Ink composition for inkjet recording and inkjet recording method

An ink composition, inkjet recording technology, applied in the direction of copying/marking method, ink, application, etc., to achieve the effect of excellent granularity and excellent reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

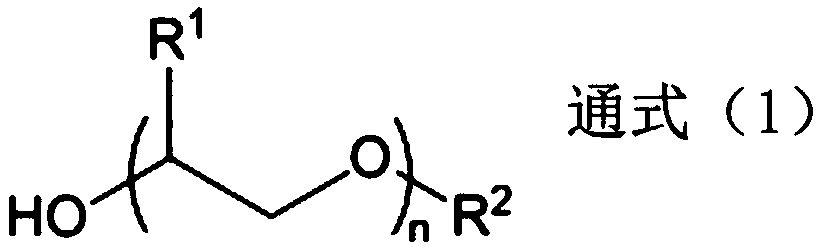

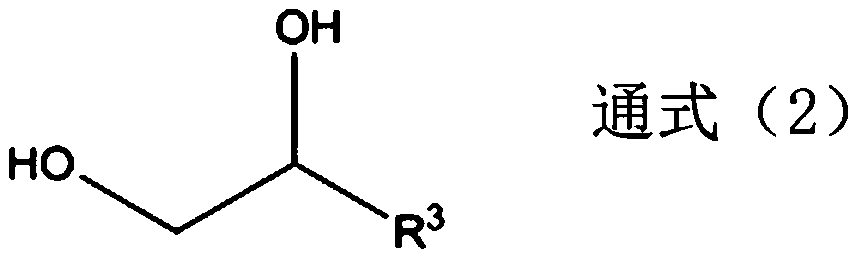

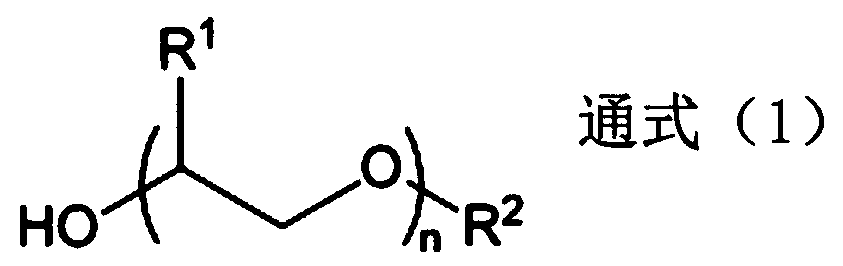

Method used

Image

Examples

Embodiment 1

[0328] Each component was mixed according to the following composition, and the ink was prepared. After liquid adjustment, coarse particles were removed using a 1 μm filter to prepare Ink 1 .

[0329] 〔composition〕

[0330] Black pigment dispersion: The pigment concentration becomes 4 parts

[0331] Organic solvent: diethylene glycol monohexyl ether (manufactured by Wako Pure Chemical Industries, Ltd.): 3 parts

[0332] Surfactant: Capstone FS-63 (manufactured by DuPont de Nemours, Inc.): 0.001 parts

[0333] Water: The total amount becomes 100 parts

Embodiment 2~ Embodiment 17、 comparative example 1~ comparative example 13

[0335] Ink 2 to Ink 15 and Ink 16 to Ink 27 were prepared in the same manner as Ink 1 except that the types and amounts of the organic solvent and surfactant were changed as shown in Table 4.

[0336]

[0337] (Ink ejection process)

[0338] A printer head manufactured by Ricoh Company, Ltd. (GELJET (registered trademark) GX5000) was prepared, and the ink prepared above was filled in a storage tank connected to the printer head.

[0339] Thereafter, the printer head was fixedly arranged so that the direction of the line head in which the nozzles were arranged was inclined at 75.7 degrees relative to the direction perpendicular to the moving direction of the stage. While moving the recording paper at a constant speed in the moving direction of the stage, the discharge conditions were set at an ink droplet volume of 2 pL, a discharge frequency of 25.5 khz, and a resolution of 1200 dpi (dot per inch)×1200 dpi. Finally, the ink was ejected in a line pattern to form an image hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com