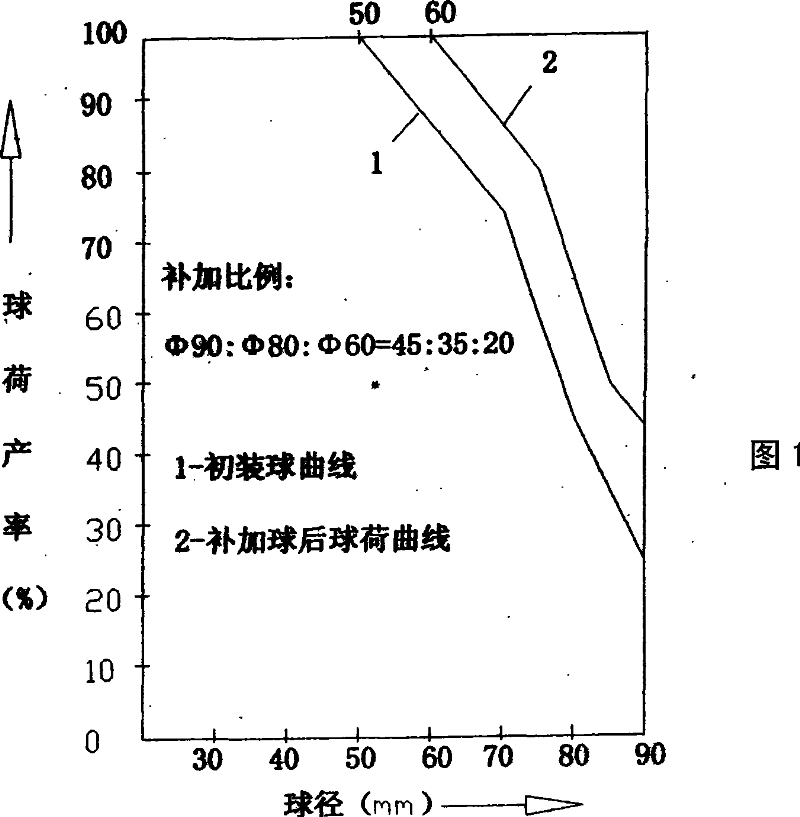

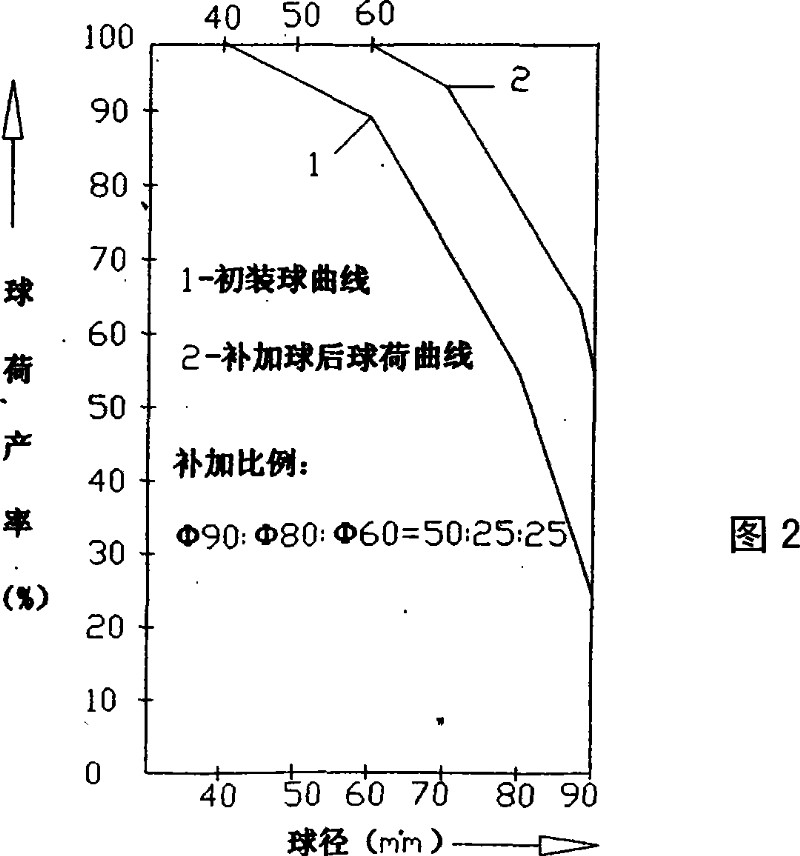

The invention relates to a precise remedy method for two sections of grind, belonging to the ore crash, the mill technical field in the method of preparation. The newly feeding ore with the largest size 25-15 mm is ground to the size smaller than 0.15 mm for two sections, wherein the size smaller than 0.074 mm reaches 70 wt% or thinner product fineness. According to the requirement, the precise makeup remedy method in two sections of grinding suggested in the invention mills the newly feeding mineral grain to the largest size 2-3 mm, wherein the size smaller than 0.074 mm is 20-30wt%, in the second grinding, the size is then ground to smaller than 0.15 mm, wherein the size smaller than 0.074 reaches beyond 70%, to replace the experience remedy method with rude and bad effect in the existing production. The invention not only used in the two section grinding circuit, but also is fit for the three-section grinding circuit, which has good product size characteristic, high sizing index, and can be applied in the grinding technology of the different ore rigidity, different mill specification, different rotating speed mill and different character of ore.

Owner:KUNMING UNIV OF SCI & TECH +1

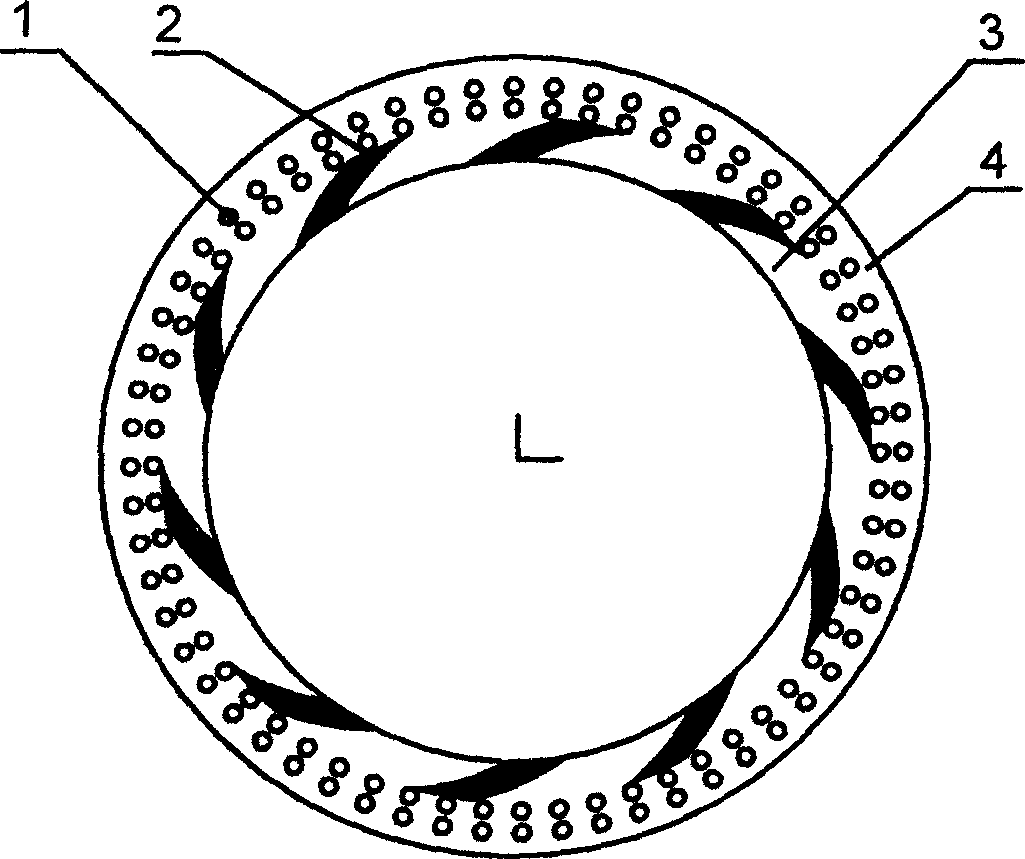

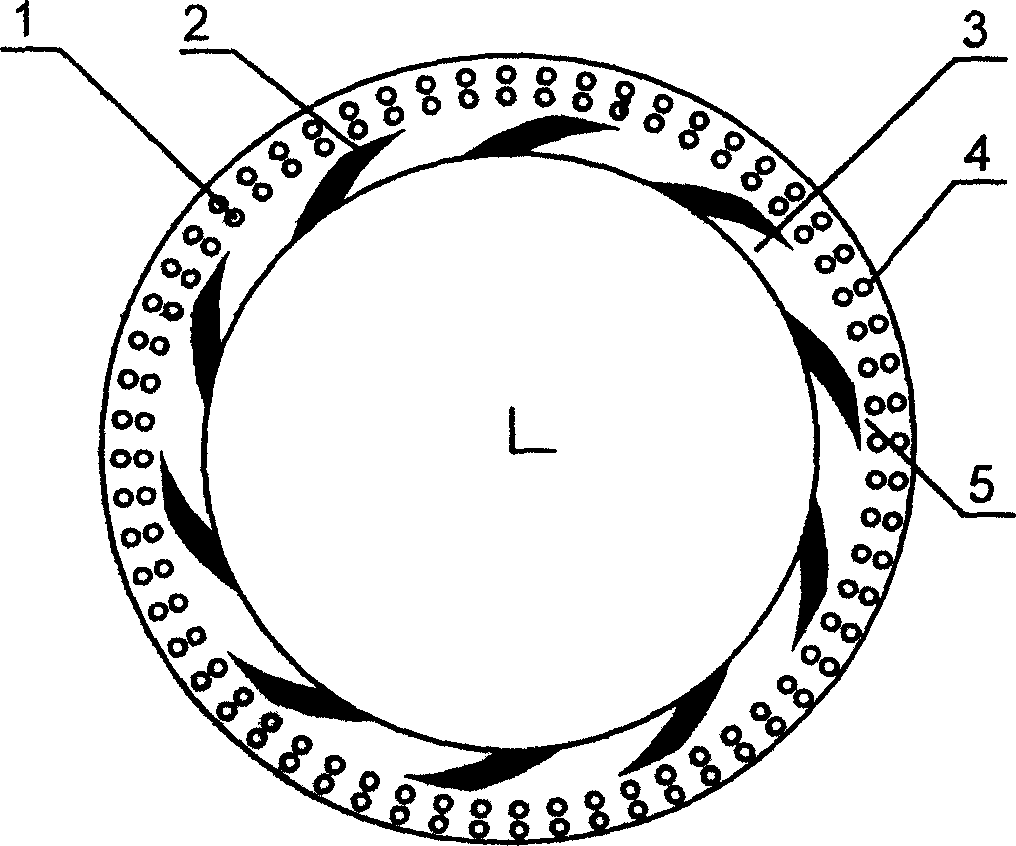

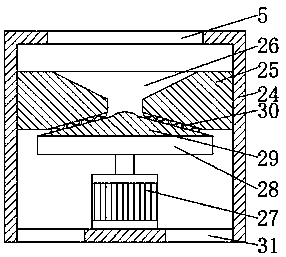

Non-contact mechanical end face sealing structure

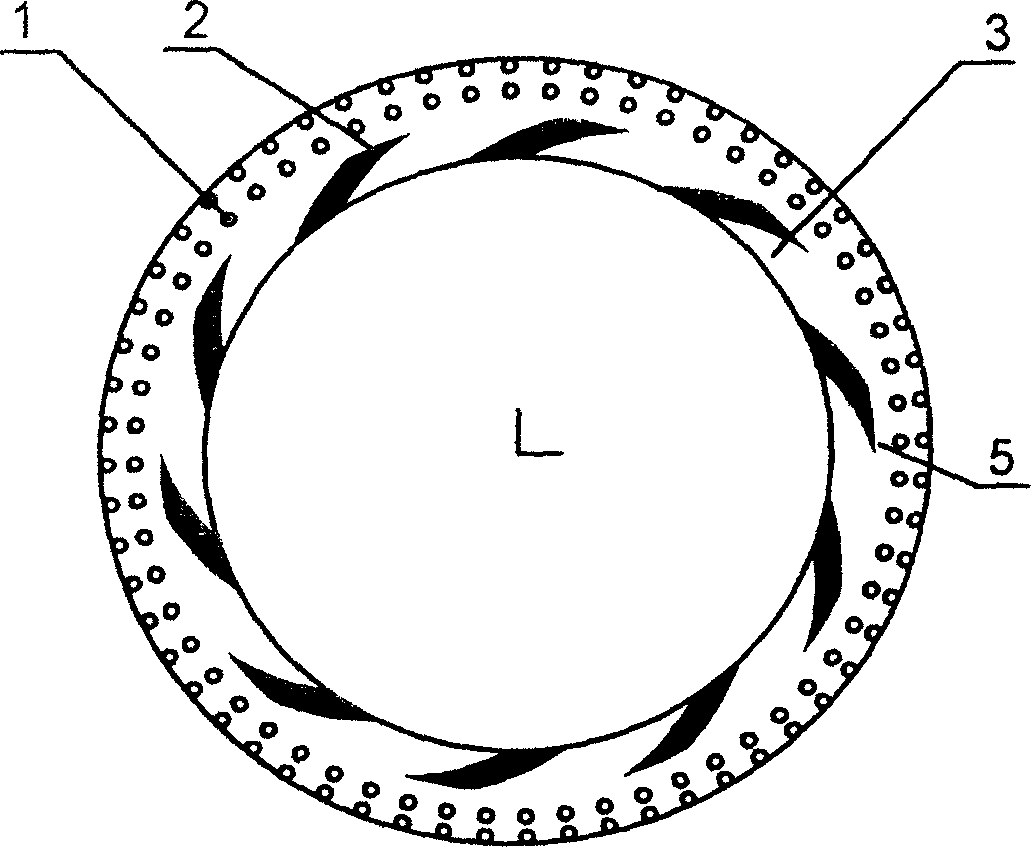

InactiveCN1828098AImprove sealing abilityExtended service lifeEngine sealsCentre of rotationEngineering

The invention relates to a non-contact mechanical end surface sealing structure, which comprises mechanical sealed movable ring and stable ring. While the end surface of stable or movable ring has micro groove and porous zone that symmetry according to the rotational center. Wherein, said zone is at the ascending part of end surface and the micro groove is at the descending part, which has a circular sealing dam beside it. The invention can be used in variable mediums to increase the ability of solid particle, the static pressure property, fluid dynamic pressure property and the pump adsorption property, to attain better sealing effect, with long service life.

Owner:ZHEJIANG UNIV OF TECH

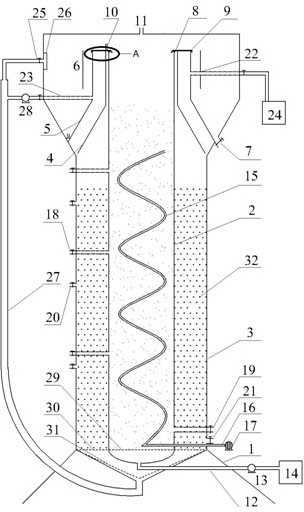

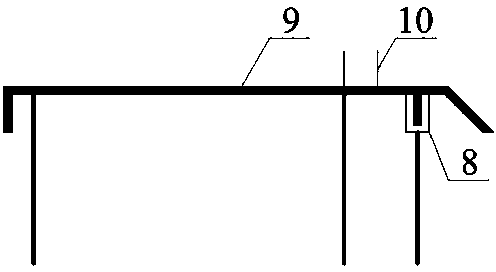

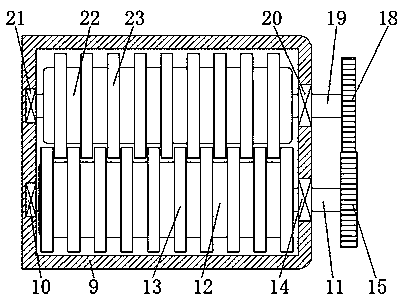

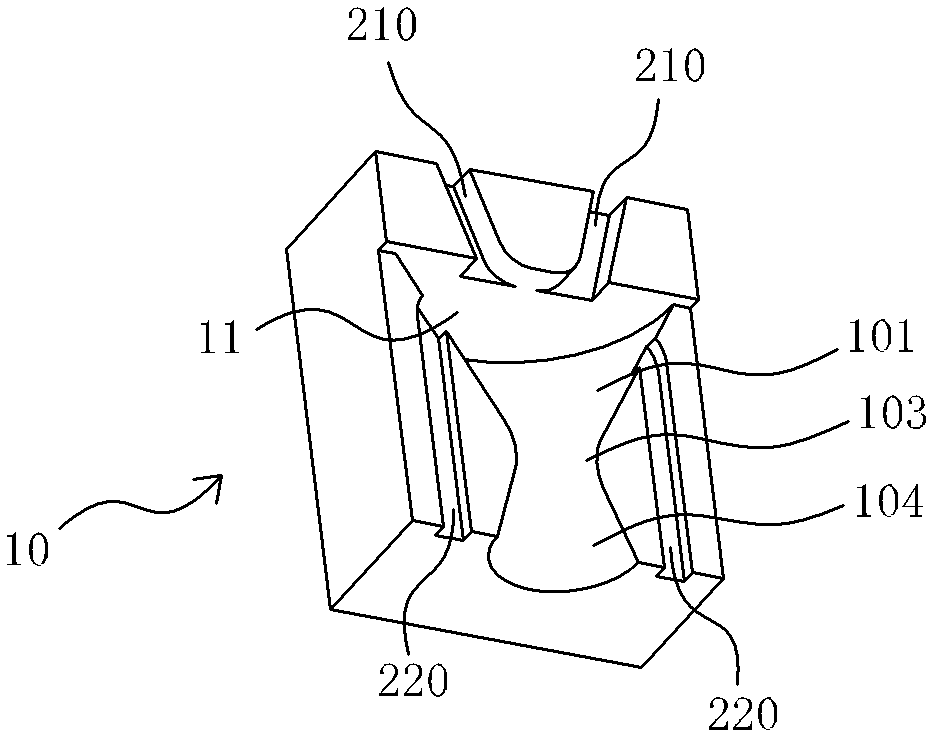

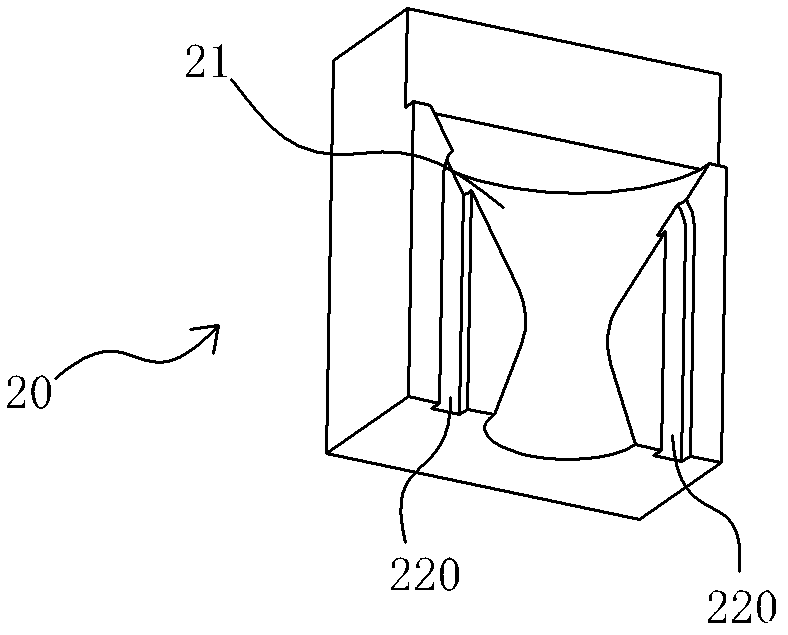

Integrated efficient autotrophic nitrogen removal reactor

ActiveCN104045156AClosely connectedSmall footprintTreatment with aerobic and anaerobic processesNitrogen removalThree-phase

The invention discloses an integrated efficient autotrophic nitrogen removal reactor. The reactor comprises an inner barrel and an outer barrel which are coaxially arranged, wherein a three-phase separator and a horn barrel which is tightly connected with an expanding part of the diameter at the upper part of the wall of the outer barrel are coaxially mounted at the upper part of the inner barrel in a sleeving manner; a space formed by the inner barrel and the outer barrel is divided into an anaerobic zone and a precipitating zone by utilizing the horn barrel; the inner barrel is taken as an aerobic zone; an annular overflow weir used for isolating the precipitating zone and the anaerobic zone is arranged on the top surface of the inner barrel; short-range nitrification sludge is inoculated in the aerobic reaction zone; a spiral micropore aeration pipe is arranged in the aerobic reaction zone; anaerobic ammonia oxidation sludge is inoculated in the anaerobic reaction zone; granule-state bamboo charcoal fillers are added into the anaerobic reaction zone to serve as a sludge carrier. According to the reactor, the individual culturing of different functional microorganisms in the single reactor is realized, so that the key operation requirements of partial nitrification and anaerobic ammonia oxidation processes can be satisfied; the efficient and stable running of the reactor is ensured. Thus, the reactor disclosed by the invention is suitable for treating wastewater with a high ammonia-nitrogen ratio and a low carbon-nitrogen ratio.

Owner:ZHEJIANG UNIV

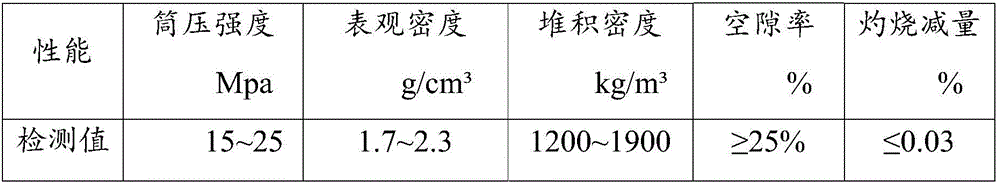

Casting-fly-ash ceramsite and preparation method thereof

ActiveCN106082841AEasy to prepareImprove performanceSolid waste managementPortland cementThermal insulation

The invention discloses a casting-fly-ash ceramsite. The casting-fly-ash ceramsite is prepared from a plurality of raw materials through mixing, granulation and maintenance. The plurality of raw materials are composed of, by weight, 95 to 105 parts of casting fly ash, 10 to 50 parts of Portland cement, 1 to 5 parts of redispersible latex powder, 1 to 5 parts of polyvinyl alcohol, 1 to 5 parts of a water reducer solution and 0 to 5 parts of bentonite. A preparation method for the casting-fly-ash ceramsite comprises the following steps: preparing the raw materials according to the above weight parts; then mixing the casting fly ash, the Portland cement, the redispersible latex powder, polyvinyl alcohol, the water reducer solution and bentonite; carrying out granulation on a mixture formed in the previous step; and subjecting pellets obtained after granulation to sealing and thermal insulation and then to maintenance. The casting-fly-ash ceramsite and the preparation method thereof realize effectively utilization of casting fly ash; the sintering-free preparation method better reduces energy consumption; so cost is reduced and environment is protected. The casting-fly-ash ceramsite has the advantages of low density, high strength, high particle integrity, etc.

Owner:北京仁创砂业铸造材料有限公司

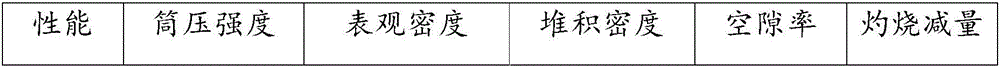

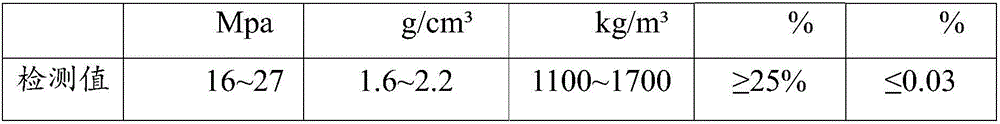

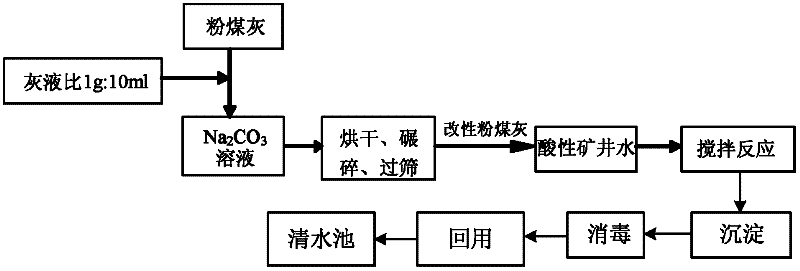

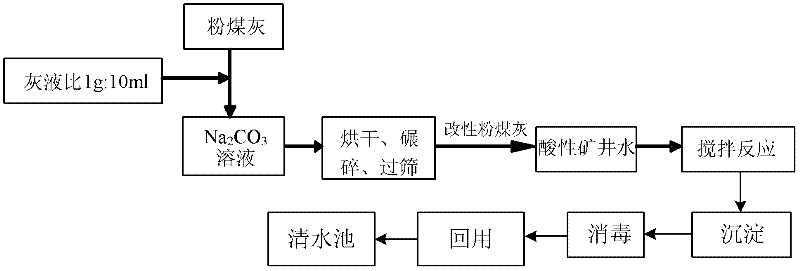

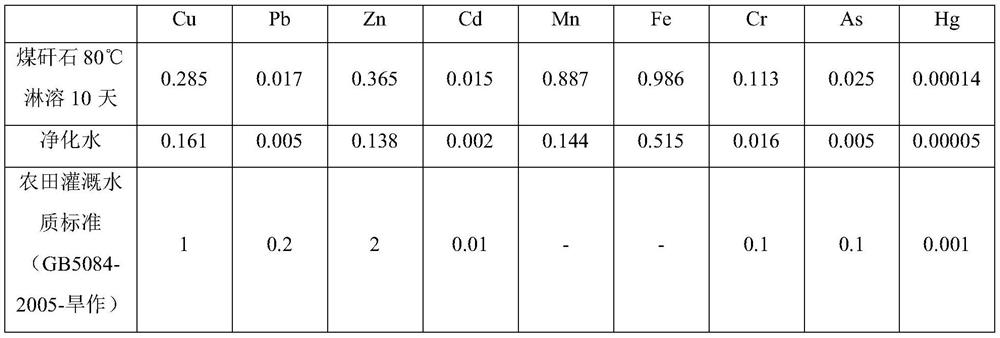

Method for treating acidic high-iron and high-manganese mine water and method for modifying fly ash

InactiveCN102303918AGood granularityWide variety of sourcesSolid waste disposalWater/sewage treatment by neutralisationPollutionWaste material

The invention discloses a method for treating acidic high-iron and high-manganese mine water and a method for modifying fly ash, and belongs to the field of waste water treatment. The method comprises: modifying fly ash, namely modifying unmodified fly ash by using a modifier to obtain modified fly ash; and treating acidic high-iron and high-manganese mine water, namely treating the acidic high-iron and high-manganese mine water by using the obtained modified fly as a treatment agent to obtain supernate. The method can solve the problems of low treatment efficiency, complex operation, high treatment cost, serious secondary pollution and the like of the conventional treatment process of acidic high-iron and high-manganese mine water in mining areas. Through the treatment of the acidic high-iron and high-manganese mine water by the modified fly ash, the effects of treating waste materials by waste materials and comprehensively utilizing resources are achieved, the power plant fly ash treatment and disposal and environment pollution problems are solved, the problem of environment pollution of acidic waste water in the mining areas is solved, the utilization rate of water resource is increased, and the sustained development of the mining areas is promoted.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

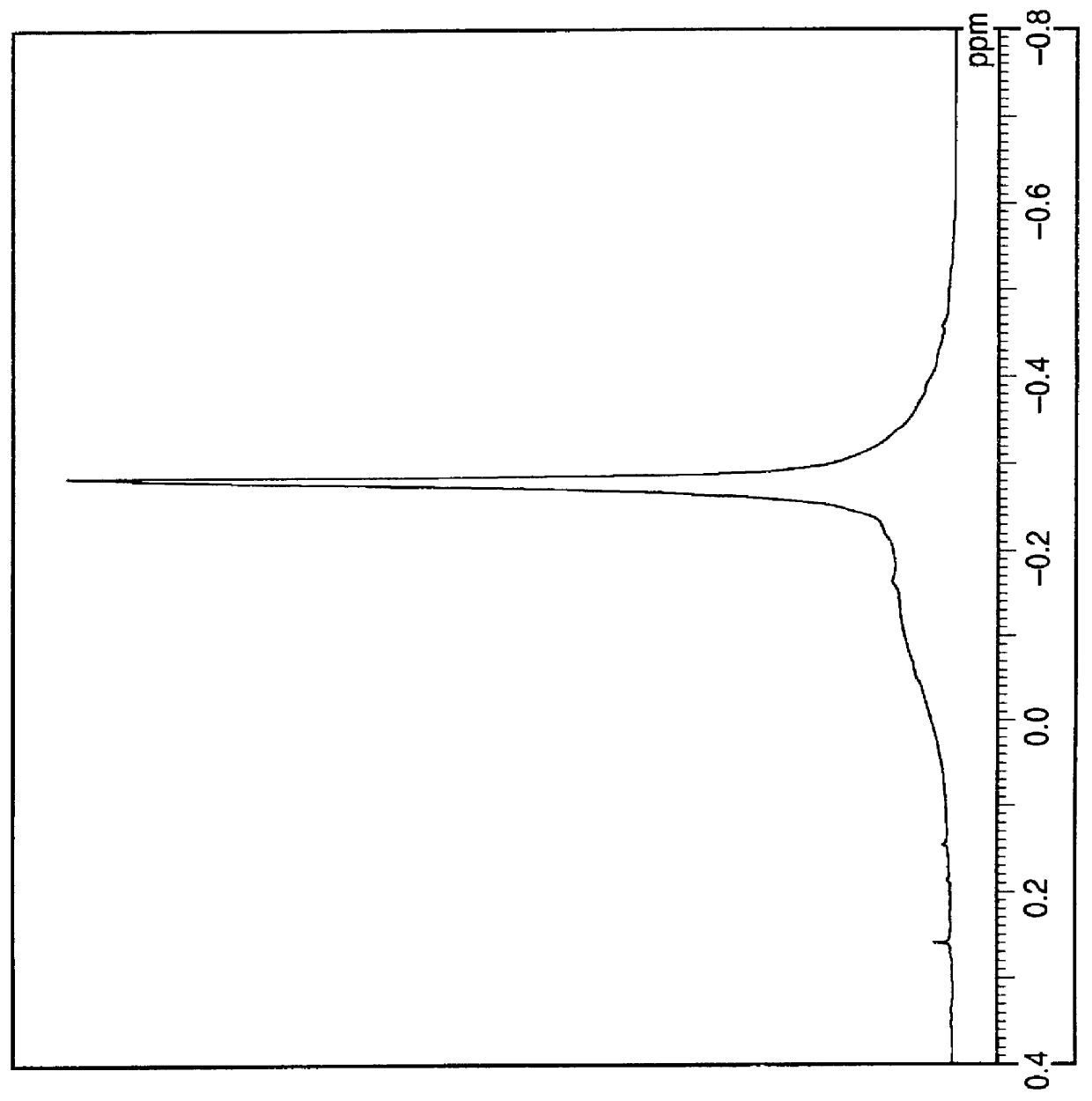

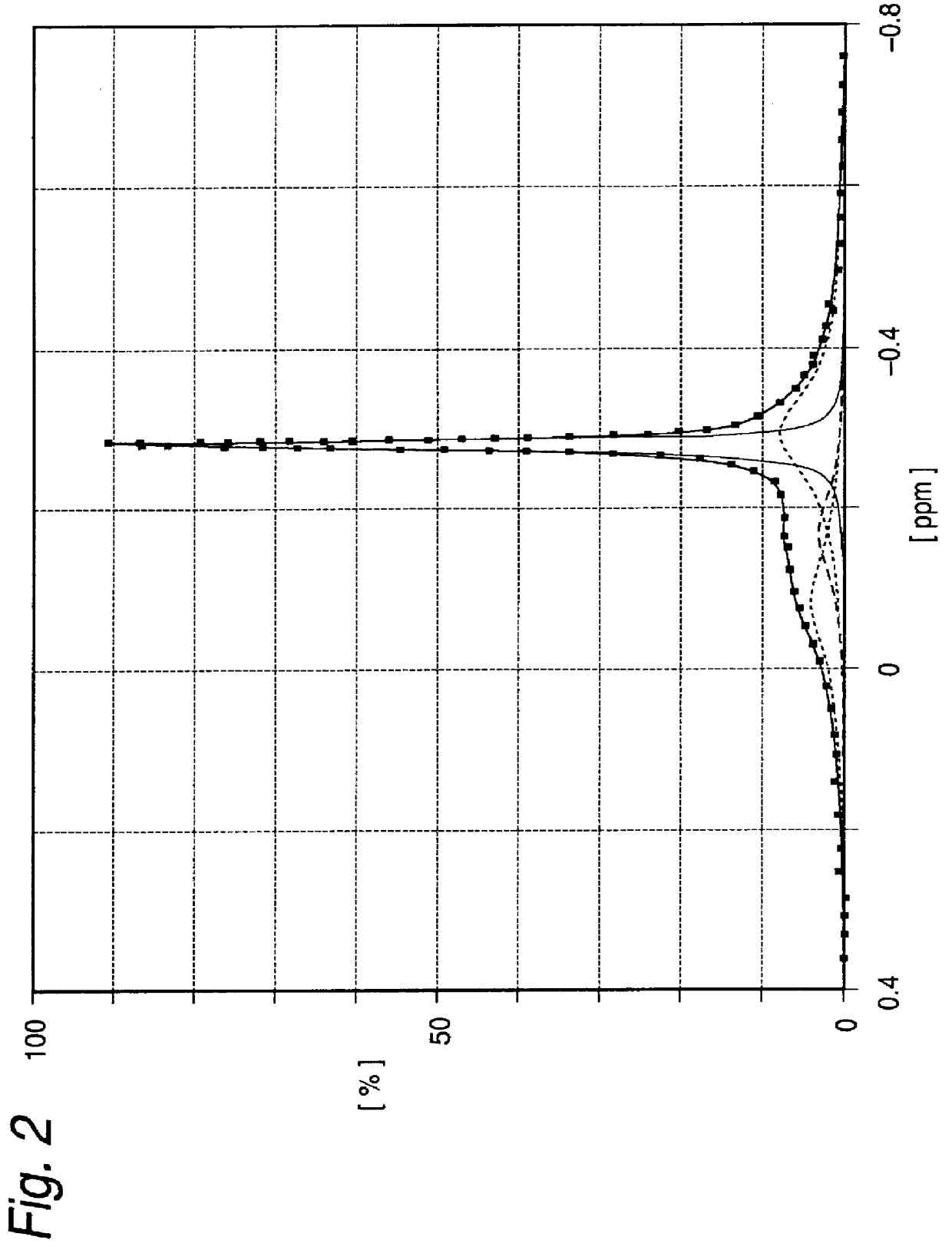

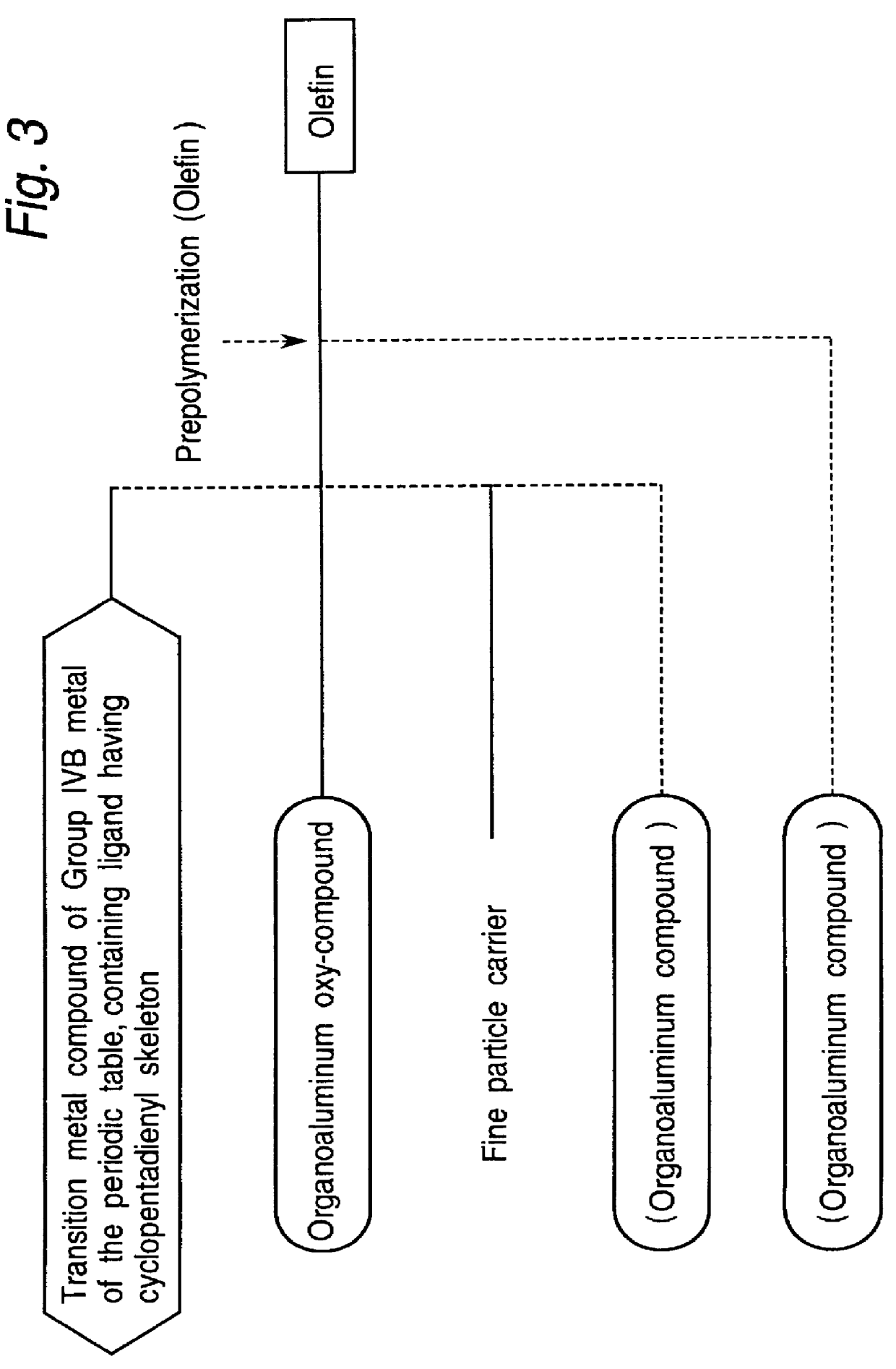

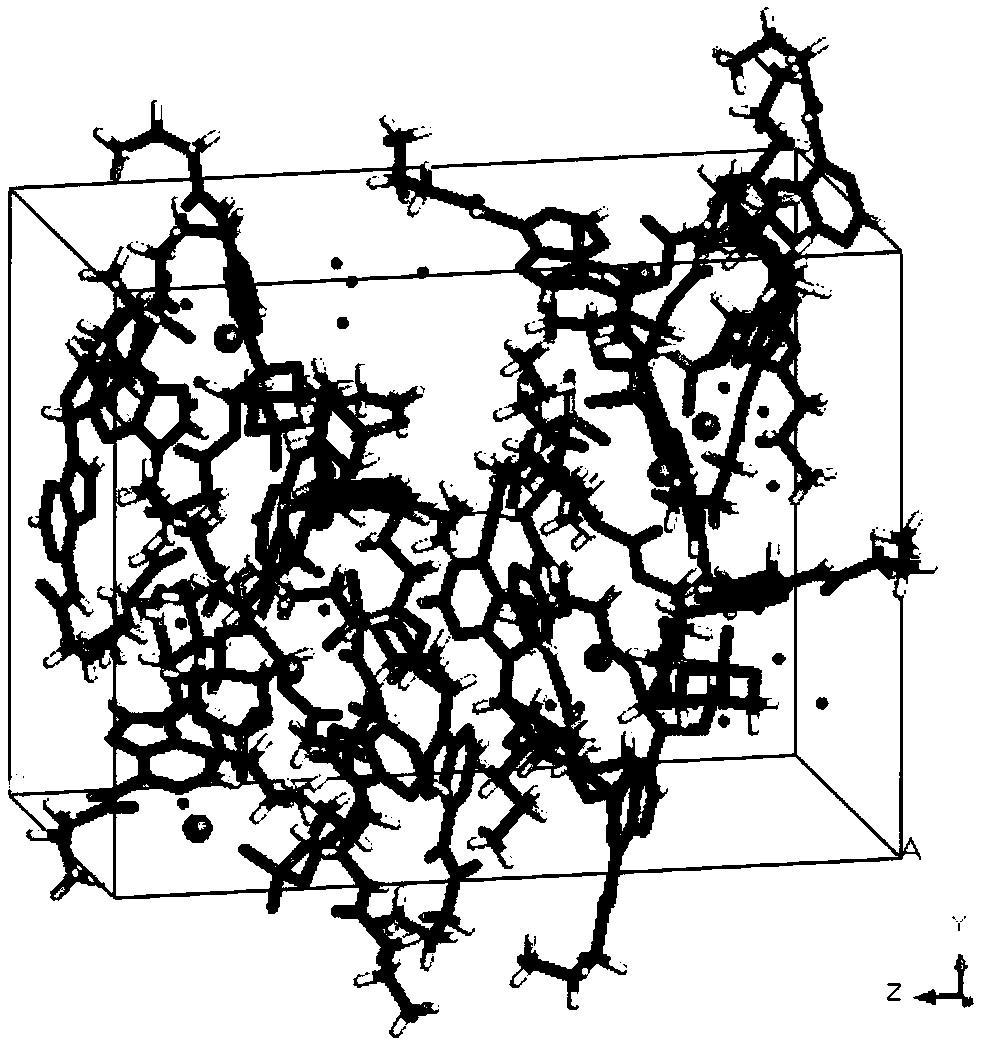

Process for olefin polymerization

InactiveUS6043325AGood granularityHigh polymerization activityOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceAluminoxane

A process for olefin polymerization, including polymerizing or copolymerizing an olefin in the presence of an olefin polymerization catalyst composed of: a fine particle carrier; (A) a transition metal compound of a Group IVB metal of the periodic table, containing a ligand having a cyclopentadienyl skeleton; (B) an aluminoxane compound; and optionally (C) an organoaluminum compound, wherein said aluminoxane compound has an alkyl groups to aluminum ratio of 1.3 to 2.1; said transition metal compound (A) and said organoaluminum oxy-compound (B) and said organoaluminum compound being supported on the fine particle carrier; and said solid catalyst having a bulk density of 0.3 g / cm3 to 0.5 g / cm3 and a fluidity index of 45 to 70 and an olefin polymerization process using the olefin polymerization catalyst; and an olefin prepolymerized catalyst obtained by prepolymerizing the catalyst, and an olefin polymerization process using the olefin prepolymerized catalyst. The olefin polymerization process produces a polymer showing excellent particle properties and an olefin polymer which does not stick to the wall of the polymerization reactor.

Owner:MITSUI CHEM INC

Process for producing solid catalyst component precursor for olefin polymerization

InactiveUS20100174038A1Good granularityMetal/metal-oxides/metal-hydroxide catalystsCompound (substance)Titanium

A production process is provided for an olefin polymerization catalyst component precursor, including the step of adding an organomagnesium compound to a solution containing a Si—O bond-containing silicon compound, a titanium compound represented by a defined formula, and a solvent, in an amount of 2.5 to 90 mol, per one liter of the solvent, of magnesium atoms contained in the organomagnesium compound added. Also provided are a production process of an olefin polymerization catalyst component using the above precursor; a production process of an olefin polymerization catalyst using the above catalyst component; and a production process of an olefin polymer using the above catalyst.

Owner:SUMITOMO CHEM CO LTD

Decontamination emulsion for hard surface cleaning and preparation method thereof,

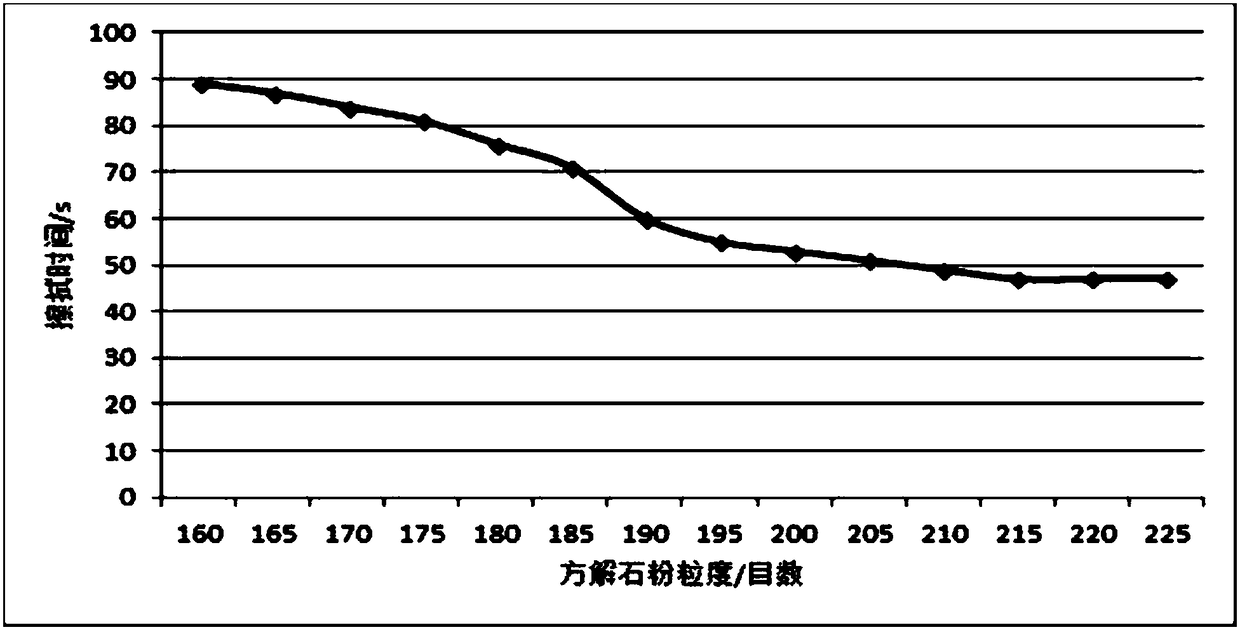

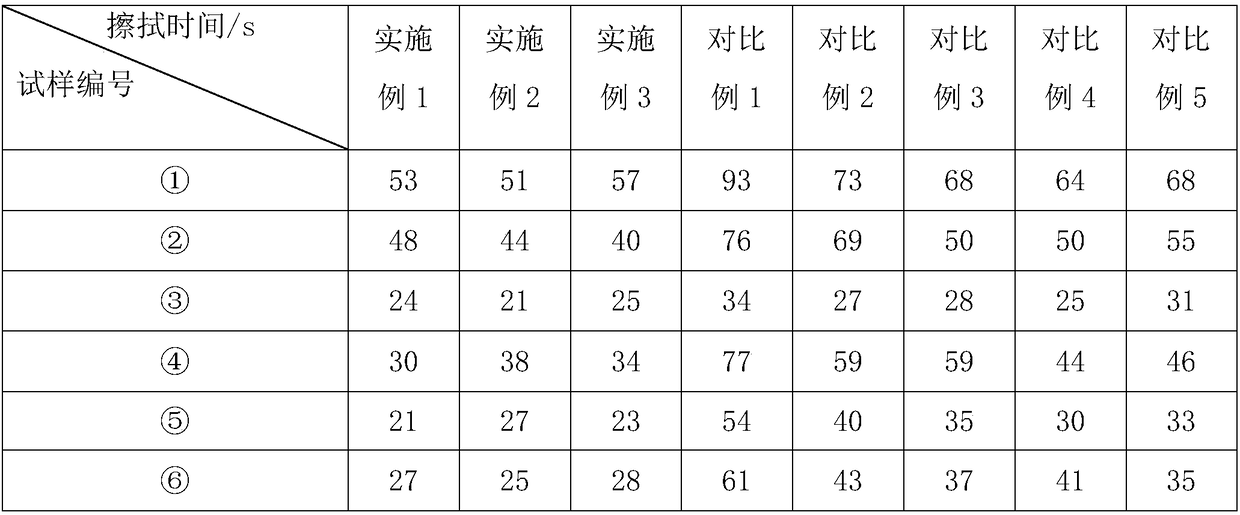

PendingCN108865487AGood granularityModerate hardnessInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsFriction effectSurface cleaning

The invention discloses a decontamination emulsion for hard surface cleaning and a preparation method thereof, and belongs to the technical field of detergents. The decontamination emulsion is technically characterized by being prepared from the following components in percentage by weight: 0.1%-0.5% of a water softener, 0.1%-0.5% of a preservative, 0.9%-1.5% of urea, 4%-10% of an anionic surfactant, 4%-10% of a nonionic surfactant, 4%-10% of ether, 0.9%-1.9% of organic alcohol, 0.5%-1.9% of a thickener, 20%-39% of an abrasive material, 0.1%-0.3% of fragrance and 24.4%-65.4% of deionized water. The decontamination emulsion has both chemical decontamination function and physical descaling function, has excellent effects of cleaning and deterging stains on hard surfaces of ceramics, stainless steel, marble, hard plastic, glass, etc., has the remarkable friction effect brought by the abrasive material besides the decontamination ability brought by the general surfactants, and has an excellent effect of cleaning dirt on the hard surfaces of utensils.

Owner:BEIJING FORNET WASHING SERVICE

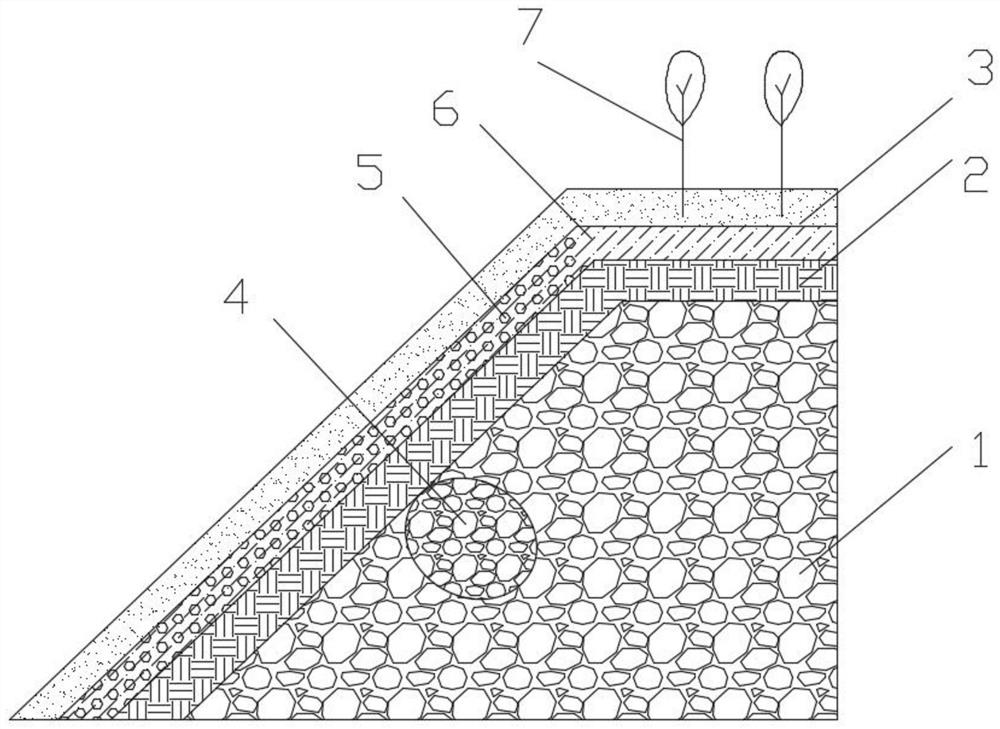

Method for repairing and managing coal gangue dump by using coal-based solid waste

ActiveCN112934944ASimple structureIncrease organic matterSolid waste managementContaminated soil reclamationEnvironmental engineeringEnvironmental protection

The invention relates to the technical field of ecological management of a coal gangue mountain, in particular to a method for repairing and managing the coal gangue mountain by using coal-based solid waste. The method comprises the following steps of: sequentially forming a drainage system on the coal gangue mountain, conducting grouting for fire extinguishing, carrying out sealing and isolating, carrying out covering with gangue mixing soil and constructing vegetation. The coal-based solid waste is used in the multiple links such as fire extinguishing of coal gangue, reburning prevention, water conservancy facility construction and greening treatment, and problems are effectively solved. The coal-based solid waste is used as a main raw material to prepare a series of materials for treating the coal gangue mountain, so natural repair materials are saved, and pollution to the environment and damage to land resources caused by solid waste accumulation are avoided.

Owner:SHANXI UNIV

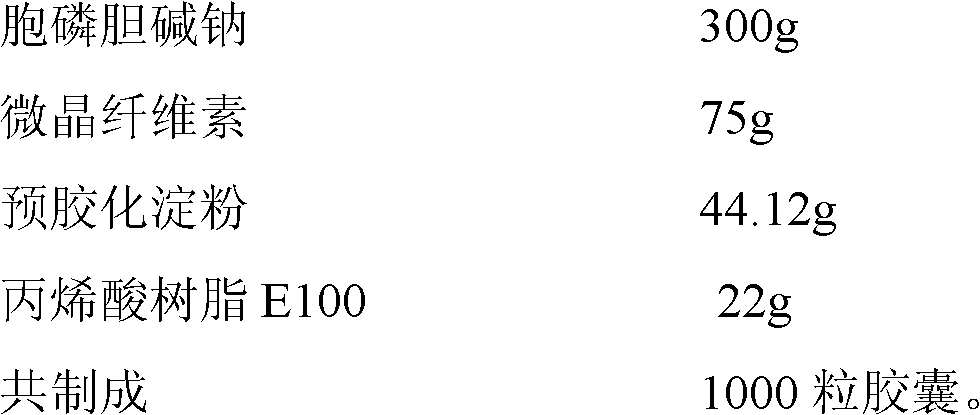

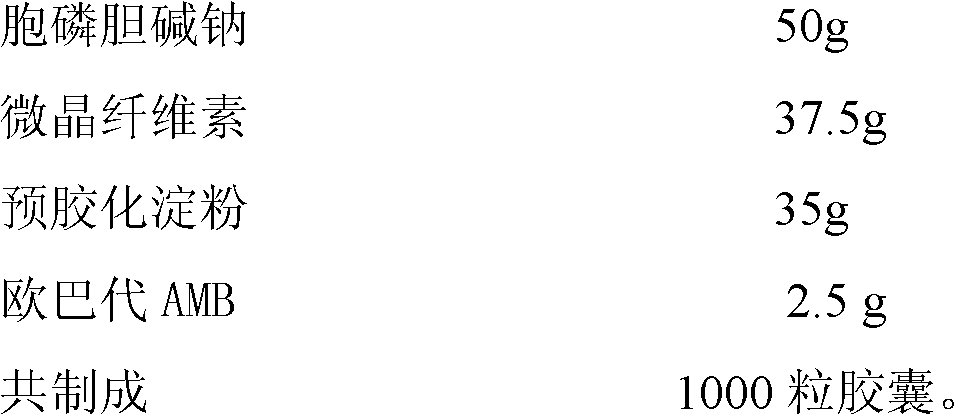

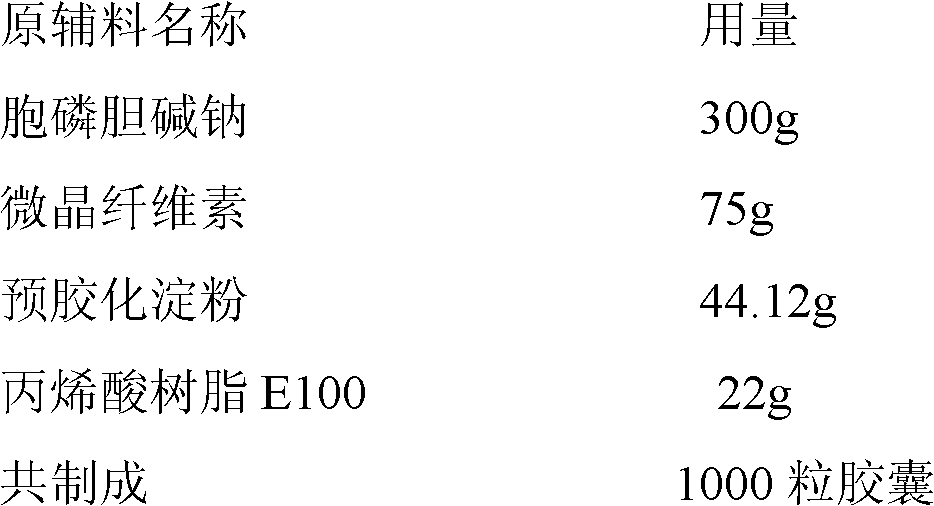

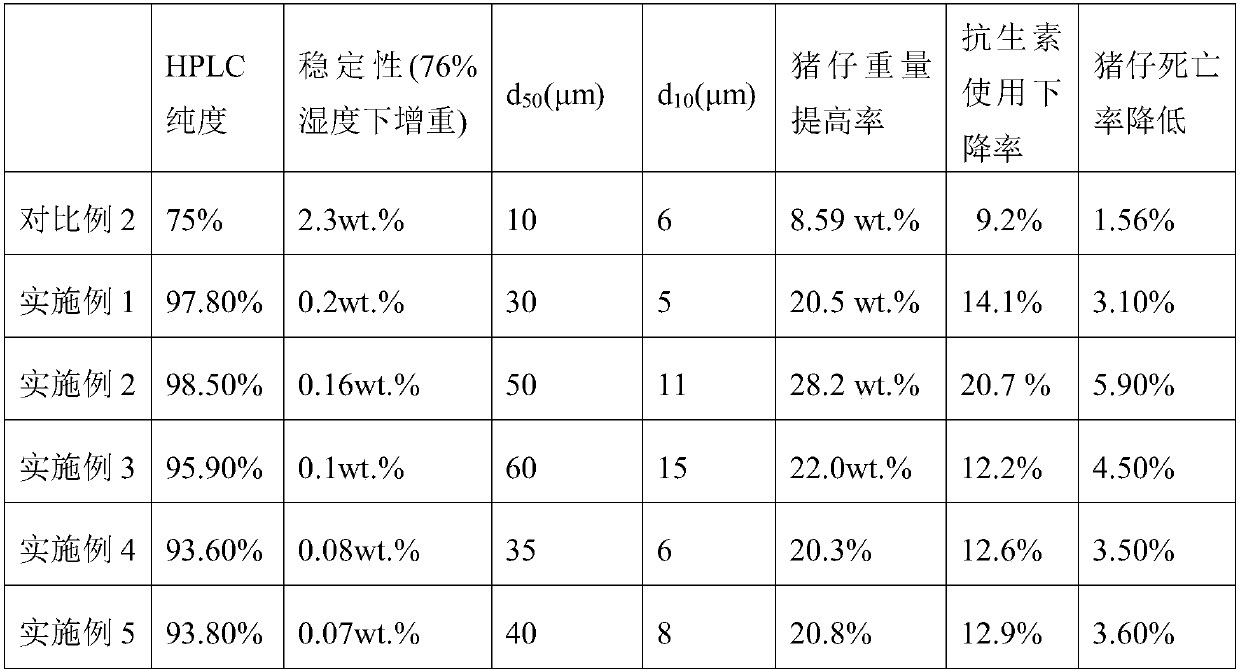

Moisture-proof coating citicoline sodium capsule and preparation method thereof

ActiveCN102525997AGood granularityGood disintegrationOrganic active ingredientsNervous disorderCiticoline sodiumMoisture absorption

The invention provides a moisture-proof coating citicoline sodium capsule and a preparation method thereof. The citicoline sodium capsule is composed of a capsule casing and quick-release moisture-proof micro pills or granules. All components in each capsule containing citicoline sodium quick-release moisture-proof micro pills or granules by percentage are 40% to 70% of citicoline sodium, 10% to 30% of microcrystalline cellulose, 10% to 30% of pregelatinized starch and 2% to 10% of moisture-proof coatings. The moisture-proof micro pills or granules are obtained by being extruded and rounded or pressed and granulated to be coated with moisture-proof coatings. The citicoline sodium capsule is good in moisture-proof function and resolves the problems that the capsule is prone to absorb waterdue to the fact that citicoline sodium is strong in moisture absorption, the capsule casing is prone to be fragile, and the like.

Owner:QILU PHARMA CO LTD

Method for deep denitriding of waste water in low carbon nitrogen ratio through denitrification

ActiveCN104787882ANo secondary pollutionGood removal effectWater treatment compoundsWater contaminantsFixed bedWater quality

The invention discloses a method for deep denitriding of waste water in a low carbon nitrogen ratio through denitrification. The method comprises the following steps: (1) performing denitriding by utilizing corn cores as an additional carbon source and a biomembrane carrier in a first section reactor A; (2) performing further denitriding by utilizing bamboo charcoal as a fixed bed to load microorganisms in a second section reactor B; (3) setting water inlet points respectively on the two sections of the reactors for raw water, and the water inlet points can be shifted in proportion according to different qualities of the raw water. The method has the following advantages that (1) an organic matter can be slowly released, secondary pollution cannot be generated, and the COD exceeding of effluent cannot be caused; (2) the method has a better removing effect on nitrate nitrogen in the waste water in the low carbon nitrogen ratio and besides can remove ammonia nitrogen in the waste water; (3) secondary pollution cannot be generated, and the standing time of the nitrate nitrogen can be prolonged, so that the quality of the effluent is improved; (4) the denitriding effect of the waste water can be improved, and the removing rate of the nitrate nitrogen is more than 80%, so that the effluent is steady; (5) the technology is simple, easy to operate, low in cost, small in floor space, short in standing time and free from power consumption, and the method has a good application prospect.

Owner:NANJING FORESTRY UNIV

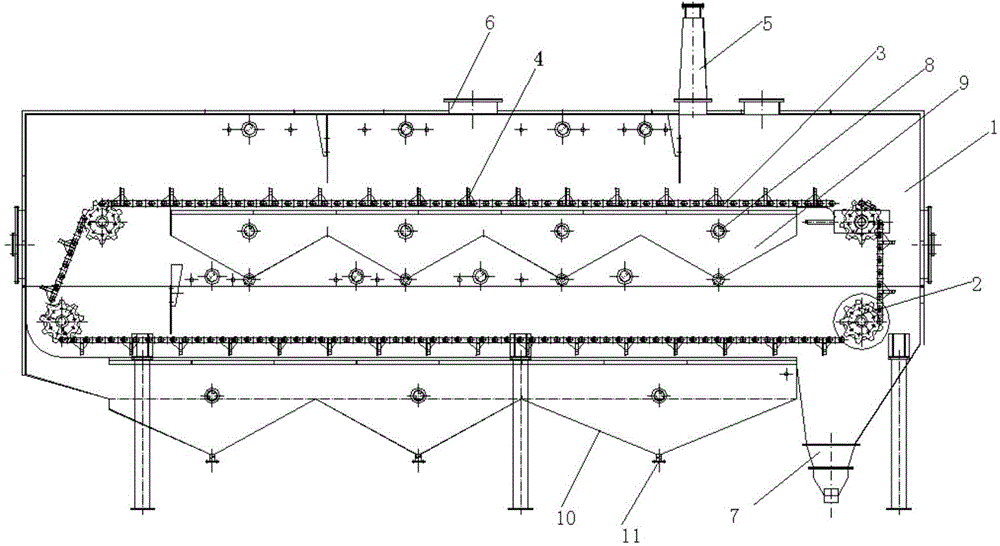

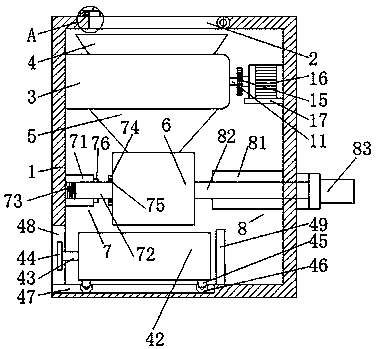

Miniature box-type leacher for special oil

InactiveCN104450171AImprove leaching production effectGuaranteed operabilityFatty-oils/fats productionEngineeringCirculating pump

The invention discloses a miniature box-type drag chain scraper flipover leacher. The miniature box-type drag chain scraper flipover leacher comprises a box-type leacher shell, wherein a plurality of driving chain wheels are arranged in the box-type leacher shell, and are sleeved by box chains; spaced push plates are fixedly arranged on the outer side of the box chains; material storage tanks, manholes and discharge holes are respectively formed in the upper end and the lower end of the box-type leacher; feeding augers are arranged below the material storage tanks; a plurality of push box lattices as leaching units are arranged in the box-type leacher; circulating mixed oil forms a soaking pond above each push box lattice; a plurality of oil buckets are formed in the bottom surface of the box-type leacher shell; and circulating pumps are arranged at oil inlets of the oil buckets. The miniature box-type drag chain scraper flipover leacher adopts a dual-layer multi-nozzle spray-type low material level, is suitable for a preform which is large in particle size and high in moisture content (5%-8%) and of which the normal moisture is not greater than 8%-10%; the equipment operation is controllable; the production operation is stable; blanking and meal discharging are stable; the residual meal discharge oil is not greater than 1.0%; the leaching time is controlled at about 90-120 minutes in general according to the oil variety; and the optimal effect of continuous production of the special oil is achieved.

Owner:DATUANJIE AGRI CO LTD

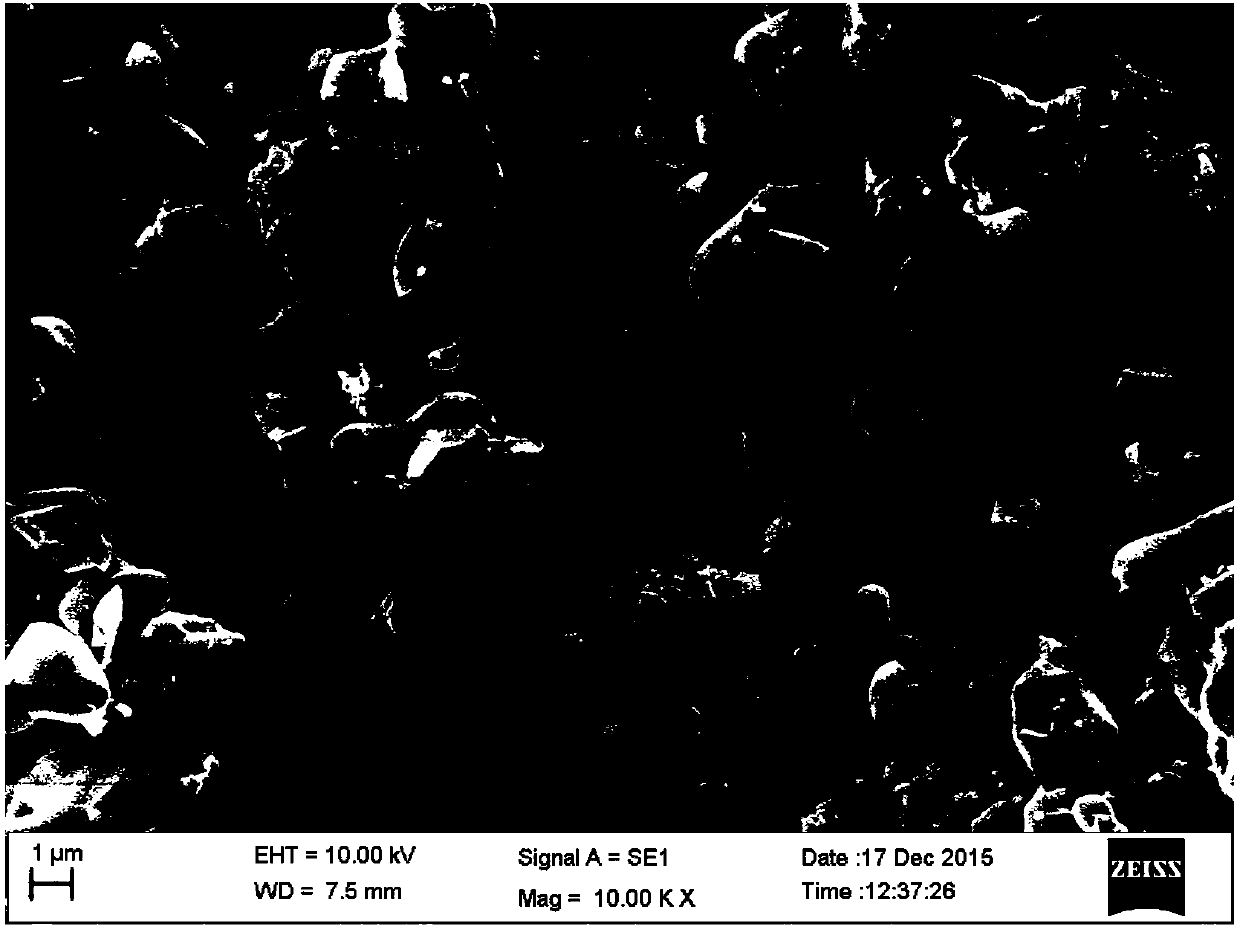

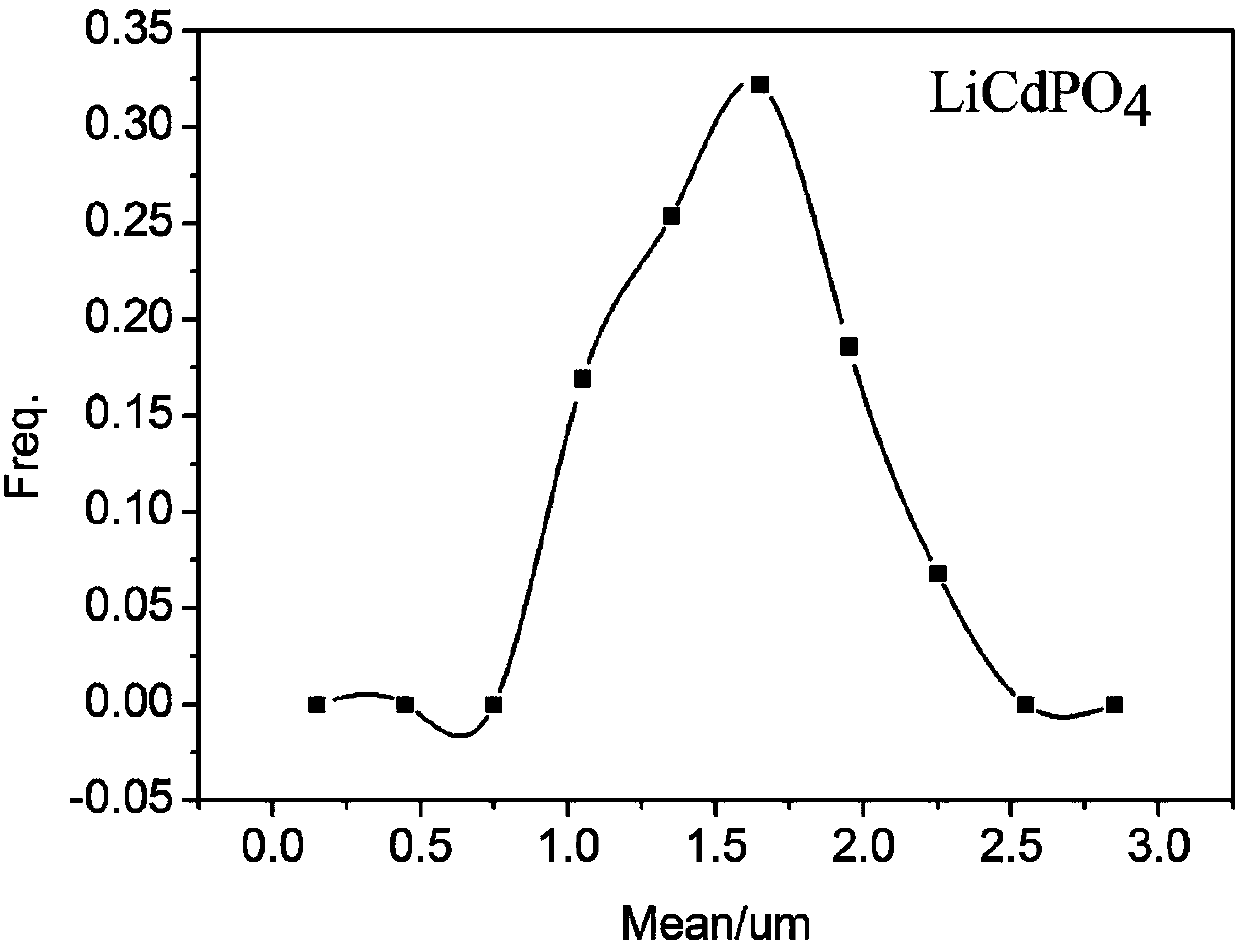

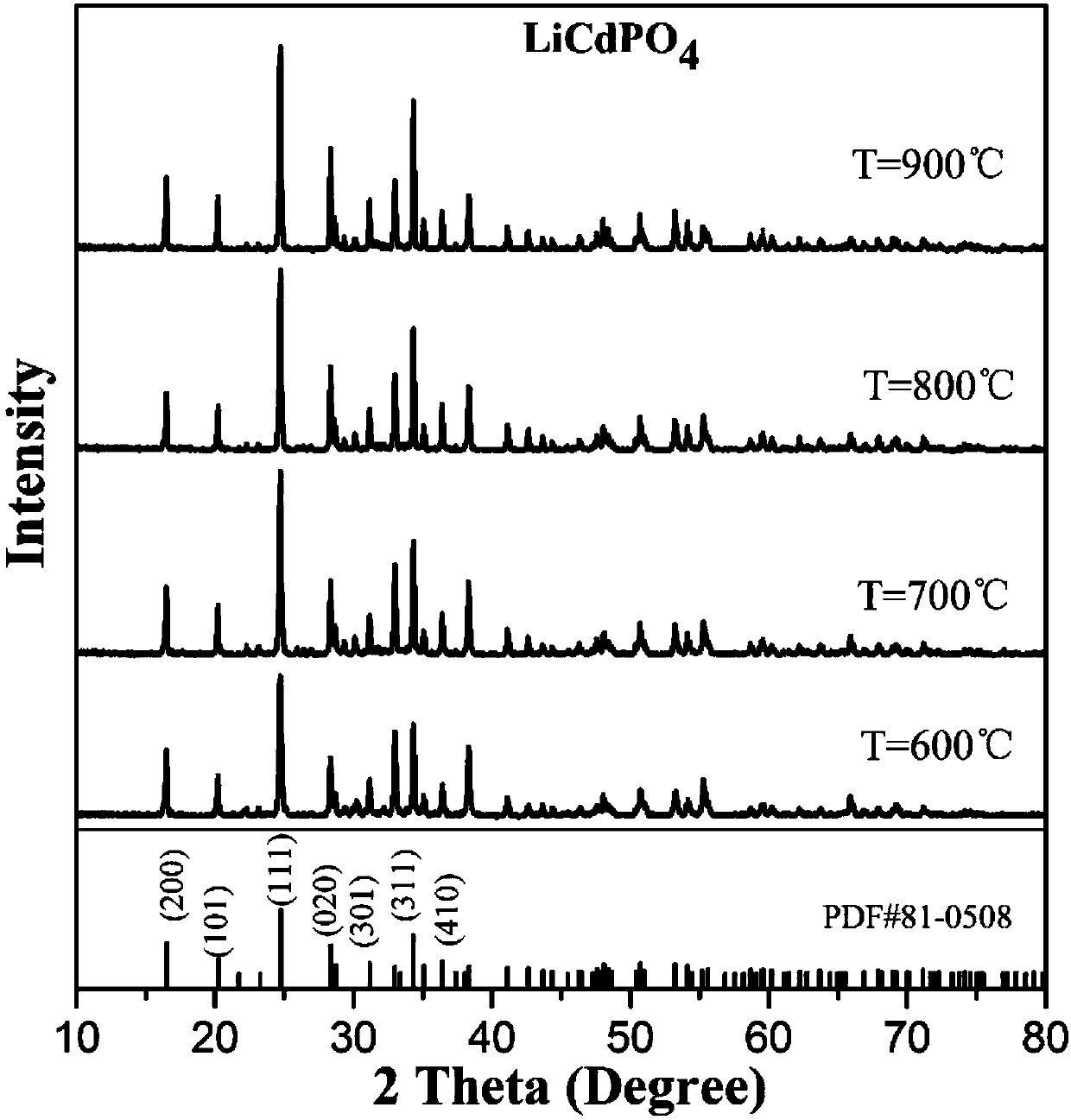

Cadmium lithium phosphate material and synthetic method thereof

The invention discloses a cadmium lithium phosphate material and a synthetic method thereof, and relates to the technical field of synthesis of inorganic materials. The method comprises the followingsteps: weighing lithium hydrate, cadmium nitrate, phosphoric acid and ethylene glycol according to ratio of 1: 1: 1: 2; then adding distilled water to dissolve and mix the components to obtain a mixedsolution; carrying out water-bath heating on the mixed solution and stirring by using a stirrer to obtain wet gel; drying the wet gel to obtain dry gel; grinding the dry gel and calcining the dry gelin a muffle furnace under the protection of activated carbon powder; and grinding the calcined gel to obtain a cadmium lithium phosphate sample. The cadmium lithium phosphate material is synthesizedby a sol-gel method, a preparation process is simple to operate, preparation conditions are gentle, costs are low, the synthesized cadmium lithium phosphate material is good in degree of crystallinity, good in dispersibility and stable in structure, the magnetic property of the cadmium lithium phosphate material prepared under the calcining conditions that the temperature is 800 DEG C and the timelasts for 12 hours is the best, and the application prospect is good.

Owner:天富(连云港)食品配料有限公司

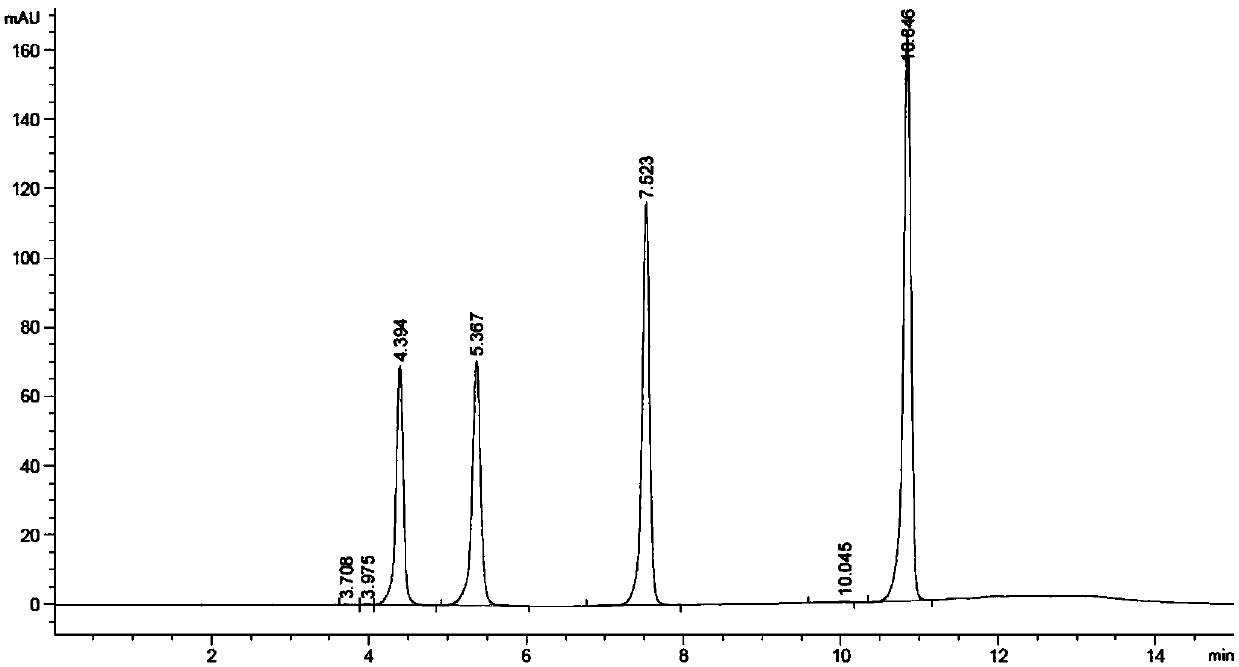

Nucleotide mixture crystalline powder and preparation method thereof

The invention discloses nucleotide mixture crystalline powder and a preparation method thereof. The preparation method comprises the following steps of performing solid-liquid separation on ribonucleic acid enzymatic hydrolysate, decoloring the enzymatic hydrolysate, regulating the pH of decolored enzymatic hydrolysate to 6.5-10.0, performing concentration, performing crystallization, performing filtration, and performing drying so as to obtain the nucleotide mixture crystalline powder containing uridylic acid, guanylic acid, cytidylic acid and adenylic acid. The nucleotide mixture crystallinepowder provided by the invention is high in purity, good in stability and free from moisture absorption, has favorable granularity and mobility, and can be widely applied to feed trade. The preparation method provided by the invention is high in yield, simple to operate and low in cost, and is suitable for industrial production.

Owner:NANJING UNIV OF TECH

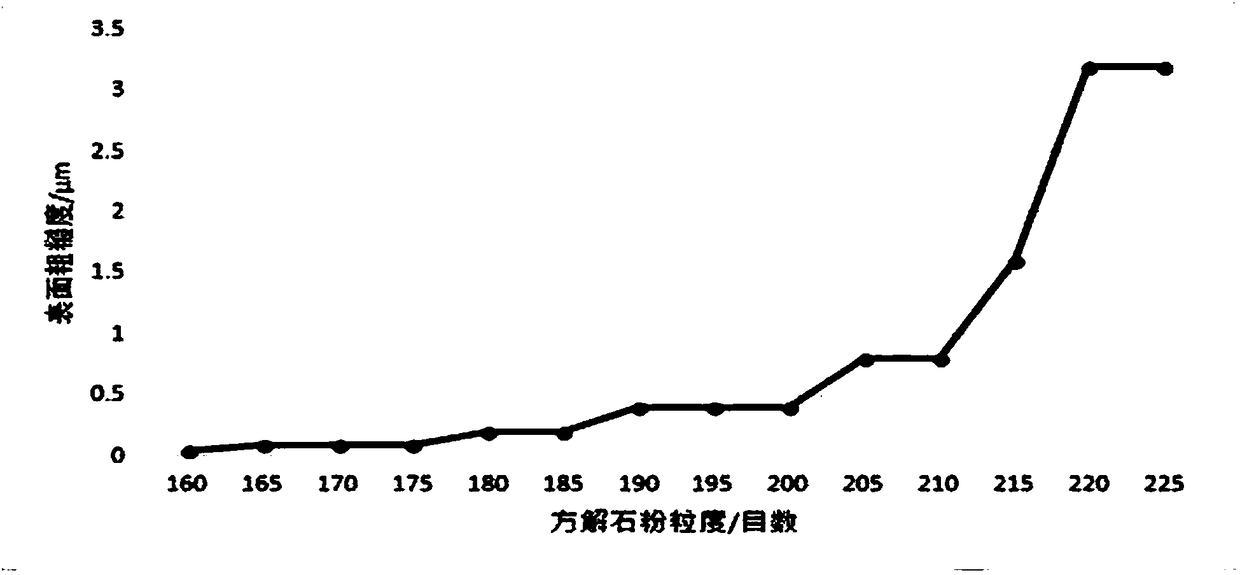

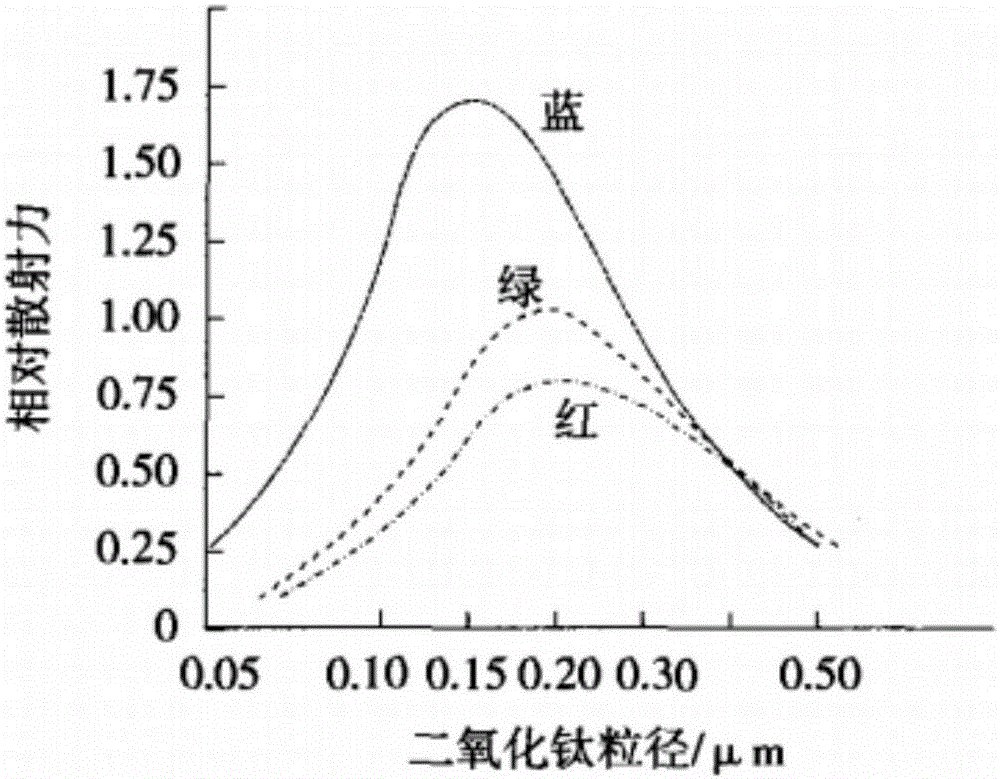

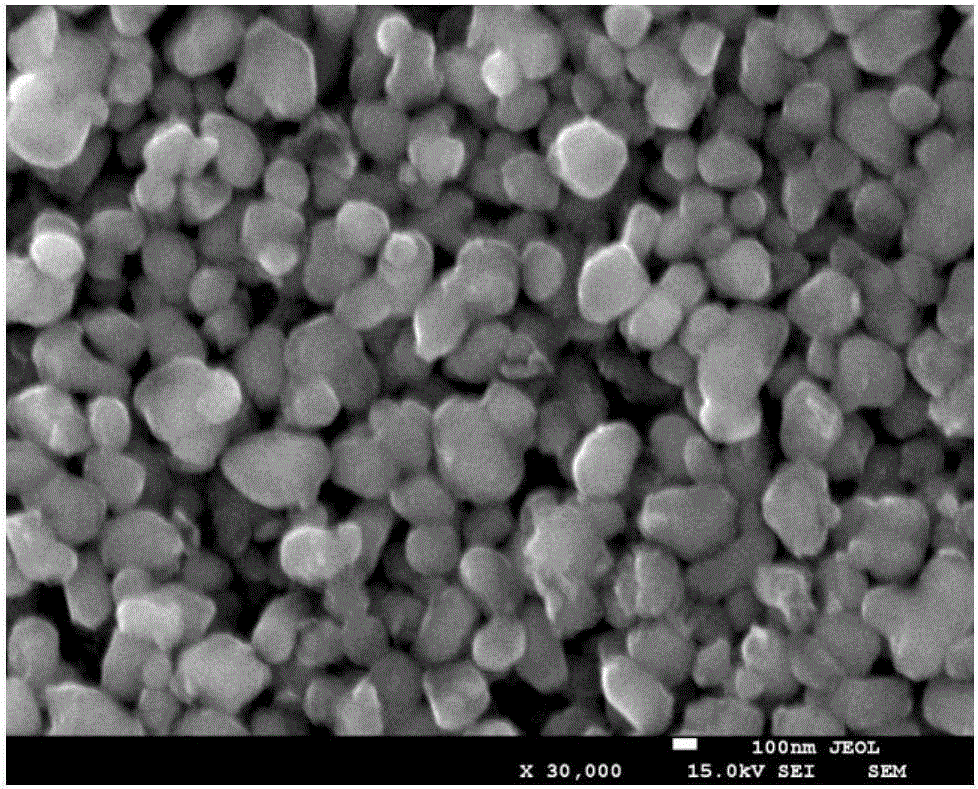

Method for reducing small-granular titanium dioxide in titanium dioxide

The invention belongs to the field of sulfate process titanium dioxide preparation, particularly relates to a method for reducing small-granular titanium dioxide in titanium dioxide and aims to solve the technical problem that the average grain diameter of sulfate process general type titanium dioxide is 250-300 nm and the proportion of small grains with the grain diameter smaller than 180 nm is higher. According to the scheme for solving the technical problem, the method for reducing small-granular titanium dioxide in titanium dioxide comprises steps as follows: a, a titanium liquid and water are preheated respectively, stirring starts, the titanium liquid is added to the water, and a mixed liquid is formed; b, the mixed liquid is heated to be boiled for the first time; the boiling state is kept, stirring and heating are stopped when the mixed liquid reaches a grey point, after 25-40 min, stirring starts, and the mixed liquid is heated continuously to be boiled for the second time; c, when the mixed liquid is boiled for the second time, water is added for hydrolysis; d, metatitanic acid obtained after hydrolysis is filtered, washed, bleached and subjected to salt treating, calcination and aftertreatment, and a titanium dioxide product is obtained. According to the method, the proportion of the small-granular titanium dioxide in the titanium dioxide product is reduced, and the covering power of the product is improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Perishable garbage in farm product markets based organic fertilizer production method

InactiveCN110092680AGood fertilizer effectGood granularityBio-organic fraction processingBioloigcal waste fertilisersResource utilizationMicrobial agent

The invention belongs to the field of garbage treatment, and specifically relates to a perishable garbage in farm product markets based organic fertilizer production method. The method includes the following steps: (1) performing junk removing, and sorting and removing junk in garbage that cannot make organic fertilizer; (2) performing pressure filtration dehydration on the junk-removed garbage sothat filter residues and filtrate can be obtained; (3) performing mechanical crushing on the filter residues to obtain filter residue debris; (4) adding the filter residue debris into the filtrate, and simultaneously adding an auxiliary agent, performing stirring for at least 1 hour under a temperature being 25-40 DEG C, and performing standing for 2-3 hours so that slurry can be obtained; (5) adding a compound microbial agent into the slurry, and performing fermentation to obtain a fermentation broth; and (6) concentrating and drying the fermentation broth, controlling water content to be at25-30%, and performing granulation so that the organic fertilizer can be obtained. The method is complete in garbage resource utilization and nutrient composition recycling, good in fertilizer efficiency of the obtained organic fertilizer, excellent in particle formability and good in slow-release effect of active ingredients.

Owner:浙江旺能生态科技有限公司

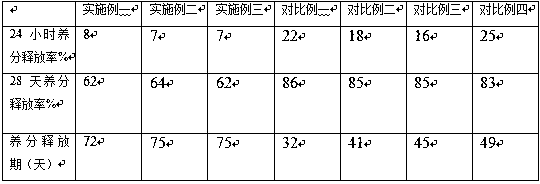

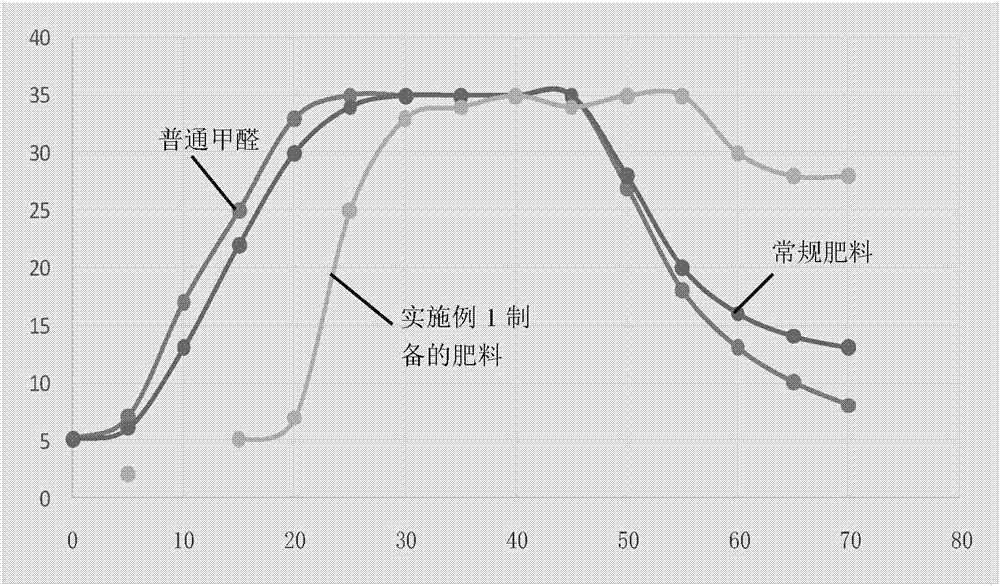

Fertilizer possessing slow-release water-retention function and preparation method of fertilizer

PendingCN107266195AImprove roundnessHigh hardnessUrea compound fertilisersFertilizer mixturesPhosphoric acidHardness

The invention discloses a fertilizer possessing a slow-release water-retention function and a preparation method of the fertilizer. The preparation method comprises: adding carboxymethyl chitin and polyacrylamide to water, performing heating to form a suspension, adding a formaldehyde solution to the suspension, performing adjustment to obtain a pasty liquid, adding urea to the pasty liquid, carrying out a reaction to form a homogeneous liquid, adding polyphosphoric acid to the homogeneous liquid, and performing granulation to obtain the fertilizer possessing a slow-release water-retention function. The prepared fertilizer is greatly improved in the hardness and has a water-retention function.

Owner:山东新朝阳作物营养有限公司

Glass crushing reusing device

InactiveCN109513512ASolving the recycling problemImprove work efficiencyCocoaGrain treatmentsEngineeringGlass recycling

The invention discloses a glass crushing reusing device, which comprises a box. The top of the box is movably connected with a cover plate through a hinge, the top of the left side of an inner cavityof the box is fixedly connected with a crushing mechanism, the top of the crushing mechanism is fixedly connected with a feeding hopper located at the bottom of the cover plate, the bottom of the crushing mechanism is fixedly connected with a material guiding hopper, and the bottom of the material guiding hopper is fixedly connected with a grinding mechanism. Through arrangement and cooperative use of the crushing mechanism, the feeding hopper, the material guiding hopper, the grinding mechanism, a first fixing column and a second fixing column, the problems that an existing glass crushing reusing device is poor in crushing effect and cannot fully crush waste glass, and the glass recovery utilization rate is decreased are solved, the efficient glass crushing reusing device has the advantage of high work efficiency, can complete processing of glass crushing at a time, is excellent in particle crushing effect, and is worth using and popularizing.

Owner:孙浩

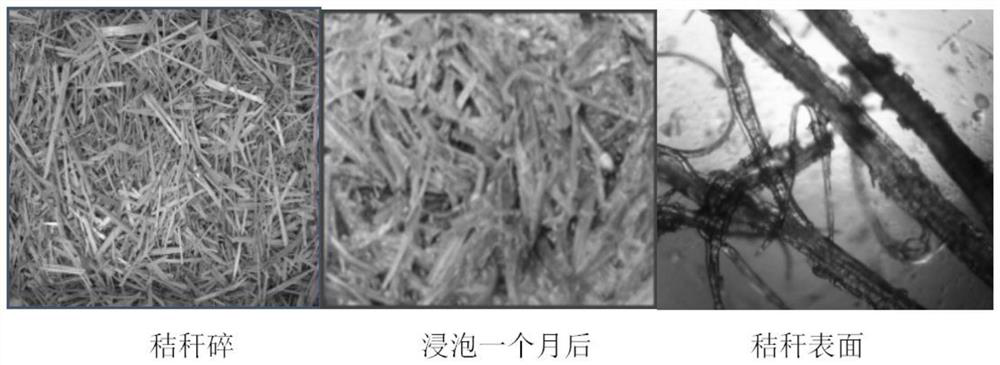

Feed capable of promoting digestion and absorption of pig

InactiveCN107198049APromote growthNutritional diversityAnimal feeding stuffAccessory food factorsBiotechnologyPolyvinyl alcohol

The invention discloses a feed capable of promoting digestion and absorption of a pig. The feed comprises the following raw materials in parts by weight: 4 to 60 parts of sorghum, 20 to 30 parts of buckwheat, 50 to 56 parts of a protein supplement, 4 to 8 parts of vinasse, 10 to 20 parts of rice bran, 10 to 18 parts of folium mori, 4 to 8 parts of fermented straw powder, 0.4 to 0.8 part of radix scutellariae , 1 to 2 parts of fructus crataegi, 0.4 to 0.6 part of fructus jujubae, 0.8 to 1.4 parts of fructus lycii, 0.6 to 1 part of radish seeds, 4 to 8 parts of a digestion promoting agent, and 2 to 5 parts of a chitosan compound. The chitosan compound is prepared by adopting the following processes: stirring chitosan, glacial acetic acid and water; adding guar gum powder and continuing stirring; adding soybean protein; adding sodium hydroxide to regulate the pH of a system to be 9 to 9.6; adding polyving akohol, microcrystalline cellulose and glutaraldehyde, mixing, and grinding by a colloid mill to obtain the chitosan compound.

Owner:宿松县春润食品有限公司

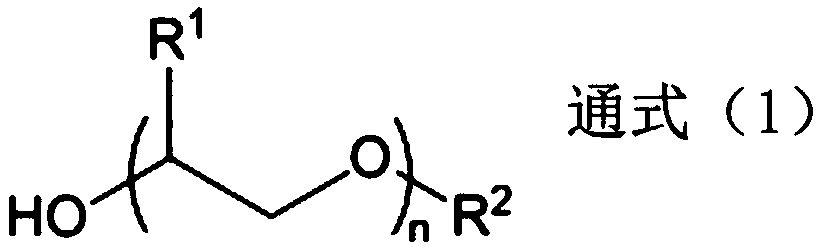

Ink composition for inkjet recording and inkjet recording method

InactiveCN111148803AImprove reliabilityGood granularityDuplicating/marking methodsInksOrganic solventActive agent

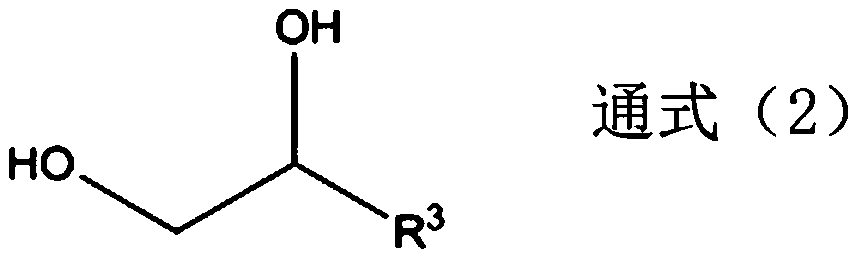

Provided is an ink composition for inkjet recording which comprises a color material, water, an organic solvent which is represented by general formula (1) or general formula (2) and which has a ClogPvalue of 0.5 to 2.7, and a surfactant having a fluorine atom in the molecule, wherein the content of the organic solvent relative to the total mass of the composition is at least 1.0 mass% and less than 5.0 mass%, the content of the surfactant relative to the total mass of the composition is at least 0.001 mass% and less than 0.1 mass%, the composition has a surface tension of 25 mN / m to 35 mN / m,and the interfacial tension with a substrate having a surface energy of 68 mN / m is at least 25 mN / m and less than 60 mN / m when the composition is placed in contact with the substrate. Also provided is an inkjet recording method. (R1 is hydrogen or methyl; R2 is, for example, a hydrocarbon having 4 to 9 carbon atoms; n = 1 to 3; R3 is, for example, a hydrocarbon having 4 to 9 carbon atoms.

Owner:FUJIFILM CORP

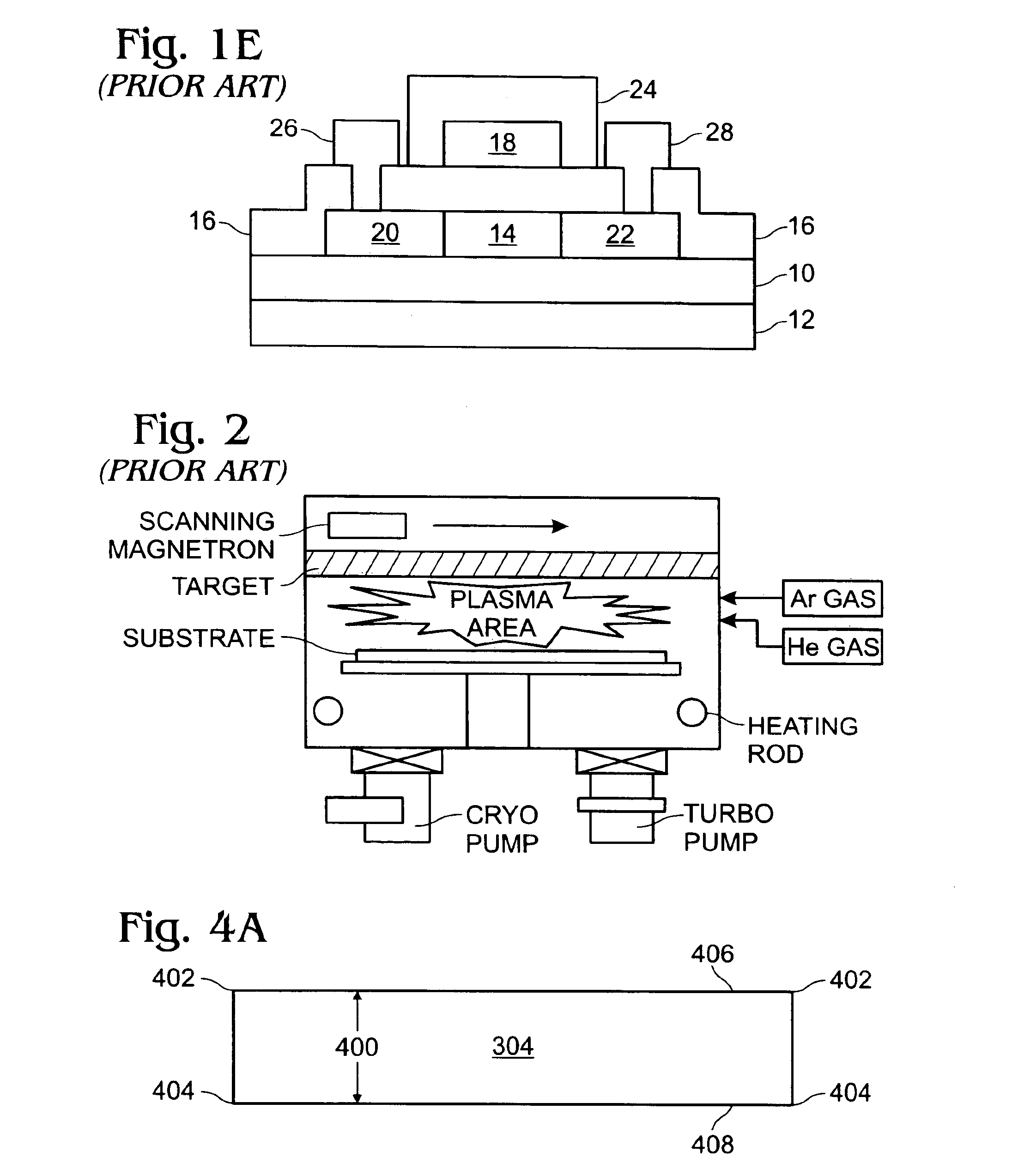

Method for fabricating silicon targets

InactiveUS6878640B2Good granularityLower levels of contaminationTransistorCellsSputter depositionSilicon

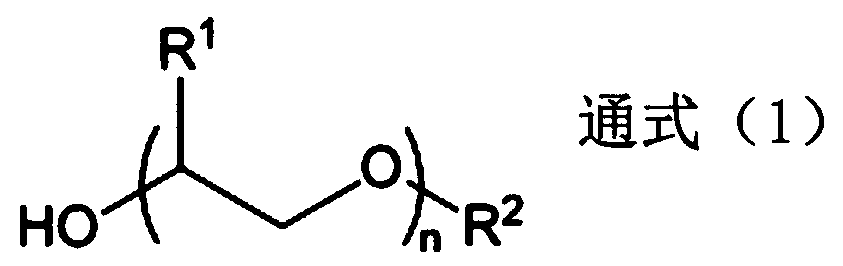

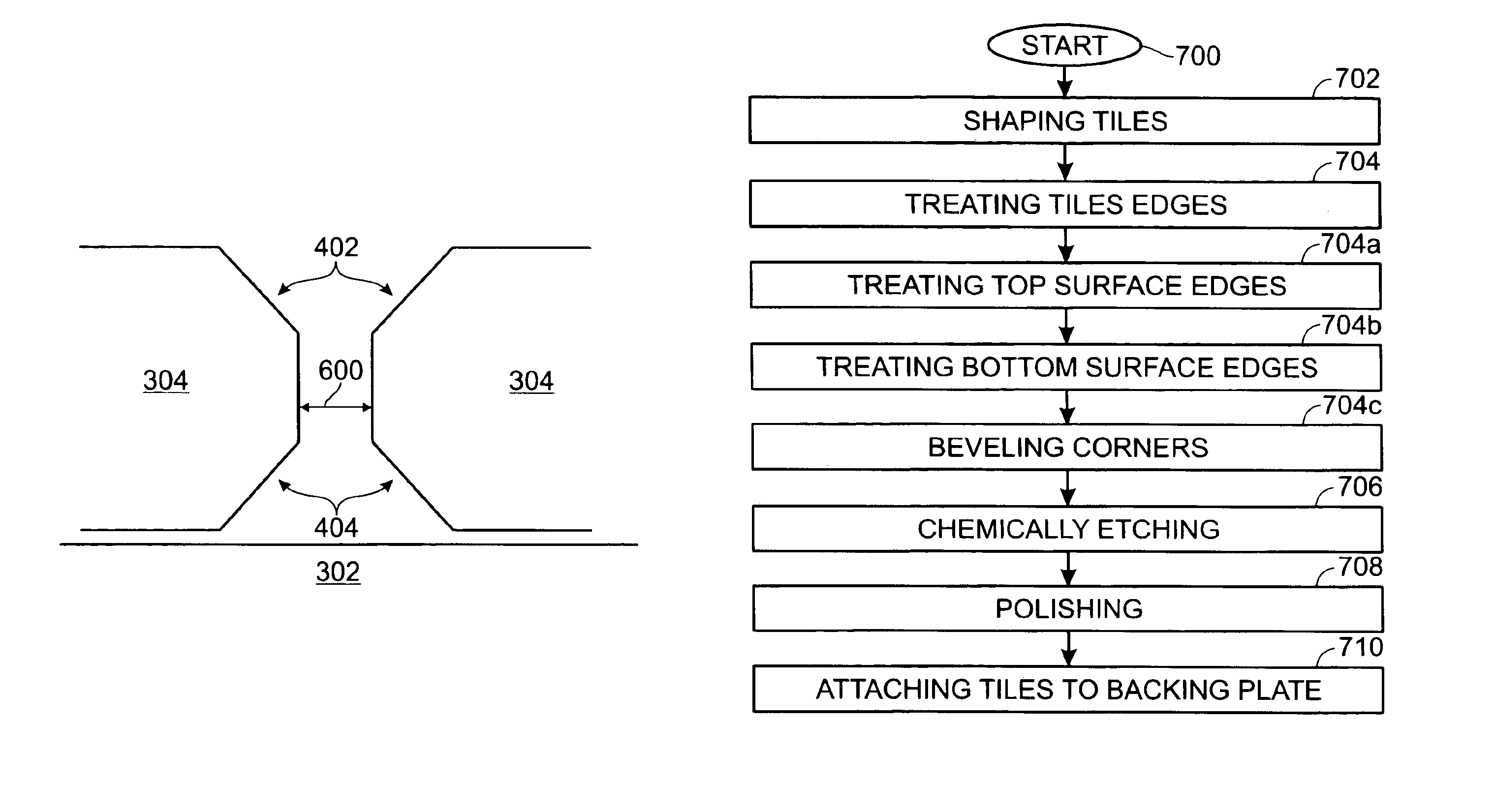

A method for fabricating silicon tiles and silicon tile targets has been provided, such as may be used in the sputter deposition of thin film transistor (TFT) silicon films. The method describes processes of cutting the tiles, beveling the tiles edges, etching the tiles to minimize residual damage caused by cutting the tiles, polishing the tiles to a specified flatness, and attaching the tiles to a backing plate. All these processes are performed with the aim of minimizing contamination and particle formations when the target is used for sputter deposition.

Owner:SHARP LAB OF AMERICA INC

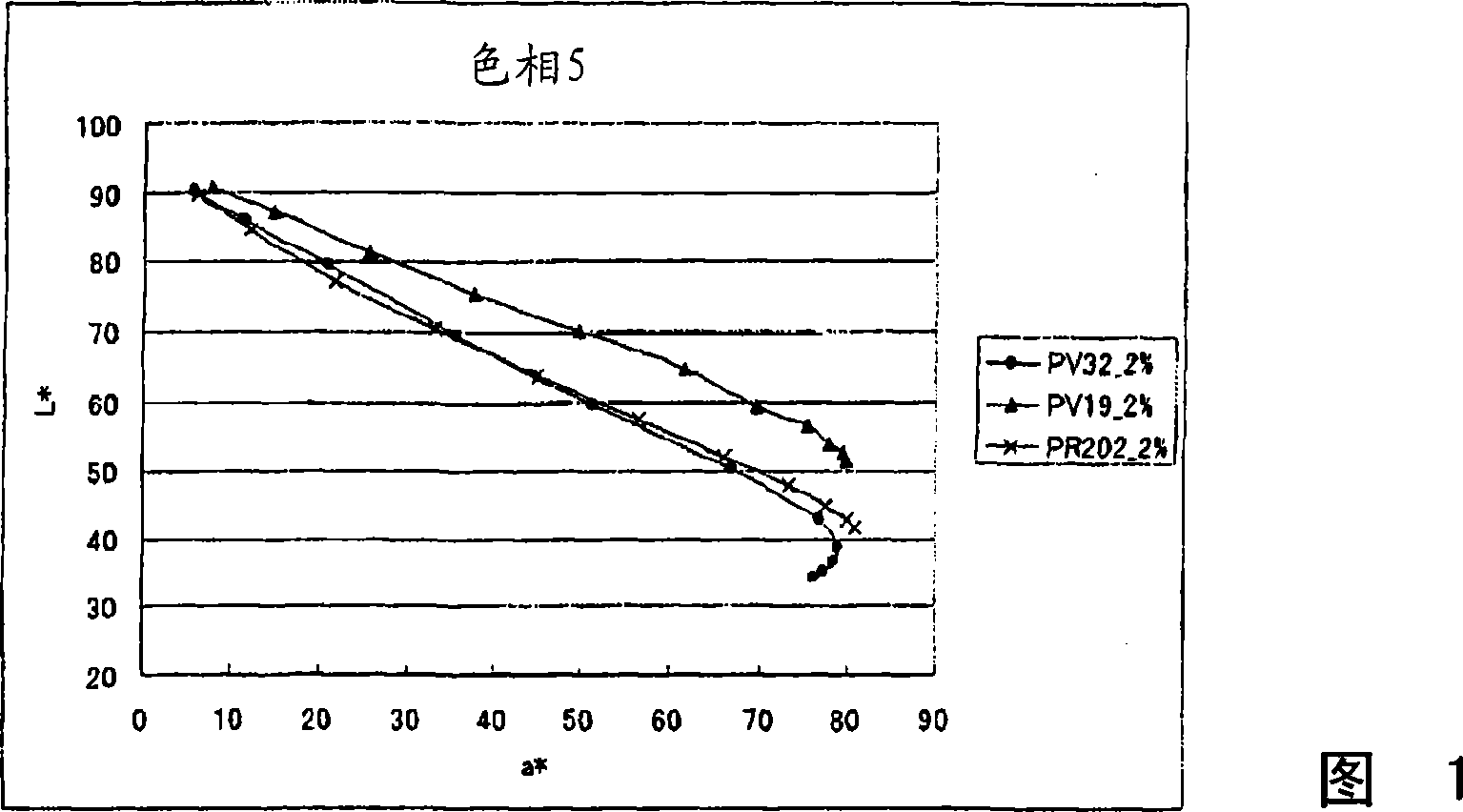

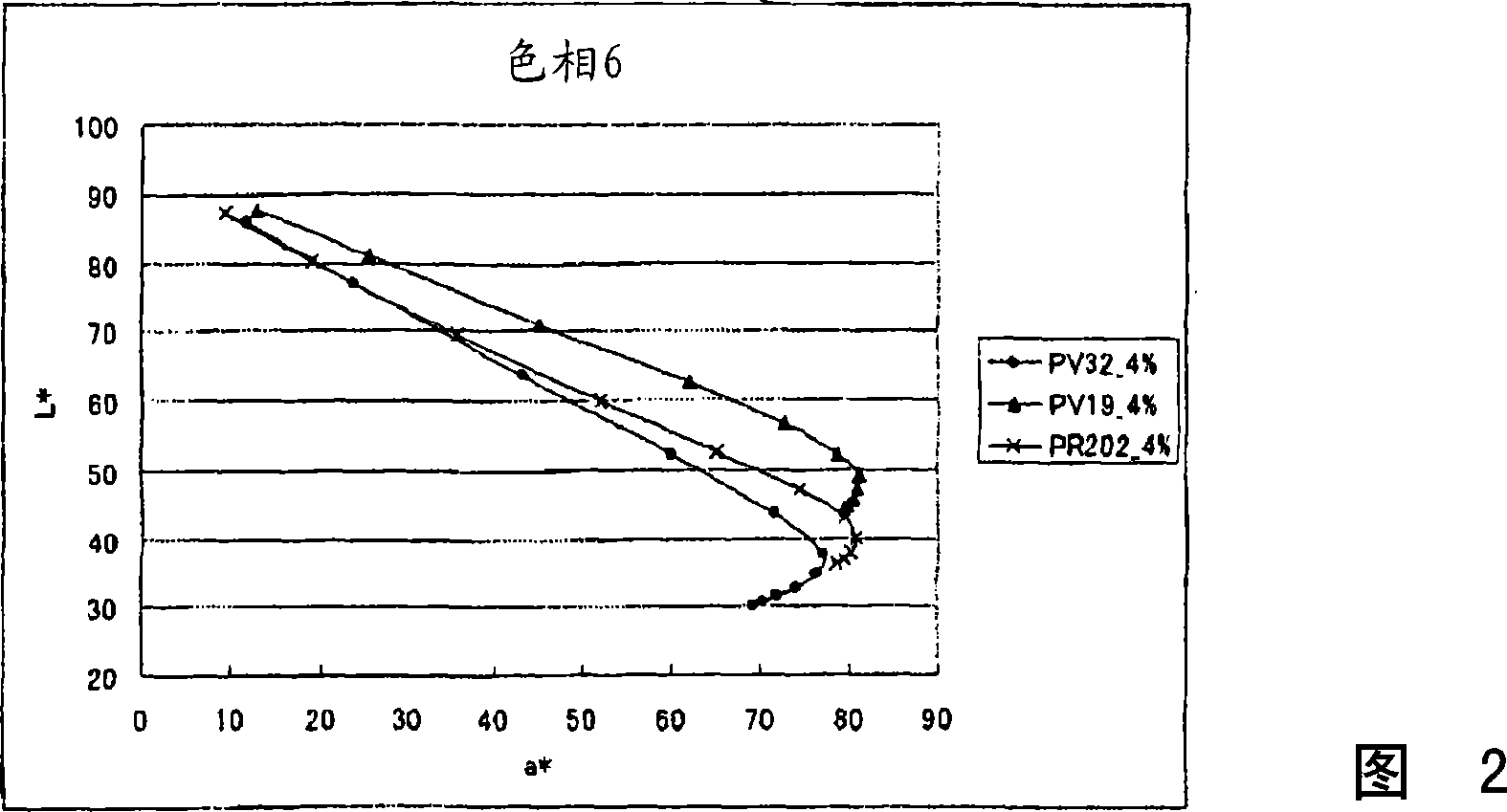

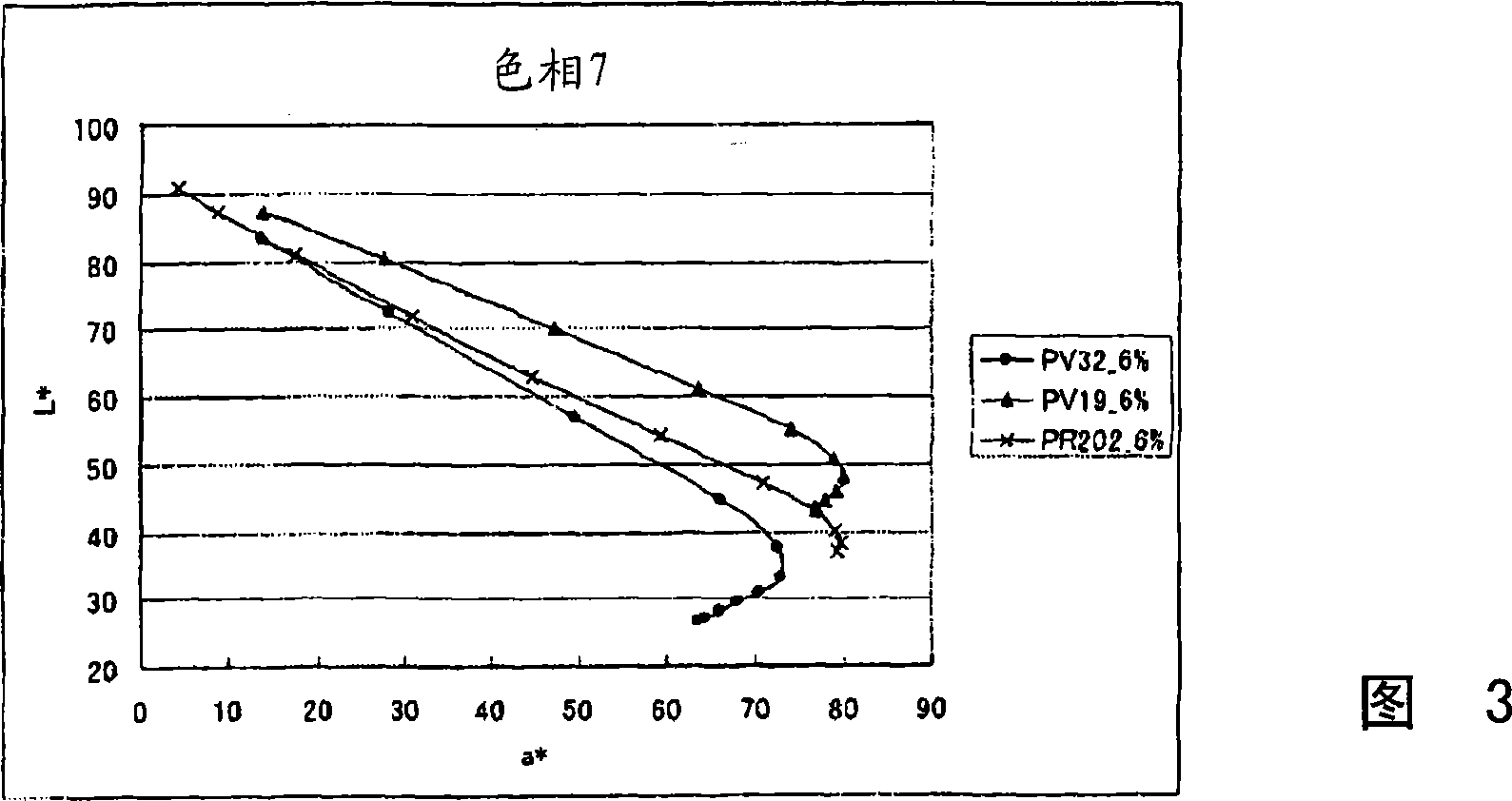

Magenta ink composition, ink set, ink cartridge, and utilizing these, method of recording, recording system and recording product

InactiveCN1969022AHigh color reproductionAvoid easy cloggingDuplicating/marking methodsInksThird generationEngineering

The object of the present invention is to provide a magenta ink which is excellent in color reproducibility in a region of high saturation and low luminosity, which is less prone to clogging in an inkjet type recording head, and whose gloss is also improved, and an inkjet ink comprising the ink Recording ink set. The present invention provides a magenta ink composition having a b* value of -29 or less when the a* value of the CIE standard calculated from the visible light absorption spectrum is 80 in a diluted aqueous solution of 10,000 times or less, and a magenta ink composition having a pigment concentration of 2 The above-mentioned magenta ink composition and an ink set containing the ink composition preferably have a CIE standard a* value of 7 or more calculated from the visible light absorption spectrum in a dilute aqueous solution of ×10-3 g / l. In addition, the present invention provides a magenta ink composition having a b* value of not less than -38 and not more than -29 when the a* value of the CIE standard calculated from the visible light absorption spectrum is 80 in a diluted aqueous solution of 10000 times or less, and the above-mentioned magenta ink composition and an ink set containing the above-mentioned magenta ink composition preferably having a CIE standard a* value calculated from the visible light absorption spectrum of 5 or more in a diluted aqueous solution having a pigment concentration of 2×10-3 g / l.

Owner:SEIKO EPSON CORP

Special nutrient package fertilizer for Honghua Dajinyuan species tobacco and preparation method thereof

InactiveCN104387211AImprove cultivation yieldQuality improvementBio-organic fraction processingBioloigcal waste fertilisersNicotiana tabacumStreptomyces thermodiastaticus

The invention relates to a special nutrient package fertilizer for Honghua Dajinyuan species tobacco and a preparation method thereof. The nutrient package fertilizer is composed of a base fertilizer and an organic-inorganic compound fertilizer, wherein the base fertilizer comprises the following raw materials in parts by weight: 60-75 parts of oil cake, 5-10 parts of bagasse pith, 0.5-2 parts of Bacillus subtilis, 0.5-2 parts of Thermophilic sporotrichum, 10-15 parts of potassium humate, 10-12 parts of potassium magnesium sulfate and 27-41 parts of water; the organic-inorganic compound fertilizer comprises the following raw materials in parts by weight: 60-75 parts of oil cake, 0.5-2 parts of Bacillus subtilis, 0.5-2 parts of Thermophilic sporotrichum, 1-4 parts of Trichoderma viride, 1-4 parts of Streptomyces jingyangensis, 5-15 parts of potassium humate, 5-10 parts of amino acid, 5-15 parts of potassium nitrate, 10-20 parts of potassium sulfate, 2.5-5 parts of borax, 1.25-2.5 parts of zinc sulfate and 27-41 parts of water; and the special organic-inorganic compound fertilizer contains microbial inoculum and can activate soil microbes, so that molecular nitrogen, phosphorus and potassium in soil are converted into organic nitrogen, phosphorus and potassium which can be easily absorbed by crops under the action of the soil microbes, thus realizing equilibrium absorption of the nutrient elements.

Owner:YUNNAN TOBACCO CO LTD KUNMING BRANCH

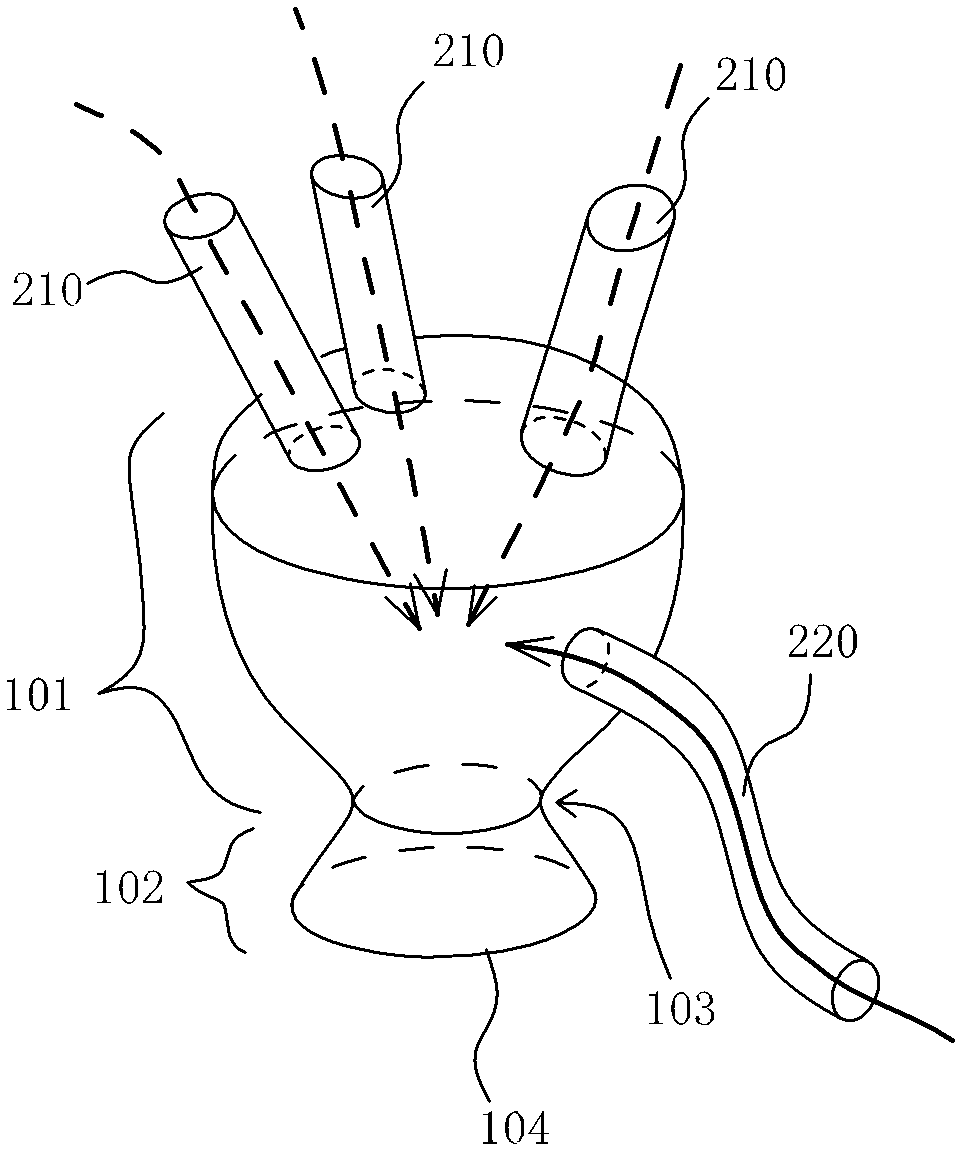

Air suction focusing sprinkling device

ActiveCN102366738AIncrease collisionGood granularitySpray nozzlesLiquid spraying apparatusInlet channelWater flow

The invention discloses an air suction focusing sprinkling device, which is characterized by comprising a converging cavity, at least two water inlet channels, at least one air suction channel and a rectifying port, wherein the converging cavity is provided with a large end and a small end of unequal sizes in the axial direction; an inner wall between the large end and the small end is in gradualtransition; the water inlet channels are communicated to the large end of the converging cavity; all water inlet channels are joined in the converging cavity towards a water outflow direction in the converging cavity; the air suction channel is communicated with the converging cavity from an external free space; the rectifying port is communicated with the small end of the converging cavity, and is provided with a throat for making water current form a liquid seal; the cross section of the throat is 1-3 times the maximum total cross sectional area of the water inlet channels; and the rectifying port gradually becomes larger from the throat to an outer cross section. The converging cavity of which the large and small ends are in gradual transition is matched with the throat which can form the liquid seal and the air suction channel for mixing air, so that the focusing and air sucking effects of water current in the converging cavity are remarkable, collision between the air and the water current is enhanced, a good outputted water particle sprinkling effect is achieved, and a large range is realized.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

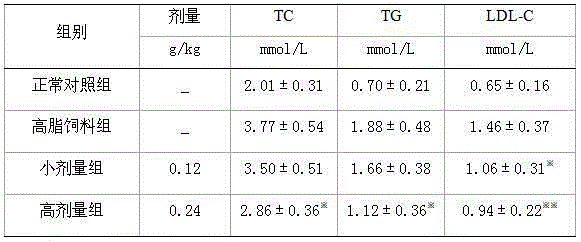

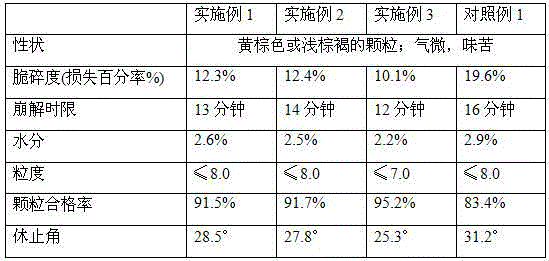

Traditional Chinese medicine health product for assisting blood-lipid reduction, namely angelica sinensis and astragalus membranaceus blood-lipid reducing granules and preparation method thereof

ActiveCN104623136AAuxiliary lipid-lowering effect is goodGood granularityMetabolism disorderCapsule deliveryExcipientChinese herbology

The invention relates to a traditional Chinese medicine health product for assisting blood-lipid reduction, namely angelica sinensis and astragalus membranaceus blood-lipid reducing granules and a preparation method thereof, and belongs to the technical field of traditional Chinese medicine preparations. The granules are prepared from the following components in parts by weight: 8-12 parts of angelica sinensis, 12-18 parts of astragalus membranaceus, 12-18 parts of kudzu vine root, 8-12 parts of rhizoma alismatis and 10-15 parts of hawthorn. The preparation method comprises the following steps: first, extracting angelica sinensis, astragalus membranaceus, kudzu vine root, rhizoma alismatis and hawthorn with water to obtain water extract, and standing the water extract to obtain supernatant; second, concentrating the supernatant to obtain thick paste, adding excipient, uniformly mixing, granulating and drying. The angelica sinensis and astragalus membranaceus blood-lipid reducing granules have relatively good blood-lipid reduction assisting effect, have good granulation forming degree, and are convenient to carry.

Owner:李元勋

Preparation method of amorphous granular resistant starch

The invention discloses a preparation method of amorphous granular resistant starch. Starch is used as a raw material, water is added, mixing is performed to make emulsion, an alkaline solution is dropwise added into the starch emulsion, stirring is performed to obtain a transparent concentrated starch solution, an alcohol acid solution is neutralized, and an ethanol solution is used for performing washing to obtain alkaline preprocessed starch; The alkaline preprocessed starch is dispersed in the ethanol solution dissolved with citric acid, even mixing, standing and drying are performed, the temperature is improved to be 110-150 DEG C so as to perform dry heat reaction, a NaOH solution is added to regulate a pH value to be 6.0-7.0, then ethanol is used for performing washing, and drying, smashing and screening are performed to obtain the amorphous granular citric acid modified starch. The citric acid is a harmless food additive and can serve as a food nutritive fortifier. The amorphous granular resistant starch produced by means of the preparation method has amorphous, granular and anti-peptic characteristics simultaneously. The starch is firstly preprocessed in the preparation process, so that the efficiency of citric acid and starch reaction is greatly improved, and the quickly-digested starch content of a product is greatly reduced.

Owner:SOUTH CHINA UNIV OF TECH

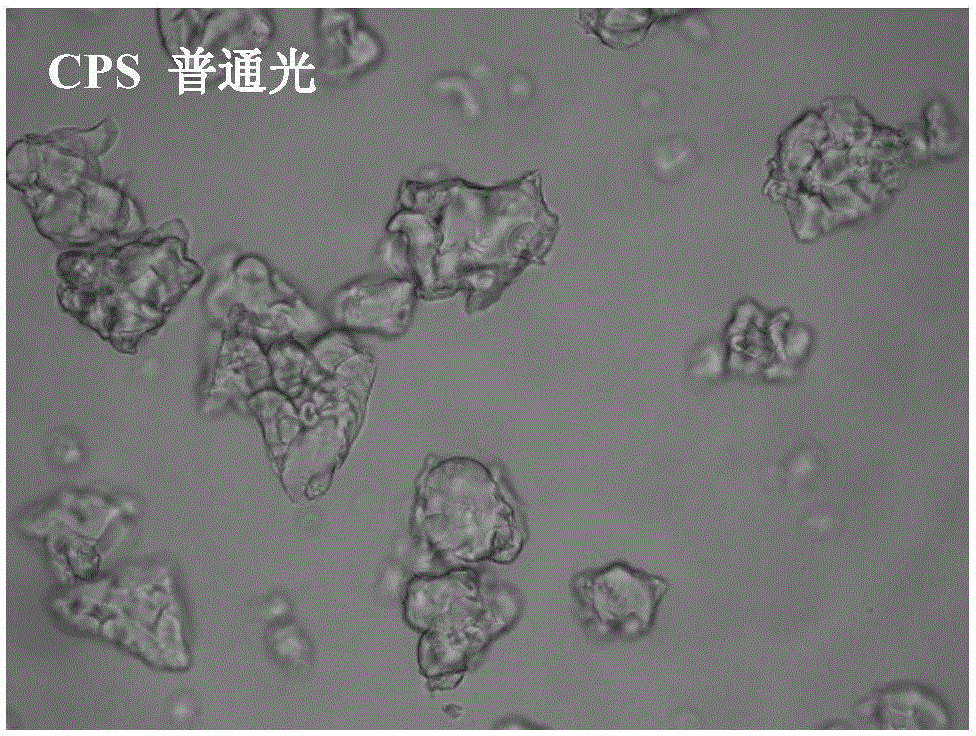

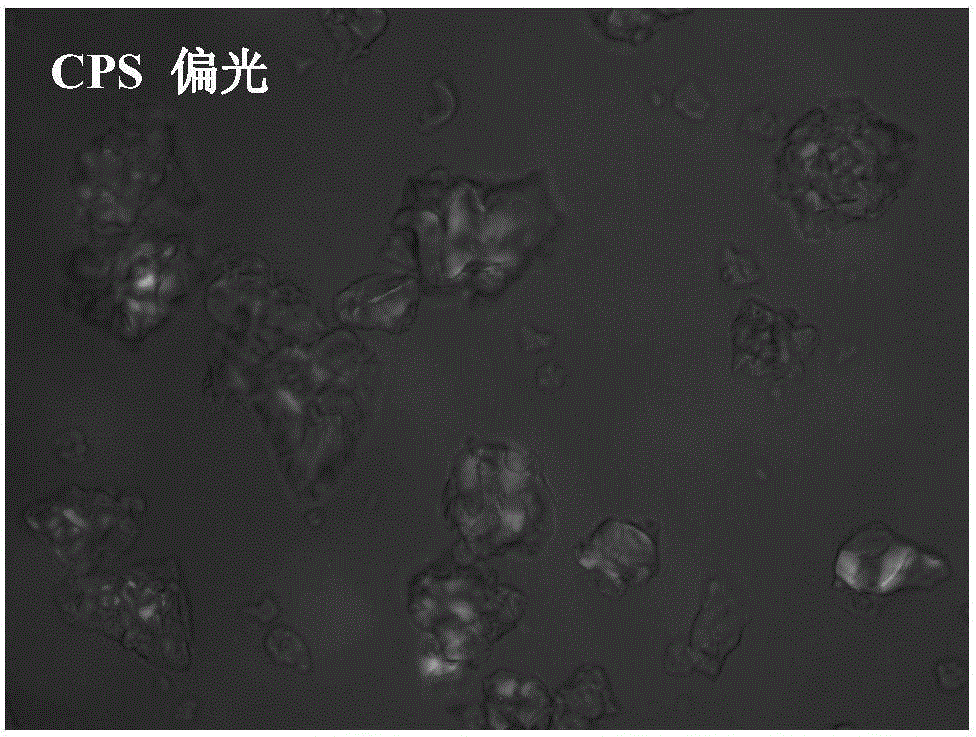

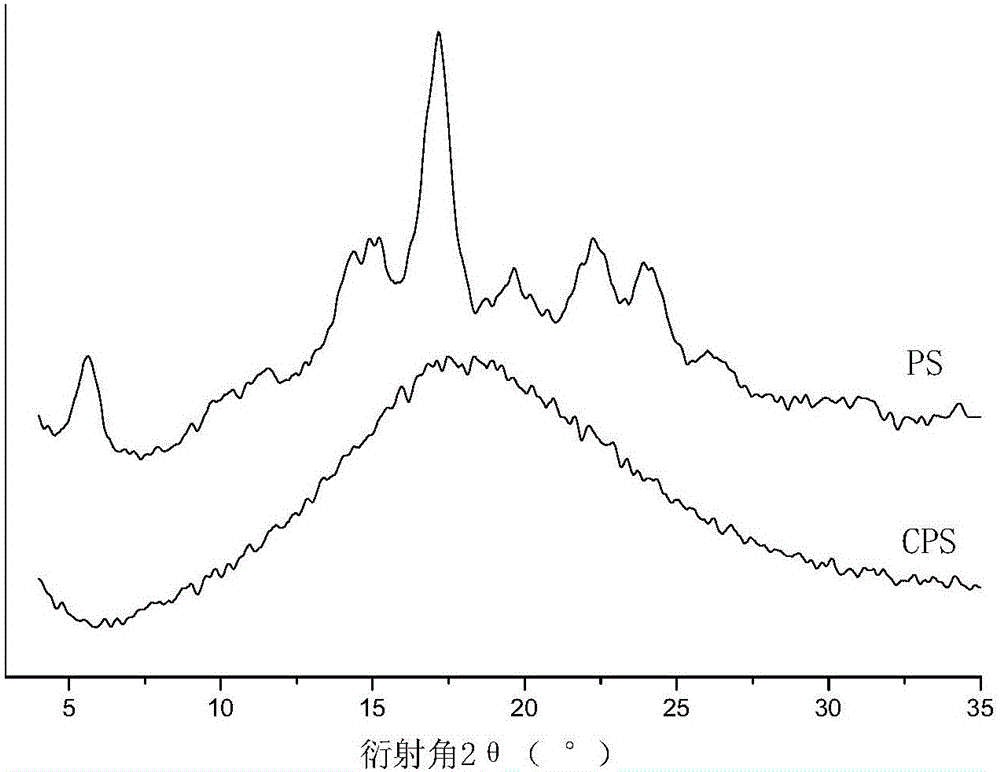

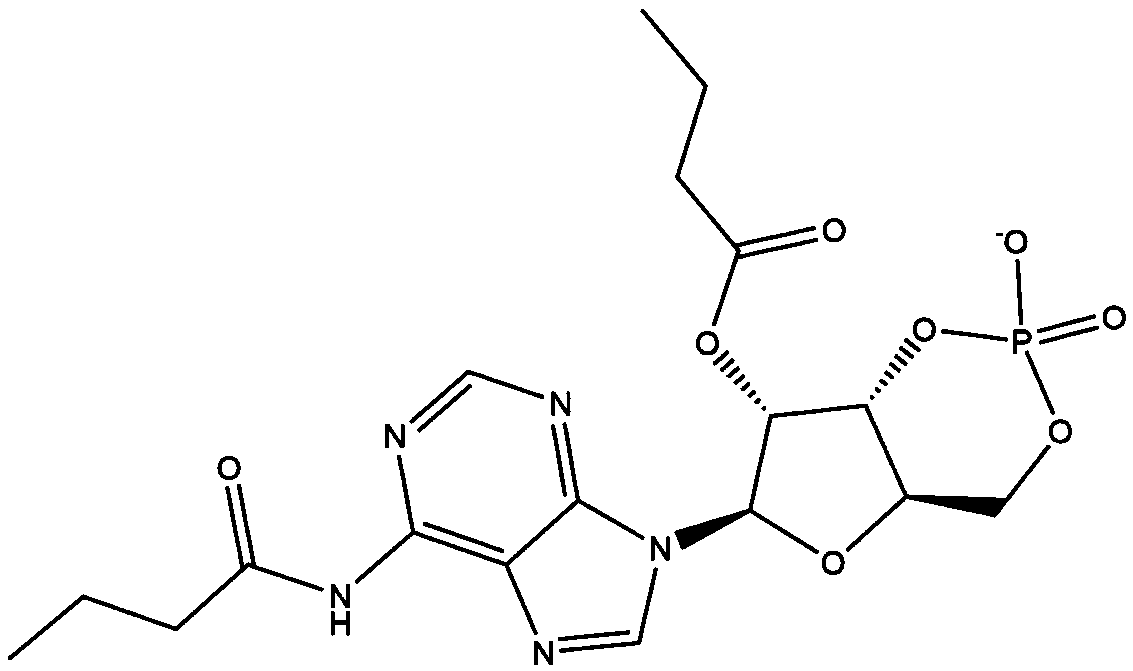

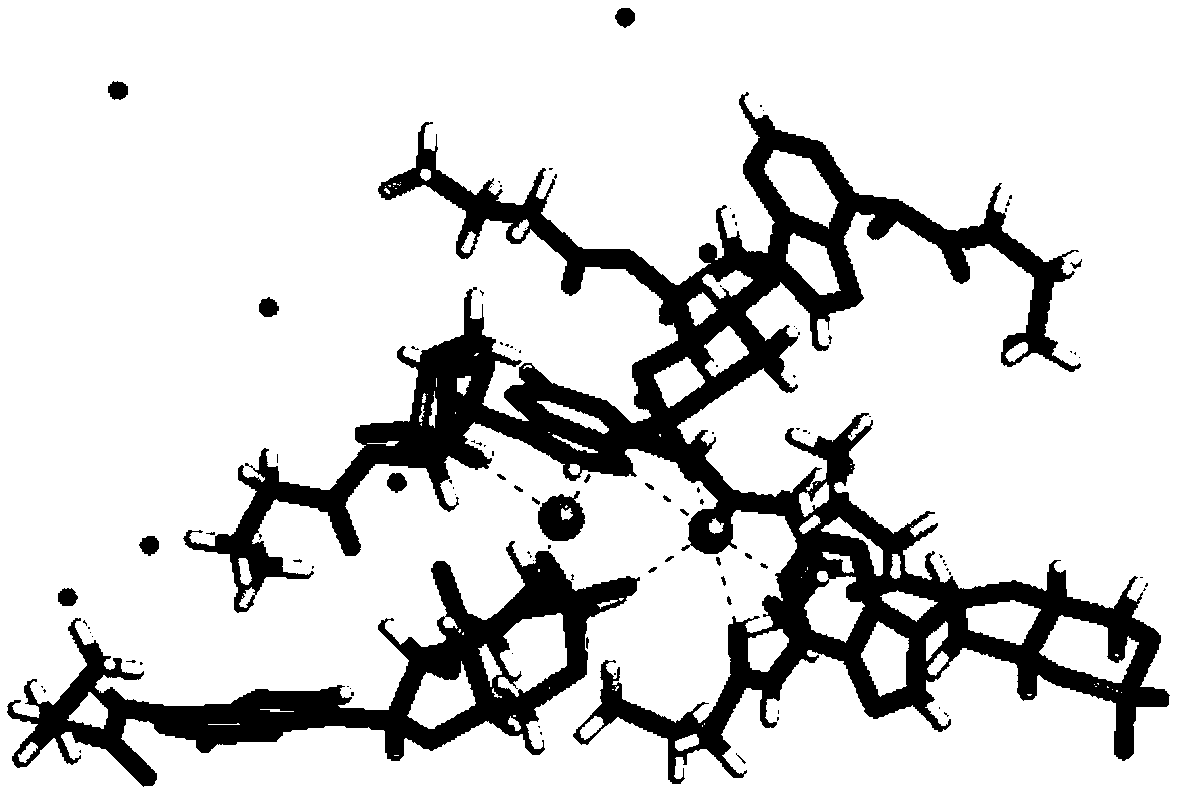

Crystal of dibutyryl adenosine cyclophosphate calcium salt

ActiveCN108997430AHigh purityGood granularityOrganic chemistry methodsGroup 5/15 element organic compoundsSpace groupAdenosine

The invention relates to a crystal of a dibutyryl adenosine cyclophosphate calcium salt, the structural formula of the crystal is C72H92Ca2N20O32P4.9H2O, belongs to an orthorhombic crystal system anda P212121 space group, the cell parameters are shown in the description, alpha=beta=gamma=90 degrees, Z=4, the cell volume V is shown in the description , R=0.07, the true density of the crystal is 1.455 kg / m<3>, each cell comprises four minimal asymmetric units, and each minimal asymmetric unit further comprises 4 dibutyacyl adenosine cyclphosphate anions, 2 calcium ions, and 9 crystal water. Thestacking density of the crystal powder is more than 0.35 g / mL, the tap density is more than 0.38 g / mL, and the HPLC purity is more than 99.2%.

Owner:NANJING UNIV OF TECH

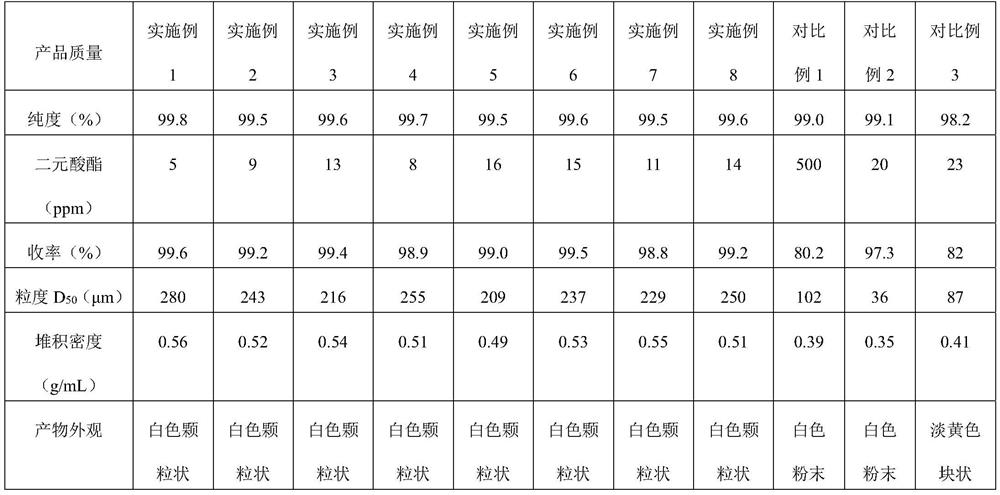

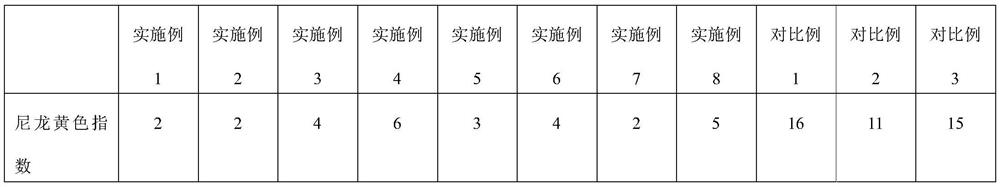

High-purity nylon 5X salt and purification method thereof

PendingCN111825557ALarge particlesHigh bulk densityAmino compound purification/separationCarboxylic compound separation/purificationDiamineAqueous solution

The invention relates to a high-purity nylon 5X salt and a preparation method thereof, wherein the purity of the nylon 5X salt reaches 99.5% or above, and the nylon 5X salt can be directly used for polymerization. According to the preparation method of the nylon 5X salt provided by the invention, pentamethylene diamine and nylon salt production processes are coupled together, and the nylon salt isproduced by a one-step method, so that the tedious and complex process flow is omitted, the equipment investment is reduced, and the production cost is saved; and the method provided by the inventionsolves the problem of low yield of nylon salt crystallization products by an aqueous solution method, the crystallization process is more effectively controlled, and explosion nucleation is avoided.

Owner:CATHAY R&D CENT CO LTD +1

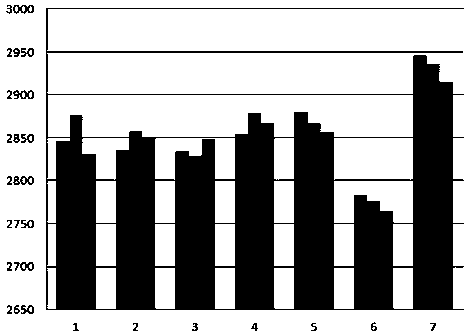

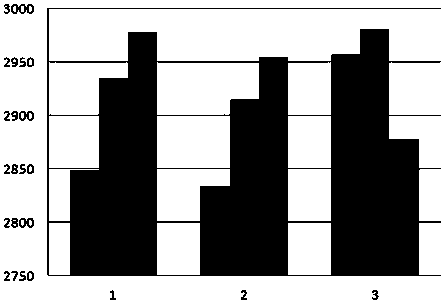

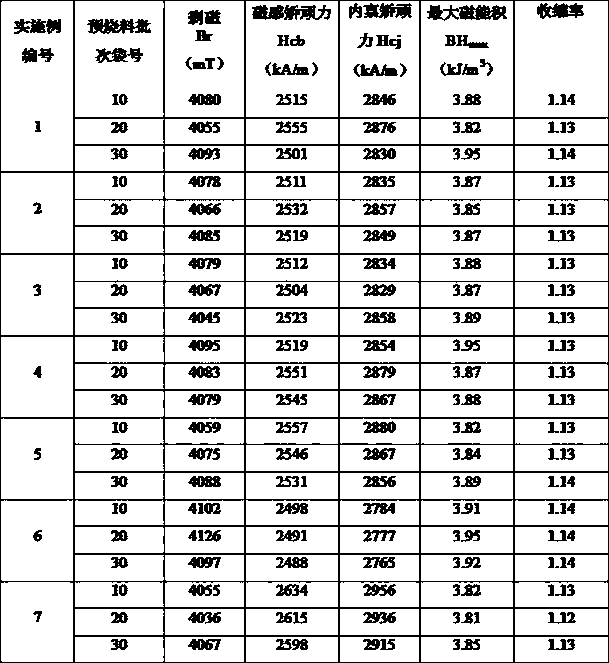

Production method of permanent magnetic ferrite pre-sintering material

The invention discloses a production method of a permanent magnetic ferrite pre-sintering material. The production method comprises the following steps: a mixture of a permanent magnetic ferrite raw material iron oxide red and strontium carbonate is placed in a material mixing tower; water, ammonia water and calcium gluconate are added; stirring and grinding are carried out; the mass ratio of ironoxide red to the strontium carbonate in material slurry at the upper end of the material mixing tower or at the lower end of the material mixing tower is controlled to be (5.95-6.65):1; the mass ratio fluctuation of the iron oxide red to the strontium carbonate in the material slurry at the upper end of the material mixing tower or at the lower end of the material mixing tower is less than or equal to 0.10:1, so that a mixed material with corrected components is obtained; and the mixed material with corrected components is subjected to dehydration, pre-sintering in a rotary kiln, cooling in acooling kiln and crushing in a ball mill according to the prior art. According to the invention, a proper amount of the ammonia water and the calcium gluconate are added in a mixing process of the raw materials of the ferrite pre-sintering material, so that a problem of consistency of the material mixing process is solved, a problem that consistency of product performance after sintering is pooris solved, and stability of products can be effectively guaranteed.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com