Production method of permanent magnetic ferrite pre-sintering material

A ferrite pre-sintered material and permanent magnet ferrite technology, which is applied in the production field of permanent magnet ferrite pre-sintered material, can solve the problem of product stability affecting the downstream supply chain, low product performance stability, permanent magnet ferrite Many grades and other problems, to achieve the effect of reducing the poor consistency of product performance, improving the granularity and dispersion uniformity of raw materials, and improving the consistency of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

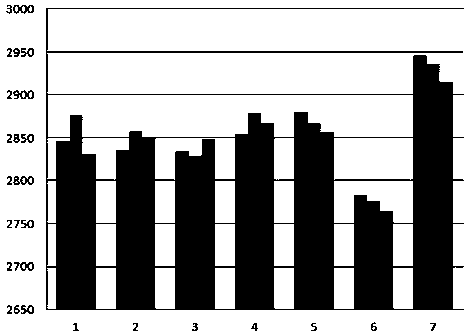

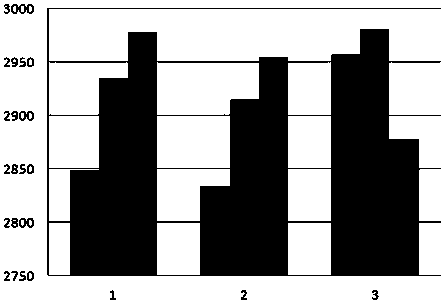

Examples

preparation example Construction

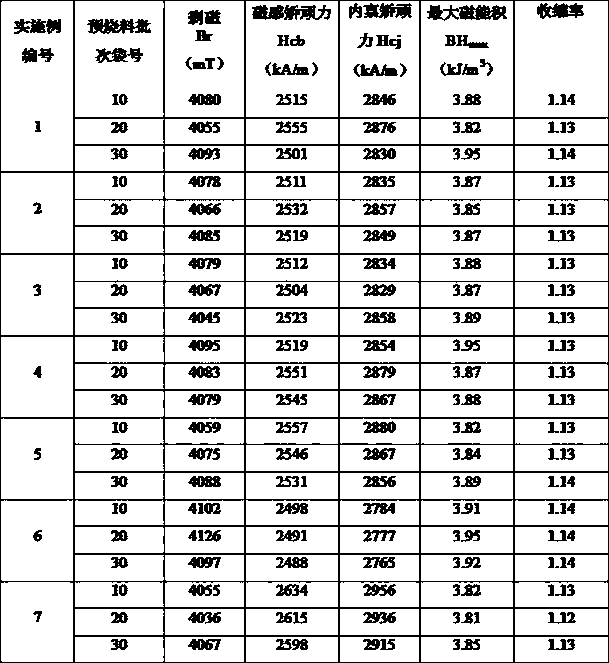

[0020] Preparation of burnt material

[0021] A kind of production method of permanent magnet ferrite calcined material, concrete steps comprise: the mixture of permanent magnet ferrite raw material iron red and strontium carbonate is placed in the mixing tower, add water (for ferrite calcined raw material iron red and strontium carbonate 1.1 times the total mass of strontium carbonate), ammonia water, calcium gluconate, stirred and ground for 4 hours, took the slurry from the upper or lower end of the stirring tower and dried it, and calibrated the components of iron red and strontium carbonate by X-ray fluorescence analyzer to control the iron red and strontium carbonate The mass ratio of strontium carbonate; and the fluctuation of the mass ratio of iron red and strontium carbonate in the slurry at the upper or lower end of the mixing tower is less than or equal to 0.10:1, and the composition-corrected mixture (belonging to the pulping stage) is obtained; the composition-corr...

Embodiment 1

[0022] In embodiment 1, the amount of ammonia water added is 0.05% of the total mass of ferrite calcined raw material iron red and strontium carbonate, and the amount of calcium gluconate added is 0.05% of the total mass of ferrite calcined raw material iron red and strontium carbonate. 0.05%, the mass ratio of iron red to strontium carbonate in the slurry at the upper end of the mixing tower is 6.50:1;

Embodiment 2

[0023] In embodiment 2, the amount of ammonia water added is 0.10% of the total mass of ferrite calcined raw material iron red and strontium carbonate, and the amount of calcium gluconate added is 0.10% of the total mass of ferrite calcined raw material iron red and strontium carbonate. 0.05%, the mass ratio of iron red to strontium carbonate in the slurry at the upper end of the mixing tower is 6.50:1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com