Nucleotide mixture crystalline powder and preparation method thereof

A crystal powder and mixture technology, which is applied in the field of nucleotide mixture crystal powder and its preparation, can solve the problems of poor feed economy, high separation cost, and long production cycle, and achieve low cost, high purity, and good growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

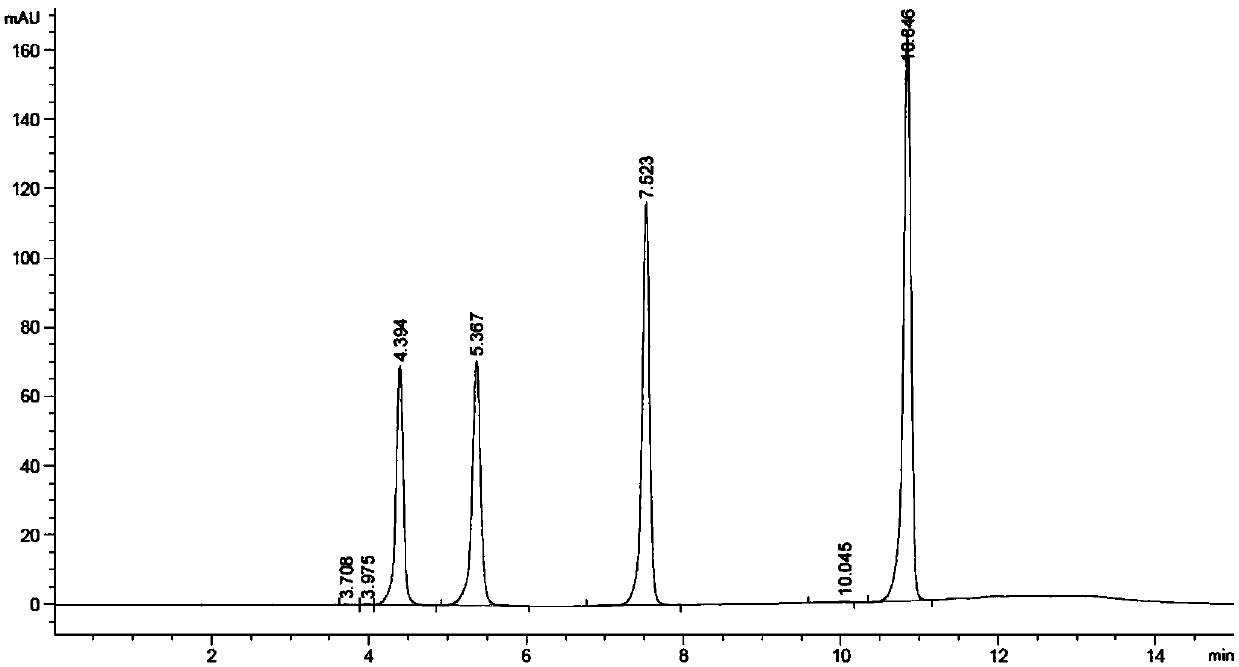

Image

Examples

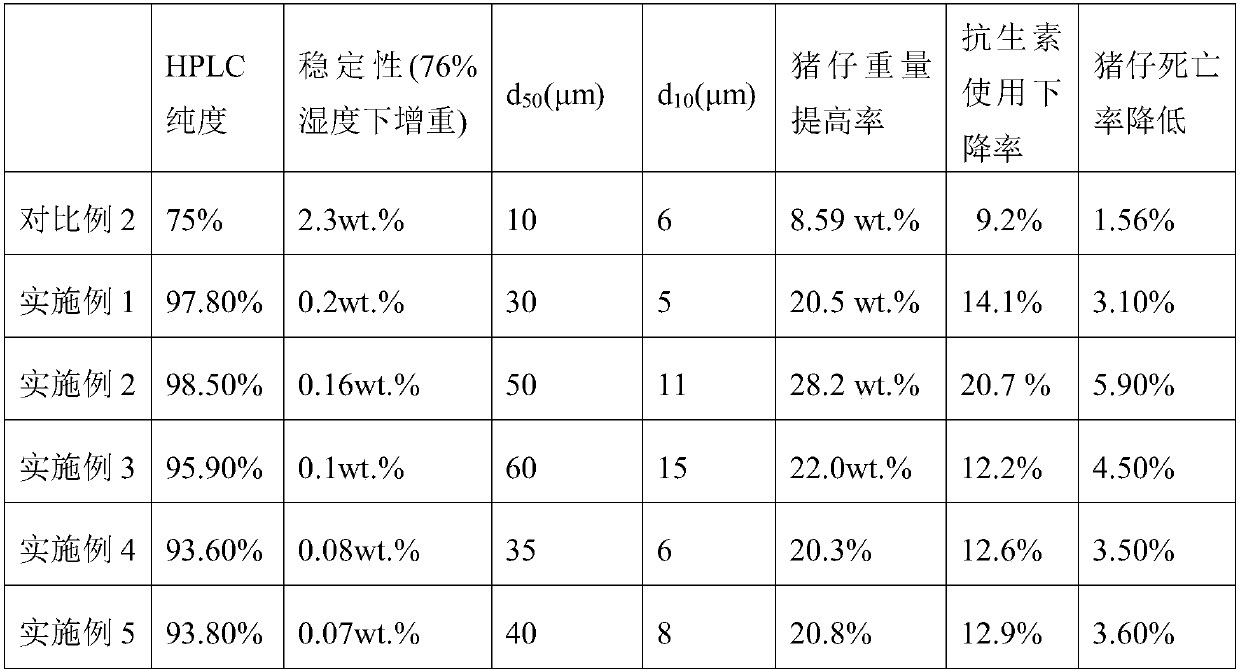

Embodiment 1

[0046] Take 400g of RNA enzymatic hydrolysis solution, its pH is 4.4, the concentration of uridine is 7.0g / L, the concentration of guanosine is 6.5g / L, the concentration of cytidine is 5.0g / L, and the concentration of adenylate is 4.8 g / L, after plate and frame filtration, add 0.5 g of activated carbon to the filtrate, stir at room temperature for 60 min, filter, and discard the filter residue. Under stirring conditions at 40°C, the pH of the filtrate was adjusted to 6.0-7.5 with 1 mol / L sodium hydroxide solution, then it was concentrated 4 times, and 2 times the volume of 95 vol.% ethanol was added to it, while adding 2 The temperature was lowered to 20°C at a rate of ℃ / h, and the crystals were transformed for 4 hours. Then, the crystal slurry was filtered, and the filter cake layer was washed with 1 volume of 90% ethanol. Nucleotide mixture of uridylic acid, guanylic acid, cytidylic acid and adenylic acid, the crystallization yield is 82%, the product liquid phase purity is ...

Embodiment 2

[0048] Take 400g of RNA enzymatic hydrolysis solution, its pH is 4.5, the concentration of uridine is 10.0g / L, the concentration of guanosine is 9.1g / L, the concentration of cytidine is 7.50g / L, and the concentration of adenylate is 7.8 g / L, after plate and frame filtration, add 1 g of activated carbon to the filtrate, stir at 50 °C for 40 min, filter, and discard the filter residue. Under stirring conditions at 35°C, the pH of the filtrate was adjusted to 7.5-8.5 with 1.5 mol / L sodium hydroxide solution, then it was concentrated 5.5 times, and 4 times the volume of 80 vol. Cool down to 15°C at a rate of 1°C / h, transform into crystallization for 3 hours, filter the crystal slurry, and use 1 volume of 95% ethanol to wash the filter cake layer. Nucleotide mixture of uridine, guanylate, cytidine and adenylate, 90% crystallization yield, 98.5% liquid phase purity of the product, uridine, guanylate, cytidine and adenylate The mass ratio of 1.8:1.5:1.2:1.0.

Embodiment 3

[0050] Take 500g of RNA enzymatic hydrolysis solution, its pH is 4.7, the concentration of uridine is 4.8g / L, the concentration of guanosine is 4.5g / L, the concentration of cytidine is 3.8g / L, and the concentration of adenylate is 3.0 g / L, after plate and frame filtration, add 2g activated carbon to the filtrate, stir at 40°C for 30min, filter, discard the filter residue, heat up to 50°C, equilibrate under stirring for 30min, and then use 2mol / L sodium hydroxide solution to remove The pH of the filtrate was adjusted to 8.5-10.0, then it was concentrated 7 times, and 3 times the volume of anhydrous ethanol was added to it, and at the same time, the temperature was lowered to 15°C at a rate of 3°C / h, and the crystallization was transformed for 3 hours. The solution was filtered and used The filter cake layer was washed with 1 volume of anhydrous ethanol, and the obtained solid was air-dried at 35°C to obtain a nucleotide mixture containing uridylic acid, guanylic acid, cytidine a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com